LED light sources are characterized by the fact that they can last for a longer period compared to incandescent light bulbs. They began to be used in the creation of various equipment and are installed as main or auxiliary lighting. In some cases, the actual service life of LED lamps is overestimated to justify the high cost of the product.

Actual service life

When indicating the service life of diode light sources, various figures are given, but in most cases we are talking about tens of thousands of hours.

The maximum declared operating period is 50 thousand hours. Incandescent lamps can last no more than 10 thousand hours. Often the information is provided by the manufacturer after testing individual elements, without taking into account how the light source is affected by the environment.

The service life of LED bulbs (in hours) is indicated by the manufacturer in the instructions for use or directly on the housing. In most cases, a numerical value is used, but appropriate markings may also be applied.

Lifespan from a scientific point of view.

Let’s understand the terminology and clarify what the average consumer should understand by the words “service life”. The service life of an LED lamp is the ability to maintain its lighting and performance characteristics over time. Physically, an LED lamp, under certain conditions, can work for up to 7 years, but how much will its main characteristics decrease during this period of time? Will its luminous flux, for example, be maintained during this time? Will the power consumption change, as will other electrical and lighting characteristics? Most manufacturers still do not have a clear answer to all these questions. LED lamps have recently begun to be in wide demand, so there are simply no reliable statistics.

What determines the service life of LED lamps?

The most important factors influencing the service life:

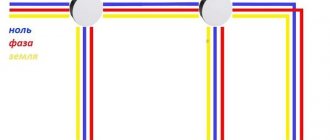

- Voltage surges and poor-quality wiring have a negative impact on all light sources. A similar problem often occurs in the CIS countries, which is not taken into account by the manufacturer when conducting research and calculations.

- Frequent switching on and off of diode lamps causes their rapid wear. This is due to the fact that at the moment the voltage is applied, the current strength is maximum.

- Weather conditions can also negatively affect the condition of diode lamps. High humidity leads to oxidation of contacts.

- An incorrectly designed lamp will cause the bulb to overheat. Therefore, the duration of work will be short.

- Physical damage to lamps. Regular vibration of the structure and other types of impact can cause various defects.

As practice shows, the actual service life is much less than stated . However, it is almost impossible to determine this indicator in advance. The company's reputation largely determines how well the stated technical characteristics correspond to the real ones.

Measuring the life of a light source

The service life of traditional light sources is determined using established testing procedures. For example, compact fluorescent lamps are tested in accordance with LM-65, published by the Illuminating Society of North America (IESNA). Statistically reliable lamp samples are tested at an ambient temperature of 25° Celsius in a cycle of 3 hours of operation and 20 minutes of rest. The point at which half the lamps in the sample fail is the nominal average life expectancy for that lamp. For 10 thousand hours of lamp operation, this process takes about 15 months. Full performance testing for LEDs is impractical due to their long lifespan. Turning on and off is not a determining factor in determining the life of LEDs, so there is no need to use the on-off cycling technique. But even in 24/7 operation, testing an LED for 50,000 hours will take 5.7 years. As technology continues to develop and evolve so quickly that products become obsolete by the time testing is completed, IESNA has developed a procedure (IES LM-80) for measuring luminous flux for LED devices (e.g., single LEDs, arrays, modules), however this method does not apply to LED lamps or replacement LED lamp elements. The LM-80 also does not provide guidance for estimating or extrapolating lumen output beyond the 6000 hours of measurement specified in the test method. To support long-life LED products, IESNA is currently developing a benchmarking method (IES TM-21) to evaluate LED lumen output and life beyond 6000 hours. TM-21 will use LM-80 data collected at several operating temperatures. Given the potentially long lifespan and impracticality of full testing, LED lifetime estimates will likely be based on extrapolation from time-limited test data. Therefore, it is important at this early stage of technology to be conservative in design decisions based on the expected useful life.

Is it worth buying cheap Chinese lamps?

Immediately after the appearance of LED lamps, the market was flooded with fakes. When using a Chinese product, you need to consider:

- The quality of the emitted light cannot be predicted, which can negatively affect human health.

- The assembly of Chinese lamps is carried out without quality control. Such a product can not only fail, but also knock out plugs or compromise the integrity of the entire structure.

- Counterfeit LED lamps will not last for a long period. Moreover, they fail at any time, even immediately after purchase.

- All indicators are overestimated. Therefore, choosing a suitable lamp will be difficult.

- Absence of any warranty obligations. Therefore, even if the lamp burns out immediately after installation, it will not be possible to replace it or return the money. Popular manufacturers provide a guarantee for their products for up to 3 years.

- Low color rendering index. Low-quality products create a flow, the color rendering of which is reduced.

- The presence of powerful pulsation. This figure should not be more than 20%, because otherwise your eyes will get tired quickly. For Chinese products this value is more than 30%.

- Numerous reviews indicate the low quality of Chinese products.

You should not trust any of the seller’s assurances regarding Chinese products. This is due to the fact that the fake is produced without complying with established standards.

Service life of LED luminaires: testing recommendations

Introduction

Many will be surprised to learn that the true reliability and service life of LED lighting systems are currently unknown.

Moreover, to determine the service life of an LED system, the relative value of the total luminous flux at a given operating time is widely used, which misleads the consumer, because Radiation degradation is only one of many components that affect the reliability of a luminaire. This anecdotal situation is most likely explained not by the desire of many manufacturers to pass off wishful thinking as reality, but by the lack of true data. In addition, in many cases, consumers do not want to check in the specification whether the values declared by the manufacturer correspond to those specified in the document. These findings don't only apply to LEDs. Quality LEDs installed in poorly designed systems can quickly fail. LED lifespan is often expressed in hours and years, but these numbers are not backed up by underlying information, making them empty promises. For example, the statement that the service life of a certain LED lamp is 100 thousand hours suggests that very little data and hard facts are still published in this regard. The situation improves at the level of finished LED modules, because Thousands of reputable manufacturers have collected a large amount of data regarding the performance of these modules in various conditions. But this is not enough.

Manufacturers of solid-state light sources and product specifiers should work together to address issues related to product life and reliability. It is necessary to record failures and investigate the mechanisms of their occurrence.

We need to find methods to ensure reliability, but without the appropriate information, experiments and models, this endeavor is doomed to failure - a program for creating reliable metrics is required.

Failure Types

An LED lamp is a much more complex device than traditional lamps. This is an entire electromechanical system, which, in addition to the light source, includes a heat sink, electrical control and optical signal generation units, a mechanical support structure and a protection system, as well as design elements. Because LEDs have a long service life, components such as adhesives and other materials should last just as long. If this capability is not provided, the service life of the entire system will be reduced.

The heat emitted during operation of the lighting installation must be removed from the diodes. For this, in addition to the radiator, a reliable heat-conducting unit is required. To ensure reliable operation, it is necessary that the power supply and electronic circuitry provide regulated control current and possibly other control functions that do not fail before the product reaches the end of its life.

Any optical components must be able to withstand intense light and possibly heat without yellowing, cracking, etc. Reflective materials must retain their optical properties.

In addition to these aspects, you should also take into account the manufacturing process, during which it is necessary, for example, to comply with the requirements for the manufacture of sealant, heat-dissipating paste, creation of wire connections, etc. Any failures inherent in electronic assemblies, as well as those caused by other reasons, also apply to the LED lamp. Figure 1 is a diagram illustrating the wide range of factors that determine system reliability.

In a well-designed and properly implemented lighting system, the main cause of failure is a decrease in the level of luminous flux - the gradual degradation of LEDs. However, other mechanisms should also be considered. According to one LED supplier, the main reasons for customer complaints include either the use of incompatible chemicals in the luminaires or the drivers overloading the LEDs. These design issues can lead to failure of other components or subsystems, as well as manufacturing defects, during the initial stages of operation. Additional causes of failure always exist and can lead to either catastrophic failure or degradation of the light output.

Luminous flux degradation

Recommended definition of service life

In standard technologies, the rated average lamp life is the time after which half the lamps stop emitting light. The luminous output of all light sources decreases over time, but by no more than 15-20% during the nominal life of the lamp, at the end of which, by definition, complete equipment failure occurs. However, a properly designed LED module has a very long rated life, but during this time the luminous flux is reduced by a greater amount than in standard technologies. Accordingly, in this case a new approach is required.

The declared service life of any lamp is a statistical characteristic. For an LED module, the service life is considered to be the operating time during which the light output drops to 70% of the initial value (L70). The life of an LED unit is generally considered to be the mean time to first failure (MTTF) under normal operating conditions (B50). In other words, after this time, half of the elements fail because their light output becomes low. For some applications, B50 may not be acceptable. In these cases, developers must start from the time after which the light output of 10% of products has decreased relative to a certain level (B10).

Thus, depending on the target market, manufacturers choose B50 or B10 indicators or some other indicator that characterizes a particular product. In LED lighting, L70 is widely used, and in other less critical cases, L50 is also acceptable. In other words, luminous flux degradation cannot be described using a single metric.

This definition of service life as degradation of the luminous flux in most cases also applies to lamps, but this definition is not enough. We must consider other failure mechanisms. The designer does not gain full information by considering a failure in terms of low luminous efficiency regardless of the cause (including catastrophic failures). If the declared service life of a product is 20 thousand hours, does this mean that after this time half of the luminaires provide half of the initial luminous efficiency, or the luminous efficiency of half of the products is almost no different from the original, while the other half has already completely exhausted its resource? Or is some intermediate option possible?

In order to answer this question, you should operate with two indicators - for example, B50 or B10 and the standard failure time of the electrical circuit F10 or F50 (failure of 10 or 50% of lamps, respectively). Both B and F should be measured using a fully assembled luminaire to take into account the interaction of its components.

Numbers B and F describe the following four types of luminaire failures.

1. All LEDs turn on, but their brightness level is reduced (determined by Bxx time).

2. There is a single catastrophic failure of an LED while other LEDs remain functional, possibly generating less lumen output (determined by Bxx time).

3. Many LEDs experienced catastrophic failures, but other LEDs remained functional, possibly generating less lumen output (determined by Bxx time).

4. Not a single LED turns on due to a failure of the system itself (determined by Fyy time).

The US Department of Energy recommends using the base L70 value for luminous efficiency and the following two values.

1. Bxx is the service life at which xx% (for example, 50%) of LEDs have luminous output below 70% of the rated initial value.

2. Fyy is the time to electrical failure at which yy% (e.g. 10%) of the LED array fails.

Ideally, these indicators should represent a sufficiently complete set of measurements that can be reported with an appropriate degree of confidence. The stated service life must at least have a certain precision and sample size to provide 50% confidence. Although even this requirement may in practice be restrictive in the near future, it is desirable that this level increase to 90%. However, our working group found that such measurements are expensive and time-consuming. In addition, not all manufacturers have the ability to meet these requirements if the product is entering the market for the first time. If the recommended minimum level of confidence is not met, manufacturers may choose not to declare the service life of products in the technical specifications, instead reporting parameters that last for a certain time.

The choice of values for xx and yy is left to the manufacturer and may vary depending on the needs of the customers or the manufacturer, but these values should be clearly stated. The above examples may not be suitable for high performance applications, but may well suit the needs of the consumer. Our definition of service life does not include the concept of color change. The definition is given only in terms of luminous efficiency and does not take into account the reasons for its degradation. Many users consider a large change in emission color to be a failure, although this manual recommends that this change be specifically stated in addition to the stated life of the product. This aspect is discussed in more detail below.

Tools for determining service life are currently not fully standardized. Additional definitions of service life and methods for calculating it using short-term measurements are discussed below.

Reliability of the declared service life

This section discusses all the necessary steps to prove that the claimed degradation time is true. The new platform and ways of working with its variations are discussed separately. The examples provided do not constitute a standard procedure. Responsibility for specific standards lies with the respective organizations and is beyond the scope of this manual.

Degradation time of the new platform

The manufacturer who has created a new platform is required to prove compliance with the declared data on its service life by testing the luminous flux of a certain sample of products over a period of time in accordance with the LM-79 standard. A separate question is the amount of time required. The IES TM21 Committee is studying the problem of extrapolating L70 from limited measurements by, for example, recording changes every 1000 to 6000 hours. Several ongoing studies have shown how difficult this extrapolation can be. The end result of the experiments will most likely show the maximum degradation of light output over the period of time required to determine the L70 value.

To establish the required compliance, the test results report must provide the following information:

– graphical representation (with error bars) of the dependence of light output, color changes and power consumption on time;

– a summary table showing how light output (percentage) has changed as a result of degradation, power consumption (percentage) and color after 6000 hours of testing;

– LM-79 data at T = 0 and T = 6000 h;

– description and components of the tested product and test installation;

– sample size and confidence interval.

Although extrapolated LM-80 data for LED modules was used to determine luminaire life (and is still used under ENERGY STAR requirements), this approach does not provide greater accuracy for many of the reasons already mentioned. Consequently, our work group recommends that the LM-79 be tested on a fully assembled luminaire to determine the degradation of light output over time.

Variations of the new platform

Because many other applications require modifications to an existing platform, additional measurements are required to ensure compliance. The amount of testing time needed to validate long-term product life data should also be minimized. In this regard, it is most prudent to consider different types of changes (or model variations) and their possible impact on service life.

For example, changes to the following blocks may require retesting:

– body/chassis;

– thermal management/heat sink;

– changing the assembly method or using different materials;

– light source (including operating current, voltage Vf and change of supplier);

- power supply.

Other changes, such as finishes or optical paths, require less re-inspection. In some cases, analytical data can be used to prove that a particular change does not affect the degradation time of the lamp. However, it is usually necessary to retest a small number of luminaires over a short period of time. Unless a manufacturer can demonstrate through analytical data or a small test that the luminaire's life will not be reduced as a result of certain changes, it should be considered a new platform and must meet the full set of qualification requirements.

This guidance recommends that manufacturers develop and document a change control process because... These companies are responsible for the accuracy of the information provided to consumers and guarantee that any changes will not adversely affect the service life of the products offered.

Color change

Relationship with service life

As already mentioned, the concept of “service life” refers only to the luminous output of the luminaire, but it implies failures caused not only by systematic degradation in accordance with the definition of the LM-80 standard, but also by some other mechanisms of general degradation of the luminous flux, incl. changes to other system components (not LEDs) or their failure. Lifetime does not include color change, even though in some applications this change may be considered a failure by the user. The decision to consider luminous efficiency as the main priority when defining this concept reflects the fact that luminous flux stability is associated with life safety issues, while color stability is only associated with aesthetic perception. However, this approach causes customer dissatisfaction, so we will also discuss this aspect.

The LM-80 standard defines the need to take into account color change and requires that the test report include a column indicating how this characteristic changes over time. However, the standard does not provide any guidance on how to calculate the amount of color change at the end of a luminaire's life, nor does it specify what changes are allowed during the design and manufacturing phase. If the relative change in the luminous flux of LEDs at a certain operating time can be extrapolated to assess the degradation of the lamp, provided that their temperature does not exceed a certain value and the control current does not change within wide limits, then this approach does not work in relation to assessing color changes.

Moreover, all full-scale color measurements are quite expensive, with the exception of assessing color change over the life of a product. Finally, another problem is that there is no accessible way to visually present the information on this parameter to the user. A characteristic such as relative color temperature in many cases is not a sufficiently accurate metric to describe changes.

It is clear that much work remains to be done before we are able to properly determine whether a particular luminaire has reached its color change limits. Given this, we recommend that manufacturers classify their products into one of the following categories: "replacement lamp", "luminaire (standard quality)" or "luminaire (specification level)" and consider the color change characteristic on a case-by-case basis. Let's characterize each category separately.

1. The first category is more accessible for color measurements in accordance with the LM-80 standard and for forecasts, since the solutions are largely of the same type and sales volumes are large. Color is determined according to Lighting Facts and the measurement results are used in non-critical applications.

2. For luminaires in the “standard quality” category, the maximum guaranteed color change is indicated. Currently, this is done using such a characteristic as color temperature. The manufacturer independently determines the specified limits and warranty period, which may not coincide with the service life of the lamp.

3. Luminaires in the “specification level” category are intended for more demanding customers. The specification includes more complex color metrics, as well as a maximum color change value over the stated service life.

All three categories of luminaires require the manufacturer to provide some means of assessing color change over a specified period of time, but the accuracy varies by category. More work is needed to improve these methods.

Color Change Assessment

The LM-80 standard requires manufacturers to collect color change data over 6,000 hours of luminaire operation. However, there is currently no validated way to use this data to extrapolate this characteristic. The IES TM21 committee, which is currently working on standards for extrapolating LM-80 data to assess light degradation, has deferred consideration of the issue of luminaire color change.

Factors that make it difficult to extrapolate color change data include differences in LED solutions, materials, manufacturing processes, optical systems, and LED operating temperatures and operating times. Many experts indicate that it will take a long time (perhaps several years) before there is general agreement on how to predict LED color changes over time.

Influence of the lamp model and manufacturing technology

Color stability, like its degradation, is not determined solely by the characteristics of the LED. Below are examples of how the luminaire model and its manufacturing technology determine quality and color change.

– As a result of differences in heat sink designs, LEDs and electronic circuits operate under different conditions, despite the same operating time and operating temperature.

– Different materials used in secondary optics wear at different rates.

– Different environmental conditions (including air quality) can have different effects on the behavior of the materials from which the luminaires are made.

– Different luminaire models may have non-uniform color characteristics: halos or different shades of color at the edges of the beam, and these characteristics may vary over time.

– Some production technologies ensure strict adherence to initial requirements, while others do not follow specified criteria, making it difficult to detect changes in color over time.

– Finally, some luminaires are equipped with an active color management system, incl. sensors and controls. However, the parameters of these elements change over time, which also affects the color of the lamp.

Expense restrictions

Because the LED industry is relatively new, we lack practical data on how much of a luminaire's color change is due to the LED and how much is due to the luminaire model. Based on this, as well as the factors already mentioned, the only way to determine the color change is to measure the parameters of the entire system, including the LEDs, other elements of the luminaire, its operating time and environmental conditions.

However, currently collecting LM-80 information at the luminaire level is prohibitively expensive for many types of luminaires for the following reasons:

– it takes several hours to stabilize the temperature of a large lamp;

– lamps are tested at a steady current, and not at a pulsed current, as is the case with LEDs;

– large space may be required for storage and installation of test equipment;

– testing luminaires according to the LM-79 standard requires experienced technicians and is labor-intensive.

Testing at the luminaire level significantly inhibits the introduction of new products, which increases overall costs and limits the speed of their introduction to the market. While this expense can be justified for a limited number of color-critical professional applications, it is likely to be the exception rather than the rule.

Description of how color changes

Ordinary consumers have no idea how color is described. They don't use concepts like "chroma", "blackbody curves", "LED bins" or "McAdam error ellipses". There is no alternative definition for consumers, although Lighting Facts describes color in terms of color temperature and uses terms such as “warm” and “neutral.” This approach is appropriate because it is similar to descriptions currently used for standard lighting, and the example of consumer adoption of food label information suggests that luminaire consumers will learn to understand the Lighting Facts label information. But even this representation of information does not provide a simple way to describe how color changes. Simple terms that reflect only relative color stability may be more appropriate.

| Rice. 1. The reliability of the system as a whole is determined by the totality of individual reliability indicators of each block |

How to distinguish high-quality products from low-quality ones?

The luminous flux of quality products meets established standards. In this case, the operational life should be divided into effective and complete. The first definition is related to the period during which the lamp intensity decreases by less than 30%. Distinctive features of quality products from fakes include the following:

- Large companies guarantee a service life that meets the industry standard L70 or LM70. For the first, the operational life is 30 thousand hours.

- Manufacturers of lower quality products do not use markings when indicating the service life. Most often the time period is specified in hours.

- The effective service life also depends on the color. For white it is 10 thousand hours. For green, red and other colors the figure reaches 25 thousand hours.

When choosing, it is recommended to pay attention to the warranty period . With round-the-clock operation of the light source, 9 thousand hours are consumed. If the manufacturer indicates that repairs under warranty are carried out only for a year, then he is not confident in the quality of the product. Original lamps have a warranty period of 3-5 years.

How to extend the life of an LED lamp?

Following some recommendations will significantly extend the life of the product. The most important are the following:

- It is necessary to periodically wipe the surface of the lamp from dust and other contaminants or vacuum it. Do not use detergents as they can damage the main elements of the lamp.

- LED strips have become widespread. They are often used for decoration, lighting, and even as the main light source. Experts do not recommend gluing tape to furniture or other elements, because... they are capable of releasing thermal energy. To place the diode strip, it is recommended to use an aluminum profile or foil, because Such materials reflect heat.

- A diode type lamp will work much longer if heat is removed effectively. Otherwise, the effect of thermal degradation cannot be avoided. To do this, create a protective structure with the possibility of fresh air entering.

- When connecting a light source, a dimmer is used. This device is designed to switch the light and adjust the brightness. The dimmer has virtually no effect on the amount of electricity consumed, while filtering the inrush current, eliminating the possibility of high voltage supply. High starting current causes the structure to overheat.

- Diode lamps should be used exclusively for their intended purpose. Some of them are not designed for long-term operation, others for a large number of on and off cycles.

- When choosing, you should consult with the seller.

In real conditions, a diode lamp lasts for 3-5 years. Depending on the quality of workmanship, a Chinese fake can be used for no more than 1 year.