Comparison of batteries used for screwdrivers

Having briefly looked at the types of batteries, let's compare them with each other according to 10 characteristics, which will help you figure out which batteries are better for screwdrivers. Let us immediately warn you that there is no absolute favorite in all categories, and you need to pay attention to those advantages that will be needed for a certain activity and area of use.

Nickel-cadmium (NiCd)

This type of battery appeared in the middle of the twentieth century. The cathode in it is nickel oxide hydrate supplemented with graphite powder. To make the movement of ions from the cathode, an electrolyte is used - potassium hydroxide. The last main element is the anode, which is made of cadmium oxide hydrate. The second embodiment is cadmium iron, used in powder form.

Dimensions

Screwdriver batteries are fixed to the tool handle. The weight of the screwdriver and the ease of holding it depend on the size of the batteries. This is especially important during long manipulations and work overhead (fastening beams to the ceiling, sheets of drywall, fixing panels in inaccessible places). The heaviest and largest are NiMh and NiCd.

Li-Ion is produced in smaller sizes. They are often made as a clip that only takes up space in the screwdriver handle, without an extended outer part.

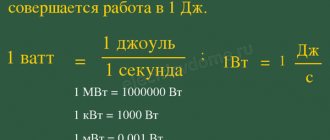

What does battery voltage mean?

For cordless models, the force and rotation speed of the screwdriver depend on the battery voltage, which must correspond to the characteristics of the tool:

- For screwdrivers, the highest value is 36 V. These are the most massive devices for working with metal and hard wood.

- 12-18 V is an average value suitable for most repair and installation processes.

- 3-10 V - are considered low-power, and are used only for assembling soft materials or small-diameter fasteners.

Installing a higher-power battery on a weaker, faster model will result in the latter breaking down. A 12 V battery on a device designed for 18 V will, on the contrary, limit the power of the tool, therefore the voltage indicator of the drive must exactly correspond to the value on the screwdriver.

Keep in mind that if you take two batteries with a similar capacity, the one with a higher voltage will ensure longer-term operation of the tool.

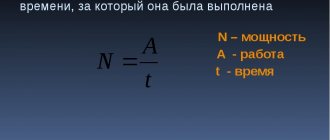

Screwdriver power

In most screwdriver operating instructions, such an indicator as power is not indicated. However, for those who choose a tool, it is perhaps the most important. But it is not indicated because the concept is, one might say, a composite one. So, what determines the power of a screwdriver? This is, first of all, battery power and torque. In order to evaluate the power of a screwdriver as a whole, you need to take all these indicators into account.

Let's consider the power components separately: - Battery voltage. It determines the engine power and torque, as well as the operating time of the screwdriver. The average power of household screwdrivers is 10.8-14.4 volts (V). However, there are models with batteries up to 36 volts. — In addition to the voltage, it is also worth assessing its capacity, which determines the operating time and is measured in ampere hours. The average battery capacity of a screwdriver is 1.2-1.5 Ah. — Torque, that is, the rotating force that the tool develops, determines the length and diameter of the screw that the screwdriver can tighten. The higher it is, the greater the power of the screwdriver . The torque rating varies depending on the material being drilled. The technical data sheet of the tool usually indicates the size of the maximum possible drilling diameter for various materials. In addition, a distinction is made between hard torque (starting power) and working torque, that is, constant. The hard moment is always higher than the constant one. It should also be noted that the torque of modern screwdrivers is an adjustable value; technical data sheets, again, indicate how many installations the screwdriver has and the maximum possible torque. The maximum torque ranges from approximately 10 to 60 newton meters (Nm). It would be useful to note that, all other things being equal, the power of a screwdriver increases significantly if it has a function of operating in pulse mode (jerks). Power is increased by periodically applying hard torque.

You should not strive to acquire the most powerful tool. If you use too much power, you will drive the screws in too hard and the head will be deeper than the surface, which will spoil the appearance and make it difficult to remove the screws if necessary.

Let's summarize. Before choosing which screwdriver power is right for you, you should decide for what purpose the tool will be used. For rare use in a home workshop, a simple low-power tool with a voltage of 12V, a capacity of 1.2Ah and a maximum torque of 10Nm is suitable. This tool can be used to assemble furniture and screw in small self-tapping screws for fastening home furnishings (curtains, paintings, etc.). The highest power is achieved with 36 V, 3 Ah and 60 Nm. Such screwdrivers are considered professional, working with them requires certain skills, and their price is quite high. In any case, before purchasing a screwdriver, you should carefully study the technical data sheet and compare all the given values in order to understand what final power is available to the tool you have chosen.

What batteries can be used for screwdrivers

Manufacturers of power tools always indicate in the properties of screwdrivers which batteries are recommended for working with them. The battery type is indicated by several English characters. To know which battery to choose a screwdriver with, you need to understand the meaning of the abbreviation and know the pros and cons of each type of battery.

Attitude towards full discharge

This is a fundamental nuance that affects the battery life, which can be significantly reduced due to improper use. All modern lithium batteries cannot be completely discharged. The average storage condition is 40% charge. If you use all the energy to 0, then this can completely destroy the drive.

Therefore, such elements must be recharged even if the tool is still working well. Nickel batteries of both types tolerate full discharge very well, and can be used until the screwdriver stops spinning.

Reverse or reverse

The presence of this function allows you to remove a self-tapping screw or a drill stuck in the material. The direction of rotation changes when the polarity of the power supply changes, which is done through a special button. It is usually installed near the trigger lever.

Examples of the location of the reverse button in a screwdriver

In most cases, the stroke direction switch button has three positions: on average, the tool is locked. This increases safety: if you accidentally hit the lever, the screwdriver will simply stop and not immediately start spinning in the opposite direction.

Work area lighting

A very convenient feature that does not greatly affect the cost of the screwdriver is illumination of the work area. With good lighting it is much easier to keep control of the instrument.

Illumination of the work area is a necessary additional function of a screwdriver

An LED is built into the handle or body of the tool near the chuck, which lights up when the start button is pressed. If you want to choose a screwdriver that is comfortable to work with, make sure that the work area is illuminated.

Connecting a 12 volt screwdriver to an ATX power supply

Battery screwdrivers are very convenient to use and are widely used by both professionals and home craftsmen. The battery is usually the first to fail. Currently, all manufacturers of power tools have switched to lithium batteries and purchasing a new nickel-cadmium battery for an old screwdriver is becoming more and more problematic, and the prices for these batteries are much higher than for lithium ones.

Of course, it is possible to purchase batteries on various services that sell Chinese goods. But it takes time for the package with the “cans” to arrive, and again, these are certain costs. There is an alternative to buying batteries/cans - connect the screwdriver to the mains power supply and forget about quickly draining the batteries. Powerful power supply on Aliexpress. There are many inconveniences due to the power cord, but you always have to sacrifice something.

Battery or mains

Having decided on the class, you will need to decide whether you need a mains-powered screwdriver or a cordless one . The disadvantages and advantages of both are obvious: the battery-powered one has higher mobility and the cord does not interfere with operation, but it weighs more. The network connection does not depend on the presence of battery charge, but not all construction sites have power supply. In general, the choice is not easy. The decisive point may be that cordless screwdriver with a good battery costs significantly more than a similar model operating from the mains. The difference is due to the presence of a battery - good options are not cheap.

For a corded screwdriver, the length of the cord is important

If you decide to choose a corded screwdriver, pay attention to the cable length. The longer it is, the more convenient it will be to work - you won’t have to carry a carrier either.

To choose the right cordless screwdriver, you need to pay attention to the type of battery. The duration of operation on one charge, as well as the order of storage, depend on this.

READ Which Company to Choose Cordless Screwdriver

- Lithium-ion (Li-lon). Holds a charge for a long time, charges quickly, has a large number of recharges, and almost never discharges during storage. In general, a good option, but expensive. Therefore, it is probably more common on professional models, where the duration of operation on a single charge is important. Disadvantages include fear of cold, which is important in our country.

Lithium-ion batteries have a long service life, are not subject to self-discharge, but are expensive

Nickel-metal hydride batteries are a good option, but they do not have a very long life.

The cheapest type of battery is nickel-cadmium, but they have a “charge memory”

So, if you choose cordless screwdriver for periodic work, a nickel-cadmium battery will do just fine. If you use it carefully, it will last a long time. If you are starting large-scale work, it is better to use other batteries - there will be less downtime, the work will move faster.

Which screwdriver is better: 12 V, 18 V or 24 V?

Battery design for cordless tools

All battery packs that are used to power hand-held power tools are designed approximately the same. Inside the block there are several standard elements - the so-called “cans”. For example, lithium-ion batteries use 18650 standard “banks” with a nominal voltage of 3.6 V and high current output as elements, while nickel-cadmium batteries use 1.2 V cells.

| Design of a modern battery for cordless tools. |

By changing the number of elements and the way they are connected to each other (series or parallel), you can obtain batteries with different characteristics. They will differ in operating voltage (in practice, units with voltages from 10.8 V to 24 V are used) and capacity (hand-held power tool batteries have a capacity from 1 Ah to 12 Ah). Some manufacturers (like DeWALT) even make convertible battery systems where the order in which the “cells” are connected through the terminals automatically changes depending on whether the battery is connected to an 18-volt or 54-volt tool.

| Methods for connecting “cans” in batteries using the example of DeWALT Flexvolt batteries. |

The relationship between voltage and power of a screwdriver: is it there or not?

From the course of electrical engineering it is known that the power of an electric motor is directly proportional to the voltage supplied to the windings. From this we can conclude that the more volts in the battery, the more powerful the screwdriver. Is it true? There is a whole abyss between bare theory and practice. In fact, the power of a cordless tool is also affected by:

- discharge current - cheap high-current “banks” deliver up to 15 A, and the current output of the elements that make up the batteries of high-quality screwdrivers reaches 25 - 30 amperes, which are necessary to tighten a self-tapping screw all the way or tear off a stuck nut;

- Gearbox design - the gear ratio of the gearbox and the strength of the gears that are inside it determine whether the tool can develop high torque and cope with tasks that require significant effort;

- motor quality - good motors that can withstand high currents and loads without damage are much more expensive than simple electric motors from cheap screwdrivers;

- electronics settings - a control electronics board that regulates current output, protects the engine from overloads and prevents excessive heating of battery elements, and imposes restrictions on the capabilities of the tool.

Cordless screwdrivers with batteries up to 12 V Tekhmann TCD-90/i12 from 1,180 UAH.

Makita DF032DZ from 1,800 UAH. Makita TD110DZ from 1,386 UAH. Bosch GDR 120-LI Professional 06019F0000 from 1,720 UAH. Makita DF033DZ from 1,194 UAH. Bosch GDR 120-LI Professional 06019F0001 from 3,999 UAH. Bosch GDR 12V-105 Professional 06019A6901 from 3,090 UAH. Bosch GDR 12V-110 Professional 06019E0002 from 3,899 UAH. Makita DF030DWE from 3,426 UAH. Metabo PowerMaxx SSD 12 601114500 from 4,999 UAH. SPARKY GUR 10.8Li-C HD Professional from 2,609 UAH. Metabo PowerMaxx SSD 600093500 from 5,330 UAH. Bosch GSR 12V-35 HX Professional 06019J9102 from 3,454 UAH. DeWALT DCF801D2 from 6,359 UAH. Makita DF031DSAE from 4,385 UAH. AEG BSS 12C LI-202C from 4,230 UAH. Stanley SCI12S2 from 2,999 UAH. DeWALT DCF610D2 from 6,079 UAH. DeWALT DCF801N from 3,599 UAH. Bosch GSR 12V-35 HX Professional 06019J9101 from 5,474 UAH. Considering the above, it is easy to conclude that the voltage of the battery pack is far from the only factor influencing the output power of a power tool. Therefore, it often happens that a “branded” 12-volt screwdriver in practice turns out to be much more powerful and useful in operation than a cheap 18-volt “Chinese” one.

| The Makita DF330DWE screwdriver and its Chinese clone are identical in voltage and design, but differ significantly in price and characteristics. |

Screwdriver classes based on battery voltage

After a short excursion into the design of batteries and the basics of electrical engineering, it’s time to take a closer look at cordless screwdrivers. They are equipped with batteries with the voltage:

- 10.8 V (12 V) - a tool of this class is characterized by its compact size and light weight due to small batteries. It is used primarily for installation and assembly work;

- 14.4V is an intermediate class that falls between compact tools and high-performance models. There are only a few manufacturers producing similar screwdrivers;

- 18 V (20 V) is the most popular segment; there is a huge selection of models with different parameters and characteristics. Screwdrivers of this class are in greatest demand because they are more versatile than others;

- 24 V - there are still few models with battery packs of this voltage, despite the fact that the increased voltage allows you to improve the characteristics of the tool.

Separately, it is worth mentioning the difference in voltage measurement methods. Japanese and European manufacturers, guided by EPTA (European Power Tools Association) rules, indicate the rated voltage, while American manufacturers indicate the full charge voltage. Therefore, the same instrument in Europe is labeled “10.8 V”, and overseas – “12 V”. The same applies to screwdrivers with 18 V and 20 V batteries - these are tools of the same class, the voltage is simply measured in different ways.

Cordless screwdrivers with batteries up to 18-20 V

Dnipro-M DTD-200 from 1,230 UAH. Makita DTD171Z from 5,426 UAH. Stark CID 1830B Body from 1,750 UAH. Einhell Expert Plus TE-CI 18/1 Li Solo 4510034 from 1,770 UAH. Einhell Expert Plus TE-CI 18 Li BL Solo 4510030 from 2,970 UAH. DWT ASS-20 D from 1,631 UAH. Ryobi RID1801M from 1,854 UAH. DeWALT DCF809D2T from 6,399 UAH. Crown CT22021HX from 1,843 UAH. DeWALT DCF887N from 3,965 UAH. Stanley SBI201D2K from 5,699 UAH. DeWALT DCF887P2 from 11,553 UAH. Makita DTD152Z from 1,999 UAH. Makita DTD156SF from 4,311 UAH. Makita DTD156Z from 1,935 UAH. AEG BSS 18CB3 LI-502C from 8,175 UAH. Worcraft CIS-S20LiB from 2,199 UAH. DeWALT DCF887D2 from 9,115 UAH. Ryobi R18IDBL-0 from 3,533 UAH. Makita DTD154Z from 5,216 UAH.

The influence of battery voltage on other characteristics of the screwdriver

All parameters of the battery tool are “linked” to each other. The higher the voltage and capacity of the battery, the greater its weight and size. For example, the battery of a 10.8-volt screwdriver may consist of only three lithium-ion “cans” of 3.6 V each, but for an 18-volt battery you need at least five (in practice, there are usually more “cans” inside the battery to increase its capacity) . In addition, increased voltage requires a more powerful electric motor and a more massive gearbox, and this also leads to an increase in the weight and size of the tool. Therefore, for work in tight spaces or overhead, it is worth buying a screwdriver with a 10.8 V battery, because it will be more compact and lighter. And 18-volt models are better for those who have enough space in their workplace to use a larger tool.

| Size difference between Bosch 18V 4Ah, 8Ah and 12Ah batteries. |

There are other nuances that should be taken into account when choosing a screwdriver. For example, the design of the engine is of great importance. Modern tools with brushless motors, even at 10.8V, have more power and torque than many 18V models with conventional brushed motors, due to reduced power consumption and lower friction and heat losses.

Battery compatibility with other types of tools

The cost of the battery (especially when it comes to high-capacity battery packs) often reaches half the price of the tool itself. Therefore, you should immediately think about how to choose a screwdriver in such a way as to subsequently save on batteries.

Fortunately, power tool manufacturers have already taken care of this. Many of them build an entire “ecosystem” of different types of tools around one type of battery. That is, the same battery can be used for a screwdriver, drill, grinder, jigsaw, renovator and other devices. Some companies even produce powerful hammer drills, concrete cutters, lawn mowers and electric bicycles that run on one, two or three standard batteries from a screwdriver. Milwaukee, for example, has an 18-volt tool ecosystem of more than 200 models.

| Over 200 models of Milwaukee tools and garden equipment can be powered by the same 18V battery. |

conclusions

It is impossible to unequivocally answer the question of which screwdriver is better: 12 V, 18 V or 24 V. Each of them is a compromise between power, operating time on one charge, size and weight. Although 18-volt models are the most popular, it doesn't always make sense to pay extra for them. It is better to choose a tool based on what work you will do with it. Is a screwdriver your main assistant and you work all day long? In this case, it is worth buying a high-quality 18-volt model with a capacious battery and a spare battery. Do you use a screwdriver as an auxiliary tool for individual operations that do not require special power? Then an inexpensive 12-volt device from some budget brand will be just right.

Features of choice

When choosing power, you should take into account not only what power of the screwdriver is indicated in the information from the manufacturer. Due to too much productivity, the device may tighten the screws too tightly, pressing their heads into the surface. As a result, the appearance of the coating deteriorates, and the fasteners, if necessary, are almost impossible to unscrew.

When choosing which voltage is best for a screwdriver, you should take into account that voltage is the main parameter of the device. For example, motor power screwdriver is 700 W, with a voltage of 14.4 V and a battery capacity of 1300 mAh and a torque of 36 Nm. Whereas the other model Hammer ACD182 has a weaker engine (22 Nm) and a less capacious battery (1200 mAh) - and it seems that this device is about 40% weaker. However, due to the 18 V voltage, the Hummer is able to tighten more fasteners without recharging, even being inferior to its competitor in terms of battery capacity.

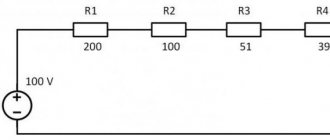

You can understand why a screwdriver that seems less productive at first glance is inferior to a more powerful one by doing a little calculation:

- the amount of energy stored by the first model is 1.2 x 1.8 = 21.6 Wh;

- the second indicator is only 1.3 x 14.4 = 18.72 Wh, i.e. 15.4% less.

When choosing a screwdriver, it is advisable to take into account the presence of a spare battery included with it. Some models even have 2 additional batteries. On the one hand, such equipment will cost more (especially since the cost of the battery is up to 80% of the price of the equipment), but it will be much more convenient to work with it. At the same time, an additional battery is not needed to perform household tasks - the time of work performed with its help rarely exceeds 1–2 hours. While in the process of constant use of a screwdriver (for example, for repair work or furniture assembly), the second battery allows you to not interrupt the work for longer than a few minutes. The discharged battery is charged, and a spare battery is installed in the device.

If there is no need for long-term work, which may require a screwdriver, it is not recommended to buy a model with additional batteries, not only because of its increased cost. It’s just that the service life of such a battery is short, and after a couple of years the user will have to buy a new part without using up even half of the life of the old one.

Screwdriver for home and work. My tips for choosing (voltage, power, etc.)

A screwdriver is a tool with which it is very convenient to twist self-tapping screws; its main purpose is precisely this. However, this is not the only limit to the functionality of this useful tool, you can also drill wood, metal and even brick (if the impact function is present).

Of course, it is not at all necessary to have a screwdriver in the house when you have a drill, however, if you often work with self-tapping screws, then a “shurik” is simply necessary.

Screwdrivers are divided into 2 main types - cordless and corded. (You can read about corded screwdrivers for the home here.) Of course, the vast majority buy cordless ones, since they can be used where there is no electricity. For example, at the dacha, when the wires have not yet been installed. So, whatever one may say, a cordless screwdriver is a necessary and very useful tool. So, how to choose this tool, what to look for, what features to look for and what brands to look for? The answers are in this article.

How many volts should I use?

If you went to tool stores, you saw that screwdrivers come in 9.6 volts, 12 volts, as well as 14.4, 18 and even 24 volts. What do all these numbers mean and how do they affect your work? The voltage supplied to the battery determines the power of the tool.

Simply put, the higher the voltage, the higher the power. In turn, the higher the power, the slower the battery discharges. Since we are choosing a tool for the home, we should not take the most powerful one, because it will be heavy. Why do we need a heavy tool if we plan to use it only when tightening screws?

For home use, 12 volts is quite enough, but I think 14.4 is the most optimal. The difference in price between the 12 and 14.4 volt Shurik is insignificant, so it’s better to overpay a little and buy a more powerful one. However, there is also no big difference in torque; 14.4 will be 20 percent more powerful. Therefore, first of all, figure out what kind of work you will be doing and, based on this, select a model of a certain voltage.

Tightening torque - how many newtons?

By and large, this is the most basic parameter of the “Shurik”. Measures the tightening torque in Nm (newton per meter). If you estimate this way, then most home models have a torque of no more than 18 Nm. How much force is needed to tighten screws? The question is certainly interesting.

Driving thick screws requires much more force than thin screws. Let's take, for example, a self-tapping screw with a thickness of 3.5 mm (standard for wood) and a roofing screw with a thickness of 6.3 mm. The difference in thickness is significant. We will also take into account the length of the screw; you must agree, it’s one thing to screw in 30 mm or 100 mm.

To tighten standard black wood screws, a small tightening torque is sufficient; as a rule, all household 12-volt screwdrivers have a torque of 10-15 Nm. This torque is enough to tighten a self-tapping screw on wood up to 150 mm long.

However, it is a completely different matter if you are going to cover the roof of your dacha using roofing screws. They are usually very thick (4.8 and 6.3 mm thick), so the tightening force must be much stronger.

As you already understand, 15 Nm is not enough here, so choose models with a more powerful tightening torque, usually from 20 Nm. And here when choosing, confusion begins, it seems that the screwdriver is powerful, 18 volts, but the torque is weak. Or vice versa, a 12 volt screwdriver has a torque of 28 Nm. How does this happen? Let's figure it out.

Although there is nothing to understand here, logically, the higher the voltage, the greater the torque. However, this is not the case with professional models; all 12-volt models have a solid torque of 24 Nm and above. For household ones, in order to achieve a tightening torque of at least 20 Nm, the screwdriver will have a higher power supply, most often from 18-24 volts.

How many batteries are included?

Also, various models have 1 or 2 batteries included. When purchasing a screwdriver, consider whether you will need a second battery. As a rule, it comes in handy when there is a lot of work to be done. While you are working with one, the second one is charging. If the first battery is discharged, you insert the second one and continue working without interruption, and immediately put the discharged one on charge.

And if you work for 20-30 minutes a day, then one battery will be enough and you won’t have to overpay.

A model with 2 batteries costs 20-30 percent more. It is worth saying that the most expensive thing in a tool is the battery; it takes up 80 percent of the cost of the entire tool. For example, a 14.4 volt battery for the Black and Dekker model costs about 1800 rubles, while the “Shurik” itself with 1 battery costs 2400.

Note that the battery life is only 2 years, so you should also not buy a tool with 2 batteries if you do not plan to use it often. Regardless of whether you often used the tool or not, after 2 years the battery will not hold a charge well and will discharge quickly.

Battery capacity.

Battery capacity is measured in ampere/hours; the higher the value, the longer the battery will hold a charge. If I may say so, the more charge will “fit” into the battery. The standard for household models will be 1.2-1.3 Ah. For a household tool, this capacity is quite enough; you can work for 2-3 hours from 1 battery. Only in professional models the capacity can be increased to 1.5 Ah and even 2 Ah, which is already quite a lot.

Impact screwdriver - is it worth overpaying?

In addition to the usual non-impact models, there are impact versions on the market. The analogy is the same as that of an impact drill, when the impact is carried out due to the mechanical action of engine parts with each other. Is a shock function necessary? The question is rhetorical.

If you don’t have an impact drill on your household, then it makes sense to buy an impact screwdriver; sometimes you may need to drill a brick. Concrete won't take it, don't even try. Well, if you have a drill on your farm, then IMHO there is no point in buying a “Shurik” with an impact - it is more expensive than a regular one, and the impact is practically of no use. A blow is also needed to “pull off” a stuck bolt. Here it is better to buy a special impact screwdriver.

How many speeds?

Screwdrivers come with 1 and 2 speeds. Cheaper models are not equipped with a second speed. The standard rotation speed is 750 rpm, but at the second speed the number of revolutions is increased to 1200. Is the second speed really necessary?

My IMHO is not necessary, since you practically won’t feel the difference between 750 and 1200 rpm. Of course, it would be preferable to work in drilling mode with a high number of revolutions, but it is not critical; you will do the same work whether you have a single-speed or a two-speed tool.

What is the difference between a screwdriver and a drill?

I’ll say right away that the difference is in the ratchet, which the Shurik has and the drill does not.

Many people ask this question when choosing, because they do not understand how a screwdriver fundamentally differs from a drill. After all, with a drill you can do the same work as with a “Shurik”, namely: drill through wood, metal, tighten, unscrew.

As for drilling, yes, there is no difference, although with a drill you will drill, for example, metal, much faster, because the number of revolutions of a drill is higher - 2400 versus 750 of a screwdriver. But tightening screws is a different matter - it’s very difficult to turn with a drill, since there is no friction clutch.

The friction clutch is a “ratchet” and is activated when the force reaches the selected value. That is, let’s say you tighten a self-tapping screw, it screws all the way to the head and then the clutch works, which prevents further screwing, you hear the ratchet working - the engine continues to spin, but the bit does not spin.

This is the whole difference, with a screwdriver you can select the force for any length when the screw is screwed all the way to the head and the friction clutch is activated, preventing further screwing. The beauty of this is that the bits have virtually no wear since they are not spinning on the screw once it is already screwed in.

The same cannot be said about a drill; when tightening screws with a drill, the bits spin on the already screwed head, because very often the operator does not have time to pull back the drill. Therefore, screwdriver bits wear off very quickly.

Manufacturing companies.

If you choose “Shurik” for household use, we recommend that you pay attention to the following brands:

Black and Dekker - an English company, as always, is at its best; its brand of “shuriki” is an excellent instrument, most suitable for the price-quality description. Models for the home are especially in demand:

EPC 12CA - option with 1 battery, minimal equipment, and the price is low, about 2000 rubles.

EPC 12 CAB - the same thing, only with 2 batteries.

Models from Skil, Hammer, Zubr, Interskol are also quite good.

We also recommend paying attention to the models of these companies. There are a lot of positive reviews about the Zubr power tool, the price-quality is at the same level. Another note: How to choose an electric planer, reviews of Interskol, Baikal models.

12 volt screwdriver power in watts

When choosing the right screwdriver for a particular task, you should pay attention to various characteristics. Among them, the most important are not only the power of the device and the capacity of its battery, but also the battery voltage, and even the torque value.

When carrying out construction and repair work, a screwdriver is an indispensable tool that simplifies the tightening of various types of fasteners, and sometimes even drilling holes. And, despite the fact that there are two versions of this device - mains and battery-powered, more often the latter option is chosen to perform household tasks. At the same time, attention is paid to the parameters of the power tool itself and to such characteristics as the voltage in the screwdriver, its power , torque and battery capacity. Each of these indicators is important for evaluating and choosing the correct device. Whereas it’s not worth buying based on suitable power or voltage alone.

Rotation speed and torque

The force with which a screwdriver can turn a screw is determined by the torque. It can be very small for household models - 10-15 Nm, or can reach 130-140 Nm for professional ones. Therefore, professional screwdrivers can easily and quickly tighten large screws and work with hard materials.

But high torque is not always necessary and not with all materials; therefore, screwdrivers provide the ability to adjust the applied force. There is a limiter for this. It is made in the form of a movable ring, which is located behind the clamping chuck.

The higher the number of revolutions, the stronger the torque

There is a mark on the ring; by placing it opposite a certain number, you set the maximum force that the tool can develop. Once this value is reached, the cartridge will spin idle - the screw will no longer be tightened. The achievement of this value can be clearly monitored - the ratchet turns on.

Many models of screwdrivers can operate in two modes: actually tightening the fasteners and drilling. Such models are called drill-screwdrivers, but they are now the majority. To switch to the drill mode, the switch is set to the extreme position (having first replaced the nozzle). At the same time, maximum speed is turned on, which allows you to drill even quite hard materials.

What does the power of a screwdriver affect?

In professional terms, it is worth taking into account all the parameters of the tool. And on the power indicator, pay doubly attention. How much screwdriver motor power is needed depends on the type of fastener or the volume of roofing work .

To put it simply, the power of a screwdriver directly depends on the force with which the self-tapping screw or screw will be screwed in. It will be problematic to screw in long fasteners at low power. And vice versa. A screwdriver that is too powerful will drive the screw along with the head, which is undesirable.

The more powerful the battery and the tool itself, the higher the dimensions and weight of the screwdriver.

Household or professional

As you know, professional screwdrivers are more expensive, but this is no coincidence. They are made with a large margin of safety, for which higher quality and more expensive materials are used. In addition, they have more power, which makes it possible to screw in longer screws and/or work with tougher materials.

The difference between a professional and household screwdriver in resource

To decide whether you need a household or professional screwdriver, assess the amount of work that will need to be done. If you are starting construction or major renovations, you probably need a professional or semi-professional model. If you need a tool periodically to unscrew/tighten something from time to time, a household tool is more than enough. With such work, the professional tool resource simply will not be in demand. So choosing a screwdriver based on this criterion is not very difficult.

READ Remaking a Computer Power Supply for a Screwdriver

How to remake it yourself

Before you remake a screwdriver, you need to clearly determine what power and what voltage the tool needs to operate. This will be the starting point.

The body of the instrument is then opened. The two halves of the housing can be fastened with screws or with glue. A knife can be very useful during disassembly.

After opening the case, a power supply or wire is inserted inside, the contacts of which must be soldered to the charger. Soldering should be as efficient as possible, using special solutions.

The second end of the wire must be intended for power supply from the network. So there must be a plug there. It is recommended to make a hole in the housing in advance through which the cable will pass.

A homemade power supply can be obtained in several ways. In any case, you will get a full-fledged tool that can be used to perform work after connecting to the network. It is advisable to first prepare a diagram that will help you avoid mistakes when creating a block.

Pulse

The operating principle of pulse systems is that the voltage is first rectified and then converted into a special pulse signal. It is important to achieve stable voltage. A transformer winding or resistors can help with this.

Switching power supplies are quite efficient and can be used in different conditions. At the same time, they have a high level of protection against short circuits and similar effects. However, in terms of power, pulsed systems are clearly inferior to transformer systems. In addition, such blocks are very capricious in terms of input voltage. If it is lower than set, then the element may simply not work.

We use a laptop charger

An excellent option is to use a laptop charger. Such devices usually operate with a voltage from 12 to 19 V. This is quite enough to ensure high-quality operation of the screwdriver. But do not neglect the output current indicators. The closer it is to what is required, the better.

In this case, converting a screwdriver to mains power comes down to simply soldering the wires from the charger to the board in the tool. It is advisable to insulate everything using electrical tape or other similar materials. After this, the wire is brought out and the tool can be used.

Reworking a Chinese-made power supply

Ordinary Chinese power supplies with an output voltage of 24 V and a current of 9 A are excellent for creating a power supply for a 12-volt screwdriver with your own hands. But since the tools use less voltage, you need to lower it first.

To achieve the goal, you need to replace the original resistor R10 with an adjustable resistor, with which you can achieve the desired voltage. This is done in several stages:

- the permanent resistor is removed;

- in its place a pre-prepared adjustable resistor is inserted, on which a resistance of 2300 Ohms will be set;

- so far the voltage is still 24 V;

- Using the resistor settings, you need to achieve the required voltage at the contacts.

After all the manipulations, you need to check that the output voltage is the required value (12 V, 14 V, etc.), and also that the current exceeds 9 A.

Reworking purchased blocks

You can also power it from any other purchased power supplies. The conversion process in this case will be almost the same, however, in addition to the resistor, you may need to solder in additional diodes. The most important thing is to achieve the required output parameters. And this can be easily done using a combination of components.

Mock Tests

Before you begin constructing a working structure, you should test everything on the knees, make sure that the screwdriver is stable under load and that there is no severe overheating in the power supply.

We take the computer power supply and check it: plug it into the network, find a greenish one in the output bundle of wires (they say it may be a different color, but I always came across greenish ones) and connect it with a jumper to any of the dark ones (all dark wires are at the output. common output , in our case it is a minus). The unit should turn on, and a voltage of 12 volts will appear between the dark and yellowish wires. You can check this with a multimeter or by connecting any computer cooler to the named terminals.

READ Screwdriver Bosch 18 how to remove the chuck

If everything is in order and the unit produces about 12 volts at the yellowish and black (-) terminals, continue. If there is no voltage at the output. We are looking for another unit or repairing this one, this separate topic will be described separately.

We cut off the plug from the output of the block and take 3-4 yellowish and dark wires coming from the block and connect them in parallel. When cutting off the plug, do not forget about the greenish starting conductor, it must be shorted to dark. We received a 12 V source with a solid current load capacity of 10-20 A, the currents depend on the model and power of the unit.

Now we need to connect our 12 V to the terminals of the screwdriver without a battery; we look at the polarity of the connection using the battery. Well, let's check the screwdriver. at idle speed, later braking by hand. At this step, I encountered a problem: when the button is fully pressed, the screwdriver works, but when the screwdriver button is pressed slowly, smoothly, the power supply goes into protection. To reset the protection, you need to disconnect the unit from the network and turn it on again. This will not work at all; it is necessary to somehow correct such inconstancy.

In my opinion, this phenomenon may appear due to the fact that the power supply and the screwdriver button are controlled by PWM controllers; due to interference along the power wires, the controllers somehow interfere with each other. We are trying to solve this problem by introducing an improvised LC filter.

I assembled the filter in 5 minutes from what was at hand: 3 electrolytic capacitors of 1000 microfarads each at 16 volts, a non-polar capacitor of at least 1 microfarad and wound 20 turns of copper wire with a diameter of 2 mm on a ferrite ring from another unit. Here is his diagram:

And this is how it looks. This is a purely trial version; in the future, this design will be transferred to the battery housing of the screwdriver and will be made more accurately.

We check the entire structure: the block does not go into protection in all positions of the button, amazing! Now you can try tightening a few screws. everything in a bunch. It feels like the screwdriver will be able to tighten even larger screws.

Well, now we need to remove all the snot and piles of wires, remove the “dead cans” from the battery case, replace them with an LC filter, and test the screwdriver in more realistic conditions.

Wood lathe

Creating products from wooden blanks is impossible without a woodworking machine. As a working surface of the machine, you can use a workbench made of wood with a flat surface.

According to the dimensions of the tool, make a bed from a lath in which the screwdriver will be located and fixed. A regular clamp is used for fixation. The bed is attached to the base using self-tapping screws or a clamp.

A mandrel with teeth is placed in the screwdriver chuck. To make the tailstock, 2 bars with an adjustment screw, sharpened to the dimensions of the cone, are suitable. The headstock is attached opposite the screwdriver . In this case, its axis should be at the same level with the headstock adjusting screw.

Use a clamp to secure the back stop to the base of the future machine. A simple wood lathe is ready to use.

Electric snowmobile

To create a simple and reliable snowmobile, cordless screwdriver is suitable. The snowmobile frame can be made from a sled with steering control. Attach a screwdriver to the iron frame. For this, a wheel welded to the rear of the frame is used.

The chain and 2 sprockets create a rotational motion that turns the snowmobile wheel, causing the sled to move. The snowmobile control consists of a cable, the end of which is connected to the screwdriver power button. The other end of the cable is attached to the steering wheel. As a result of clamping and releasing the handle on the steering wheel, the screwdriver .

READ Imax B6 Screwdriver Battery Reconditioning

A circular saw

You can make a circular saw from a used impact wrench. To fasten future equipment, a plywood sheet is used, in the central part of which a hole is cut to the size of a screwdriver . The tool is secured at the top and bottom of the base with self-tapping screws or clamps.

The cutting element of the saw can be secured using an M10X 50 bolt, onto which a washer and a rubber gasket are placed. The cutting part is tightened in the upper and lower parts of the bed.

To create the sides of a circular saw, a plywood sheet measuring 11.5x15 cm is used. They are assembled using self-tapping screws. A cut (27x40 cm) is cut in the central part of the frame to install the disk. It is important to securely fasten the saws to the frame in order to prevent it from playing during operation.

Bench Drilling Machine

No less important in a home workshop is a drilling machine. An old screwdriver is also perfect for doing it yourself.

First you need to disassemble the tool, removing the engine, gearbox and cartridge from it. You can secure the head of the future machine using clamps made of textolite. To avoid distortions, it is recommended to process the clamps simultaneously. Restrictive posts are made of bushings with threads located in the inner part. The bushings must be the same size.

After this, you should start making 2 bosses from caprolon. A hole is drilled in their central part. The result is 2 eccentric bushings.

Install a clamp on the rod and adjust the backlash. An eccentric is used for this. To ensure the possibility of returning the drilling head to its initial position, the wooden lever is attached to a metal rod with a spring.

Electric current is supplied through the use of a transformer power does not exceed 150 W. Now all that remains is to install the capacitor with a diode bridge and the drilling head on the frame. The lathe is ready for use.

Children's catamaran

To create such a vehicle, you can use plastic pipes. Plastic ties are used to secure them. The catamaran motor can be made from a screwdriver engine.

Manufacturers

Unknown companies spend less on advertising campaigns. Therefore, their brand products are inexpensive, but they are not particularly reliable. In general, choosing a brand is a choice between price and quality.

MakitaDDF454RFE

Reliable Makita brand made in Japan. By owning this product, you can count on its durability. The parts of the device are made of rubber, steel and plastic, which guarantees long service life.

- integrated lithium battery;

- powerful four-pole electric motor;

- power up to 80 Nm;

- two 18-volt lithium-ion batteries with a capacity of 3 Ah, which ensure long, uninterrupted operation;

- charges in 30 minutes;

- automatic control shutdown of the tool when disengaged;

- compatibility with Makita batteries with a capacity of 4 Ah is ensured;

- quality assurance.

Bosch GSR 1440-LI

Professional screwdriver with protection against overheating, full discharge and overload. This model has a 2-speed gearbox with 25 positions. You can work at 200 rpm. / min. or 650 rpm. The compact design allows you to work in very confined spaces.

Advantages of the German device:

- good built-in grip providing the necessary comfort;

- automatic clutch stop;

- comes with a 14.4 V, 1.5 Ah lithium-ion battery;

- three years warranty.

Among the budget options, one of the most reliable 14-volt screwdriver models.

Cartridge

This parameter may not seem so important, but it is a fairly significant part of a screwdriver . The size of the chuck determines the range of tasks that the mounted drill can perform. It also determines the maximum shank size of the product. The standard chuck size today is 1.3 cm. This is enough to perform a variety of tasks, including drilling holes in wood and concrete.

For information. A new model has entered the market - a screwdriver with two cartridges, in which the cartridges are changed quite quickly by turning the holder after pressing the button. The quick change of two cartridges is designed more for professionals. At home, where time is not of critical importance, this is unlikely to be of interest, since it is significantly reflected in the price.

Comfort

When working, you have to hold it in your hand for quite a long time. Therefore, manufacturers provide a plastic handle for convenience. The handle itself has a durable rubberized surface, which provides maximum comfort when working. When choosing a screwdriver, undoubtedly, you need to pay attention to comfort.

The word comfort also means that:

- balanced instrument;

- The size corresponds to the size of the hand and the strength in the wrist.

Additionally, nickel-cadmium batteries cost less and provide sufficient performance, making them a good alternative for the average worker.

Important! In all aspects, comfort should be one of the main factors when choosing a tool.

How much current does a screwdriver consume?

A friend asked me to assemble an external power supply for a screwdriver. Together with a screwdriver ( Fig. 1 ), I brought a power transformer from an old Russian burner-engraver “Ornament-1” ( Fig. 5) - to see if it could be used?

At first, naturally, we disassembled the battery compartment and looked at the “banks” ( Fig. 3 and Fig. 4 ). We checked each “can” for functionality with a charger through several charge-discharge cycles - out of 10 pieces, only 1 was excellent and 3 were somewhat normal, while the others were completely “dead.” This means that you will definitely have to make an external power supply.

To assemble the power supply, it is important to remember how much current the screwdriver consumes during operation. Having connected it to a laboratory source, we find out that the engine starts to spin at 3.5 V, and at 5-6 V decent power appears on the shaft. If you press the start button when 12 V is supplied there, the protection on the power supply is triggered - which means the current consumption exceeds 4 A (the protection is configured for this value). If you start the screwdriver at low voltage and then increase it to 12 V, it works normally, the current consumption is about 2.4 A, but at the moment when the screw is screwed in halfway into the board, the protection of the power supply is triggered again.

To see the full picture of the current consumption, the screwdriver was connected to the car battery, placing a resistor with a resistance of 0.1 Ohm in the positive wire gap ( Fig. 5 ). The voltage drop from it was fed into a computer sound card with an open input, and the SpectraPLUS program was used for viewing. The resulting graph is shown in Figure 6 .

The 1st pulse on the left is the starting pulse when turned on. It can be seen that the highest value is 1.8 V and this situation indicates a flowing current of 18 A (I=U/R). Then, as the engine speeds up, the current drops to 3.5 A. In the middle of the 2nd second, the screwdriver head is clamped by hand until the “ratchet” is activated. the current then rises to approximately 17 A, then drops to 10-11 A. At the bottom of the 3rd second, the start button is released. It turns out that to perform the work of a screwdriver, you need a power supply with the ability to deliver a power of 200 W and a current of up to 20 A. However, taking into account that the battery compartment says that it is 1.3 A/h ( Fig. 7 ), then It's probably not as bad as it might seem.

READ Hitachi screwdriver Convert to Lithium Ion

How much current does a screwdriver with aliexpress deko consume?

We open the burner's power supply and measure the output voltages. The highest is about 8.3.2 V. Not enough, naturally. Taking into account the voltage drop across the rectifier diodes, the output voltage on the filter capacitor will be about 10-11 V. However, there is nowhere to go, we try to assemble the circuit according to Figure 8 . The diodes used are brand KD2998V (Imax=30 A, Umax=25 V). The VD1-VD4 diodes are mounted by hinged mounting on the petals of the contact sockets of the burner ( Fig. 9 and Fig. 10 ). As a large-capacity capacitor, parallel connection of 19 pieces of the smallest capacity was used. The entire “battery” is wrapped with masking tape and the capacitors are sized so that the entire bunch fits into the battery compartment of the screwdriver with slight effort ( Fig. 11 and Fig. 12 ).

The fuse block in the burner is very awkward, so it was removed, and the fuse was soldered “directly” between one of the 220 V wires and the terminal of the noise-suppressing capacitor C1 ( Fig. 13 ). When closing the case, the network wire is tightly crimped with a rubber ring through it; this prevents the wire from dangling inside when bending it from the outside.

READ How to Correctly Cut a 45 Angle

Checking the functionality of the screwdriver showed that everything works fine, the transformer, after half an hour of drilling and tightening screws, heats up to approximately 50 degrees Celsius, the diodes heat up to the same temperature and do not need radiators. A screwdriver with such a power supply has the least power compared to powering it from a car battery, alas, this is understandable - the voltage on the capacitors does not exceed 10.1 V, and as the load on the shaft increases, it further miniaturizes. When, decently “lost” on a supply wire about 5 meters long, even using it with a cross-section of 1.77 sq. mm. To check the drop on the wire, a circuit was assembled according to Figure 14 , here the voltage on the capacitors and the drop voltage on one conductor of the supply wire were monitored. The results in the form of graphs under various loads are shown in Figure 15 . Here in the left channel is the voltage on the capacitors, in the right channel is the drop on the “negative” wire running from the rectifier bridge to the capacitors. It can be seen that when the screwdriver head is stopped by hand, the supply voltage drops to levels below 5 V. At the same time, approximately 4.5 V drops on the power cord (twice 1.25 V), the current is pulsed in nature and is associated with the rectifier service bridge ( Fig. 16 ). Changing the power cord to another, with a cross-section of about 3 sq. mm, served to increase the heating of the diodes and transformer, so they returned the old wire.

READ Connect Screwdriver K 220

Converting a screwdriver to a network one. Test of different power supplies

We looked at the current in the circuit between the capacitors and the screwdriver itself, assembling the circuit according to Figure 17 . The resulting graph is shown in Figure 18 , “shaggy”. these are ripples of 100 Hz (the same as in the last 2 pictures). It can be seen that the starting pulse exceeds the value of 20 A - most likely this is due to the lowest internal resistance of the power supply due to the use of parallel connection of capacitors.

At the bottom of the measurements, we looked at the current through the diode bridge, connecting a 0.1 Ohm resistor between it and one of the terminals of the secondary winding. The graph in Fig. 19 indicates that during motor braking, the current reaches a value of 20 A. In Fig. 20 there is a section with the highest currents extended over time.

And therefore, while we decided to work with a screwdriver with the described power supply, in that case there will not be enough power, then we will have to find a more powerful transformer and install diodes on the radiators or replace them with others.

Well, of course, it makes no sense to accept such a text as dogma. There are absolutely no obstacles to the production of power supply according to a different scheme. For example, of course, change the transformer to TS-180, TSA-270, in other words, you can try to power the screwdriver from a computer pulsed power supply, alas, most likely, it will be useful to check the ability of the circuit to deliver 12 V current 25-30 A.

Source

Top review of the best cordless screwdrivers

“Which cordless screwdriver is best?” – this question is fully answered by a comparative review of the best screwdrivers for the home. Therefore, the most popular models of screwdrivers will be considered below. For an objective assessment, a screwdriver test was carried out.

Based on the test results, places are distributed as follows:

- DeWALT DCD790D2;

- Metabo POWER MAXX BS;

- Makita DDF454RFE;

- Hitachi DS18DFL;

- Bosch GSR 1440-LI;

- SKIL 2602 MK;

- HILDA 12 V.

A detailed review, the same rating of screwdrivers, provided an exact answer to the question of which screwdriver to choose for the job. An American-made device came out on top.

Additional options

- reverse, with which you can unscrew and screw in;

- cartridge available on all models;

- an automatic brake that allows the device to stop on its own when it has been tightened to the required force.

There are also additional options such as backlight, magnet, belt hook. These options are more needed for the work of professionals.

Sources:

https://booktube.ru/moshhnost-shurupoverta-12-volt-v-vattah/ https://tehnopanorama.ru/instrumenty/peredelka-shurupoverta-na-pitanie-ot-seti.html https://tehnopanorama.ru /instrumenty/chto-mozhno-sdelat-iz-starogo-shurupoverta.html https://elquanta.ru/instrument/shurupovert-akkumulyatornyjj-kakojj-luchshe.html