A staircase is an integral attribute of any cellar. To ensure comfortable movement, the structure must be strong, reliable and stable. A do-it-yourself cellar staircase, made according to ready-made drawings and recommendations, will last for many years.

An attached or marching structure is built in the cellar

What are the types of stairs to the cellar?

The simplest and cheapest option is a ladder. No installation is required, as it can be removed and installed at any time. The safest marching structures made of wood and metal. Concrete monolithic structures are expensive, but at the same time the most reliable.

An extension staircase to the cellar in a private house is simple to implement. Two vertical posts are fastened with crossbars. Usually they are used to equip shallow small basements. A properly made cellar ladder can last a long time. Reliability will be ensured by a combination of materials: wood for the steps and a metal profile or corner for the frame.

The attached combined ladder is fixed at some distance from the wall and reinforced with vertical metal rods

Experts consider a flight of stairs to be the most convenient and reliable design for a cellar. It can only be installed in a large storage facility. Usually they set up one march without a platform. If the room is small, make two narrow flights.

The staircase is made of wood, metal or concrete. Sometimes materials are combined to strengthen the structure and give it an attractive appearance.

To prevent wood from bending due to humidity in the basement, it is treated with water-repellent agents.

Monolithic concrete structures for cellars require the manufacture of complex formwork and reinforcement. In practice, such structures are reinforced with a metal corner.

To make the structure last longer, it is coated with sealant and faced with floor tiles

If there is very little space in the cellar, install a spiral staircase. Such structures look attractive. Typically the frame is made of metal and the steps are made of wood.

What material to build from?

Wood is an affordable and easy-to-process material, but it needs additional protection.

Special compounds protect the structure from insects, moisture, and moss growth

A staircase made of a metal profile or corner is more reliable, but more expensive to manufacture. The frame is treated with anti-corrosion agents and painted in the required color.

Concrete cellar stairs are durable. Like any material, they require treatment with moisture-resistant agents. They are built in basement-type basements, in spacious rooms.

Concrete stairs are faced with floor tiles, wood or painted. If necessary, the product is coated with an anti-slip rubber agent. The structure is additionally reinforced with concrete pouring or a metal corner.

Attention! A brick cellar staircase is built extremely rarely, only in spacious rooms. The descent is filled with soil or other bulk material.

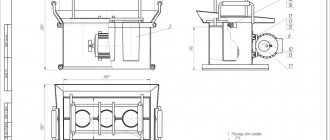

Options, drawings and dimensions of stairs to the cellar

When arranging the staircase to the cellar, determine its purpose. This allows you to most accurately select the design and material for manufacturing.

Having made the necessary calculations, the drawing is applied to paper

Before creating a project, they study the criteria that the staircase to the cellar must meet. This takes into account:

- cellar size;

- width and length of the release hole;

- frequency of use of the ladder;

- load on steps;

Stairs to the cellar on bowstrings are reinforced with a steel rod so that the structure does not move apart

- where the construction begins, outdoors or indoors;

- estimated dimensions of the stairs;

- compliance with the interior;

- price.

They also take into account the convenience of the design from the point of view of use: ease of moving the legs, space in the width and height of the flight

. Based on the specified parameters, a drawing is made. The width of the stairs to the cellar is usually at least 70 cm. The height of the steps is 16-22 cm. The width of the tread is 25-30 cm.

Bowstrings are made from a solid board 5-6 cm wide

Almost any staircase is equipped with railings. This simplifies the descent and ascent into the cellar. The stringer is made from a single board. The teeth are cut to the size of the treads.

To secure the tread on the stringer, fillets are used, which are secured with dowels or dowels

The next cellar design takes into account filling the space under the stairs. This arrangement of shelves allows you to take a jar without falling down onto the storage floor.

The angle of inclination allows you to build a convenient handrail

Extension stairs to the cellar are made of wood or metal profiles. Treads for frame structures are made from boards 3-5 cm thick.

The attached structure has a steep slope of 40-600

Spiral staircases to the cellar consist of a support post and steps. Metal structures are welded to the base. The stand is made of a steel pipe with a cross-section of 10-12 cm. Decorative steps made of wood or metal mesh are attached on top of the frame.

The treads are cut into a triangular shape, its size allows you to set a screw descent

General recommendations for constructing stairs

The question: “?” worries those people who are building a house without a project. Its presence saves the owner from such torment, since in the project, on the plans of each floor, the locations of the stairs are marked, and when the ceiling is installed, appropriate openings are immediately provided for in them.

However, even with a project, unforeseen situations happen. For example: as a result of an error, the entrance to the basement floor with a staircase is not provided at all, or it was not in the place where it was supposed to be. As a result, you have to make an opening in the already finished ceiling.

Opening for stairs

If the ceiling has a beam structure, everything is much simpler. The main thing here is that additional beams are installed around the perimeter of the hole. In the case of monolithic or prefabricated reinforced concrete floors, diamond cutting services are used to create openings.

Reinforcing an opening in a concrete floor

Beam ceiling: do-it-yourself staircase to the ground floor

So:

- Cutting the opening is carried out only after it has been reinforced with a steel angle or the supporting walls have been erected. It is advisable that the opening for the stairs be located along the load-bearing wall.

- In this case, the opening can be strengthened to a minimum, and it becomes possible to install not an inconvenient spiral staircase, but a marching staircase, or, say, a bolt staircase, which, due to its design, is attached only to the wall.

- In a basement floor covered with ceiling beams, their location is the guideline for placing the opening for the stairs. In general, before making an opening, you need to calculate its dimensions, or even better, order a design for the stairs to the ground floor.

Drawing with approximate dimensions of the flight of stairs

Note! The staircase from the ground floor to the house, like no other, requires strict compliance with building codes, because in the absence of windows or a separate exit, this is also the only way of evacuation from the premises in case of fire.

Basement staircase installed in cramped conditions

If you make the opening too small (1m*2m), then you can’t even dream of comfortable movement along the stairs. Of course, even in such a situation, you can build a staircase, providing instead of a landing in it a sharp turn of several steps tapering on one side. You can see a similar design in the photo above.

However, we note that although it looks beautiful, it is inconvenient and unsafe to use. This option is good only when combining apartments on two levels, which does not allow making a large opening in the ceiling.

In the basement floor, you can also provide a more convenient staircase, which requires an opening of at least 2m*3m. It may be more - but this depends on the type of staircase and the dimensions of the house.

Stair sizes

Ideally, the width of the stairs should not be less than 80 cm, or even better – 1 m, because you will not only have to walk on it, but also carry furniture.

So:

- For flights of stairs, the maximum slope should be 42 degrees.

- To make it comfortable to step on the steps, their width must be at least 250 mm.

- You can increase the depth of the tread by using the edge of an overhead wooden or ceramic step, the toe of which protrudes beyond the vertical plane of the riser.

- If the staircase is, say, metal, with glass steps, then this possibility will no longer exist.

Increasing tread depth due to protrusion

Note! The height of the risers is determined by calculation, and optimally it is 15-20 mm. It is important that the height of each step is the same, with an error of no more than 3 mm. The total span height is the distance between the finished floor marks of the upper and lower rooms.

The calculation is done like this:

- Let's say the height of the stairs for the basement is 295 cm, and you want to make steps 16 cm high.

- Dividing 295 by 16, you determine the number of steps - you get 18.44. Since this number is fractional, it should be increased to the whole number -19.

- An odd number of steps is considered the most convenient , since in this case a person stands on both the first and last step with the same foot.

- Then you need to adjust the height of the steps, dividing 295 now by 19 . As a result, you get a final step height of 15.5 cm.

Requirements for cellar stairs

The design of the staircase is calculated based on ease of use by humans. The average step length is 63 cm.

Key parameters when designing a staircase:

- The recommended width for the cellar is 70-90 cm and depends on the size of the room;

- clearance - from the steps to the ceiling depends on the height of the cellar, to make it comfortable to go down, the head should not touch the ceiling (make it 10-20 cm higher than the person’s height from the steps);

- the slope of the cellar stairs varies from 45-750;

- the height of the structure, convenient for moving at full height, is 2 m;

- tread width comfortable for a person is 30 cm;

- Experts consider the height of steps 15-22 cm to be the most comfortable;

- the number of steps is calculated after the angle of inclination, width of the tread and height of the structure have been determined (the total height is divided by the height of the riser).

If, when counting the number of steps, a non-integer value is obtained, the height of the step is adjusted using the lower or upper riser

Calculation of dimensions

The construction of a staircase in the basement of a house begins with calculations and drawing up a drawing. The optimal dimensions of the staircase structure are:

- March width. For the standard version, parameters of 0.9–1 m are suitable. If the space of the room allows, you can slightly expand the march.

- Clearance. This is the height from the position of the step to the basement floor. This parameter is important during operation. The user should not touch the ceiling with his head. In the narrowest possible place, the clearance should be equal to the average height of a person plus 10-20 cm.

Related article: Advantages of transforming stairs and their varieties (popular manufacturers)

- Steepness. The largest slope for an attached structure is 75. If a stationary staircase is installed, the less steep it is, the easier it will be to move along it when descending or ascending. But it also takes up more space. The best option is 26-32.

- Step depth. This value is usually no more than 30 cm. In normal situations, they try to make the depth of the step in accordance with the size of the person’s foot. For a basement, this condition is not necessary, since an increase in parameters increases the length of the entire structure and, therefore, it takes up more space.

- Step height. It ranges from 15 to 20 cm. This is the best option for comfortable movement. You won't need to raise your legs high. It is necessary to ensure that the height of all steps is the same. In the case when the length of the march is not divided entirely, then extra centimeters are added either to the first or last step.

You can calculate the number of steps in the following way: the length of the structure is divided by the expected height of the steps. For example, with a staircase height of 2.5 m and a step of 0.15 m, the result is 16.6 elements. Since the number is not an integer, they proceed as follows: 2.5 m divided by 16 and get a height of 0.156 m or by 17, then the height of the step will be 0.147 m.

What tools and materials will be needed

Having chosen the type of construction and materials for the manufacture of the stairs to the cellar, they are prepared.

The following tools and materials may be required:

- boards for bowstrings or stringers 5 cm thick;

- channel for fastening steps;

- for the frame structure you will need a metal profile with a cross section of 3*5 cm;

- metal corner 5*5 cm;

- a corner 10*10 cm for covering the floor of the first floor, it will serve as reinforcement;

- for steps, sheet metal, mesh or wooden boards 5 cm thick;

- boots for fastening boards;

- concrete mortar to strengthen the base of the stairs;

- paint or moisture-repellent protective coating for metal and wood;

- welding machine;

- level;

- electric drill;

- screwdriver;

- grinding machine;

- spanners.

Attention! If you choose a monolithic concrete structure, grade 400-500 cement is purchased for its construction. This will improve the strength of the concrete.

How to calculate the stairs to the cellar

The calculation of the stairs to the cellar is made based on the anthropological characteristics of the person. The ratio of the height and width of the riser and tread is calculated based on a person’s step length of 63 cm.

To avoid hitting your head on the ceiling, the height of the clearance is made 10-20 cm higher than the height of the person standing on the step

The width of the tread is calculated using the formula: 2 * comfortable height + x = 60. For example, a comfortable step height is 16, which means:

2 * 16 + x = 60, or

32 + x = 60, then

x = 60 – 32 = 28 cm.

Similarly, the height of the riser is calculated based on the width of the step. Supposedly the width is 30 cm, which means:

2 * x + 30 = 60, or

2x = 60-30, which means

x = 30/2 = 15 cm.

The number of treads is calculated by dividing the length of the structure by the height of the steps. The standard room height of 250 cm is taken as a basis. The optimal height of the steps is 16 cm. The result is 250/16 = 15.625. The result is a fractional number. This means that you will need to build 15 steps 16 cm high and a step: 16 cm * 15 pieces = 240 cm-250 cm = 10 cm. The error is caused by the upper or lower steps of the stairs.

Calculation of parameters

For the staircase to the cellar, two types of construction are recognized:

- Attached - considered the standard option used by country owners and private homeowners. Mostly made of wood and metal. It is classified into two types - stationary and mobile.

- Marching is a complex structure, the design of which is developed during the construction of the entire facility. Thanks to the gentle slope, walking is comfortable.

Any type of staircase entrance requires proper design.

Commonly accepted calculation parameters

Do-it-yourself staircase to the cellar will require taking into account the design characteristics:

- Tilt angle – varies between 22-75°. A large slope value is used in the construction of attached elements.

- Width – the classic option is 70-90 cm, suitable for moving the average person. If there is a large room, it is possible to construct a wide opening.

- Clearance is determined by the height of the cellar itself. The height of the room is calculated taking into account the minimum value of 1.9 m.

- The width of the step depends on the area of free space in the room. A common value is 25-32 cm.

- Step height – the standard height is 13-22 cm.

- The height of the railing – the value corresponds to 80-90 cm from the step.

- Number of marches - one curl includes 18 steps, the march is rotated by 90° or 180°.

There is a formula for calculating the height and width of a step. The generally accepted average step for a person is 60-64 cm. It is equal to the sum of twice the height and width of the step. For example, the height of the step is 18 cm. Calculation: 18*2+x=60, hence x (step width) = 24 cm.

The number of steps is calculated by dividing the height of the structure by the height of the steps. If a 2-meter staircase is made, then the number of steps with a standard height of 14 cm will be equal to 2.0: 0.14 = 14.3. This amount can be distributed at the same height. It is possible to make the end steps incorrect.

How to make a simple staircase to a cellar out of wood with your own hands

Before making a wooden staircase to the cellar with your own hands, choose the type of construction: on stringers or bowstrings.

Stages of work:

- Stringers are made from boards 30 cm wide and 5 cm thick according to the diagram below:

Cuts are made according to a pre-made template made of cardboard or plywood - Using clamps, the template is attached to the board and the teeth are cut out with a jigsaw. Markings are made using a pencil and ruler, indicating the dimensions on the board.

- The first stringer is attached to the wall. The second one is installed in a permanent place and secured to the first one with a steel pin in the middle.

The evenness is checked by placing a board on the crossbars, and a level on it, while the parts are not secured, adjustments are made - The stringers are secured to the interfloor ceiling.

Metal brackets designed to strengthen floor beams will help hold stringers together - From below, the stringers are attached to the support beam. Steps are laid on the teeth. The structure is coated with an antiseptic. Then varnish or paint is applied. If necessary, install railings.

Before attaching the boards to the stringer, make a hole in the tread for a self-tapping screw.

Production of monolithic reinforced concrete stairs with lower formwork

The primary conditions for the construction of a concrete descent into the basement is the presence of a solid foundation. This can be a poured reinforced floor or a specially prepared small foundation.

There are two options for how to make a staircase to the basement with your own hands from concrete. The first is made in the form of a monolithic reinforced concrete descent supported on the floor over the entire area. The second one provides for installation of lower formwork during installation for pouring concrete and the presence of free space under the flight of stairs.

In each of the options, the structure can be installed tightly against the wall or in the middle of the room.

Reinforcement and installation of formwork

The procedure for constructing a concrete staircase differs from monolithic foundation work. In this case, the formwork fences are assembled in two stages. Initially, only the lower formwork is installed, a reinforcing frame is assembled, which is then sheathed with side sheets and riser partitions. The formwork material can be multi-layer plywood or 30 mm thick boards.

During the assembly of the frame, the individual reinforcement elements are connected to each other using soft knitting wire. First, the lower longitudinal row of reinforcement is laid along the entire length of the flight. The number of rods with a diameter of 12 mm is at least 4, 10 mm is at least 6.

In order to raise the laid strings by 3-5 cm above the lower formwork, it is recommended to use polymer fasteners of the “star” or “stand” type. The laid longitudinal rods must be connected with transverse reinforcing inserts with a diameter of 8-10 mm every 250-300 mm. If the staircase is adjacent to the wall, it is recommended to hammer the edges of the transverse bandage into the building structure.

On a horizontal platform, reinforcement is carried out in the form of flat meshes 8x100x100 laid in 2 rows in height. The finished frame should exactly follow the outline of the staircase with all the steps and the landing, but be 3-5 mm smaller than it.

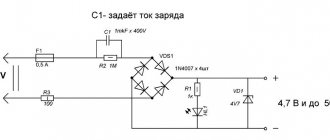

How to make a staircase to a cellar from metal and a profile pipe with your own hands

A small metal staircase to the cellar is made from a 3-4*5 cm profile. The structural elements are attached using a welding machine.

Operating procedure:

- A resistant structure is made from a metal profile 4*5 cm, which is equal to the length of the stairs.

The profile is attached to the ceiling from above - After an equal interval (the height of the steps), a supporting piece of the profile is welded onto which the steps will be attached. They are made from reinforcement with a cross section of 1.5 cm.

From below, the structure is welded to reinforcement concreted at the base

Attention! If you make a bowstring from a metal rod, which consists of three parts with an interval of 10 cm, then it can simultaneously serve as a handrail for lowering and ascent.

Installation of metal stairs

A staircase made of metal profile pipes in the basement can be installed much easier than a concrete one. It is much lighter in weight. But the microclimate of the basement can negatively affect the metal, so the structure is fully protected from corrosion.

To install a metal staircase to the basement you will need:

- channel No. 10;

- fittings;

- metal corners measuring 50×50 mm;

- welding machine;

- Bulgarian;

- steel sheets;

- building level.

Stage No. 1 – Preparing the base

Preparing the base for an iron staircase in the basement of a private building can be done in two ways. Both of them begin with the construction of a recess measuring 1 × 0.4 m and a depth of 0.5 m. A layer of crushed stone is poured onto the bottom of the pit. The further process is different.

In the first case, concrete is poured not reaching the edge of the recess 15 cm. It is completely filled after installing the structure on the base. In the second case, the concrete is poured completely, but the embeds are first provided. Their role is played by reinforcement with a cross section of 12 mm. The ends should protrude 25 cm above the floor level.

Stage No. 2 – Installation of stairs

The channels will act as a support on which the steps are fixed. They are attached to the upper ceiling using bolts at a distance of 0.9 m from each other. Their lower ends are installed on the base and welded to the mortgages.

If you need to build a two-flight metal staircase to the cellar, then first assemble the platform. A square is welded from the channels in such a way that there are protruding edges on all sides. They will allow you to secure the workpiece to the basement walls.

Article on the topic: Staircase on bowstrings: features of installation of the structure (fastening and installation of the bowstring)

To obtain full-fledged stringers, metal corners must be welded to the previously installed channels. Fastening is carried out from the inside. The result should be what is shown in the photo below.

Stage No. 3 – Final finishing

After the structure is completely welded, they begin to finish it. They start by grinding the metal. Welding seams are polished first. Many craftsmen perform this cleaning during the welding process. Then, with light movements using a grinding wheel, rust is removed from the metal elements. The cleaned structure is completely coated with a primer.

Next, they begin covering the steps. For this, either sheet steel or wooden boards are used. Railings are welded on the sides.

In the video: an example of making a simple metal staircase.

How to make a staircase to the cellar from a corner

To weld the stairs to the cellar, you will need a metal corner or channel.

Operating instructions:

- Bowstrings are welded from a channel and sheet metal so that a block of 20*10 cm is obtained. According to the selected drawing, sections equal to the width of the tread are cut from the corner. The bowstrings are welded to the ceiling between the first floor and the cellar.

Welding areas are thoroughly cleaned using a grinder so that no burrs remain. - Parts from the corner are welded to the bowstrings so that a staircase without steps is obtained. It is recommended to decorate such a structure with wooden treads.

To prevent the steps from creaking during operation, a little polyurethane foam is applied between the metal and wood.

Technology and stages of manufacturing and installation

Making a staircase with your own hands involves the following stages of manufacturing and installation:

- calculations;

- preparatory work;

- production of blanks and parts;

- frame installation;

- construction of the structure;

- decorative finishing.

Don't forget to prepare the material

Metal

The metal requires little maintenance (there must be an anti-corrosion coating), is durable, functional, fireproof, and looks good. Almost its only drawback is noise. But in combination with special types of wood, noise can be reduced to a minimum.

If you ordered a design calculation from a special company, then such organizations use computer programs to create the design. In such a program, parameters can be easily changed, and after the customer approves the final version, the computer produces drawings. If you did not contact a design company, but decided to complete the drawings yourself, it will be a little more difficult.

Before starting work, you need to prepare all the necessary equipment.

When the calculations and preparatory work are completed, it comes to the blanks. You will need stringers; for this you need a square profile pipe. The role of support will be performed by iron corners. We will make steps and risers from sheet steel 4 mm thick.

The simplest staircase design is based on a channel placed on its side. If you want to finish the stairs to the basement, you need to prepare sheet metal or wooden boards for this.

To make your own metal porch, it is recommended to use non-slip materials, such as corrugated metal sheets, when covering the stairs. Railings and fences for this design are made from angle steel. To make supports for the stair treads, reinforcing steel should be prepared.

Next, let's look at step-by-step instructions on how to make a metal staircase with your own hands:

- Cutting reinforcement into fillets - special supporting devices that are placed on the beam. The required number of fillies and their sizes are selected according to the design documentation.

- The next step is to weld the mounting containers to the side of the filly on which the step will be placed.

- Then we weld the fillets to the channel; they can also be secured with bolts. At this stage, pre-made markings will help you.

- Next, attach the next channel to the beam with fillets attached to it and, if necessary, correct the markings.

- The next stage is assembling the metal staircase using welding.

- Then treat the material with a primer and wait until it dries completely.

- Treat the metal with a special anti-corrosion compound.

- Place the building on supports. As a support, you can use metal corners attached by welding to beams or channel racks.

- The structure is ready, all that remains is to sheathe the steps.

Various materials are used to cover metal stairs. The most popular finishing for stairs on a metal frame is wood.

Most often, wood and metal are used to make railings, less often stone, glass, and PVC.

Tree

The most commonly used material for staircases is wood. In combination with metal, for example, stairs on a metal frame are more durable and creak less. Softwoods are the cheapest, but not wear-resistant. Birch and maple are the optimal combination of price and quality. Elite types of wood are very expensive and are used mainly for finishing. Very stable and durable laminated wood.

Before starting work on the manufacture of wooden stairs for a cellar, appropriate calculations are required. You can either draw up a diagram for the upcoming design yourself or use a ready-made template on our online resource.

A standard march is made with the steps supported by strings running on both sides. Another fastening option is also possible - supporting the steps on stringers. Next, you need to correctly connect the bowstrings and strengthen the structure with supporting bars. The bottom and top of the bowstring must be secured to the walls, ceiling and floor.

When making a wooden staircase, do not forget to take into account a number of details

How to make a brick staircase to a cellar

The brick structure is installed in a spacious room. You can make a staircase to the cellar with your own hands according to the photo instructions:

- At the stage of construction and laying the foundation, excavations are made in the soil according to the size of the steps. Fill a cushion of sand and crushed stone 10 cm high and compact it well.

- The risers are made from brick. Steps made of tiles or porcelain stoneware are laid on them. Each row is carefully checked with a level.

- Balusters and railings are attached to the steps.

- Brick stairs are durable and reliable.

Finishing work

The steps will finally gain strength after 30 days. But the formwork itself can be removed after 10–15 days. Since its assembly was carried out using screws, dismantling is quick. To do this you need:

- Carefully remove the formwork of the steps.

- Remove the sides of the stairs.

- Remove the deck of the structure.

Finishing work consists of polishing the concrete and protecting it from external factors. If desired, the staircase to the cellar is lined with the selected material.

How to make and pour a concrete staircase to a cellar

To build a concrete staircase to the cellar with your own hands, you need to make formwork and reinforce it with reinforcement.

Work order:

- Formwork for the selected monolithic structure is constructed from boards and plywood. The base is made from plywood. Metal pipes and wooden beams are used as support.

Teeth are cut into the side crossbars for fitting reinforcement - After erecting the formwork, the surface is carefully covered with plastic film. A mesh is tied from metal rods.

The reinforcement is installed at a distance of at least 3 cm from the base, for this purpose laying pads made of boards or other - Install stair risers. The structure is reinforced with longitudinal boards.

The risers are set according to the level, since it will be impossible to correct them in the future. - The sides are additionally reinforced with boards. They begin concreting the structure. Filling is carried out in one step so that the solution is strengthened at the same time without cracks or chips. Concreting begins from the bottom step, gradually moving to the top. The rules are to level the steps.

It is important to eliminate all voids; for this, a deep vibrator is used - For high-quality aging of concrete, it is moistened with water daily for two weeks. The structure is covered with plastic film. The formwork is removed two weeks after pouring the concrete. First, remove the sides. After ten days, the remaining formwork is dismantled. The steps are sanded and if any irregularities are found, they are puttied. Before decorating, coat with a deep penetration antiseptic. Lay wooden risers and treads.

The cladding of wooden steps of a monolithic structure is carried out three weeks after dismantling the last elements of the formwork

Construction of a concrete staircase

A concrete staircase for a basement in a country house is an ideal option. The advantages are obvious:

- does not corrode;

- does not bend;

- will not creak over time.

The disadvantages include the fact that it is better to install it during the construction of a private house. If such a situation occurs that the idea came later, then you need to prepare for this labor-intensive process and, possibly, considerable costs.

Before you make a staircase to the basement with your own hands, you need to calculate not only its parameters, but also the amount of material needed:

- cement, sand, crushed stone;

- reinforcement fittings;

- lumber for formwork.

All the nuances are thought out at the stage of drawing up the drawing, since the structure is monolithic and it will not be possible to make adjustments.

Individual calculations are especially important in the case of installing a screw structure or an option with winder steps.

Stage No. 1 – Making the foundation

Preparing the foundation for a concrete staircase depends on the type of flooring in the basement. If the concrete slab is quite thick, then there is no need to build a foundation. Otherwise, in the place where the product adjoins the floor, mark an area slightly larger than the width of the flight.

To ensure the foundation, remove the top layer 0.5 m deep. Fill in crushed stone 20 cm thick and compact it well. Concrete consisting of sand, cement and crushed stone is poured over the layer.

Stage No. 2 – Assembly of the reinforcing frame and installation of formwork

Before pouring the stairs, be sure to install the formwork exactly according to the dimensions shown in the diagram. It is the formwork that gives the required shape to the structure. And to give strength, mandatory reinforcement is carried out.

First, the sides are installed. Their rigidity is provided by the wall on one side, and support boards are installed on the opposite side. The sides prevent the concrete from spreading and serve as a base to which the formwork for the steps is attached.

At the next stage, the deck is installed, that is, the base for concrete. Its role is played by a durable sheet of plywood or OSB. Its thickness is 18-20 mm. The deck is fixed from below with a support to prevent deflection under load. For supports, use bars with a cross-section of 50×50 mm or boards 150×50 mm.

When providing formwork, adhere to the basic rules:

- All fastenings are made only with wood screws; nails are not acceptable.

- The stability and strength of the formwork is the guarantee that it will not fall apart during pouring and that the future structure will turn out correct.

Related article: Making reinforced concrete stairs: calculations, formwork, pouring concrete with your own hands

After preparing the base, reinforcement begins. Reinforcement with a cross section of 10-12 mm is used to strengthen the monolith. They need to be connected in the form of a grid with cell sizes of 100x120 mm. The binding is made with a special soft wire. Many specialists weld the reinforcement frame, but this process makes the structure less reliable, since the welding seams can break under load.

To strengthen the steps and prevent breakage of their edges, transverse reinforcement of the elements is carried out. At the final stage, before pouring, cross members are installed, which serve as formwork for the steps.

The main rule when reinforcing: the reinforcement must be positioned so that it is subsequently covered with concrete by at least 4 cm.

On video: the nuances of making a frame for a concrete staircase.

Stage No. 3 – Pouring the stairs

The formwork must be filled with concrete mixture at one time. Therefore, a sufficient amount of material is prepared. Otherwise, the solidity of the structure may suffer and the likelihood of cracks increasing.

Filling the concrete staircase with mortar begins from the bottom step. Movement is carried out along the edges of the formwork. The mixture is poured into each step, evenly distributed and thoroughly compacted. The surface is leveled with a trowel.

After the concrete has set a little, small wooden cylinders are immersed in the concrete at the places where the railings are attached. Metal corners are pressed into the edges of the steps to prevent future chipping.

After 24 hours, the formwork is dismantled and the surface is covered with cellophane. This will ensure uniform drying of the monolith.

Stage No. 4 – Finishing

Finishing a concrete staircase in the basement of a house includes installing railings and finishing the steps. Railings can be made of wood or metal. Although in basements, in many cases, railings may not be installed. The surface of the steps is first carefully polished. Then, at the request of the residents, they can be tiled with ceramic tiles or wooden steps can be installed.

Recommendations

To make the descent and ascent comfortable, experts do not recommend building too steep structures. The choice of material should be approached carefully. When choosing, take into account the humidity of the cellar. If a reliable design is required for long-term use, water-repellent agents are used.

When building a staircase to the cellar with your own hands without the help of specialists, you should take care of safety precautions. Some owners of private houses order the production of a ready-made metal frame, and do the decoration and protection from moisture themselves.

Twice a year it is recommended to inspect the stairs in the cellar after winter and in the fall, before loading products for winter storage. If necessary, the structure is tinted, metal parts are welded, or rotten boards are replaced with new ones.

Selection of material for manufacturing

The material for making the stairs plays an important role. The choice depends on the complexity of the work, financial capabilities, as well as how strong, reliable and durable the staircase should be.

The main options are:

- Wood. It is characterized by ease of processing and affordable price. But, a wooden staircase to the basement requires careful processing and protection from moisture, mold and fungi. The microclimate of the basement is not entirely favorable for wood. Therefore, in addition to the material itself, you need to spend money on protective substances.

- Metal profile. A metal staircase is a very reliable and durable design. Along with this, the price of its device also increases. Requires processing and protection from moisture. It is necessary to remove the rust and cover the material with paint in several layers.

- Concrete. One of the most durable materials. But, suitable only for spacious basements. The concrete structure itself is bulky and takes up more space than wood or metal. Despite the strength of concrete, it also needs protection. To do this, the steps are finished with paint, tiles, and rubber coating.

If you choose wood or metal, you can design and install a spiral type of staircase. The advantage of this type of product is its compactness.

Necessary formulas for calculating the stairs to the basement

The safety and duration of operation of the staircase structure directly depends on the thoroughness of the calculations performed, therefore, when arranging and designing the structure, the following nuances must be taken into account:

- Flights. Along the entire length of the stairs, the spans should be the same width, the standard indicator is 70-90 centimeters, however, if space allows, it is recommended to increase this coefficient.

- Marches. If the structure is equipped with flights, then between them there should be a platform, the length of which is 140-150 cm. If the flights have different directions, then they can be connected by foreign steps, but the width of the stairs in this case should not exceed 100 cm.

- Clearance. Careful calculation of the room's clearance is necessary to ensure that the residents of the house do not touch the ceiling of the cellar with their heads when descending into the basement. To do this, the distance between the ceiling and the steps needs to be 15 centimeters greater than the height of the tallest family member. The optimal length of a flight of stairs is 2 meters.

- Slope angle. The permissible slope angle of the flight of stairs should vary between 20-75°. However, in this case it should also be taken into account that both too steep and too flat structures are not very convenient for use. Therefore, the optimal angle of steepness is considered to be 45°.

In this video you will learn more about calculating the stairs:

This is interesting: how to make a staircase to the garage basement.

The smaller the angle of steepness, the more area the staircase occupies, so this nuance must be taken into account during construction.