How much concrete will be produced from a 50 kg bag of cement?

When carrying out construction work, builders need to correctly calculate the amount of binder component needed to make the mortar. To do this, you need to determine how much cement mixture is needed per cubic meter of concrete. Then you should calculate the volume of building materials used for the work. The result should be as accurate as possible. It is important to choose the right brand of the main component of the mixture. How can a beginner find a way out of this situation and how to make calculations correctly?

How much concrete will be produced from 50 kg of cement?

In order to determine how many cubic meters of concrete will be obtained from 1 50 kg bag of cement, you need to calculate how many kilograms are in 1 m3. If there is not enough binder component, then the work will not be completed, and if there is excess left, then during long-term storage it will lose its properties. In both cases, incorrect calculation of cement consumption per cubic meter of concrete will lead to unnecessary waste of money.

What determines the volume of concrete produced from cement?

Cement mortar is a mixture that contains the following components:

It is mixed in different proportions, it all depends on the purpose. To fill the floor you will need several bags: one of cement and three of sand. In general, the ratio of materials should be: 1 – 3 – 0.5, where the latter is part of the water. Based on a bag of dry material equal to 50 kg, the proportions are: 50 – 150 – 25 (kg-kg-l). These figures are relative, and in practice depend on the brand of solution and the chemical composition of the sand. It is important to consider the use of plasticizers, which affect the proportions of materials.

Parameters that are taken into account when performing calculations:

1. Brand of concrete – selected depending on the purpose of the construction work;

2. Packaging of cement and its class.

The binding element is packaged in bags from 5 to 50 kg.

Calculation of mass based on the nominal volume of the bag

In order to correctly determine how many cubic meters of concrete will be produced from one package weighing 50 kg, you should calculate the number of kilograms in 1 m3. You need to know the dry density of the mixture. For cement, this parameter = 1.3 t/m3. The volume of the container (in this case, the bag) is equal to the product of density and weight.

For concrete, this parameter directly depends on the fillers included in its composition. There are several types:

Lightweight, filled with air;

Heavy, with the addition of crushed stone, gravel and limestone;

Particularly heavy, with barite and hematite.

In order to find out how much M500 grade concrete can be prepared from a bag of cement (in cubic meters), certain proportions must be observed. Professional builders advise using a ratio of 1-2-3, cement - sand - crushed stone, respectively. The final result for concrete is equal to 300 kg. Portland cement is best suited for various types of construction work.

Basic counting rules

The less cement there is in the solution, the better mobility the concrete will have. That is, in order to mix the mixture, the error in calculating the hardener should be no more than one kg, and the error of crushed stone should be no more than 5 kg. If you add a small proportion of hardener, the solution will not support the weight of crushed stone and its binding elements. Under any adverse weather conditions: wind, rain, severe frost or high temperatures, it will become unusable in just one season. This is not scary if the plans include decorative paths, but if a wall is being built, then you should play it safe and add an extra kilogram.

What should be taken into account when making calculations?

There are some features that must be taken into account when making calculations, in particular:

- brand of concrete mixture used for specific work;

- brand of cement composition;

- the amount of material packed into a bag.

The brand of solution is indicated in the documentation. If there are no relevant documents (for example, during private construction), then you need to find out what class of cement is used to perform such work. Thus, for the manufacture of pillows at the base of a building, M100 is usually used, and M150 is used for floors, paths, foundations of fences and gates. In the construction of low-rise buildings, the most common brands are considered to be M200, M250, M300. Builders do not use other classes (more than M300) when constructing low-rise buildings. The binder is sold in a bag, it is packaged in five, ten, twenty-five and fifty kg. This distribution of building material allows builders to purchase the required volume of a component. As a rule, the substance is purchased fifty kg in one bag or two bags of twenty-five kg.

Concrete mix volume calculations

The solution contains several components: sand, binder, gravel or crushed stone and water. Proportions and volume depend, first of all, on what kind of design results: its features and purpose. The volume is also affected by the base component that reacts. In accordance with the established Building Codes and Regulations, the amount of composition with cement must be at least 200 (non-reinforced products) and 220 (reinforced products) kg per cubic meter.

Also, calculations depend on the layability of the mortar with concrete and the consumption of one binder component. Workability is a characteristic that shows how easily concrete is poured into wooden formwork. This parameter is almost not taken into account in private construction. In this case, it is customary to apply the values specified in Building Codes and Rules 82-02-95 (cement M400): M100 - one hundred eighty, M150 - two hundred to two hundred twenty-five, M200 - two hundred fifty-five, M250 - three hundred five, M300 – three hundred thirty-five kg.

Thus, from one bag weighing fifty kg, the following amount of mortar is obtained:

- for products without reinforcement - 50/200 - 0.25 cubic meters;

- for products with reinforcement - 50 220 - 0.23 cubic meters.

Return to contents

How much concrete will be produced from 50 kg of cement: composition and proportions of components

How to independently calculate all the numbers without errors, and how much concrete of a given grade can be prepared from a bag of cement, read in our article.

What does the volume of the solution depend on?

Now let's go through the technology of preparing the solution to see how the different components of the mixture are distributed in the total volume. For a clear example, let’s take a conventional cube (1000 l). It will be filled as follows:

What should be taken into account when making calculations?

There are some features that must be taken into account when making calculations, in particular:

- brand of concrete mixture used for specific work;

- brand of cement composition;

- the amount of material packed into a bag.

Return to contents

Concrete mix volume calculations

Thus, from one bag weighing fifty kg, the following amount of mortar is obtained:

- for products without reinforcement - 50/200 - 0.25 cubic meters;

- for products with reinforcement - 50 220 - 0.23 cubic meters.

Kawabanga! Why are expansion joints made in concrete structures?

Return to contents

Useful tips

Return to contents

What features of the components are important when making a solution?

Experts highlight the following characteristics:

- cement – mass, activity, hardening time;

- sand – mass, voidness, degree of humidity, presence of organic substances;

- crushed stone – hollowness, mass, degree of moisture, density, structure.

Return to contents

How much cement should be used per cubic meter of concrete mixture?

In addition, it is necessary that the strength of crushed stone and gravel is several times higher than the strength of hardened concrete, in the manufacture of which the above fillers are used.

Return to contents

Conclusion

Failure to comply with the required proportions leads to the fact that the material becomes too thick or liquid. Correct calculation allows you to make a high-quality solution, the use of which will help solve the given construction problem.

Useful tips

When making calculations, it is important to take into account the number of components, know the norms for using cement mortar and the proportions of other ingredients of the mixture. When making concrete mortar for foundation bases, the following proportion is considered optimal: 1:3:5 (cement composition; sand; crushed stone). To more accurately determine the amount of building materials for concrete, you need to learn about their main characteristics. In addition, you should pay attention to what kind of concrete should be made (brand). The consumption of building material components per cubic meter will depend on the listed criteria.

How much cement should be used per cubic meter of concrete mixture?

Calculation per cubic meter must be made as accurately as possible. This is necessary to determine the certain strength and stability of the finished building material. The lower the cost of the cement composition, the more reliable the concrete mixture will be. For economical consumption of cement, it is important that the grade exceeds the class of concrete. These indicators are taken into account directly at the output.

If low grades of cement are used in the mixture, then a large amount of dry composition will have to be added, which will increase the cost of producing concrete. Nowadays M500 cement is often used for construction needs. In this case, the best proportion for the cement base is 1:3 (cement and sand). To quickly calculate the amount of ingredients needed to make the mass, it is better to measure them in parts. For example, you can use the following proportion: 1:5 (1 indicates cement consumption). It is possible to produce the required volumes of concrete mortar of a certain consistency only by using a cement composition of a grade that exceeds the class of the required building material. In particular, for the production of concrete mixture M150, experts advise adding the cement composition M400.

In addition, it is necessary that the strength of crushed stone and gravel is several times higher than the strength of hardened concrete, in the manufacture of which the above fillers are used.

When mixing concrete manually, you can make calculations easier by filling a special tray with several buckets of aggregate (no more than five), onto which cement should be poured. All ingredients are thoroughly mixed with a construction shovel in a certain direction until a homogeneous mass is formed.

How much solution will be produced from 50 kg of cement?

Very often you need to quickly prepare a mortar for masonry, but you don’t want to buy extra cement, because you’ll have to overpay for it. How to calculate the exact amount of cement required in bags? Let's try to calculate.

Cement mortar is a building material generally consisting of three components:

- Cement of different brands as a base-binder.

- Sand as a filler. Depending on the purpose of the solution: river, quarry or alluvial.

- Water as a separator.

At the same time, depending on the purpose (construction of floor screed, sealing cracks, plastering, brick laying, etc.), different proportions of components are mixed. For example, to prepare a solution for floor screed, use the following proportions:

- One bag of cement brand M400-M500, weighing 50 kg (1 part)

- Three bags of sand (3 parts - 150 kg).

- Water – 25 liters or ½ the amount of cement.

Without a doubt, these figures are quite approximate, and in practice they need to be adjusted depending on the required brand of mortar according to GOST, brand of cement, sand characteristics and other factors.

“Other factors” include the use of additives – plasticizers. Plasticizers significantly affect the proportional ratio of the components of the solution.

However, if we talk about private “do-it-yourself” construction, the above data can well be used in practice. Ultimately, from a bag of cement weighing 50 kg, a little more than 0.2 m3 of solution is obtained.

The next common type of mortar is a material for sealing cracks and irregularities on walls. In this case, the solution is mixed in proportions of 50/50, only water and cement without filler (sand). In this case, 0.1 m3 of solution is obtained from a bag of cement.

How much mortar will be obtained from a 50 kg bag of cement?

“Other factors” include the use of additives – plasticizers. Plasticizers significantly affect the proportional ratio of the components of the solution.

However, if we talk about private “do-it-yourself” construction, the above data can well be used in practice. Ultimately, from a bag of cement weighing 50 kg, a little more than 0.2 m3 of solution is obtained.

Kawabanga! Service life, shelf life and warranty period - liability periods

The next common type of mortar is a material for sealing cracks and irregularities on walls. In this case, the solution is mixed in proportions of 50/50, only water and cement without filler (sand). In this case, 0.1 m3 of solution is obtained from a bag of cement.

Other options for preparing the solution

Helpful advice - the best option for “ballast filler” is three parts of stone or gravel chips mixed with one part of river sand. In this case, from 1 bag of cement, the yield of the finished material is 0.3 m3 of concrete (mortar).

In any case, before you start preparing and mixing the components, carefully study the instructions with possible proportions available on each bag of cement.

Other options for preparing the solution

For the convenience of preparing mortar or concrete for pouring the foundation, the composition of the components is usually given in proportions, depending on the amount of cement. For example, a ratio of 1:5 tells us that to prepare a solution or concrete, you need to take 1 part of cement (you can use 1 bag, 1 bucket, 1 scoop or any other container) and 5 parts of ballast filler (a mixture of sand and gravel) - 5 bags, 5 buckets, 5 scoops, etc.

Helpful advice - the best option for “ballast filler” is three parts of stone or gravel chips mixed with one part of river sand. In this case, from 1 bag of cement, the yield of the finished material is 0.3 m3 of concrete (mortar).

The masonry mortar used for the construction of walls made of brick, foam block, cinder block or shell rock is prepared as follows: cement and sand in a ratio of 1:5 if the masonry is above the ground surface and 1:3 if the masonry is below ground level. According to the last proportion, the yield of material from 1 bag of cement is 0.2 m3.

In any case, before you start preparing and mixing the components, carefully study the instructions with possible proportions available on each bag of cement.

How much concrete will be produced from 50 kg of cement?

Question. Hello! It is required to purchase cement in 50 kg bags to prepare a certain amount of concrete. How much concrete will be produced from 50 kg of cement? Since there is nowhere to store it, I don’t want to buy extra cement. Thank you in advance!

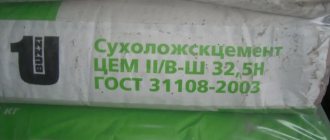

Answer. Good afternoon In private construction, as a rule, heavy concrete grades are used: M150, M200 and M300. Heavy concrete consists of cement (binder), crushed stone (coarse aggregate), sand (fine aggregate) and water (setter). The most popular grades of cement used for heavy concrete are: TsEM I 32.5N PTs and TsEM I 42.5N PTs (old designation M400 and M500). This will be the initial data for our calculation.

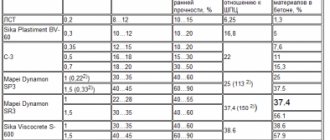

In accordance with the rules for preparing concrete, the amount of cement is taken as 1 (part), and the remaining components are also added in parts in certain proportions depending on the brand of concrete and the brand of cement. For the convenience of calculations, we tabulate the proportions of components for various grades of concrete prepared using cements TsEM I 32.5N PTs and TsEM I 42.5N PTs:

| Concrete grade | TsEM I 32.5N PC, kg | Crushed stone, kg | Sand, kg | Water, kg |

| M150 | 1 | 5,3 | 3,4 | 0,9 |

| M200 | 1 | 4,4 | 2,8 | 0,7 |

| M300 | 1 | 3,3 | 2,0 | 0,6 |

| Concrete grade | TsEM I 42.5N PC, kg | Crushed stone, kg | Sand, kg | Water, kg |

| M150 | 1 | 6,0 | 3,9 | 1,0 |

| M200 | 1 | 5,0 | 3,3 | 0,8 |

| M300 | 1 | 3,8 | 2,4 | 0,7 |

In our case, “1 part” of concrete weighs 50 kg. Based on this, we calculate the amount of other components in kilograms (multiply 50 by the proportions of the components), determine the amount of concrete in kilograms (sum up the masses of the components) and summarize the results in tables:

| Concrete grade | TsEM I 32.5N PC, kg | Crushed stone, kg | Sand, kg | Water, kg | Concrete, kg |

| M150 | 50 | 5.3x50=265 | 3.4x50=170 | 0.9x50=45 | 50+265+170+45=530 |

| M200 | 50 | 220 | 140 | 35 | 445 |

| M300 | 50 | 165 | 100 | 30 | 345 |

| Concrete grade | TsEM I 42.5N PC, kg | Crushed stone, kg | Sand, kg | Water, kg | Concrete, kg |

| M150 | 50 | 300 | 195 | 50 | 595 |

| M200 | 50 | 250 | 165 | 40 | 505 |

| M300 | 50 | 190 | 120 | 35 | 395 |

We received a mass of concrete that can be prepared from one bag weighing 50 kg. In construction, it is customary to operate not with the mass of concrete, but with its volume in cubic meters. We convert “kilograms” of concrete obtained from one 50 kg bag into “cubic meters” and put them in tables:

Cement-based concrete TsEM I 32.5N PC

| Concrete grade | Weight of 1 m3 of concrete, kg | Volume of concrete obtained from 50 bags of cement, m3 |

| M150 | 2278 | 0,23 |

| M200 | 2285 | 0,194 |

| M300 | 2301 | 0,149 |

Example. The calculation is carried out as follows. We take the mass of 1 m3 of concrete as 100%, and the amount of concrete obtained from a 50 kg bag as x. We solve the proportion and get the amount of concrete in % FROM 1 and 3: 530/2278 = 0.23 m3

How to calculate consumption?

In answering this common question, a number of assumptions must be made. The amount of solution obtained from a bag of cement depends on the following objective factors:

- Solution brands: M75, M100, M200, etc.;

- Type of mortar: masonry, for screed construction, for plaster, etc.;

- Cement bag capacity: 20, 40 or 50 kg;

- Cement grades: M200, M300, M400, M500, etc.;

- Types of cement: pozzolanic Portland cement, ordinary Portland cement, slag Portland cement, sulfate-resistant Portland cement, alumina cement, etc.

Due to the fact that the question of how much mortar is obtained from a bag of cement is, as a rule, of interest to non-professional builders who are involved in construction or repairs from time to time and purchase materials at retail, we will give an example of calculation for the most common option:

- Brand of cement-sand mortar: M150. This brand is suitable for almost all work: masonry, pouring screed, plastering, caulking joints and other repair and construction work;

- Cement grade: M400;

- Bag weight: 50 kg;

- Type of cement: Portland cement.

How much mortar will be produced from one bag of cement?

Question. Hello! I am planning small plastering work, as well as minor repairs to the screed and brickwork of the heating boiler chimney. In order not to overpay for excess cement, I would like to know: how much solution will be produced from one bag of cement weighing 50 kg? This means how many cubic meters of solution and standard galvanized buckets with a volume of 10, 12 and 15 liters.

Answer. Good afternoon For all the work you specify, a solution prepared from cement, clean sand (filler) and clean water is used. Before you start calculations, you should decide on the brand of cement and the type of sand. At the moment, one type of packaged cement for general construction use can be purchased in wide retail sales - Portland cement CEM I 32.5N PC (M400). We will use it in calculations. The so-called “construction” or quarry sand is used as a filler.

Amount of m3 of mortar from a bag of cement

We decide on the proportions: cement: sand: water. As practice shows, the most optimal proportions of components for preparing a cement-sand mortar suitable for plaster, masonry and screed: 1 part cement, 3 parts sand, 0.6 parts water.

In order to determine “cubic meters of solution”, it is necessary to reduce the value “50 kg bag of cement” to the value “volume of a bag of cement in m3”. The generally accepted measure taken for calculations is 1300 kg of cement per 1 m3. By solving the proportion, we determine how many m3 of cement is in 1 bag: 50x1/1300 = 0.038 m3. We calculate the number of cubic meters of solution obtained from a bag of cement: 0.038+(0.038x3)+(0.038x0.6)=0.1748 m3 of material.

The amount of solution from a bag of cement in buckets of 10, 12 and 15 l

It's very simple. The volume of one ten-liter bucket in m3 is: 10/1000=0.01 m3. Accordingly, the volume of mortar from a bag of cement in buckets: 0.1748/0.01=17 buckets. Using this form, you can determine the volume of solution in 12 l and 15 l buckets: 0.1748/(12/1000)=14.5 buckets and 0.1748/(15/1000)=11.6 buckets of solution.

For reference! The amount of water indicated in the calculations is oriented, therefore it may differ up or down depending on the degree of moisture in the sand. All other things being equal (correct measuring of cement and sand), water is added until the consistency of the solution is obtained - “thick sour cream”.

How much concrete will be produced from 50 kg of cement?

SNiP regulates the amount of binder when hardening concrete under natural conditions:

- minimum content in unreinforced structures - 200 kg/m³;

- in reinforced ones - 220 kg/m³.

The optimal content is determined by multiplying the typical content by increasing factors associated with the size of the aggregates. In individual construction its value does not exceed 1.15. Typical standards are shown in the table:

The workability of a concrete mixture is an indicator characterizing the plastic properties of the material. In the table, select the lower flow rate in the corresponding column.

Now you need to do the reverse calculation. The minimum consumption of binder in unreinforced products is 200 kg per cubic meter. Accordingly, 50 kg of cement will be contained in:

50/200=0.250 m³ with a filler fraction of 20 mm (crushed stone) and a sand fineness modulus of 1.5.

In reinforced concrete this value is:

The recommended quantity of PC M500 for the most popular concrete M300 is 250 kg. One bag of such cement is enough to prepare:

50/250=0.2 m³ of mixture.

Ratios for solutions of other brands:

- M150 - 50/200=0.250 (use PC M400)

- M200 - 50/200=0.250 (PC M500)

- M250 - 50/220=0.227

- M350 - 50/290=0.172 m³.

Examples of calculations

The dimensions of the monolithic structure and its volume are determined in the drawing or in kind.

Example 1. It is required to pour a foundation 0.5 m deep, 0.3 m wide and 20 m long. The volume of the structure is:

The material used is PC M500, the required grade of concrete is M200. One bag is enough to make:

50/200=0.25 m³ solution.

Required number of 50 kg bags:

Thus, twelve bags will be required to complete monolithic work.

Example 2. Construction of a garden path 10 m long, 0.6 m wide and 10 cm thick.

Volume of concrete cover:

The grade of concrete for such structures is M150, and Portland cement is M400. From one bag you can make 0.250 m³ of mixture. To build a path you will need:

0.6/0.25=2.4 packages weighing fifty kg. In order not to buy extra material, you can purchase two bags of 50 and one weighing 25 kilograms.

Tables for calculating Portland cement consumption

Depending on the brand of concrete and cement, it is easy to determine how many 50 kg bags of PC are in a cube of the mixture. The exact need for binder is determined using a ready-made table: