Calculation of heating element power by resistance - All about electricity

A tubular electric heater (TEH) is an electric heating element in the form of a metal tube of arbitrary shape, in which a spiral of nichrome or fechrome wire with leads at the ends is placed.

To insulate the spiral and transfer heat from it, the tube is filled with quartz sand. The heating element has no polarity, so it does not matter to which terminal the phase and zero are connected. The heating element was invented and patented on September 20, 1859 by American George Simpson.

Almost any modern electric heating devices, such as an electric kettle, an iron, an automatic washing machine, or a heater, use heating elements as a heat source.

If heating does not occur in an electrical appliance, this does not mean that the heating element has failed. It is quite possible that the cause of the malfunction may be the switch, thermostat or other controls. But usually the heating element is checked first, since checking it is not difficult. Any home master, having read this article, even without experience in checking and replacing heating elements, can easily cope with this task by choosing the most accessible method of checking.

Design of a tubular electric heater (TEH)

As can be seen from the drawing below, the heating element is a metal tube made of copper, stainless steel or iron, in the center of which there is a nichrome spiral, twisted in the form of a spring.

The tube inside is completely and tightly filled with sand, which allows you to effectively remove thermal energy from the spiral and prevent it from coming into contact with the tube. The ends of the spiral are connected by welding to contact rods, which are fixed inside the tube using ceramic insulators. To supply power voltage, threads are cut at the ends of the contact rods or contact plates are welded.

Tubes for the manufacture of heating elements are used in different diameters and, depending on the purpose, they are given different shapes, up to spiral-shaped. A good example is an electric boiler.

What are the types of heating element malfunctions?

Most often, heating elements fail due to the breakage of the nichrome spiral thread, which occurs due to the melting of the nichrome thread due to its overheating. Overheating occurs if a thick layer of scale has formed on the heating element or the heating element, designed to operate in a liquid environment, is turned on without it. The coil can burn out due to the initial low quality of the heating element.

The spiral in the center of the heating element tube is held in place by its dense filling with sand. If, when filling in sand, it was poorly compacted or the spiral moved from the center to the wall of the tube, then over time, due to vibration, the spiral may move and touch the inner surface of the tube.

If the spiral touches only at one point, then in the absence of connecting the grounding wire of the RCD in the apartment electrical wiring, the heating element will not lose its functionality and the electric kettle or any other heating device will continue to work. But in this case, there is a possibility of a phase getting into the body of the product, and if it is metal, then there is also the possibility of electric shock to a person when touching the body.

If the electrical appliance is grounded, then as a result of shortening the spiral, the released power will increase significantly and if the circuit breaker does not work, the spiral will melt and the heating element will fail completely.

If the spiral touches the tube in two or more places at the same time, as in the photo, then in the absence of grounding and an RCD, if the circuit breaker does not operate in time, the spiral will immediately burn out.

Thus, heating elements can have one of two malfunctions - a break in the nichrome spiral or a short circuit to the metal tubular shell. Any of these failures cannot be eliminated and the heating element must be replaced.

In modern electric kettles, multicookers and irons, heating elements are welded to the body of the product, and when the heating element fails, you have to buy a new electrical appliance.

Depending on the availability of measuring instruments, you can check the heating element in one of the following ways. Measure the resistance of the spiral and the resistance between the spiral and the tube using a dial tester or multimeter, ring using a phase indicator or an electrician's control.

Checking the heating element using a dial tester or multimeter

To check, you need to turn on the device in the minimum resistance measurement mode and touch the leads of the heating element with the ends of the probes of the device.

If the spiral is broken, then the pointer tester will show a resistance equal to infinity, and the multimeter will show “1” instead of the real resistance, which is equivalent to infinite resistance.

You can calculate what resistance the heating element coil should have depending on its power using an online calculator.

It is enough to enter into the calculator windows the voltage for which the heating element is designed and its power. Typically these values are embossed on the tube. You can use information about the power consumption of an electrical appliance. For example, the resistance of the heating element of an electric kettle with a power of 2000 W will be 24.2 Ohms.

If the spiral is intact, then you need to touch any of the heating element terminals with one end of the multimeter probe, and the metal tube with the other. If there is no short circuit between the spiral and the tube, then the dial tester will show infinite resistance, and the multimeter will show “1”. If the device shows a value different from the specified value, then a short circuit is evident and such a heating element is not subject to further operation.

Source: https://contur-sb.com/raschyot-moschnosti-tena-po-soprotivleniyu/

Calculation of the power of heating elements

The optimal source of energy for heating the evaporation tank is a residential electrical network with a voltage of 220 V. You can simply use a household electric stove for these purposes. But, when heating on an electric stove, a lot of energy is spent on useless heating of the stove itself, and is also radiated into the external environment from the heating element, without doing any useful work. This wasted energy can reach decent values - up to 30-50% of the total power expended on heating the cube. Therefore, the use of conventional electric stoves is irrational from an economic point of view. After all, for every extra kilowatt of energy you have to pay. It is most effective to use elec- tronics embedded in the evaporation tank. Heating elements. With this design, all energy is spent only on heating the cube + radiation from its walls to the outside. The walls of the cube must be thermally insulated to reduce heat loss. After all, the cost of heat radiation from the walls of the cube itself can also amount to 20 percent or more of the total power expended, depending on its size. For use as heating elements embedded in a container, heating elements from household electric kettles or other suitable sizes are quite suitable. The power of such heating elements varies. The most commonly used heating elements with a power stamped on the body are 1.0 kW and 1.25 kW. But there are others.

Therefore, the power of the 1st heating element may not correspond to the parameters for heating the cube and may be more or less. In such cases, to obtain the required heating power, you can use several heating elements connected in series or series-parallel. By switching various combinations of connecting heating elements, a switch from a household electric. plates, you can get different power. For example, having eight embedded heating elements, 1.25 kW each, depending on the switching combination, you can get the following power.

- 625 W

- 933 W

- 1.25 kW

- 1.6 kW

- 1.8 kW

- 2.5 kW

This range is quite enough to adjust and maintain the required temperature during distillation and rectification. But you can get other power by adding the number of switching modes and using different switching combinations.

A series connection of 2 heating elements of 1.25 kW each and connecting them to a 220V network gives a total of 625 W. A parallel connection gives a total of 2.5 kW.

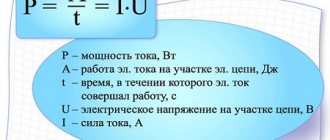

You can calculate using the following formula.

We know the current voltage in the network, it is 220V. Next, we also know the power of the heating element, knocked out on its surface, let’s say it’s 1.25 kW, which means we need to know the current flowing in this circuit. Knowing the voltage and power, we find out the current strength from the following formula.

Current = power divided by line voltage.

It is written like this: I = P / U.

Where I is the current strength in amperes.

P is power in watts.

U is voltage in volts.

When calculating, you need to convert the power indicated on the heating element body in kW into watts.

1.25 kW = 1250W . We substitute the known values into this formula and get the current strength.

I = 1250W / 220 = 5.681 A

Next, knowing the current strength, we calculate the resistance of the heating element using the following formula.

R = U / I, where

R - resistance in Ohms

U - voltage in volts

I - current in amperes

We substitute the known values into the formula and find out the resistance of 1 heating element.

R = 220 / 5.681 = 38.725 Ohms.

Next, we calculate the total resistance of all series-connected heating elements. The total resistance is equal to the sum of all resistances connected in series with heating elements

Rtotal = R1+ R2 + R3 , etc.

Thus, two series-connected heating elements have a resistance of 77.45 Ohms. Now it is easy to calculate the power released by these two heating elements.

P = U2 / R where,

P - power in watts

U2 - voltage squared, in volts

R is the total resistance of all lines. conn. heating elements

P = 624.919 W , rounded to 625 W.

Then, if necessary, you can calculate the power of any number of series-connected heating elements, or refer to the table.

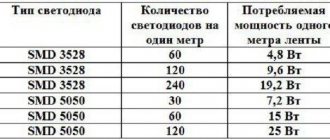

Table 1.1. Values for series connection of heating elements at a voltage of 220V.

| Number of heating elements | Power , W) | Resistance (Ohm) | Current (A) |

| 1 | 1250 | 38,8 | 5,7 |

| 2 | 625 | 77,5 | 2,8 |

| 3 | 416 | 116,2 | 1,9 |

| 4 | 312 | 154,9 | 1,4 |

| 5 | 250 | 193,6 | 1,1 |

| 6 | 208 | 232,4 | 0,9 |

| 7 | 178 | 271 | 0,8 |

| 8 | 156 | 309,8 | 0,7 |

Table 1.2. Values for parallel connection of heating elements at a voltage of 220V.

| Number of heating elements | Power , W) | Resistance (Ohm) | Current (A) |

| 2 | 2500 | 19,4 | 11,4 |

| 3 | 3750 | 12,9 | 17 |

| 4 | 5000 | 9,7 | 22,7 |

| 5 | 6250 | 7,7 | 28,4 |

| 6 | 7500 | 6,5 | 34 |

| 7 | 8750 | 5,5 | 39,8 |

| 8 | 10000 | 4,8 | 45,5 |

Another important advantage that the series connection of heating elements gives is that the current flowing through them is reduced several times, and, accordingly, the heating element housing is low, thereby preventing the mash from burning during distillation and does not introduce an unpleasant additional taste and smell into the final product. Also, the operating life of the heating elements, with this inclusion, will be almost eternal.

Calculations were performed for heating elements with a power of 1.25 kW . For heating elements of other power, the total power must be recalculated according to Ohm’s law, using the above formulas.

Heating element calculation – Electrician School

PowerHow to determine the power of a heating element by resistance

Calculation of the power of a tubular heating element of a water heater

5 (100%) : 1

It is logical that all buyers, when purchasing an electric water heater, want the device to bring the required volume of water to the desired temperature in the shortest possible time.

Regardless of the type of device - flow-through or storage - the heating rate depends on its power parameters.

This is where the main questions arise: what equipment should I choose? Will the kilowatts allocated for an apartment or house be enough to function? Which boiler is better suited so that there is enough water and the load on the network is normal?

Manufacturers offer the following scale for the ratio of the power of a tubular electric heater and the volume of the tank:

- 1kW – 15 l;

- 1.5 kW – up to 50 l;

- 2 kW – up to 100 l;

- more than 5 kW – up to 200 l.

The power of a tubular electric heater (TEH) depends on its parameters. Its main function is to heat water in a household water heater. It turns out that the higher the power, the faster the temperature of the liquid will rise.

Let’s say that to heat 15 liters to 60 °C, a device with power parameters of 1.5 kW will take about an hour and a half. This volume will be enough, for example, for one cycle of one-time operation of a washing machine and dishwasher. Taking a shower will require approximately 100 liters of water.

How to calculate the heating power yourself

To do this, you need to square the supply voltage and divide by the power. The use of such elements is most appropriate in a moving air environment, for example, in fan heaters and heat guns. Electric heating elements are used in household and industrial appliances. Electric water heaters, more commonly referred to as boilers, also contain heating elements. Currently, boilers with a “dry” heating element are also produced by other companies, for example, Electrolux and Gorenje.

Accepted forms of heating elements, calculation of the power of heating elements for various operating conditions and products, the design of heating elements, see below in the reference data. The basis of many heating elements is wire with high electrical resistance. Once upon a time, homemade electric stoves, water boilers and “goat” heaters were in use.

In this case, the spiral will simply have to be calculated. In fact, air heating elements are designed to operate in various gas environments. Water heating elements are also not necessarily used in water; this is the general name for various liquid media. This can be oil, fuel oil and even various aggressive liquids. The layer of scale that forms during operation will also not benefit water heating elements.

It all depends on the design of the heating device in which the heating element is supposed to be installed. For example, in the instantaneous water heater of a washing machine, coiled heating elements are used. Some heating elements have protection elements.

Calculation of the number of heating radiators

Heating elements can be equipped with fittings with threads M 14x1.5, M 16x1.5, M18x1.5, M20x1.5, M22x1.5, M24x1.5, etc., flanges G 1 1/4″, G2″, G 2 1/2 ″ and others, with various plates. ATTENTION! The manufacturer can produce heating elements of any power at the customer’s request, but a guarantee is not provided if the power of the heating element exceeds GOST requirements. The use of various heaters is known to everyone. These are electric stoves, frying cabinets and ovens, electric coffee makers, electric kettles and heating devices of various designs.

And most often this wire is made of nichrome. The oldest heating element is, perhaps, an ordinary nichrome spiral. It was known what diameter the wire was and what length was required to wind the spiral of the required power.

One of such protections is protection based on a bimetallic plate: heat from an overheated heating element bends the bimetallic plate, which opens the contact and de-energizes the heating element

Everything here is simple and clear. In this case, the table shows the length of the resulting spiral. What to do if there is a wire with a diameter not indicated in the table? If necessary, calculating the spiral is quite simple. To do this, it is enough to divide the given power by the voltage and obtain the amount of current passing through the spiral. Power in watts, voltage in volts, result in amperes.

Recommendations for selecting heating elements for various environments

Two types of heating elements are used to heat the air:

- Heating elements for “calm” air . The marking of such heating elements according to GOST 13268-88 is “S” and “T”. The specific power per unit surface is respectively 2.2 watts/sq. cm and 5.0 watt/sq. see. Maximum temperature on the surface is 450 and 650 degrees. Heat is removed from the surface of the heater due to convection of “quiet” air in contact with the heated surface.

- Heating elements for “moving” air , also called “blown”, marked “O” and “K”, with a specific power of 5.5 W/sq. cm and 6.5 W/sq. see. Heat is removed from the surface of the heater by a moving air jet, created, for example, by a fan, and this jet moves at a speed of at least 6 m/s (according to GOST). Naturally, a “blown” heating element, compared to a “quiet” one, having the same characteristics (dimensions, material, voltage, etc.), can have significantly greater power and generate more heat on its surface. In this case, the “blown” heating element does not overheat, because excess heat is intensively removed by moving air.

When it comes to heating ordinary rooms in which the air temperature needs to be raised to a level of 20-25 degrees, the choice of heating elements is not difficult: from the table of heating elements on the website, a heating element of the required size, power and voltage is selected, the number of heating elements is determined by the total required power based on ( on average) 1 kW per 10-12 sq. m of room area with a standard ceiling height of 3 m and generally accepted insulation of the building.

In this case, the temperature of the heating element increases slightly, i.e. This is the heating element’s own temperature plus 20-30 degrees. The situation is different when the air temperature needs to be raised to 150, 200 and even 250 degrees. This happens in dryers, bakeries, and painting booths. In this case, the overall temperature of the heating element will be very high: the heating element’s own temperature plus 250 degrees of ambient air.

Such a temperature can adversely affect the “health” of the heating element - it can simply overheat.

Let's look at a specific example. Let’s say that in the chamber for powder coating of products it is necessary to create a temperature of +200 degrees. Omitting the details of the calculation, we use for this purpose a heating element 140 V13/2.5 T 220 (tube 140 cm long, 13 mm in diameter, power 2.5 kW, made of stainless steel). This heating element has a power density of about 4.8 W/sq.m.

cm, and its own temperature is about 600 degrees. In operating mode, the temperature of the heating element reaches 600+200=800 degrees, which exceeds the maximum permissible temperature of the heating element. And if we take into account the “allowed” voltage surges (+10%), the allowed deviation in the power of the heating element (+5%), then the overall temperature of the heating element can be even higher.

The durability of such a heating element becomes questionable.

Let's take a heating element 140 V13/2.0 T 220 (the same as the previous one, only with a power lower than -2.0 kW instead of 2.5 kW). This heating element has a power density of 3.86 W/sq. cm, its own temperature is approximately 480 degrees, the total temperature of the heating element is about 680 degrees, which is not so critical.

Obviously, the first heating element, as a more powerful one, will heat up the chamber faster; the number of these heating elements, based on the required total power, will be required to heat the chamber to the required temperature. But in the end, these “pros” may be offset by “cons”: more powerful, but overheated heating elements will fail more often, and this will require more frequent stops of the spray booth and assembling and disassembling heating elements assemblies.

CONCLUSION: when selecting air heating elements, it is necessary to link such parameters as:

- dimensions and material of the heating element tube;

- power and own temperature of the heating element;

- operating conditions - air temperature, airflow quality, etc.

Heated medium – water

Designation of these heating elements according to GOST 13268-88:

- “R” – material of the heating element tube – black steel;

- “J” – heating element tube material – stainless steel.

The permissible specific power (R permissible) on the surface of the heating element is 15 Watt/sq.cm. This indicator determines the maximum permissible power of the heating element. When selecting water heating elements, the following rules must be observed:

- When operating a heating element, it is necessary to take all measures to prevent the formation of “scale” on its surface - these are deposits on the heating element tube of various impurities present in the liquid. Impurities are present, for example, in dirty or hard water; they envelop the heating element tube in the form of a film of varying thickness. The thicker the film, the worse the heat transfer from the heating element to the liquid, and at some point the heating element may overheat and fail. Water extracted from artesian wells is especially dangerous in this sense. Therefore, from the very beginning of the operation of heating elements, it is necessary to take care of installing all kinds of filters and liquid softeners, as well as carry out preventive cleaning of heating elements and tanks.

- The active part of the heating element must be completely immersed in liquid. Let us recall that the active length of the heating element is equal to its full length minus the length of the “non-heating zone” of the heating element (this is the amount by which the contact pin from the end enters inside the heating element). Most water heating elements have cold zones A = 40 mm and B = 65 mm, so such heating elements must be almost completely immersed in the liquid. In the case of using heating elements with other non-heating zones (C=100 mm; D=125 mm; E=160 mm; F=250 mm; G=400 mm, etc.), the liquid level should be 20 - 30 higher than the non-heating zone mm.

- Sometimes, for technological reasons, the heated liquid must be drained from the reservoir at some intervals. In this case, the heating elements are exposed and move from the aquatic environment to the air, i.e. operate in the “water-air” media change mode (of course, when the liquid is drained, the heating elements are turned off). In such cases, it is not recommended to use heating elements made of black steel, because when heated, cooled and changing environments, black steel begins to intensively corrode (rust) and quickly collapses. But, for example, such conditions do not have a detrimental effect on stainless steel.

- To install the heating element in the tank and seal it (sealing gasket), fittings are attached to the ends of the heating element - bushings with threads and a flange for the gasket. The fitting is secured to the end of the heating element in different ways. One of them is crimping the fitting with special press shears. This method creates a strong and fairly tight connection between the fitting and the heating element tube, which allows the heating element to be used when heating liquid in tanks with an internal pressure of no more than 0.25 MPa (2.5 atm.). That is, in conventional heating systems, in conventional heating tanks, heating elements with pressed fittings are used very widely.

How to calculate heater power

Calculation of the power of the heating element required to maintain a given temperature in a particular room is discussed in paragraph 1 of the “Reference Data”.

To check whether the marking data corresponds to the actual parameters

The heating element must be checked with an ohmmeter while it is hot. In this case, various coefficients can be neglected. Р=U*U/R , where P is the power that needs to be found, W; U —operating voltage, V; R is the measured resistance of the heating element when hot, Ohm. For example: The network voltage is 220 Volts, the measured resistance is 22 Ohms. Then the power of the heating element matters: P=220*220/22=2200 W=2.2 kW.

To calculate the time it takes for the heating element to heat the water, we use the thermodynamics formula.

In this case, for simplicity, we will assume that the environment, transient processes, capacitance, etc. do not affect our heating element system - liquid: A = C (T1-T2)m , where A is the work that needs to be done to change the temperature of a liquid of mass “m” from T1 to T2. C is the specific heat capacity of the liquid; and the formula for the work of electric current: A = Pt , where A is the work of electric current, P is the power of the installation (in our case, heating elements), W, t is the operating time of electric current, sec. Example: How long will it take a heating element with a power of 2.0 kW to heat water weighing 1.0 kg. from 20 to 80 degrees? Reference data: C for water = 4200 J/kg*degree. С(Т1-Т2)m=Рt, hence t=C(T1-T2)m/P=4200*(80-20)*1.0/2000=126 seconds. Answer: water weighing 1.0 kg will be heated by a 2 kW heating element from 20 to 80 degrees in 2 minutes and 6 seconds.

3.Selection of a heating device with optimal power.

The power of the heater determines its ability to maintain a certain temperature in the room. The second quantity on which this depends is the volume of the room. There is one condition - the thermal insulation of the room must be acceptable for the given climate zone. For the standard height of residential premises in Russia of 2.2-2.5 meters, the ratio of power to area is 1:10, i.e. a 1 kW heater can heat a room of 10 square meters. meters. If the room height exceeds the above value, then a correction factor must be used. For example, if the height of the room is 3 meters, then: K = 3 meters/2.5 meters = 1.2. Those. in this case, the ratio of the power of the device and the heated area will be 1.2 kW: 10 square meters.

Dependence of the volume of coolant (liquid) of the heating system on power.

An approximate calculation of the volume of coolant in a heating system can be made using the following ratio: for a heating system with a 1 kW boiler, 15 liters of coolant are required. Accordingly, the volume of a heating system with a 10 kW boiler will be approximately 150 liters.+ The data obtained from this calculation of the volume of coolant in the heating system does not take into account the characteristics of a specific heating system and is only approximate

How to check a heating element with a multimeter

Electric water heating devices are widely used by modern people to solve everyday problems. Their main element, which ensures heating of water to the required temperature, is a tubular electric heater (TEN).

The wire spiral located inside the TEN has a high resistivity and heats up when an electric current passes through it, transferring heat to the body of the device through the thermally conductive filler. If a washing machine, electric kettle or other household appliance stops heating water, then the cause of the problem is most often a breakdown of the thermoelectric heater.

In this material we will talk about how to check the heating element with a multimeter to make sure it is faulty or to establish that the problem is not in the heater.

Check Features

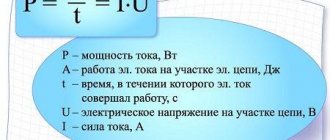

Before checking the serviceability of the heating element, it is necessary to calculate its resistance using the formula R=U2/P. The letters in it mean:

- R – resistance of the electric heater.

- U is the magnitude of the applied voltage.

- P is the power of the device, indicated on its body.

It is necessary to know the resistance value in order to compare the results obtained during testing with it.

Having calculated it using the given formula, you can proceed directly to diagnosis. Checking the heating element is performed in the following order:

- Disconnect the device cord from the power supply.

- Place the tester switch in the resistance range in which the indicator obtained during the calculation is located.

- Apply the multimeter probes to the body of the household appliance and, in turn, to the output contacts of the heater.

- Decipher the readings on the multimeter display. If the tester shows a resistance equal to that obtained in the calculations, the heating element is working. The number “0” indicates the closure of the spiral located inside the element. The number “1” or infinity means that the spiral is broken.

The whole process is detailed in the video:

Having finished testing, you should ring the heating element to find out if there is an electrical breakdown on the body part.

This procedure is also performed using a multimeter in this way:

- Use the regulator on the tester panel to set the meter to buzzer mode.

- Touch the probes to the body and, in turn, to all contacts of the electric heater.

If, when the probes touch the terminals, the device emits signals at a high frequency, this indicates that electricity is “breaking through” to the housing. You cannot touch such a device if it is connected to the network, otherwise a strong electric shock may occur.

How to check the heating element of a water heater?

The boiler is checked for serviceability of the electric heater in a manner identical to that described above. The only peculiarity of this procedure is that, in addition to the heating element, you also need to check the thermostat. The resistance value of serviceable heating elements of water heaters, depending on the brand of device, can range from 0.37 to 0.71 MOhm.

As was said, after diagnosing the electric heater, you should check whether there is a breakdown in the body part. We have already told you how to ring a heating element using a multimeter: you need to set the meter to buzzer mode, and then, touching the contacts with the multimeter probes, listen to the signals that the device emits.

How is the heating element of a washing machine checked?

The main difficulty when checking a washing machine heater is that it is quite difficult to find - especially for many modern units, the internal structure of which is quite confusing. Most often, the heating element in washing machines is located near the back cover, just below the loading tank. However, in some models it is installed on the front side, and in top-loading machines, electric heaters are often located on one of the sides.

Checking the heating element of a washing machine has one more nuance - these heating elements are equipped with three outputs, but when checking you need to connect only to two of them, and it is important not to confuse these contacts. Typically, the terminals to which you need to connect (neutral and phase) are located at the edges, and between them there is a grounding contact, which is not important for testing.

Otherwise, diagnostics of the heating element of the washing machine are carried out in accordance with the instructions given above.

The resistance value of a working electric heater in modern washing machines in most cases ranges from 25 to 60 Ohms.

Checking the heating element of an electric kettle

The electric heater of these devices always has free access, and finding it is not difficult. To check it, you must first calculate the resistance of the element using the formula.

Then you need to set the measuring device to the minimum resistance mode, then attach the probes to the terminals of the heating element and see what data is reflected on the tester’s display.

If the heater is faulty, the value of the resulting resistance will differ markedly from the calculated one. If the multimeter shows “1” or infinity, the spiral is broken.

We can talk about the presence of a short circuit if the device produces the same indicators when one of its probes is applied to a metal pipe and the other to the heating element.

The following video shows the process of checking the heating element of an electric kettle:

Conclusion

In this article, we figured out how to properly check the heating elements of various household appliances using a multimeter. Finally, it must be said that if a heating element malfunction is detected due to a short circuit or a broken coil, the functionality of the household appliance can only be restored by replacing the non-working element. The same must be done if the electric heater causes a breakdown on the device body, otherwise the operation of such a device may lead to electric shock.

Source: https://YaElectrik.ru/elektroprovodka/kak-proverit-ten-multimetrom

How to determine the resistance of a heating element with a multimeter

The last step in checking tubular electric heaters of household appliances, be it an iron, kettle, water heater or washing machine, with a multimeter is to measure the resistance. Only after this you will surely decide whether the heating element is the cause of the malfunction of household appliances or not.

1. De-energize the electrical appliance - unplug it from the outlet

2. Disassemble to get to the contacts

3. Disconnect the wires from its contacts (it is necessary to ring for leaks - described above)

4. Set the resistance test mode on the multimeter (for household equipment, a range of up to 100 Ohms is sufficient)

5. Connect the multimeter probes to the contact rods or terminals of the heating element, each to its own

6. Possible results:

– “1”, The heating element is faulty, the internal conductive rod, spring or thread is broken.

– “0” or a value close to it indicates a short circuit inside the heating element. Electric current does not pass through the entire heater as expected, but flows directly between the contacts, for example, through a conductor with low resistance (through tube material, filler, water, etc.)

– Shows some value other than “0” and “1”. This is the value of the internal electrical resistance of the heating element, which means it is working. It remains to determine its power, whether it is sufficient for heating.

As you can see, the measurement of the internal resistivity of a tubular electric heater almost exactly corresponds to the dialing mode. And why this is so and what is the difference between them, be sure to read in our article - “How to dial with a multimeter.”