What is a hydro generator?

In the general scientific understanding, a hydrogenerator is an electrical installation that is capable of generating electricity for hydroelectric power plants. Their design and parameters are strictly regulated by the requirements of state and international standards. They can be very large for stations generating energy for cities, or small. The latter can be used in your farmstead by installing it on a river. Or supply electricity to a town or village. Is it really profitable? Look at the picture below. This is a huge generator installed at the Irganay hydroelectric station.

Is it really big? The station is located in the Republic of Dagestan, Utskulsky district, r. Avar Koisu. Such a station generates almost 1,300 million kWh of electricity per year. The first unit was put into operation in 1998.

It is a branch of JSC RusHydro - Dagestan Branch. Power 400 MW. The energy is very high, therefore, during operation, the windings and parts of the generator become very hot; air coolers are used to cool them, and they are cooled using water. The station is the third in terms of performance in the Caucasus, after Georgian and Russian. For the Georgian station in 2014, we manufactured air coolers in 2100 with an improved design, taking into account the characteristics of the station. In 2015, it is planned to modernize the following units.

Not much about the station and stations

It consists of the station blocks themselves with equipment, dams and reservoirs with a depth of 83 meters, very deep. In 2006, two of the 4 hydraulic units were launched at full capacity. In Russia, at the end of 2013, there were already 102 stations operating with a capacity of more than 100 MW! And even more less powerful ones. We'll talk about the little ones now. And so we move on.

We looked at large units, but there are also small ones that are convenient to use in smaller areas.

Micro-hydroelectric power station

This is called micro-hydroelectric power station. Your home can be self-contained. All you need is a river next to your fortress and then you become independent from external sources. The power of such a little thing can be up to 4000 W! Need more? Install several, minimum costs, and what is the effect.

Price from 6000 rubles. Considering that I pay about 2,500 rubles for electricity, I might think about buying it. Once you pay and that's it! And no one will disconnect you, let’s say so for not paying. And, if such a motor is not enough, you can always install a more powerful installation, this is a mini-hydroelectric power station.

Mini-hydroelectric power station

If necessary, you can install more powerful ones by calculating how many devices you have that consume energy, simply adding up the power and plus 25% in reserve, as they say, so that everything is ok! Below in the picture is a mini-hydroelectric power station with a capacity of 20 kW.

There are more powerful ones, of course. You can step up and buy a more powerful hydroelectric power station to supply an entire town or village. Our plant produces spare parts for hydraulic turbines and hydrogenerators for industrial and domestic use. And so we move on.

Main types of hydro generators

In the usual understanding, hydraulic generators are special synchronous devices of a vertical type that produce their rotation from a hydraulic turbine. But there are both capsule and horizontal hydrogenerators, the operating principle of which is somewhat different from the vertical ones, which are the norm. These types of hydro generators are used in special sections of rivers. This is a scientific concept, and we discussed the main types above. These are large hydraulic units for hydroelectric power stations, micro-hydroelectric power stations for the home, mini-hydroelectric power stations for a large house or farm, and small hydroelectric power stations for villages.

How to make a mini hydroelectric power station at home

The operating principle of a small homemade hydroelectric power station can be understood using the example of a bicycle with a headlight and a dynamo (generator).

- From roofing iron we make three blades with a length equal to the radius of the bicycle wheel (the distance from the central hub to the wheel rim) and a width of 3-4 cm.

- We install the blades between the spokes of the wheel, bending the edge of the blade around the spokes to secure it. The blades should be aligned evenly while maintaining the same angles between them.

- We immerse the wheel with blades in a fast river to a depth of one third to half the diameter of the wheel. The generated electricity will be enough, for example, to light a tent.

A drawing of one of the options for constructing a mini hydroelectric power station.

An example would be a small hydroelectric power station for a farm with a capacity of 3-5 kW from scrap materials:

- The rotor can be made from an old metal cable drum with a diameter of 2.2 m. Using a grinder and welding at an angle of 45 degrees to the radius, 18 blades need to be welded. The rotor rotates on bearings. Support – metal pipe or angle.

- On the rotor you need to install a chain gearbox with a gear ratio (gear ratio) of 4. Next, the rotation will be transmitted through the VAZ 2101 driveshaft. The use of a driveshaft will reduce vibration, and the coaxiality of the drive and generator when using the shaft will be uncritical.

- You will need a step-up gearbox (coefficient - 40) and a three-phase generator. The generator rotation speed is about 3000 rpm. The total reduction ratio of the two gearboxes will be 40 x 4 = 160. The generator should be covered with a casing to protect it from moisture and safety. The estimated rotation of the water wheel should be about 20 revolutions per minute.

- An asynchronous motor can be adapted for the generator, and the control unit can be taken from any small machine. You will need a VVG NG cable 2x4 long from the rotor to farm buildings.

Operating principles of hydrogen generators

All hydrogenerators, unlike other rotary units, have a fairly low speed of revolutions per minute. It rarely exceeds 500. But the diameter of their turbines is usually huge - up to 25 meters. This is due to several factors. Firstly, the vertical orientation of the generators, since most of them have this design, and secondly, the specifics of the operation. If the device has a horizontal orientation, then the principle of operation of the hydrogenerator changes, because the rigidity and stability of such a structure is extremely difficult to ensure. Hydrogen generator diagram: where to get it?

When you purchase a hydrogenerator from the manufacturer, you receive detailed operating instructions and all the hydraulic generator diagrams that are necessary for maintenance, diagnostics and repair work on the installation. If such diagrams are lost, they can be found on the manufacturer’s website, ordered separately, or found in the public domain on specialized resources for hydrogen generators on the Internet.

It is advisable not to regret and buy high-quality units and spare parts for them.

Using a propeller

A propeller is a wheel similar to the wheel of windmills, but located under water. It is completely submerged in water (unlike a water wheel), and the width of its blades is minimal (unlike an air wheel).

For different speeds of water flow, blades of different widths are selected. So, at a speed of 0.8-2 m/s, the optimal width is 2 cm. Manufacturers of equipment for mini-hydroelectric power plants offer propeller models suitable for a particular speed of water flow. But you can make the corresponding propeller yourself.

Damless hydro generators: garland hydroelectric power station and Darrieus rotor

There are two more types of damless mini-hydroelectric power plants: garland hydroelectric power station and Darrieus rotor. Their design is more complex, and therefore such hydrogenerators are used less frequently.

The garland hydroelectric power station got its name from its appearance: a steel cable with a diameter of 10-15 mm, on which rotors are strung like beads. The cable in this case serves as a flexible shaft. They block the river bed, while the rotors are completely immersed in the water. One end of the cable is connected to the bearing, and the other to the generator shaft. The water flow rotates the rotors, and they, in turn, rotate the cable.

Already in the 50s of the twentieth century, craftsmen built garland mini-hydroelectric power plants using a generator from a car, and tin cans as rotors.

Today, technology has moved forward and the industry offers different types of rotors to increase the efficiency of the generator.

It is more effective to use propellers (analogues of children's turntables) made from thin metal sheets as hydrowheels rather than cans. One such hydraulic wheel provides up to 2 kW of energy at a water flow speed of 2.5 m/s. The depth of immersion of the rotors depends on the time of year: in summer they are lowered to about.2 depths from the surface of the water, and in winter - to about.5 depths from the surface of the ice (if the water flow freezes). At the same time, the depth of the water flow should not exceed 1.5 m. That is, such mini-hydroelectric power plants are installed on small rivers and streams.

Design of a garland hydroelectric power station with a turbine-cable drive:

- bearing;

- support;

- metal cable;

- electric generator;

- river water level;

- river bed.

The disadvantages of garland hydroelectric power stations are obvious:

- high material consumption, which leads to quite significant initial costs;

- design complexity, which reduces equipment reliability;

- the need to block the river bed, which can pose a danger to others.

The most significant disadvantage is the blocking of the riverbed. This is almost impossible to do in a more or less busy place: children, fishermen, boats - all this interferes with the normal operation of the hydrogenerator, and even installing warning signs helps little. All that remains is to fence off a section of the river in such a way as to prevent unwanted visitors from accessing the equipment, but this is not always possible. Therefore, garland mini-hydroelectric power plants are used mainly in relatively uninhabited places (for example, in summer pastures).

A safer option for a garland mini-hydroelectric power station for others is a submersible installation enclosed in a frame. In this case, there is no need to block the entire river bed. In addition, the equipment can be installed at almost any depth and width of the river (if the depth is too great, the frame is equipped with floats).

Submersible mini-hydroelectric power station with horizontally located transverse rotors.

Operating principle of the Daria rotor

The Darrieus rotor is the fourth version of a mini-hydroelectric power station. This is a vertical rotor with blades of a special design: the flow of water exerts different pressure on them, and due to this, rotation occurs. The effect is similar to the lift on an airplane wing, which is caused by the difference between the air pressure above and below the wing.

In the design of a hydrogenerator, the Darrieus rotor is used least often, because it must be untwisted before starting operation. The advantages of such equipment include the fact that the untwisted Darrieus rotor continues to work regardless of seasonal changes in the speed of water flow, etc. It can only be stopped by complete freezing of the water. But this type of equipment is expensive and difficult to operate.

Advantages of hydro generators

If you are planning to install a hydro generator, keep in mind that many small streams freeze during the cold season. In addition, they are characterized by changes in the level, volume and speed of water depending on the season. And some reservoirs simply dry up in the summer. All these factors affect the performance and efficiency of the hydrogenerator.

Moreover, because of them, mini-hydroelectric power stations may turn out to be only a seasonal source of energy. For example, if a river or stream dries up in the summer, the hydrogenerator will only work in the cold season, and if it freezes to its full depth in winter, it will be able to provide your household with electricity only at above-zero ambient temperatures.

The periods when the hydrogenerator is not in operation are used for maintenance. Of the main triad of fuel-free energy - hydro, wind and solar energy - the first requires the most significant initial costs, and the equipment is the most difficult to operate and has the shortest service life (work is carried out in an aggressive environment).

But there are also obvious advantages: equipment for mini-hydroelectric power plants has been produced for a long time, it has been thoroughly tested and reliable - you know what to expect from it. It is produced by many companies, including domestic ones, which offer various configuration options designed for all possible types of water flows and operating conditions. Currently, mini-hydroelectric power plants equipped with automatic control devices are being manufactured. This equipment works safely “on its own”, without requiring constant human presence.

Hydrogen generator design for power plants

In those power plants that use water flow to generate energy, the design of a hydrogenerator is comparable to that of an engine. They not only produce, but also consume energy. They are distinguished by an improved thrust bearing design, which allows the rotor to spin in any direction.

If the hydrogenerator is capsule and horizontal, then it is a sealed capsule, which contains not only a hydrogenerator, but also a hydraulic turbine, as well as all the necessary systems to ensure its operation. This capsule is placed under a flow of water at the station.

Operating principle of hydroelectric power station:

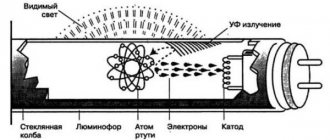

In a simplified understanding, the operating principle of a hydroelectric power station can be represented as follows. The water flow necessary for the operation of a hydroelectric power station is supplied from several hydraulic structures. The pressure of the water mass presses on the blades of the hydraulic turbine, which are driven into rotational motion. From the moment the blades begin to rotate, mechanical energy is transferred to hydrogenerators, which in turn begin to generate electricity.

Hydrogenerator design and its elements

The design of a hydroelectric generator is determined primarily by the needs of the hydraulic turbine, and they depend on the climate and weather conditions of the region where the hydroelectric power plant is located. The water pressure at the construction site is also important. Therefore, for each individual hydroelectric power station, its own hydrogenerator is created. But they all have common parts: the rotor, stator, crosspieces, thrust bearing and bearings, which form the backbone of the structure. Industrial air coolers are also installed there to cool the windings. Coolers also use water to cool heating tubes. Therefore, the materials from which the heat exchanger is made depend on what kind of water is used, its chemical composition and impurities. It can be either simple steel and brass, or stainless steel or cupronickel MnzhMts, if, for example, water with a high salt content or sea water is used.

Hydro generator calculation

For the creation of each new hydroelectric power station, a calculation is made of the hydrogenerator that will operate there. To begin with, design the dimensions of the stator and rotor, the length of the windings and insulation, structural elements and components, as well as the general fastening of all parts. All calculations are performed by professionals at manufacturing plants. A very large plant is the Elsib enterprise, which produces such generators. And, also a huge enterprise, Power Machines, which everyone probably knows about. The calculations are carried out by specialists, and you and I will benefit from the fruits of their labor.