Advantages of paving slab stairs

The need to equip steps with this type of material is associated with the presence of height differences on the plot. For convenient passage, stairs are installed to access the porch and veranda.

The popularity of the material is associated with the ability to implement various design solutions, durability and quality of the coating. Steps lined with paving slabs have an attractive appearance both outdoors and indoors. The main advantages include:

- low cost;

- strength;

- wear resistance;

- ease of maintenance.

A staircase designed using paving stones organically fits into the design of the area if the paths are also lined with this material.

Design solutions and material selection

Drawing up a layout of paths is part of the work. At this stage, it is recommended to consult with a landscape designer to take into account the features of the territory and emphasize the advantages of the surface.

When creating a project, it is recommended to take into account the norms associated with anthropology. The steps should be comfortable for walking, so their depth is maintained within 25-35 cm, and their width is 80-120 cm, the optimal height is 17 cm.

Each tread can hang over the risers by no more than 5 cm; comfortable lifting is ensured at an angle of no more than 40°. To ensure natural water drainage, the treads are tilted by 2 mm. Steps are not installed in front of the door; a flooring is installed for this purpose. According to the standards for construction, tiles measuring 30x30 cm are used.

The building materials market is represented by a wide range of paving stones for arranging sidewalks, so it is important to decide which color scheme and shape to give preference to.

Depending on the production technology, tiles made by vibration pressing or casting are distinguished. Cast products are presented in an assortment of shapes, colors, and patterns.

The tiles are made in various thicknesses (20, 40, 60, 80 mm). The smaller the thickness of the laying elements, the neater the step looks. The disadvantage of this type of coating is low frost resistance. Under heavy mechanical load, the tiles lose their strength, and after rain the surface becomes slippery, which negatively affects the safety indicator.

How to lay a porch with paving slabs

The most common are ready-made concrete structures and curbs, which require the formation of a substrate.

- Concrete structure. To do this, formwork is prepared and concrete mixture is poured into it. For strength, reinforcement from metal rods is used. After hardening, the porch is ready for cladding. Laying begins from top to bottom, using a special adhesive solution. First, the horizontal plane is laid, and then the vertical plane is set. Do not forget that paving begins from the edge of the canvas. So, the process consists of several steps:

- applying up to 1 cm of mortar to the tiles with a notched trowel;

- the tile is attached to the corner of the first row;

- then the module is placed from the second edge of the canvas;

- when hardening, the tiles are connected with a long rule or fishing line to determine the level of the rest of the covering.

- Curb porch. The structure consists of a concrete frame and a sand base for laying tiles. In order for the porch to last as long as possible, you need to carefully select the base, taking into account the load that the steps will have to withstand. Based on the same parameters, you should choose concrete modules that can withstand different weights.

The shape of the porch can be set to any shape, depending on the exterior and personal preferences of the owner. Do not forget about the basic technological requirements:

- the height of the step is 15 cm;

- Width for comfortable foot placement: 30 cm.

These parameters should be taken into account when choosing a sidewalk curb. Laying is done from the bottom up, a minimum amount of adhesive solution is applied to the vertical slab, and a maximum layer is applied to the horizontal slab. The thickness of the sand for the substrate should be about 30 cm, and well compacted. The remaining space can be filled with construction waste, etc.

If you have already laid paving slabs on sand with your own hands, this task will be quite feasible and understandable. For those who don’t have the skills and time to do this, I’m always happy to help improve your site. Our specialists know everything about paving with paving slabs of any size, as well as cladding porches of any complexity.

Technologies used for masonry

Among the variety of methods for arranging stairs from paving slabs, installation using curbs is most often used. With this method, these elements act as a frame. The base can be positioned horizontally or at an angle.

When arranging an ascent along a pedestrian path, a trench is made along the entire length of the path. In the case of arranging a porch at the bottom of the flight of stairs, a curb stone is mounted in a vertical position. The voids between the curbs are filled with gravel and sand.

After thorough compaction using tools, paving slabs are laid on the sand-cement mixture. Installation is carried out from the bottom up, the tiles are laid on a mixture of sand and cement. The upper level of the laying fragments must coincide with the height of the boundary stones.

Installation without the use of a curb is time consuming. The products are laid on a layer of concrete. To seal the joints, liquid mortar or fine dry sand is used. Depending on the location and purpose of the flight of stairs, the following is used:

- reinforced concrete base;

- metal carcass;

- monolith with compacted sand backing.

Any installation method requires preparation of support for the structure. To create a strong frame on which the tiles will be laid, the help of a specialist is required.

Standard parameters for steps: expert advice

The uniqueness of steps made of paving slabs is that their installation in the garden can advantageously emphasize its appearance and visually divide it into several levels. During construction, it should be taken into account that the height of the steps should not exceed 18 cm, because otherwise it will be inconvenient to use them, this is clearly visible in the photo.

Many experts recommend using brick in tandem with tiles when building porches and steps. The latter is quite convenient to use for laying rises.

The main rule to follow is that the tiles should be laid from the bottom to the very top. Based on this, you can make all kinds of patterns from it, as well as combine the color palette to create an “elegant” atmosphere.

Laying tiles on a substrate with close groundwater

Construction methods

We offer three ways:

- The first method of construction is to simply install bricks or wall blocks on a pre-prepared concrete base in the lower level. Then all voids are filled with soil-sand mixture. The tile itself is laid on top. This method is perfect not only for steps, but also for the porch.

Careful sealing of seams is an important point

- The second construction method is acceptable only if the height between the two levels is significant. The tiles are laid on a prepared cement-sand mixture (concreting). It is quite easy to prepare - it consists of 6 parts sand, 1 part cement and water to obtain the required consistency.

- The third method is used when the garden soil is very soft and moist. In this case, the base will be crushed stone and concrete, on which a layer of brick steps and a special substrate will be laid. Only then can the brick be covered with paving slabs - you can look at the photo above.

Gluing tiles to concrete

This method involves making a base on which the paving elements will be laid. The process of completing the work is complicated by the fact that the dimensions of the tiles may not coincide with the parameters of the base. In this regard, constant trimming of the installation elements is required.

The load of the upper row along the riser created during operation entails the destruction of the elements. Therefore, when choosing tiles, it is recommended to pay attention to the manufacturing method.

Pressed elements have better resistance to mechanical stress. After installation, careful sealing of joints and surface treatment with a hydrophobic material are required.

Before laying the tiles on concrete, the base is cleaned of dust and acrylic impregnation is applied. The tiles are laid on glue, starting from the tread of the top step. If necessary, each element is cut to the required size, taking into account the protrusion of the end above the vertical plane.

The tiles are laid on glue, the thickness of the applied layer is 7-10 mm. When laying, you need to take into account the width of the steps and tiles. You cannot install elements smaller than 1/3 of the tile on the tread. Compliance with this rule allows you to create a reliable structure that will maintain integrity under load.

Recommendations for the selection of facing materials and their installation

Paving slabs for the porch are a cheaper option. In terms of presentability, it is in no way inferior to tile. The street porch can be decorated with either very simple or patterned or relief tiles made of concrete and other materials.

Paving slabs of the same type can be used for both the path leading to the house and the porch itself. This design is relevant and looks beautiful.

Laying a staircase with tiles is somewhat more difficult. Thin material requires a perfectly flat surface and careful grouting of the seams. Tile can be an excellent extension of a hallway or hall.

Facing the porch with tiled tiles requires a competent selection of materials. Particular attention should be paid to the surface of ceramic tiles. It should not be too smooth, as this is dangerous.

READ MORE: The best way to remove tiles from a wall

The decoration of the porch of the house, a photo of which can be found on the Internet, should be selected depending on the material from which the span and steps are made. A wooden porch in a private house can be covered with special overlay panels.

They are made from wood. For cladding steps, it is better to choose hardwood, such as beech, oak or hornbeam. Wood for the porch should be treated with an antiseptic, which will prevent it from rotting. It should also be coated with varnish for exterior use.

Before finishing the porch of the house with wood, make sure that all steps are under a protective canopy. This will minimize the ingress of moisture on them and keep them presentable longer.

The porch is finished with paving slabs from top to bottom. The first stage of this process is to remove unevenness and roughness from the concrete surface of the steps. This is necessary so that the facing material lies on them as evenly as possible.

The DIY installation technology is quite simple, but requires compliance with certain rules. To do this you will need a building level, a small rubber mallet, a spatula and a container for mortar.

Paving slabs on the porch should be laid gradually, one after another. It is attached to the surface using a cement-sand mortar. A small portion of concrete is applied to the step, and tiles are laid on top of it. Its position is checked with a level and, if necessary, trimmed with a blow of a mallet.

Remaining mortar should be removed from the surface before you lay new tiles on it.

Before tiling your porch, you should know what is important to pay attention to when choosing it. The staircase cladding should ideally match the exterior of the house. If the facade is finished with rusticated stone or clinker, then it is also better to finish the porch with clinker tiles. If the exterior of the house is finished with siding, then steps made of porcelain stoneware will look great in combination with it.

The shape of the porch must also be taken into account when choosing materials for cladding. Any material is suitable for a standard staircase. It is better to line a round porch with paving slabs. It is much easier to divide it into fragments of a certain shape.

Before tiling your porch, be sure to also consider the maximum possible load on the steps. Not every wooden staircase can withstand cement-sand screed and tiles, while for a metal or reinforced concrete porch this finishing option is not a problem.

The first and main advantage of finishing porch steps with clinker tiles is the high quality of this material. Clinker is wear-resistant, resistant to mechanical damage and is not afraid of moisture and sudden temperature changes.

Using this material you can make a beautiful porch in a country house. Clinker tiles are considered an environmentally friendly material because they do not contain harmful impurities.

Laying clinker tiles on porch steps is also safe, since the rough surface of the material prevents possible injuries in slippery weather.

Porcelain tiles for outdoor porches should be rough. It costs more than regular material with a smooth surface. If you do not have the funds to purchase special tiles for street decoration, but you still want to line the porch with porcelain stoneware, you can apply large marks to its surface using an engraver.

You can also increase the safety of a porcelain stoneware porch using anti-slip rubber strips. They are screwed to the edges of the steps.

It is also important to know how to properly line a porch with porcelain stoneware. This is what determines how long the facing material will last. There should be no voids or differences under it.

Before laying tiles on a porch in the shape of a semicircle, it should be taken into account that according to SNiP, the angle of inclination of the march should be no more than 45-50 degrees. The ideal option would be steps with an angle of approximately 30-37 degrees.

Laying tiles on the porch with your own hands in this case should be done in stages. First you should measure one row and cut off the required amount of material. Remember that it is advisable to soak the tiles in water for about an hour before cutting.

Each tile should be checked with a level. If the ends of the porch are high, they should first be reinforced with reinforcing mesh for better adhesion of the material to the surface.

Natural stone cladding material is available for sale today. Before laying tiles on the steps, you should carefully approach the issue of choosing a stone. For simpler houses, granite is suitable. A porch lined with such tiles will look great in combination with a brick or stone facade.

For houses with columns and other architectural elements, it is ideal to use marble tiles. It is expensive, but in terms of presentation it is superior to other materials.

Working with natural stone is very labor-intensive. The video below demonstrates how to tile steps with granite tiles.

Laying granite on porches and railings has been a practice for a long time. A clear confirmation of this is St. Petersburg, where almost the entire Nevsky Prospect is lined with this stone. Professional builders recommend using granite tiles because of their durability and strength.

A granite porch, the photo of which is presented below, can last more than a hundred years. The main thing is that the technology for laying stone slabs is followed.

One cannot help but pay attention to the presentability of this type of cladding. Granite tiles will look harmonious with both classic and modern facades.

Materials used to create this article

Laying steps from paving material on a sand and gravel base

laying on sand and gravel base

laid steps on a sandy base.

Low strength of the adhesive composition can lead to damage to the coating during operation. When water collects in the seams, it freezes and breaks off the coating from the base. To avoid problems, it is better to lay the material on a sand bed.

This method involves designing each step in the form of a container filled with a sand and gravel mixture. For stairs consisting of 2-3 steps, you can use a curb. Long stones are laid in a cascade on a stringer, a parapet made of brick.

Before installing paving slab steps, it is recommended to pour a concrete base. To strengthen the structure, you need to cast an intermediate frame that will hold the curb. When installing round steps, you can use paving stones or bricks as a border.

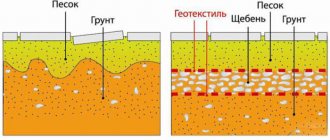

After laying the covering elements, the seams are carefully sealed. The concrete base can be supplemented with a metal frame made from a corner. To prevent the growth of weeds and ensure high-quality drainage, a geotextile fabric can be laid under the sand cushion.

Steps on cinder blocks or bricks

Laying paving slabs on a stone base is a simple and quick way to arrange steps. The cladding technology is similar to gluing concrete. In this case, cinder blocks or bricks used as a base are laid on a compacted mixture of sand and crushed stone. At the same time, flights of stairs are formed from the elements.

To give the structure strength, the lower and upper rows are tied with welded reinforcement and wire. In this case, the steps are mounted on a concrete mixture, and the risers are laid on glue. The base can be laid out from rejected fragments.

Manufacturing steps according to the classical scheme

Installing paving on a concrete base is a reliable and simple option.

Preliminary work:

- pouring the foundation for a massive stepped concrete structure;

- production of formwork frame;

- pouring sand-cement mortar into the formwork.

The foundation is planned to be poured at the stage of designing the staircase to enter the residential building.

Scheme of laying paving on a concrete base.

- In the area adjacent to the entrance door of the building, markings are made in accordance with the drawings of the staircase structure and the calculations performed. A hole is dug under the base, a reinforcing metal frame is installed (the stiffer it is, the less subsequently the deflection of the flight of stairs and the risk of chipping the facing tiles).

- To fill the steps, removable wooden formwork is made and securely fixed to the foundation.

- The structure is being concreted (it is recommended to use M100 cement for the solution).

- Before dismantling the formwork structure, the cement mass must be allowed to dry completely and gain its strength characteristics. In summer, 3-4 days are enough for this, at other times 8-10 days.

- Before facing, concrete surfaces are cleaned of construction dust and treated with a special deep penetration compound made on the basis of acrylic.

- Laying the slabs begins with the tread of the top step of the staircase structure. Each product is cut to size before being placed on the adhesive. The end of the tile should protrude above the vertical riser at a distance equal to the sum of the thicknesses of the adhesive layer (0.7-1 cm) and the facing material itself. The risers are lined using a similar technology.

READ MORE: What you can make from leftover laminate flooring with your own hands

After finishing work is completed, the tile seams are rubbed halfway deep with acrylic primer mixed with sand, the remaining space is rubbed with fine sand.

Expert advice:

- It is not recommended to lay blanks on the tread that are 1/3 times smaller than the size of a solid tile.

- If the width of the tread is greater than the dimensions of one tile, it is better to cut and lay 2 products equally.

- The upper edge of the tread overlaps the end part of the riser. In this case, the projection of the drip edge should be within 10-15 mm.

Steel frame steps

An affordable arrangement option is to make a metal base. Provided the support platform is concreted, the creation of a staircase is possible within 1 day. First you need to make a stringer - the load-bearing part of the supporting structure of the flight of stairs.

To arrange the lower platform, a support with anchors is concreted. Racks can be made from angle or reinforcement. Each step is made in the shape of a rectangular frame, the width of which matches the size of the tile.

The operating conditions of this type of ladder provide for the most uniform load on the surface material. To achieve this, the step frames are often additionally reinforced with reinforcement or sheet metal.

The tiles are laid after treating the metal with an anti-corrosion coating. The tiles are laid along the edge, and for reliability they are fixed with a steel corner.