Definition

Working under voltage is considered to be an option for servicing an entire or only a section of an electrical installation, when the operating voltage is not removed from it, and repair or test operations are carried out in the normal operating mode of the electrical installation. The safety of workers is ensured through devices and tools made of insulating materials, which are designed to create a separation in the circuit between voltage and ground. Depending on the location of the insulation in relation to a person, there are three methods of performing work under voltage.

Techniques for working under voltage

The method of working under voltage, due to the threat of electric shock to personnel, requires special vigilance and strict adherence to safety measures. Since when a worker closes parts of an electrical installation to the ground, electric current begins to flow, safe performance of work can be ensured provided that the person is isolated from the ground, or only from live parts, or from both at the same time.

Isolation of man from the earth

One option for working under voltage is to isolate the worker from grounded elements. Most often used on the contact network of urban transport and railway enterprises, power lines, lighting fixtures, etc. With this method of professional testing or repair of lines, the rule of uniform potential must be observed. This means that all crew members, tools and work areas must be brought to the same potential as the power line.

Figure 1: Isolated railcar tower

Consider Figure 1, here is an example of a device for isolating a worker on the contact network and the grounded part. This is a railcar tower that allows you to work without relieving stress.

The figure shows the tower itself A , the transition platform B and insulators I. To ensure safety, the tower is equalized to the potential of the wire by means of a shunt rod. This means that it is supplied with contact line voltage, which automatically passes under the worker’s feet and the person is at the same potential as the live parts and the working platform. While the I separate them from ground and prevent current from flowing, the insulators keep the circuit open and allow live work to be carried out safely.

Transition platform B in this situation acts as a neutral element, which allows you to move from the grounded deck of the railcar to the platform, which is energized. The direction of the person's movement is shown by the blue line. The transition technology prohibits the simultaneous movement of more than one person when working under voltage. One person moves first from the deck to platform B , and then from it to work platform A.

In the event of an emergency (breakdown of the insulator I , falling of a wire to the ground, overlapping of the insulation of the site), nothing will threaten the personnel. Since in the presence of a shunt element, current will not flow through the worker.

In this case, only a particular method of potential equalization is considered. But besides it, there are other devices:

- In electrical networks, aerial platforms and insulated ladders are used for this purpose.

- On the railway, in addition to the already discussed railcars - leiter.

- For overhead lines 330 – 750 kV, helicopters can be used.

All of the above methods of working under voltage should only be performed by persons who have passed the knowledge test of industry regulations.

Isolation of a person from live parts, without isolating him from the ground

This live work requires the worker to be directly on the ground or on a permanently grounded structure. And all the manipulations that he performs on switchgears or on the line must be carried out using electrical protective equipment. They separate the worker from those elements that are energized and must be selected by the responsible manager in accordance with the voltage class for which the electrical installation is designed.

Work examples.

As an example, consider live work to replace a fuse, which can be done for devices up to 1 kV or above, depending on the situation.

Figure 2: Replacing a live fuse

As you can see in Figure 2, operation under voltage during fuse replacement in a device greater than 1 kV is shown. In this case, the employee must comply with the following safety requirements:

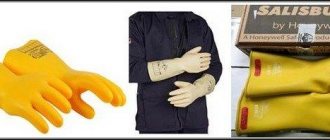

- Use dielectric gloves;

- Use a special shield to prevent sparks from getting into your face and eyes, in case such occur;

- Hold the pliers up to the restrictive rings at arm's length;

- Use only tools that are tested and suitable for the job.

Quite often, under voltage, fuses up to 1 kV are replaced in control circuits, and they are promptly removed during any scheduled or emergency work. In this case, the safety measures differ from work in circuits over 1 kV - the use of a face shield is not required, and the clamps are selected for a certain voltage class, and can be without restrictive rings, but in this case, separation of the person from the ground with an insulating stand, shoes or mat is required.

Another example would be working with an operating bar. At the same time, the employee can easily perform any manipulations with the same single-pole disconnectors and other operations.

Figure 3: Working with an insulating rod

Here, when maintaining electrical installations above 1 kV, much more stringent safety measures are applied. According to the technological maps, the employee is required to wear dielectric gloves and a shield. Check the operation of the rotating mechanism on the insulating rod. When performing manipulations without disconnecting the line, you must strictly observe the position of your hands relative to the restrictive ring.

Another option is to work with a voltage indicator in networks 6 - 110 kV. This device allows you to make sure that there is no voltage on the current-carrying elements when disconnecting the consumer. But first, the repair personnel are obliged to check its functionality, which is done by touching with a probe those tires or elements that are known to be energized.

Figure 4: Testing the voltage indicator

As you can see, Figure 4 shows the probe touching one of the AC buses in phase C, which is indicated by the letter A. If there is voltage in indicator B, the lamp will be visible. This work is also performed with dielectric gloves; the mark of the restrictive ring must be observed.

Isolation of the worker from live parts and ground

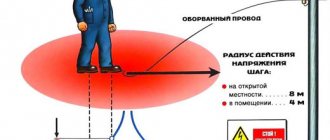

These works under voltage when operating electrical installations require special instructions. A person, in such a situation, must be simultaneously protected by insulating elements from both the ground and live parts. It should be noted that in various types of work, insulation from the ground can be performed for the purpose of protecting from step voltage, and sometimes it is performed as an additional or main barrier to the flow of current.

As an example of working under voltage in networks up to 1 kV, we can consider cleaning electric motor panels under load, testing insulators, and others.

Figure 5: Insulator performance test

As you can see, this work under voltage is performed from an insulating removable tower (leiter) L. During such manipulation, a person must be protected from live parts, due to the fact that the test simultaneously involves both the current-carrying and grounded part of the insulator. Personnel, at the same time, use dielectric gloves and a special measuring rod in order to protect themselves from voltage. But gloves and a bar are only additional protective equipment, while the leiter functions as the main means of isolating the worker from the ground.

Methods of protection

In order to remove these parts of electrical installations, a lot of effort will be required, and it can also be difficult if it is an important high-voltage line and there is no way to turn it off. That is why working under voltage is a developing and improving modern technology for servicing power systems, which significantly speeds up the process of troubleshooting.

There are several ways to work near live objects. Specific means of protecting a worker from electric shock correspond to each method. Next we will look at three of them.

Isolating the worker from the ground

In this case, work is performed under voltage, as well as under the potential of the wire. The activity of a worker standing on an isolated area using special equipment here is a methodology for working under load. His suit is designed in such a way that an insulated stand can be easily connected to it.

Before starting repairs, you must first equalize the potentials of the working stand and shielding suit with non-energized live parts. Alignment is carried out by connecting the insulated area and the current-carrying section thanks to a copper conductor.

Current-carrying areas with grounded parts of metal structures similarly have a potential difference. Because of this, a worker is strictly prohibited from approaching them at a distance that exceeds the permissible standards for a given line voltage class. Otherwise, the worker may suffer serious electric shock. For example, a worker is prohibited from approaching metal structures closer than 2 and a half meters when working on 330 kV distribution networks.

Each employee must undergo special training and testing on their knowledge of the technology of working using this method, as this is a big risk. To plan the work process, special technological maps are drawn up, as well as special instructions.

Isolation of the worker from conductive areas without isolating from the ground

With this method, the use of special electrical protective equipment is mandatory. They are selected based on the nature of the work and the voltage class of the electrical installation. There are basic and additional electrical protective equipment for working with voltages up to 1000 volts and above.

Basic protective equipment allows you to work for some time under load. They protect the worker from the influence of arc and electrical voltage in the electrical installation area.

The use of additional protection is intended only for auxiliary protection in addition to the primary protection. Thanks to them, it is impossible to work under load; they can only protect against touch voltage and step voltage. This method of work is perhaps the most commonly used in electrical installations.

For clarity, here is an example:

Checking the voltage indicator in electrical installations above 1 kV. The main insulating device is this indicator, and it must be used only with dielectric gloves. In this example, they will represent an additional protective agent.

Isolation of the worker from live parts and ground

The most popular example is performing electrical work on a network under voltage of up to 1000 volts. These include distribution panels, as well as relay protection and automation cabinets.

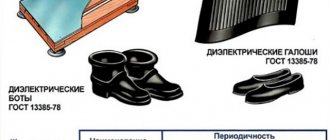

In this method, protective devices provide reliable safety to the worker from electric shock. Dielectric gloves and tools with insulating handles such as wire cutters, screwdrivers, pliers, etc., serve to isolate the worker, and in electrical installations where the voltage reaches 1000 volts, they are the main means of protection against electric shock. There are also additional means for insulating from the ground, namely a dielectric mat and an insulating stand.

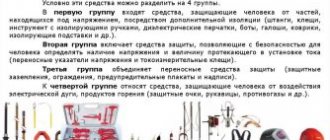

Electrical protective equipment used in work

All protective devices, according to their ability to protect a person from the harmful effects of current, are divided into basic and additional means. So, when working in devices up to 1 kV, the same gloves will act as the main one, but in distribution networks above 1 kV, they will act as an additional one. Because alone they are not able to completely eliminate leakage currents or may be subject to breakdown. But the dielectric mat in all cases is exclusively an additional tool.

Look, the tables below show the division of protective equipment according to voltage class.

Table 1. Basic electrical protective equipment for working in electrical installations:

| Up to 1000 V inclusive | Over 1000 V |

| Insulating rods | Insulating rods of all types |

| Insulating pliers | Insulating pliers |

| Clamp meter | Clamp meter |

| Voltage indicators | Voltage indicators |

| Dielectric gloves | Devices for creating safe working conditions when carrying out tests and measurements in electrical installations (voltage indicators for phasing, cable damage indicators, etc.) |

| Tool with insulating coating |

Table 2. Additional electrical protective equipment for working in electrical installations:

| Up to 1000 V inclusive | Over 1000 V |

| Dielectric shoes | Dielectric gloves |

| Dielectric carpets | Dielectric shoes |

| Insulating pads Insulating pads | Dielectric carpets Insulating pads |

| Insulating hoods | Insulating pads |

| Voltage alarms | Insulating hoods |

| Protective fences (boards, screens) | Bars for transfer and potential leveling |

| Portable grounding | Voltage alarms |

| Safety posters and signs | Protective fences (boards, screens) |

| Other remedies | Portable grounding |

| Safety posters and signs | |

| Other remedies |

Method of working in contact.

Scheme in Fig. 1.6 illustrates work under voltage on the wire of the lower right phase of an overhead line, in which the safety of the electrician is ensured by the use of

Rice. 1.6. Scheme of work under voltage using the method of working in contact; 1 - wire; 2 insulating pads; 3 - insulating ladder for logical operations of insulating gloves and tools with insulating handles. An electrician performs technological operations while being in close proximity to the wire, which is why this method of performing work under voltage is called “contact work.” If we designate the zone of normal working movements of the fitter (shaded at 1.6) by D, then when working in contact, all or some wires of the line with voltage up to 1 kV will be in contact with this zone. The insulation of gloves and tools must exceed, with a certain margin, the voltage of the elements on which the work is performed. Since in the process of working in contact on an overhead line, the electrician is located on grounded support structures, and energized wires of other phases also fall into the zone of his action, to increase safety, the electrician is dressed in a suit with insulating elements (see Chapter 6) that prevent contact current-carrying and grounded parts of the line are placed on an insulating ladder, and all wires and insulators located within the operating area are temporarily covered with special insulating sheaths. When performing live work in other electrical installations, for example, in 0.38 kV distribution panels, secondary circuit devices, insulating mats are used as additional protective equipment, and live elements are either fenced off with screens or covered with insulating shells. In cases where it is inconvenient to carry out work in contact with an overhead line support, the electrician is placed in an insulating cabin of the lift, which also protects him from touching the grounded parts of the support and other phases of the line.

Mandatory requirements for protective equipment

During operation, protective equipment may lose the properties that ensure they perform their assigned tasks. To prevent any accidents, some products must undergo periodic testing and inspection, while others must undergo inspection only. All procedures are recorded in the appropriate logs, and information about suitability is recorded after testing on the protective equipment itself.

Before starting work, the responsible person must check the suitability of the insulating tool or product. And in case:

- expired date;

- lack of information about tests;

- presence of damages exceeding those established by the rules;

withdraws such funds for repairs and unscheduled inspections.