Compound

Concrete is widely used in construction. It is used for various purposes and according to this, the requirements for its preparation are established. However, in all cases it includes the following components:

- cement;

- sand;

- aggregate (small stones);

- water.

Additives can be used to give the material the necessary properties: moisture resistance, resistance to low temperatures, and others. Pebbles or small stones of various sizes can be used as filler. They increase the density of concrete, reduce drying shrinkage and make it more durable.

Various types of fillers Source spbbeton.org

Concrete grades have different properties suitable for solving specific problems. The consumption of materials depends not only on the type of concrete, but also on the type of cement used.

Next, the components that are necessary to create concrete will be discussed in more detail.

Crushed stone

It is necessary to give strength to concrete. As you know, concrete usually hardens completely in 28 days. From this time on, it acquires its maximum strength. During this process, the material shrinks. Properly selected aggregate can reduce shrinkage to a minimum.

By size, the stones used are divided into fractions according to their sizes:

- 2-20 mm;

- 20-40 mm;

- 40-70 mm.

This material is divided according to the type of stones used:

- from sedimentary rocks (limestone);

- obtained by crushing granite rocks;

- made by crushing pebbles.

Granite crushed stone Source piterpesok.ru

Granite crushed stone gives the solution maximum strength. It is used for concrete structures that are in difficult conditions. It is best suited for foundations, floors and other similar structures.

It is necessary to ensure that there is no clay or other impurities in the crushed stone.

Special Additives

They are used to improve the performance of concrete.

The following types of additives are used:

- Modifiers improve strength characteristics and resistance to frost.

- Designed to make concrete set faster. Although complete drying occurs in four weeks, it gradually gains strength during this period. When using setting accelerators, the material will gain maximum strength within the first 24 hours.

Antifreeze additive Source static.orgtorg.org

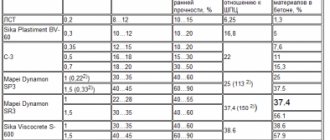

- Plasticizers help increase the mobility of the composition. This is especially important in cases where the concrete fills a complex shape. With high mobility, it will completely fill not only the entire volume, but also all the details of the structure. Plasticizers also improve the water resistance of this material.

- If concrete is used at low temperatures, its resistance to freezing is important. To increase cold resistance, special anti-frost additives are used.

- Mobility regulators promote slow cooling of the mixture. They can be useful during transportation to prolong their stay in a liquid state.

The amount of additives used should be determined based on the recommendations given by the additive manufacturer. Use in violation of the recommended proportions may reduce their effect or greatly change the result.

Additive for cement Source img.edilportale.com

See also: Catalog of stone house projects

Using sand

This material seems to be easily available, but you need to take into account that to create a concrete mixture you need sand of a certain quality. River or quarry sand is most suitable. In the first, the granules are larger in size. This sand is considered more preferable.

It is advisable to sift the sand before use so that there are no impurities left in it. The density is 1.3-1.6 tons per cubic meter.

Component Requirements

The quality of concrete, its technical and operational characteristics depend on the ratio of the components. In addition, we should not forget about the economic component, which is determined, first of all, by the amount of cement consumed.

Therefore, correctly selected composition of the concrete mixture and determining how much cement is needed per 1 cubic meter of concrete not only ensures the quality of construction, but also makes the costs of its production economically justified.

Cement

Modern industry produces several different types of cement, produced using different technologies. For concrete, in most cases, four grades of Portland cement are used, from M300 to M600. The grade of cement means the amount of load that the prototype can withstand.

In private construction, the most common type of Portland cement is M400.

The industrial construction of buildings and structures, as well as the operation of reinforced concrete factories, are based on the use of M500 cement. The lowest grade is used for the preparation of concrete structures. not subject to loads. For example, for wall partitions and void fillings.

Sand

To prepare concrete, sea, river or washed sifted sand is used. This filler does not contain dust, debris, clay particles and other additives that can deteriorate the quality of the final material.

Based on the size of the constituent particles, sand is divided into:

- thin less than 1.2 mm;

- very fine 1.2-1.6 mm;

- small 1.6-2.0 mm;

- average 2.0-2.5 mm;

- large 2.5-3.0 mm.

For concrete, all types of fractions can be used, but the best particle size will be in the range of 1.2-2.5 mm. When preparing a concrete mixture, it is necessary to take into account the moisture content of the sand, which can reach 10% of the volume, and make adjustments when adding water to the mixture.

Crushed stone and gravel

Used as a second filler, crushed rocks also have a gradation in size and are divided into:

- very small 3-10 mm;

- small 10-20 mm;

- average 20-40 mm;

- large 40-70 mm.

The first two fractions are called gravel, and the larger stone is called crushed stone. Sea or river pebbles, which have a smooth surface, cannot replace artificially crushed particles, as they will not provide proper adhesion of the components.

When choosing a coarse filler, it is necessary to take into account that the size of the largest particles should not exceed 1/3 of the future concrete layer.

An important technical characteristic of crushed stone and gravel is their voidness, which determines the volume of free space between individual particles.

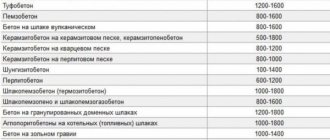

The higher the void ratio, the more cement and sand will be required to prepare a high-quality concrete mixture. Depending on this, stone fillers are divided into porous up to 2000 kg/m3 and dense over 2000 kg/m3.

How to make concrete

It is possible to do it yourself. To do this, it is necessary to use high-quality raw materials, strictly observe the proportions and manufacturing rules. Sometimes it is more convenient to purchase a ready-made composition. In industrial production, the accuracy of the recipe and production in accordance with technological rules are guaranteed.

Self-production Source klimatlab.com

If you need to obtain a small amount of material, it is not difficult to do it yourself. Before starting work, it is necessary to calculate the volume that the concrete structure will occupy and prepare the required amount of materials based on the calculations made.

Factors affecting cement consumption

Determining the cement consumption per cube of mortar requires taking into account the following factors:

- It is necessary to bind the fillers into one whole. The amount of bulk materials required amount of cement.

- The higher the grade of cement, the better and stronger it is.

Mixing components Source manesu.com

- The brand of concrete mortar that is planned to be prepared. For any type of concrete there is a recipe that calls for the use of a specific brand of cement in a strictly defined quantity.

To determine the consumption of cement of the appropriate type, it is necessary to be guided by the requirements for the production of concrete of a particular type.

See also: Catalog of companies that specialize in the construction of wood concrete houses

How much cement is needed for a cubic meter of concrete?

The grade of concrete will be selected according to the purpose of use. It will determine the performance characteristics of the material.

Table showing the grades and strength classes of concrete Source konspekta.net

The following are the proportions of cement consumption per 1 m3 of solution that must be followed to produce a cubic meter of concrete:

- To make M200 you will need to use M400 cement, crushed stone, sand and water in a ratio of 1:3.8:2.8:0.7. Calculated per cube, this will be respectively: 286 kg, 1080 kg, 795 kg and 210 liters.

- To make an M250, the proportion looks like this: 1:3.3:2.3:0.65. This will require 332 kg of cement, 1080 kg of crushed stone, 750 kg of sand, 215 liters of water.

- To obtain M300 you need to adhere to the proportion 1: 2.8: 1.9: 0.6. To obtain a cubic meter of concrete, 382 kg, 1080 kg, 705 kg, and 220 liters of materials will be needed, respectively.

To find out the concrete consumption, you need to determine the required volume.

How many kilograms of cement are in a bucket

When mixing concrete in a concrete mixer, the components are often poured into buckets. You can find out exactly how much a bucket of cement weighs if you have ordinary scales. First, weigh the container and add binder. But it should not be compacted in any way. Simply pour the substance out of the bag or use a shovel to scoop it out from the pile. Place it on the scale and subtract the tare weight from the resulting figure. According to statistics, a standard 12-liter bucket contains 15.6 kilograms.

Table of volumetric weight of building materials. Including how much a cube of cement and a bucket of cement weigh

If there is less cement in your bucket or your container is not 12 liters, or the cement is fresh, which is very good, or you were sold a low grade binder, one of the distinguishing features is less weight. You can also focus on color. Portland cement has a grayish-green color, while Portland slag cement is gray with a bluish tint. These are the brands that can be called good. The rest are grey, yellowish-gray or grey-brown. If your material is light in weight and does not have a bluish or greenish tint, you were sold a binder of lower strength.

Video description

This video shows how to calculate the amount of mixture for a screed:

The amount of sand is determined in a similar way. Two-thirds of a cubic meter, taking into account its density, will be 576 kg. To obtain the required amount of material, you need to multiply this value by the volume of the screed.

Plaster

When making it, a proportion of 1:4 is used. A cubic meter should contain a quarter of the volume of cement and three quarters of sand. To carry out calculations, you need to calculate the volume of plaster and determine how much cement and sand it should contain.

Concrete plaster Source bauramix.kz

How many bags of cement to buy

To understand how many bags of cement will be needed to prepare the mixture, use proportions and volume. So, if you prepare a batch for floor screed and use a ratio of 1:4, it turns out that you need a quarter of a cube of cement. The bulk density of the binder shows that a liter contains 1.4 kilograms.

Binder consumption can be calculated differently. So, if the thickness of the screed is 10 centimeters, then for one square you need 0.1 cubic meter of solution. It contains 10 times less cement than a cube: 350 kg / 10 = 35 kilograms. For a screed 5 centimeters thick you need 35 / 2 = 17.5 kilograms of cement.

It is worth remembering that the rate of cement consumption also depends on the activity of the binder. It is usually determined experimentally, during the process of mixing control samples, and during strength testing. But this cannot be done on site, so you should focus on the shelf life of the material. The fresher the better, since over time cement can lose up to 20% of its activity per month. After keeping bags of M500 cement in the warehouse for about three months, you can already work with the M400 brand.

Concrete prepared using technology and with the correct consumption of cement is able to withstand all loads, demonstrate optimal parameters and properties, guaranteeing the durability and reliability of structures.