Electrical Hazard

The main facilities that need to develop plans to extinguish a possible fire include thermal power plants (TPPs), hydroelectric power plants (HPPs) and nuclear power plants (NPPs), as well as various distribution stations and substations. In all of these structures there is a danger of electric shock, so it is necessary to follow all safety precautions when working with electricity.

During a fire, it is difficult to cut off power to all energized objects. For example, it will take at least an hour and a half to completely shut down a nuclear reactor. At the same time, the nuclear power plant will continue to generate electricity. And when trying to extinguish, when the extinguishing agent reaches the object of extinguishing, it may cause electric shock to a person.

People on shift during evacuation may accidentally touch any conductive parts, which will lead to inevitable electric shock.

All actions to extinguish fire at power plants can be divided into two stages: before the arrival of the fire department and after their arrival. At the first stage, the fire must be dealt with by the personnel on shift. They must use available fire extinguishing equipment. After the fire brigade arrives (at the second stage), qualified specialists begin extinguishing the fire.

Features of fire extinguishing on different types of equipment

Fire extinguishing methods and techniques differ not only in voltage class, but also depending on the type of equipment, its design and operating principle. If the windings of synchronous machines catch fire, they are disconnected from the network with a parallel switching on of the magnetic field suppression machine and switching on carbon dioxide cooling. The ignited hydrogen generated as a result of gas leaks is extinguished using carbon dioxide fire extinguishers after closing the valves on the faulty section of the pipeline. Fires of oil-filled equipment are dangerous due to the risk of explosion of hydrocarbon gases formed in the oil under the influence of high temperatures.

After the voltage is removed, the fire is extinguished using water, air foam, powder and carbon dioxide fire extinguishers. In the event of an internal fire, extinguishing agents are supplied to the tank through hatches. Spilled transformer oil is extinguished using sand, air foam, powder compounds and water sprayed from fire hydrants.

Article sent by: NitroSam

I like (35)

Articles on the topic

0 49

Primary fire extinguishing agents. Use of fire safety equipment. Fire extinguishers. Fire shield. Sand. Asbestos sheet

Published: January 27, 2017

Firefighting

Primary fire extinguishing agents. Use of fire safety equipment. Fire extinguishers. Fire shield. Sand. Asbestos sheet

Published: January 27, 2021 Primary fire extinguishing agents are tools designed to localize the source of a fire, reducing the area of its spread. They are located in specialized places in production or in social institutions. Their use is designed to fight fire until the arrival of a professional fire brigade...

- Fire water supply. Fire water supply system

- Fire water supply. External fire-fighting water supply. Fire water supply inspection

- Gas fire extinguishing. Gas fire extinguishing system. Gas fire extinguishing installation.

Own powers

Any incident, including a fire at an electrical power facility, is first reported to the shift supervisor. Under no circumstances should you attempt to extinguish a fire yourself while the object is energized.

All orders for de-energizing installations, calling fire departments, and forming teams to extinguish a fire using improvised means are given by the person senior in the shift. In this case, a group of people consisting of at least two people can independently extinguish a fire.

To put out a fire, sometimes it is not possible to completely disconnect power from the equipment or wait until the current stops being generated. Therefore, it is considered possible to eliminate a fire in an electrical installation under voltage of up to 0.4 kV (400 V). The main types of fire extinguishing means are fire extinguishers.

It is impossible to equip the premises with air-foam fire extinguishers, therefore for liquidation the following are installed:

- freon (voltage up to 0.38 kV);

- powder (voltage up to 1 kV);

- carbon dioxide (voltage up to 10 kV).

At the same time, do not forget about the safety of personnel and personnel. It is worth preparing dielectric gloves and boots in advance, as well as providing respiratory protection. Of course, fire extinguishing tactics can be slightly modified depending on the resources available, but the basic principles of safety must be observed.

Over 0.4 kV

Admission of the fire brigade to the site of the fire and extinguishing fire in electrical installations over 0.4 kV is carried out only after removing the voltage on the equipment, carrying out grounding measures and obtaining electrical protective equipment. To extinguish fires of various substances, materials and flammable liquids in the open air, foam, water-foam and carbon dioxide fire extinguishers . In closed switchgears and rooms without air access to extinguish fires and ignitions, the use of carbon dioxide fire extinguishers is unacceptable due to the risk of creating a high concentration of gases that are dangerous to life. In case of large-scale fires with the release and ignition of transformer oil, complex fire extinguishing methods using water and powder agents are used.

Automatic installations

Currently, all transformers and reactors are equipped with automatic fire extinguishing systems. Moreover, if there are people in this block, then the fire extinguishing installation is switched from automatic mode to remote control. After people have left the room, the installation switches to automatic mode.

If a fire occurs, the automatic fire extinguishing system is activated at the moment the equipment is completely de-energized. If it does not turn on, then it is turned on manually.

It is acceptable that some equipment does not have an automatic fire extinguishing system. Then the fire is extinguished by people wearing special protection and observing the correct grounding of the fire nozzle.

Fire brigade

Fire extinguishing cards are prepared in a timely manner for all energized equipment. These cards indicate the location of the equipment and the location of grounding devices. In the event of a fire, these cards help determine the optimal routes for the fire brigade and develop optimal fire extinguishing tactics.

And of course, any energy facility is assigned to a specific fire department. Therefore, real fire training to extinguish this object should be held at least once a year. Therefore, in the event of a fire, cooperation between the fire brigade and the shift supervisor will lead to real results.

Engineering and technical personnel must bring the fire brigade up to date, conduct a brief briefing, and resolve various issues regarding the operation of electrical equipment. The head of the engineering staff reports to the head of the fire brigade about all monitoring and changes in the operation of equipment.

The fire extinguishing manager, depending on the visibility of the extinguishing objects, the removal of tension from the devices and other various factors, develops tactics for extinguishing the fire.

Extinguishing electrical installations can only be done with a spray jet with NRT-5 nozzles from a distance of at least 5 m. The compact jet, due to its low resistance and good conductivity, is not suitable for extinguishing live installations. When extinguishing by air-foam method, foam generators, fire nozzle and fire truck pumps must be grounded. The entire fire brigade is equipped with dielectric gloves and boots or boots, this also applies to drivers of fire trucks.

Extinguishing live electrical equipment.

Water conducts electricity well, so it is not used to extinguish live electrical installations.

The use of inert and non-flammable gases (argon, nitrogen, carbon dioxide, freons, etc.) is based on diluting the air and reducing the oxygen concentration in it to values at which combustion stops.

Carbon dioxide fire extinguishers (OU-2A, OU-5, OU-8) are used to extinguish electrical installations under voltage up to 1000 V and some materials.

Powder fire extinguishers (OPS-6, OPS-10) are intended for extinguishing metals, flammable liquids, gas liquids, organosilicon compounds, installations operating under voltage up to 1000 V.

Freon fire extinguishers are marked as OX (OX-3, OX-7) or OAX-0.5 (in an aerosol installation).

When extinguishing live electrical installations, the following mandatory conditions must be observed:

1. Firefighters are not allowed to approach live parts of electrical installations at a distance less than safe;

2. The routes for firefighters to move to combat positions must be agreed upon by the fire extinguishing director (FEC) with the on-duty personnel of the power facility and specifically indicated to each firefighter during briefing;

3. Firefighters and drivers of fire trucks providing the supply of fire extinguishing agents must work in dielectric gloves, shoes or boots;

4. The supply of fire extinguishing agents must be done after grounding hand-held fire nozzles and fire trucks;

5. Extinguishing live electrical installations using manual means when visibility is less than 10 m is not allowed;

6. Rearrangement of forces and assets, changes in combat positions, etc. must be carried out by the RTP after agreement with a senior official from among the engineering and technical personnel of the energy facility.

When extinguishing live electrical installations, it is prohibited:

1. Use foam, except in special cases;

2. Deliver sprayed water jets from hand-held fire nozzles from dangerous distances;

3. Perform any shutdowns and other operations with electrical equipment for the personnel of fire departments;

4. Use water with wetting agents when supplying compact jets, both for extinguishing and for cooling live electrical equipment and building structures;

5. Persons not directly involved in fire extinguishing should approach machines and mechanisms used to supply fire extinguishing agents to burning electrical installations that are under voltage.

Fire notification and alarm systems

Chemical foam fire extinguisher

Of the chemical foam fire extinguishers, chemical foam extinguishers are the most common in practice. They are used to eliminate fires of solid materials and flammable liquids (with small combustion areas).

31. Explosion of a mixture of dust and air; ignition (explosion) limits

A dust explosion occurs when the combustible part instantly combines with oxygen in the air and forms a blast wave. About 50% of PVA explosions occur when working with flour, grain, sugar and other products.

8% with metals, 6% with coal dust in fuel crushing plants, 4% with sulfur, 6% in the non-technical oil refining industry.

Conditions (factors) necessary for the occurrence and occurrence of combustion.

Combustion is a rapid physical and chemical transformation of substances, accompanied by the release of heat and light. For the combustion process to occur, three factors are required:

flammable substance;

oxidizing agent;

ignition source (pulse)

Most often, the oxidizing agent is atmospheric oxygen, but some other substances can also play its role: chlorine, fluorine, bromine, iodine, etc.

Ignition sources can be random sparks of various origins (electric, resulting from the accumulation of static electricity, sparks from gas and electric welding, etc.), heated bodies, etc.

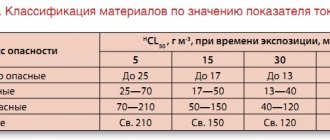

Based on flammability, substances and materials are divided into the following groups:

1) non-flammable - substances and materials that are unable to burn in air. Non-flammable substances may be fire and explosion hazards (for example, oxidizers or substances that release flammable products when

interaction with water, air oxygen or with each other);

2) low-flammability - substances and materials that can burn in air when exposed to an ignition source, but are unable to burn independently after its removal;

3) flammable - substances and materials capable of spontaneous combustion, as well as ignite under the influence of an ignition source and burn independently after its removal.

Basic concepts about fire and its development.

Fire is an uncontrolled combustion that develops in time and space, dangerous to people and causing material damage. Fire and explosion safety is a system of organizational measures and technical means aimed at preventing and eliminating fires and explosions.

Fires in industrial enterprises, in transport, and in everyday life pose a great danger to people and cause enormous material damage. Therefore, issues of ensuring fire and explosion safety are of national importance.

The main parameters characterizing a fire are: the area of the fire, the intensity of combustion, the speed of spread and the duration of the fire.

Under the fire

understand the place (area) of the most intense combustion under three main conditions:

· continuous supply of oxidizing agent (air);

· continuous supply of fuel (combustible materials);

· continuous release of heat necessary to maintain the combustion process.

The space in which a fire develops can be divided into three zones:

• combustion zone (fire source)

- this is the part of the space in which the processes of thermal decomposition or evaporation of flammable substances and materials occur in the volume of the diffusion flame. This zone may be limited by building fences, walls of technological installations, and apparatus. External signs of an active combustion zone are the presence of a flame, as well as smoldering or hot materials;

• heat affected zone

– this is the space around the combustion zone in which the temperature as a result of heat exchange reaches values that cause a destructive effect on surrounding objects and are dangerous to humans;

• smoke zone

- this is a part of the space adjacent to the combustion zone and filled with flue gases in concentrations that pose a threat to human life and health. The smoke zone is considered safe if the visibility of objects is 6÷12 m, the oxygen concentration is at least 17%, and the toxicity of the gases does not pose a danger to people without smoke protection.

The most important fire parameters that determine fire extinguishing conditions are the fire load and the rate of fire load burnout.

Fire load is the mass of all materials located at the facility, divided by the floor area of the room. If materials are exposed to open air, then their mass is related to the surface area.

The burnout rate of a fire load is characterized by the loss of mass of combustible materials per unit surface over time.

All fires can be classified by external signs of combustion, the location of the fire and the time of arrival of the first fire departments.

A) According to external signs of combustion, fires are divided into external, internal, simultaneously external and internal, open and hidden.

External fires include fires in which signs of combustion (flame, smoke) can be detected visually. Such fires occur when buildings and their structures, stacks of lumber, coal, peat and other material assets located in open storage areas burn; when burning oil and petroleum products in tanks, etc. External fires are always open.

Internal fires include fires that arise and develop inside buildings. They can be open or hidden.

Signs of combustion in open fires can be established by inspection of premises (for example, burning of property in buildings for various purposes; burning of equipment and materials in production shops, etc.).

In hidden fires, combustion occurs in the voids of building structures, ventilation ducts and shafts, inside torn deposits or peat stacks, etc. Signs of combustion are detected by smoke escaping through cracks, changes in the color of the plaster, etc.

The most complex fires are both external and internal, open and hidden. As the situation changes, the type of fire changes. Thus, when a fire develops in a building, hidden internal combustion can turn into open internal combustion, and internal combustion into external combustion and vice versa.

B) According to the place of origin, fires occur in buildings, structures, in open areas of warehouses and in combustible areas (forest, steppe, peat and grain fields).

C) Based on the time of arrival of the first fire departments, fires are divided into started and unstarted.

Neglected fires include fires that, by the time the first fire departments arrived, had developed significantly for various reasons (for example, due to late detection of the fire or notification to the fire brigade). To extinguish neglected fires, as a rule, the forces and means of the first units are not enough.

Unexpected fires in most cases are extinguished by the forces and means of the first arriving unit, the population or workers of the facility.

The process of fire development can be divided into three phases. In the first phase, combustion spreads when the fire covers the bulk of combustible materials (at least 80%). In the second phase, after reaching the maximum rate of burning out of materials, the fire is characterized by active flaming combustion with a constant rate of loss of combustible materials. In the third phase, the burnout rate drops sharply and smoldering materials and structures burn out.

The causes of fires at industrial facilities can be divided into two groups:

Violation of fire regulations or careless handling of fire;

· violation of fire safety measures during the design and construction of buildings.