What is polystyrene concrete and is it suitable for floor screed?

Firstly, polystyrene concrete is similar in characteristics to classic concrete filled with crushed stone or other stone (in full compliance with the set of rules SP 29.13330.2011). Secondly, it has a number of advantages at comparable costs for the components of the concrete mixture. Moreover, polypropylene granules of various diameters are available for free sale.

Composition of polystyrene concrete:

- Portland cement grade 400-500 as a binder;

- filler made of polystyrene foam granules, which accounts for up to 85% of the total volume of materials;

- in some cases, washed sand to give increased strength to the finished screed;

- plasticizer to prevent granules from floating when stirred.

The proportions of the components are selected based on the required density of the solution. Basically, they change the volume of cement - the more of it in one cubic meter of polystyrene concrete, the stronger the screed will be. But at the same time the weight of the finished base increases. This is taken into account when pouring floors, when there is a limitation on the load capacity of the floors. The only exception is the first floors of buildings that do not have basements.

Advantages and disadvantages of the material as a floor screed

Due to its lightweight filler, polystyrene concrete is lighter in weight compared to its analogues. Therefore, it is better suited for screeding floors in an apartment or house on the second level and above, including on wooden floors, instead of wooden boards on joists. Lightweight concrete shrinks less and puts less load on the foundation and load-bearing walls.

There are also advantages:

- the screed dampens sounds up to 70 dB (depending on the thickness);

- every 10 cm of polystyrene concrete is equivalent to 30 cm of ordinary concrete;

- floors last a long time at temperatures from -60°C to +70°C;

- The material is not afraid of moisture, mold, fungi.

Among the disadvantages, they note the need to use special dowels and anchors when fastening various structures. During subsequent work, it is recommended to avoid exposing the screed to organic solvents such as gasoline or acetone (they will ruin the polystyrene granules). But the floors do not require costs for insulation and waterproofing. The finishing self-leveling screed is immediately poured onto the surface and the flooring is laid.

Types of polystyrene concrete screeds

Due to the characteristics of the main filler - polystyrene granules, dry and semi-dry floor screeds cannot be made with it. Otherwise, the floor surface will “play” and be too floating under load. And short-lived compared to wet, which involves preliminary mixing of a concrete mixture with water, cement, and sometimes sand. But screeds made of polystyrene concrete differ in purpose.

There are two options:

- Thermal insulation. Performed under or above a classic concrete floor for better heat retention. It is characterized by an increased volume of granules, increased plasticity and resistance to a humid environment. Designed for weights up to 250-500 kg per cubic meter. m.

- Structural and thermal insulation. Assumes a denser solution, weighing 600 kg per 1 m³. Such a screed will be durable and resistant to abrasion, but it will retain heat less well.

The density of polystyrene concrete for the first type of floor screed is lower, so a finishing compound or ordinary concrete must be poured on top of it, which increases the rigidity of the flooring. It can withstand mechanical loads better, including shock. Plus, the polystyrene layer is completely protected from the risks of damage from household and construction chemicals, and exposure to open fire.

There is also a division according to the method of using granules. In the first case, a layer of polystyrene is poured in the form of a cushion under the concrete screed. In the second, the components are pre-mixed in a concrete mixer or a special installation, which then automatically delivers the solution to the right place (through a special hose).

Disadvantages of polystyrene concrete

Polystyrene concrete is not famous for its durability.

There is only one downside to this material, but it is quite significant. Polystyrene concrete floors have low strength and poor abrasion resistance.

Because of this, the surface will need to be further strengthened. If you plan to use the mixture for walls, additional surface covering will be required both inside and outside.

This material can only be used for residential or public buildings. For technical premises, if external treatment is necessary, the use of such a composition is highly not recommended. Indoors, you will also need to take care of protecting the top layer or topping. For more information about the qualities of the material, watch this video:

Topping will not be needed unless tiles are installed later. The adhesive mixture and tiles will provide the necessary level of protection for the surface.

Toppings are used to strengthen the surface of the screed.

For other types of flooring, the surface must be strengthened.

If work is carried out in a public space with heavy loads, topping is done using special solutions. When you do the screed yourself and you plan to lay the flooring in the future, we recommend grinding the iron. It must be done after the polystyrene concrete has partially set. This procedure will help:

- partially strengthen the concrete;

- finally level the surface, which is a key requirement for further covering.

Composition of the solution

The easiest way is to use ready-made mixtures in bags indicating the brand of polystyrene concrete. Their composition makes it possible to obtain a solution with the same quality regardless of the volume (area and thickness of the screed). Since our article is about preparing the solution yourself, we will give examples of mixing.

An example of the composition of the D200-D300 brand:

- cement – 160 kg;

- polystyrene granules – 30 kg;

- water – 100 l;

- plasticizer – 1 kg.

Sand begins to be added to solutions of the D600 brand, which are higher in mechanical strength than in the example given. It is recommended to use washed, sifted material to prevent the formation of unstirred lumps. They will reduce the strength of the screed until potholes appear during operation. A uniformly mixed composition will serve no less than classic concrete made from a sand-cement-crushed stone mixture.

Foaming additives are needed to improve the adhesion of granules with cement mortar, which thanks to them envelops their surface. As a result, polypropylene is distributed evenly throughout the total mass of concrete, without the formation of “clumps” with reduced mechanical strength. Instead of a plasticizer, liquid soap or detergent is sometimes added.

Proportions of polystyrene concrete for floor screed

There are a lot of preparation recipes, they are all similar to each other, they differ only in the number of polystyrene foam granules and the percentage of the additive added.

Standard proportions for preparing a mixture for floor screed are as follows:

- Expanded polystyrene fraction up to 5 mm, at least 50 liters will be required;

- Water – 7-8 l;

- Cement M400 – 10 l;

- Washed sand, the finest fraction, will require at least 20 liters;

- Additive to enhance the formation of air bubbles, at least 35 ml.

The air-entraining additive should only be used for concrete; no liquid detergents or cheap lime substitutes in the form of saponified resin from wood distillation should be used. A good plasticizer will be needed very little, approximately 0.7-0.6% of the total volume of the batch.

You can often find recommendations not to use sand, but a similar recipe is used for molding ready-made building blocks. To pour polystyrene concrete screed onto the floor, sand is required.

Materials and equipment for making the solution

The technology by which polystyrene concrete is produced is based on mixing the specified components until a uniform mass is achieved. It is imperative to ensure that the mixture does not contain granules that are not moistened with cement solution. If you plan to make concrete screed grade D600 or higher, you will need to add the appropriate amount of quartz sand.

Equipment for mixing mortar:

- Concrete mixer. Involves manual mixing, unloading of the finished material, and transfer to the site. Productivity depends on the speed of the operator.

- Construction mixer. Useful for making a small volume of polystyrene concrete when finishing or redoing a floor. For example, after dismantling part of it.

- Mobile station. It has a capacity of up to 80 m3 per shift, supplying 8-10 m3 of liquid polystyrene concrete per hour.

The third option is preferable because with it the work goes faster and it is easier to plan. In addition, such equipment is usually rented by our company. When the contract is signed, the equipment is delivered to the site along with the construction materials. All that remains is to prepare the place for pouring in advance and agree on the time of work.

The mobile station will simplify the filling of a large floor area. In the case of a concrete mixer, after laying each batch, you have to wait for the next batch to be mixed. During this time, the material slightly sets and as a result the surface turns out to be “not monolithic”. Continuous supply of concrete allows you to obtain a flat surface over the entire area of the room.

Proportions

The composition of the polystyrene concrete solution affects the technical characteristics of the finished material. So, the mechanical strength of the screed depends on the amount of cement. As the diameter of the granules increases, the sound and heat insulating properties increase, but the concrete becomes more plastic and requires pouring over a “reinforcing” finishing layer.

Approximate composition:

- polystyrene granules - 1 cubic meter. m;

- cement – 290 kg;

- water – 120 l;

- plasticizer – 0.7 l.

As the grade of polystyrene concrete increases, the volume of sand, Portland cement and water added increases (sand is needed for grade D600 and higher). Less plasticizer is used. At the same time, the mass of 1 cubic meter of the mixture also increases; this must be taken into account when calculating the load on the floors. When pouring the first floor, it does not play a special role (provided there are no basements).

Advantages of polystyrene concrete screeds

- durability of the material;

- there is no need for waterproofing;

- frost resistance ≥ 100 cycles;

- dense filling of all cracks and cracks, which prevents insects and unpleasant odors from the street from entering the buildings;

- high water resistance, which is especially important in cases of floor flooding during emergencies in water supply networks;

- polystyrene concrete floors are five times lighter than cement concrete floors, which significantly reduces the load on the floors;

- vapor permeability due to the cellular structure of the material;

- good thermal insulation characteristics provide a significant reduction in heating costs;

- non-flammability (fire hazard class G1), ensured by dense enveloping of polystyrene granules with cement laitance;

- good sound insulation;

- Pouring the floor with polystyrene concrete is easy to perform;

- environmental friendliness due to the use of polystyrene used in the food industry for the manufacture of disposable tableware;

- ease of mechanical processing when performing repair work on utility lines;

- chemical inertness;

- low cost of raw materials.

Kneading process

Due to the characteristics of polystyrene granules, the procedure must follow the sequence of laying the components. So, they begin work by adding cement and water in a ratio of 1:2 to obtain a liquid solution. Then a plasticizer is added (fumed wood resin such as SDO or detergent). Approximately 20 ml is poured into each bucket of water. Sometimes the finished mixture is immediately poured into the primary solution. This approach allows you to mix it evenly.

Next steps:

- Pour in polystyrene granules (measure the volume in advance).

- Stir until their surface is evenly wetted.

- Pour in the remaining cement, pour in the remaining water.

- Mix the solution until completely ready.

If the recipe requires the addition of sand, a means of accelerating setting, they are added simultaneously with the second batch of cement. The higher the grade of polystyrene concrete, the longer the mixing process will take (due to the hardness and thickness of the mixture). When mixing “manually” with a mixer, it is important to achieve uniformity of the mass throughout the entire volume of the container.

When using a mobile station, it is enough to follow the boot sequence. After the cycle is completed, the polystyrene concrete will be ready to be pumped to the screed site. Immediately after the tank is empty, it is ready to load the next batch of material. If you buy a ready-made mixture, it’s easy to put the production on stream (as long as there are enough workers).

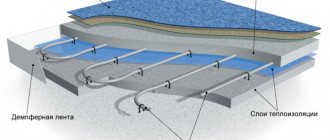

Filling and Alignment

The process of pouring a polystyrene concrete floor screed is similar in sequence to conventional concrete. So, the room is pre-prepared - the surface is cleared of debris and large contaminants, horizontal beacons are set, and a damper tape is laid along the perimeter. Before pouring, it is recommended to moisten the entire area generously with water.

Stages:

- finished polystyrene concrete is laid between the beacons;

- the floor surface is pre-leveled;

- After about a day, the beacons are dismantled;

- the cavities are filled with the same solution.

All that remains is to wait until the concrete mixture hardens completely (up to 28 days) and it is ready for further work. Typically, the next step is to fill the finishing screed with a self-leveling mixture to hide the “bumps” formed by the polystyrene granules. This layer also creates a denser surface on which the substrate and finishing coating are laid.

The use of polystyrene concrete is used to solve several problems at once.

Thus, it is possible to fill the floor instead of using a plank covering and not particularly load the floors. Plus, get rid of the need to spend on additional insulation and sound insulation. It is also easier to bring the required amount of material into the apartment than in the case of mixing concrete based on crushed stone. BACK TO LIST

Video of the Polystyrene concrete screed process:

"Express Floor" Polystyrene concrete screed +7-499-997-90-97

Your browser does not support the video or formats. Your browser does not support the video tag.

| page content: | |

| polystyrene concrete description | light_screed |

| advantages of technology | lightweight screed |

| Polytherm filler | lightweight single layer screed |

| price order for polystyrene concrete | comments |

Floor screeds made of polystyrene concrete mixture, which is suitable for insulating the floors of basements and first floors of buildings, etc., application layer of at least 40 mm, excellent characteristics for sound insulation of interfloor ceilings, layer of 50 mm, followed by the installation of a semi-dry screed of 35 mm, covering communications, electricians , water supply, heating pipes, etc.