Why does the discrepancy occur?

Despite the fact that in the conditions of modern competition, manufacturers are doing their best not to lose their customers, some of them resort to deception. To do this, they save metal by reducing the diameter. It is enough to remove just a couple of square millimeters, and over hundreds of kilometers of cable this will pay off with a significant reduction in cost.

And then the price will be reduced for the buyer, and they themselves will be satisfied. But the consumer ultimately puts himself at risk due to the fact that the conductor resistance is much lower than stated. And in the place where such a wire is laid, there is a risk of fire.

Cable selection according to PUE and GOST tables

When purchasing a wire, it is recommended to look at the GOST standard or the technical specifications according to which the product is manufactured. GOST requirements are higher than similar parameters of technical specifications, so you should prefer products made according to the standard.

Tables from the rules for electrical installations (PUE) represent the dependence of the strength of the current transmitted through the conductor on the cross-section of the conductor and the method of installation in the main pipe. The permissible current decreases as the individual cores increase in size or as multi-core cable insulation is used. The phenomenon is associated with a separate clause in the PUE, which stipulates the parameters of the maximum permissible heating of the wires. The main pipe is understood as a box, including a plastic one or when laying wiring in a bundle on a cable tray.

In order to successfully buy a wire, before purchasing you need to measure the diameter of the wire

, otherwise you may become a victim of deception.

You will also have to measure the cross-section of the wire if you add a new electrical point on the old wiring, since there may not be a letter marking on it. The information below will help you choose the right method for measuring wire diameter

and use it effectively in practice.

At the same time, the question will immediately arise: “What is the point of a company spoiling its reputation?” There may be several explanations for this: But the whole point is that even after making the correct calculations of the wire cross-section, you may still encounter a problem, despite the fact that you buy a wire with the appropriate diameter

. An accident may occur due to the fact that the marking of the wires will indicate a cross-section of conductors that does not correspond to the actual one. This may happen as a result of the fact that the manufacturing plant saved on the material, or the company producing this product did not comply with all the characteristics of the product. You can also find wires on the shelves that have no markings at all, which initially casts doubt on their quality.

1. In order to save money. For example, the factory made the wire diameter

less by only 2 mm. sq. with a 2.5 mm core, which made it possible to win several kilograms of metal per linear meter, not to mention the profit in mass production.

2. As a result of great competition, the company reduces the price of electrical wiring, trying to lure most of the consumers. Naturally, this occurs due to a decrease in the diameter of the wire

, which cannot be determined with the naked eye.

Both the first and second options take place in the sales market, so you better play it safe and make your own accurate calculations, which will be discussed further.

Methods for determining wire cross-section step by step

There are several ways to measure the cross-section by core diameter. If the wire is single-core, then measurements will be made immediately on it, but one conductor must be untangled from the cable coil. After this, it is cleared of insulation so that only metal remains.

Rice. 1: Removing the insulation from the wire

To calculate the area of a circle through the radius, use the formula: S = π × R 2, where:

- π – constant equal to 3.14;

- R is the radius of the circle.

But, due to the fact that from a practical point of view it is much easier to calculate a diameter equal to two radii, the calculation formula will take the following form: S = π × (D/2) 2.

Rice. 2: Wire diameter

Depending on the methods for measuring the diameter, such methods for calculating the cross section are distinguished.

By diameter using a caliper or micrometer

The most relevant option to measure the diameter are instruments such as calipers and micrometers. These devices allow you to measure the diameter as accurately as possible. To do this you will need a wire and a micrometer

Rice. 3: Wire and micrometer

Consider an example of determining the cross-section for a single-core wire (Figure 4).

Rice. 4: Micrometer measurement

To do this, latch B is moved to the open position. The micrometer handle is unscrewed to such a distance that the wire easily fits in the space between probes A. Then, using handle G, the device is twisted until the ratchet operates. After this, readings are recorded on all three scales at point B.

In this example, the diameter is 1.4 mm, therefore, to calculate the cross-section, you need S = 3.14 × 1.4 × 1.4 / 4 = 1.53 mm 2. The same procedure for determining the cross section can be performed using a caliper.

The advantage of this method is the ability to measure any round conductor, even if it is already installed and used to power any electrical device. The main disadvantage of the method is the high cost of the devices; naturally, purchasing them for a couple of measurements is completely impractical.

By diameter using a pencil or pen

This method of determining the cross-section is based on the fact that the wire has the same diameter along its entire length. Take a regular pencil, pen or felt-tip pen and wrap the wire around it in a spiral. To eliminate the thickness of the insulation, it must be cut along its entire length. The rings should be placed as tightly as possible; the larger the space between the rings, the lower the accuracy.

Rice. 5: Defining the section with a pencil

Since all wires have the same thickness, to determine the diameter of the copper wires, measure the length of the entire winding and divide by the number of turns. In this example, D = 15 mm / 15 turns = 1 mm, respectively, using the same calculation formula, we obtain a section S = 3.14 × 1 × 1 / 4 = 0.78 mm 2. Note that the more turns you make, the more accurately you determine the cross-section.

It is worth noting that the advantage of this method is that only available means can be used to determine the cross-section. The disadvantage is low accuracy and the ability to wind only thin conductors. In the example, a relatively thin wire was used, but the distance between the turns is already visible. Because of which the accuracy leaves much to be desired, it goes without saying that aluminum wire cannot be bent in this way.

By diameter using a ruler

Let’s immediately make a reservation that for measuring with a ruler you can only take a relatively thick wire; the smaller the thickness, the lower the accuracy. The diameter of the vein can be determined by thread or paper; the second option is the most preferable, as it gives greater accuracy.

Rice. 6: Preparing paper for measuring

Tear off a small strip and fold it over on one side. Thinner paper is preferable, so there is no need to fold the sheet several times.

Figure 7: Paper wrapping

Then the paper is applied to the wire and wrapped around the circumference until the strip touches. At the point of contact, it is bent a second time and applied to the ruler for measurement.

Figure 8: Measuring with a ruler

Using the resulting circumference L, the vein diameter D = L / 2 π is found, and the cross section is calculated as shown earlier. This method of determining the cross-section is well suited for large aluminum conductors. But the accuracy in this method is the lowest.

By diameter using ready-made tables

This method is suitable for standard gauge wires. For example, you have already determined the diameter using one of the above methods. Then you use the table to determine the section.

Table 1: determination of cross-section through wire diameter

| Conductor diameter | Conductor cross-section |

| 0.8 mm | 0.5 mm 2 |

| 0.98 mm | 0.75 mm 2 |

| 1.13 mm | 1 mm 2 |

| 1.38 mm | 1.5 mm 2 |

| 1.6 mm | 2.0 mm 2 |

| 1.78 mm | 2.5 mm 2 |

| 2.26 mm | 4.0 mm 2 |

| 2.76 mm | 6.0 mm 2 |

| 3.57 mm | 10.0 mm 2 |

| 4.51 mm | 16.0 mm 2 |

| 5.64 mm | 25.0 mm 2 |

Read also: Making clamps with your own hands video

For example, if your diameter is 1.8 mm, then this means that the cross-section according to the table will be equal to 2.5 mm 2.

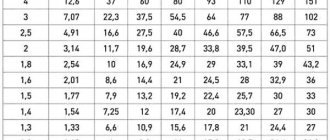

By power or current

If the conductivity of the core is known, then the cross-section can be determined using it. To do this, you will need one of the parameters of the conductor - current or power. The same can be done if you can calculate the load. Then you must select the appropriate option from the tables below. But it is necessary to take into account whether the wire is made of aluminum or copper conductors.

Table 2: to select the cross-section of the copper wire, depending on the current consumed

| Maximum rated current, A | 1,0 | 2,0 | 3,0 | 4,0 | 5,0 | 6,0 | 10,0 | 16,0 | 20,0 | 25,0 | 32,0 | 40,0 | 50,0 | 63,0 |

| Standard cross-section of copper wire, mm 2 | 0,35 | 0,35 | 0,50 | 0,75 | 1,0 | 1,2 | 2,0 | 2,5 | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 |

| Wire diameter, mm | 0,67 | 0,67 | 0,80 | 0,98 | 1,1 | 1,2 | 1,6 | 1,8 | 2,0 | 2,3 | 2,5 | 2,7 | 3,2 | 3,6 |

Table 3: to select the cross-section of copper wire, depending on power consumption

| Electrical appliance power, watt (W) | 100 | 300 | 500 | 700 | 900 | 1000 | 1200 | 1500 | 1800 | 2000 | 2500 | 3000 | 3500 | 4000 |

| Standard cross-section of copper wire, mm 2 | 0,35 | 0,35 | 0,35 | 0,5 | 0,75 | 0,75 | 1,0 | 1,2 | 1,5 | 1,5 | 2,0 | 2,5 | 2,5 | 3,0 |

Table 4: to determine the cross-section of aluminum wire cores

| Wire diameter, mm | 1,6 | 1,8 | 2,0 | 2,3 | 2,5 | 2,7 | 3,2 | 3,6 | 4,5 | 5,6 | 6,2 |

| Wire cross-section, mm 2 | 2,0 | 2,5 | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 16,0 | 25,0 | 35,0 |

| Maximum current under continuous load, A | 14 | 16 | 18 | 21 | 24 | 26 | 32 | 38 | 55 | 65 | 75 |

| Maximum load power, kilowatt (kW) | 3,0 | 3,5 | 4,0 | 4,6 | 5,3 | 5,7 | 6,8 | 8,4 | 12,1 | 14,3 | 16,5 |

For example, if, when installing electrical wiring made of aluminum, you know that the maximum current that the wire can carry under long-term load is 21 A, then to select the cross-section you need to look at the line above - 4 mm 2.

Calculation of the cross-section of a stranded wire

If stranded wire is used, in which all conductors are the same, the total cross-section is determined by adding the area of all. For example, measure the size for one core using any of the above methods. After which the actual cross-section is determined by the formula So = n × Si, where

- So is the total cross-section of the entire conductor;

- n – number of conductors of the same diameter;

- Si – cross-section of one wire.

Calculation of cable cross-section using online calculators

How to straighten a wire and measure its diameter

Hello, dear readers and DIYers!

Surely some of you have had the opportunity to wind transformers or inductors yourself. Then you know very well that a very important parameter is the diameter of the wire. Of course, if you have a measuring tool like a caliper or micrometer, no questions arise, but what to do if you only have a regular ruler?

In this article, the author of the YouTube channel “Idea Generator” will tell you about the classic method of measuring the diameter of a wire, as well as a simple way to align it.

Materials needed for homemade products. — A wooden block made of hardwood.

Tools used by the author. — Digital caliper or micrometer — Pliers, wire cutters, vice — Screwdriver, drills. Measurement process. So, to measure the diameter of the wire you will need a mandrel in the form of a tube or a round pencil. The author clamps the edge of the copper tube together with the end of the wire in a vice.

Next, the wire is tightly wound around the tube, turn to turn, about 20 turns. The more turns are made, the higher the measurement accuracy will be. In the case of very thin wire, more turns will have to be made. So, the result is 21 turns (n), and the total winding length (L) is 55 mm. Calculations are made using the elementary formula D=L/n. As a result, according to the calculation, the wire diameter is 1.78 mm.

The accuracy can now be checked using a digital caliper and the diameter is 1.73mm.

Leveling process. Deformed wire can be easily straightened, for which you need to select a drill of a suitable diameter. The drill should be slightly larger than the diameter of the wire, and the master’s “nearest” drill has a diameter of 2 mm. With this drill, he makes a through hole in a thick block of hard wood.

The board is fixed in a vice, and the end of the wire is passed through the hole.

I thank the author for a simple way to align the wire and measure its diameter.

I wish you all a New Year's mood, good health, and interesting ideas! Subscribe to the telegram channel

site so as not to miss new articles.

The author's video can be found here.

Source

Tips from an electrician

If you are selecting a VVGNG wire or cable to power the electrical network, pay attention to the following points:

- Look at the color of the copper and aluminum wire, as the manufacturer could save money and use an alloy, which significantly increases the electrical resistance and does not allow the use of permissible cross-sectional loads.

- No matter how thin the insulation of a flexible cable is, to calculate the cross-section you still need to measure only the core. Since the extra millimeters will allow you to use a wire with a smaller cross-section to power an excessive load, and this is fraught with damage.

- If at some stage you doubt the sufficiency of the cross-section or realize that using devices of lower power will not work, it is better to mount the wiring with a thicker wire.

How to determine whether the parameters match?

As a rule, extreme care on your part allows you to avoid such incidents during the purchase:

- A normal wire must have its marking, which provides the buyer with all the information about the model, operating features, and parameters. If you encounter questionable products, you may find that the product data is not presented in full or is completely missing.

- If the conductor is really good, he must be provided with quality certificates. The technical documentation indicates that it was not only manufactured in accordance with the ND, but also passed the appropriate tests.

- A good wire cannot cost a penny - since the price of materials is quite high, the cheapness should make you wonder if there is some kind of catch in this. If you wish, you can come to the store with a micrometer or caliper and perform a test to clear your doubts.

In order to successfully buy a wire, before purchasing you need to measure the diameter of the wire , otherwise you can become a victim of deception. You will also have to measure the cross-section of the wire if you add a new electrical point on the old wiring, since there may not be a letter marking on it. The information below will help you choose the right method for measuring wire diameter and use it effectively in practice.

At the same time, the question will immediately arise: “What is the point of a company spoiling its reputation?” There may be several explanations for this: But the whole point is that even after making the correct calculations of the wire cross-section, you may still encounter a problem, despite the fact that you buy a wire with the appropriate diameter . An accident may occur due to the fact that the marking of the wires will indicate a cross-section of conductors that does not correspond to the actual one. This may happen as a result of the fact that the manufacturing plant saved on the material, or the company producing this product did not comply with all the characteristics of the product. You can also find wires on the shelves that have no markings at all, which initially casts doubt on their quality.

1. In order to save money. For example, the factory made the wire diameter smaller by only 2 mm. sq. with a 2.5 mm core, which made it possible to win several kilograms of metal per linear meter, not to mention the profit in mass production.

2. As a result of great competition, the company reduces the price of electrical wiring, trying to lure most of the consumers. Naturally, this occurs due to a decrease in the diameter of the wire , which cannot be determined with the naked eye.

Both the first and second options take place in the sales market, so you better play it safe and make your own accurate calculations, which will be discussed further.

How to determine the cross-section of a stranded wire

Sometimes stranded conductors are used - consisting of many identical thin wires. How to calculate the cross-section of the wire by diameter in this case? Yes, exactly the same. Carry out measurements/calculations for one wire, count their number in the bundle, then multiply by this number. So you will find out the cross-sectional area of the stranded wire.

In order to successfully buy a wire, before purchasing you need to measure the diameter of the wire

, otherwise you may become a victim of deception.

You will also have to measure the cross-section of the wire if you add a new electrical point on the old wiring, since there may not be a letter marking on it. The information below will help you choose the right method for measuring wire diameter

and use it effectively in practice.

At the same time, the question will immediately arise: “What is the point of a company spoiling its reputation?” There may be several explanations for this: But the whole point is that even after making the correct calculations of the wire cross-section, you may still encounter a problem, despite the fact that you buy a wire with the appropriate diameter

. An accident may occur due to the fact that the marking of the wires will indicate a cross-section of conductors that does not correspond to the actual one. This may happen as a result of the fact that the manufacturing plant saved on the material, or the company producing this product did not comply with all the characteristics of the product. You can also find wires on the shelves that have no markings at all, which initially casts doubt on their quality.

1. In order to save money. For example, the factory made the wire diameter

less by only 2 mm. sq. with a 2.5 mm core, which made it possible to win several kilograms of metal per linear meter, not to mention the profit in mass production.

2. As a result of great competition, the company reduces the price of electrical wiring, trying to lure most of the consumers. Naturally, this occurs due to a decrease in the diameter of the wire

, which cannot be determined with the naked eye.

Both the first and second options take place in the sales market, so you better play it safe and make your own accurate calculations, which will be discussed further.

Three main ways to determine wire diameter.

There are several methods, but each of them is based on determining the diameters of the core with subsequent calculations of the final results.

Method one. Using instruments. Today there are a number of instruments that help measure the diameter of a wire or wire strand. This is a micrometer and caliper, which come in both mechanical and electronic (see below).

Read also: Lost wax casting method

This option is primarily suitable for professional electricians who are constantly installing electrical wiring. The most accurate results can be obtained using a caliper. This technique has the advantage that it is possible to measure the wire diameter even on a section of a working line, for example, in a socket.

After you have measured the diameter of the wire , you need to make calculations using the following formula:

It must be remembered that the number “Pi” is 3.14, so if we divide the number “Pi” by 4, we can simplify the formula and reduce the calculation to multiplying 0.785 by the diameter squared.

Method two. We use a ruler. If you decide not to spend money on a device, which is logical in this situation, then you can use a simple proven method for measuring the cross-section of a wire or wire?. You will need a simple pencil, ruler and wire. Strip the core of insulation, wind it tightly onto a pencil, and then use a ruler to measure the total length of the winding (as shown in the figure).

Then divide the length of the wound wire by the number of cores. The resulting value will be the cross-sectional diameter of the wire .

But the following must be taken into account:

- the more cores you wind on a pencil, the more accurate the result will be; the number of turns should be at least 15;

- press the coils tightly against each other so that there is no free space between them, this will significantly reduce the error;

- take measurements several times (change the measuring side, the direction of the ruler, etc.). Several results obtained will again help you avoid a large error.

Please note the disadvantages of this measurement method:

1. You can only measure the cross-section of thin wires, since it will be difficult for you to wind a thick wire around a pencil.

2. To begin with, you will need to purchase a small piece of the product before making the main purchase.

The formula discussed above is suitable for all measurements.

Method three. We use the table. In order not to carry out calculations using the formula, you can use a special table that indicates the diameter of the wire ? (in millimeters) and conductor cross-section (in square millimeters). Ready-made tables will give you more accurate results and will significantly save your time, which you will not have to spend on calculations.

People who are just getting acquainted with electricity must know how to determine the cable cross-section by diameter. This parameter can be considered one of the most important and therefore every electrician should have information regarding it. But still, it is a little difficult for novice electricians or students to determine the cable cross-section by the diameter of the core and therefore this issue should be discussed in more detail.

You need to understand that any cable consists of a certain number of cores, which in cross-section have the shape of a circle. It is the cross-sectional area of a particular cable that will determine its conductivity parameters. The thicker the cable, the more electricity it can conduct.

We are looking for the wire cross-section by diameter: formula

The wires in the cable have a circular cross-section. Therefore, when calculating, we use the formula for the area of a circle. It can be found using radius (half the measured diameter) or diameter (see formula).

Determine the cross-section of the wire by diameter: formula

For example, let's calculate the cross-sectional area of the conductor (wire) based on the size calculated earlier: 0.68 mm. Let's use the radius formula first. First we find the radius: divide the diameter by two. 0.68 mm / 2 = 0.34 mm. Next, we substitute this figure into the formula

S = π * R2 = 3.14 * 0.342 = 0.36 mm2

You need to calculate it like this: first we square 0.34, then multiply the resulting value by 3.14. We obtained a cross-section of this wire of 0.36 square millimeters. This is a very thin wire that is not used in power networks.

Let's calculate the cable cross-section by diameter using the second part of the formula. It should be exactly the same value. The difference may be in thousandths due to different rounding.

S = π/4 * D2 = 3.14/4 * 0.682 = 0.785 * 0.4624 = 0.36 mm2

In this case, we divide the number 3.14 by four, then we square the diameter and multiply the two resulting numbers. We get a similar value, as it should be. Now you know how to find out the cable cross-section by diameter. Whichever of these formulas is more convenient for you, use that one. No difference.

What is a cable?

A cable is a long wire, inside of which there are several wires that interact with each other. Several metal cores are required in order to increase the power of the cable. If there are not enough cores, then during voltage surges in the network, this wire will overheat greatly and may burn out.

If you need to determine the cable cross-section, it is enough to pay attention to just one parameter - its diameter. How exactly to use it to carry out the necessary calculations and which tools are suitable for this is worth considering in more detail.

How to measure wire diameter

When installing electrical wiring, it is necessary to ensure that the actual cross-section of the conductor corresponds to that specified in the project. Since this parameter determines the resistance to electric current, and if there is a discrepancy, overheating and a risk of fire will occur. In practice, there are situations when the purchased wire is not marked at all or the electrician has doubts about the compliance of the declared characteristics with the actual ones. In this case, you need to know how to determine the cross-section of the wire at the work site.

Detailed instructions for taking measurements

The entire process of calculating cable cross-section parameters can be divided into 6 stages, each of which has its own specifics and must obey specific rules.

Stage 1

You need to take a cable for which a person is going to determine the cross-section parameter. Most often, wires consisting of 2 or 4 cores are used for this purpose. The cores must be insulated from each other with special materials.

As a rule, the cores inside the cable have the same diameter, but you can also find wire options where one of the cores is much thinner than the other options. If the cable has one thin wire, it means it is intended for grounding.

Stage 2

The wires must be very carefully removed from the wire insulation - for this purpose you need to use a small but very sharp knife.

Then take a caliper or micrometer and, using the tool, calculate the diameter of the core. The value obtained in millimeters should be written down somewhere. Using this parameter, you will need to calculate such an indicator as the cross-sectional area. To do this, a person will have to multiply the coefficient of 0.25 by the number P, which is equal to 3.14, as well as by the resulting diameter squared. The general formula for this calculation looks like this - S = 0.25 x P xD squared . The resulting value must be multiplied by the number of cores that are present in a particular cable.

Additionally, you need to calculate the wire resistance, for which you will need the following indicators:

- wire length;

- cable section;

- the material from which the cable is made.

Having these parameters, you can easily calculate the resistance indicator.

Stage 3

To understand how measurements are made in practice and find out the necessary information, you need to consider the moment of calculation using a specific example. If the user has a copper cable in his hands, which consists of 4 cores, and its diameter is 2 mm, then you can look for its cross-sectional area.

Advice! To take measurements, it is better to use a micrometer, which will allow you to obtain more accurate indicators, which means that the entire calculation will be as accurate and correct as possible.

To determine this parameter, it is worth considering the moment of calculating the cross-sectional area for one of the cores. The following formula allows you to do this:

S =0.25x3.14x2 squared = 3.14mm squared

The calculation principle is very simple and as understandable as possible. By determining the cross-sectional parameter of one of the wires, you can find this indicator for the whole cable. To determine it, it is enough to multiply the indicator obtained using the formula above by the total number of cables.

Stage 4

By determining the cross-section parameter, a person can find out what maximum current can flow through the selected cable. Also, having the above indicator in hand, a person can determine the resistance. For example, the maximum current for a copper cable can be calculated using the ratio 8A per 1mm squared. Based on this, the limiting current value will be 8x12.56=100.5A . for aluminum cable, slightly different parameters are used, which are 5A per 1mm square.

Read also: Connecting a residential building to electrical networks

Stage 5

Knowing the cable length, you can easily get ahead of its resistance. To understand how this is done, you need to look at everything using a specific example. For example, if the length of a particular cable is 200 m, then to determine the resistance index, you need to multiply the resistivity of the material by the length of the cable and divide by its cross-sectional area. Having made these calculations, you can easily determine the desired parameter.

Wire diameter and methods for determining wire cross-section by diameter

The diameter of any conductor must match the parameters specified in the documentation that comes with it. However, such a complete coincidence, unfortunately, does not always occur. For example, if the marking says that the cable is 3 X 2.5, then its cross-section should be at least 2.5 mm2. But when you check it yourself at home, the result may well not be what the manufacturers promised. It will not be surprising if it turns out that the wire is 20-30% less than the stated figure. Therefore, it is better to check and determine the wire cross-section by diameter additionally.

To determine the diameter of the wire, you need to measure it. In this case, the measuring instruments can be a caliper or a micrometer. They use mechanical and electronic (with digital screen). The first option is more common and is measured more often, but in some cases electronic devices are preferred.

Basically, they measure wires and cables using a caliper, since this device can be found in almost every household. It can also measure the diameter of wires in a working network, for example, a socket or panel device.

In fact, there are several ways to determine the diameter of a wire. Each is based on determining the diameter of the core with subsequent calculations of the final results.

Method one. Using instruments that help measure the diameter of a wire or wire strand. And also using the formula.

This option is primarily suitable for professional electricians who are constantly installing electrical wiring. That is, the person conducting the measurements must have experience in this area. Of the two measuring instruments, the most accurate results can be obtained using a caliper. The advantage of this device is that it allows you to measure the diameter of a wire even on a section of a working line, for example, in a socket.

Determining the wire cross-section using the formula

After you have measured the diameter of the wire, you need to make calculations using the following formula:

The above formula is suitable for all measurements.

It must be remembered that the number "Pi" is 3.14, so if we divide the number "Pi" by 4, then we can simplify the formula and reduce the calculation to multiplying 0.785 by the diameter squared.

Also, to determine the cross-section, the formula for finding the area of a circle by diameter is also suitable. It looks different: S = π/4 X D2. This formula is more labor-intensive, but, in any case, by substituting the numbers and solving the example, we get the same result. In cross-section, any cable core has the shape of a circle. It doesn't matter whether it's wire or wire. What is the wire cross-section? This is nothing more than the cut circumference area of the wire. And the area of any circle, knowing its diameter and radius, can be easily calculated using a simple formula familiar to everyone from school: S = πR2. “π” is a constant number and is always equal to 3.14, “R2” is the radius squared.

We substitute the values into the formula, first dividing the diameter by two to find out the radius, because in this formula the area is found out precisely with its help. It turns out: S = 3.14 X 0.342. All you have to do is solve this simple example, the result is 0.36. What does it mean - the cross-section of the wire being tested is 0.36 mm2. But it is better not to use such a “weak” wire in the power network.

Measuring wire cross-section using a ruler. If you do not have one of the special measuring devices and you decide not to spend money on purchasing one, then you can use an available proven method for measuring. Take a simple pencil, ruler and wire. Strip the core of insulation. To do this, wind it tightly onto a pencil, and then use a ruler to measure the total length of the winding.

Then divide the length of the wound wire by the number of cores. The resulting value will be the diameter of the wire cross-section.

So you need

1. Clean the insulating layer of the core;

2. Twist the turns around the pencil tightly to each other (there should be at least 15-17 pieces);

3. Measure the winding length;

4. Divide the resulting value by the number of turns.

Rules to consider when performing this work:

- the more cores you wind on a pencil, the more accurate the result will be; the number of turns should be at least 15;

- try to press the turns tightly against each other so that there is no free space between them, this will significantly reduce the error;

- The measurements must be repeated several times (while changing the side of the measurement and the direction of the ruler). By getting multiple results, you have a better chance of avoiding large errors.

Disadvantages that you should pay attention to with this measurement method:

- You can only measure the cross-section of thin wires, since it will be difficult for you to wind a thick wire around a pencil.

- You will need to purchase a small piece of the product first before making the main purchase.

Method three. Measuring the cross-section by wire diameter using a table. Using this particular method, you do not have to carry out calculations using the formula. In a specially selected table for your convenience, the diameter of the wire (in millimeters) and the cross-section of the conductor (in square millimeters) are already indicated.

Calculation of section parameters using a table

Having made the necessary measurements, you can determine the cable cross-section using the indicators in a special table. By measuring the thickness of the core diameter using a special table, you can determine the cross-section.

The cable cross-section calculation table is as follows:

Thanks to this table, you can find out the necessary information very quickly and without unnecessary problems. The table shows the cross-sectional area of different cables and allows you to significantly simplify the calculation process, because some novice electricians, using only a formula, find it difficult to determine this indicator.

Additional information and tips

If you install a low-quality cable at home, it can simply burn out from the slightest fluctuations in the network. To prevent this from happening, craftsmen, before installing the wiring, measure the cross-section of the cable by its diameter. This helps to understand how much voltage a particular wire can withstand and whether it is worth installing. If the cross-section calculation is carried out and the parameter turns out to be underestimated, then the user runs the risk of encountering the following danger:

- the load capacity of the wire decreases;

- if a smaller or larger current is passed through the wire, it will be completely destroyed;

- a fire may ignite in any area of the cable and start a fire.

Statistics show that there are now a lot of fires due to the fact that the electrical wiring system does not work properly. Therefore, in order to avoid fatal consequences, it is worth calculating the cable cross-section based on its diameter.

Advice! When choosing a cable in a store, you should not always believe the information on it. Often, manufacturers provide better technical data than they actually are, just to sell their products and make good money on it.

Determining cable cross-section using a ruler

It is possible to measure the cable cross-section by using a simple ruler. This is a very old method of taking measurements, but it is no less effective than carrying out the same actions using special instruments. To take a measurement using a regular ruler, follow these instructions:

- carefully strip the core of insulation;

- tightly screw the core onto a regular pencil;

- measure the total length of the winding using a ruler;

- divide the winding length by the total number of cores present in the cable.

When winding a core around a pencil, you need to make sure that you get at least 15 turns. The coils should be pressed very tightly against each other, so that there is no free space between them. It is necessary to take measurements not just once, but several times in order for the result to be as accurate as possible.

It is important! This method is only suitable for determining the diameter of thin wires. If the cable is thick, it will be very difficult to wind it, which will not allow you to do everything efficiently and take accurate measurements.

How to find out the cross-section of a wire without a micrometer

If you have a caliper on hand, that's great. You can find out the diameter of the wire without a micrometer, using just a caliper. However, often there is no caliper at hand, and then a pen or pencil comes to the rescue.

You can find out the wire cross-section using a pencil as follows:

- Strip the wire of insulation to obtain the most accurate measurements;

- Wrap it as tightly as possible around a pen or pencil. The longer the winding, the more accurately you will be able to find out what cross-section the cable is.

To find out the diameter, you need to count the number of turns and then divide them by the length of the winding. Thus, you can quite accurately determine the cross-section of the wire without a micrometer and calipers.

Advice from professional electricians

Experienced electricians already know how to determine the cable cross-section correctly even by eye. For those who do not understand this matter very well or are taking measurements for the first time, professionals are ready to give some useful tips. And so, experts advise people who want to take cross-section measurements to follow these rules:

- you need to pay attention to the quality of the metal from which the core is made (the aluminum or copper core must have a rich color, otherwise a low-quality metal alloy was used, and this can be dangerous for use);

- the section should be performed exclusively along the core, because the insulating material should not be taken into account;

- If you doubt the size of the conductor, you need to take a thicker cable, since then there is definitely a guarantee that it will withstand a certain load.

Using these tips, everyone can independently deal with electrical cables and calculate the required value.

Methods for determining wire cross-section

It will not be difficult for an experienced electrician to determine the cable cross-section simply by eye. But for a person who does not have the appropriate skills, calculating this value can become a real problem.

In fact, the wire cross-section can be determined using several methods that are not difficult even in the absence of appropriate training.

The easiest way is to pay attention to the marking of cable and wire products, applied externally to the insulating coating and repeated at a certain frequency.

You can also find out about this value from the seller. But if the cross-section is not indicated, or we are talking about an old wire, about the characteristics of which there is no information, the indicated value can be found out using the methods indicated below. First you need to find out the diameter.

Using instruments

Instruments with which you can measure the cross-section:

- calipers,

- micrometer.

I think everyone can use these devices; the video below explains how to use a micrometer:

Winding method

If these devices are not available in your home tool kit, the cross-sectional area can be calculated using an alternative method in which a ruler and a pencil (or any other rod) are sufficient.

The core, cleared of insulation along a length of up to 500 mm, is wound onto a pencil, with the turns tightly adjacent. To calculate the cross section, you will need to measure the following quantities:

- total length of the wound section in mm;

- number of turns.

To determine the diameter of the core, it is enough to divide the resulting length by the number of turns.

Also read: How and with which fire extinguishers to extinguish electrical equipment

To calculate the cross-sectional area, all that remains is to substitute the obtained result into the formula given below.

Determining the cross section using the diameter calculation method

This method is based on an introductory geometry course and does not involve complex calculations. To determine the initial indicators required when performing the calculation, you should use a caliper. Using this tool, the diameter of the core, stripped of the insulating coating, is measured.

The calculation is made using the following formula used to determine the area of a circle:

S = πR², in which

- π is a constant value equal to 3.14 in the nearest rounding;

- R is the radius of the wire cross-section, determined by dividing the resulting diameter value by 2.

If we insert the diameter into the indicated formula instead of the radius, we get the following:

S = (πD²)/4,

where D is the value of the core diameter.

Having transformed the indicated formula, after dividing the numerical values, we obtain the following relationship:

S = 0.785D².

Substituting the measured diameter, we obtain the cross-sectional area of the wire. Taking into account the rounded value of π, the answer will be obtained with a certain error, but the accuracy of the calculation is quite sufficient for the tasks at hand.

Flexible cable cross-section measurement

For a multi-wire flexible cable, its own method of measuring cross-section is used. This method consists of the following points:

- wrap one vein from the bunch around a pencil;

- measure the length of all turns;

- divide the length by the number of turns and multiply the result by the total number of wires.

The method is quite simple and understandable, so absolutely everyone can use it. To take measurements correctly, you need to perform all actions as carefully as possible.

This procedure is not difficult for professional electricians, but it will not be so easy for beginners to cope with this task. In such a responsible process, the main thing is to do everything carefully and then you can get the most accurate result.

Conclusion

You can quickly determine the cable cross-section by diameter. In order to visualize this parameter, a person can use one of several available methods. The main thing when performing the measurement process is to carry out all actions carefully and accurately. To quickly calculate the required indicator, you can use a special table that contains all the data. If a person does not use a table, then he will be able to perform all the calculations using a special formula.

Whatever method a person chooses, all actions should be carried out carefully and carefully. Anyone can take measurements of this nature, taking into account the advice given by professional electricians. Measurements can be taken using special instruments or a regular ruler.

You can measure the cross-section of a cable in just a couple of minutes, finding out whether it can be used for a specific purpose. When choosing a cable, you should always remember this. That the markings on them do not always correspond to reality. That is why it is worth checking the necessary parameters yourself in order to know what quality products are being used. Having calculated the required parameter, a person can verify the quality of the cable and use it to replace the wiring. The main thing is to carry out all the measurements correctly and then the wire used will be as safe as possible for home use; there will be virtually no risk of any short circuits or other troubles.

What diameter are the wires and how to determine the cross-section by diameter. Diameter table

Content

- Wire diameter and what materials the wires can be made of

- Wire diameter and methods for determining wire cross-section by diameter

- Determining the wire cross-section using the formula

- Wire diameter and diameter correspondence table with definition of cross-section

- Conductor markings (wire diameter)

- Determining the cross-section of a stranded wire

- Aluminum cable with sector conductors

- Power (wire diameter)

- Electric current (wire diameter)

- Load (wire diameter)

- Wire diameter - conclusion

Before purchasing a wire, be sure to measure its cross-section. Moreover, if you change the wiring or add a new point to the old one, then in this situation you will need to measure the cross-section of the wire. Since all wires are of different diameters, their cross-section is different. Nowadays, there is often deception on the part of the manufacturer. For example, the specified wire diameter for sale is not entirely reliable. Therefore, rather than be deceived, it is better to determine the size of the conductor yourself. We will teach you how to determine the cross-section of a wire by diameter.