Sand is an indispensable material in construction. But, before using it, you need to find out about its technical characteristics and features. Different types of sand have different characteristics. Therefore, when purchasing, you should check its chemical and fractional composition, the presence of impurities, pay attention to the brand and other important factors.

What is river sand, description and composition

All natural sand is divided into several types, differing in many factors. River sand is most in demand in construction.

Washed

Smooth, uniform grains of sand of yellow or gray color are obtained from the bottom of rivers. They contain oxides of silicon and iron. Its chemical formula is SiO2. River sand usually does not contain clay particles or other impurities, as it washes naturally. Most grains of sand are of medium size.

Coarse grain

Coarse-grained river sand, which is much less common, is most valued, for this reason it costs much more. It is usually mined in the beds of dry rivers. This type of sand is used for finishing, masonry, and design work. It is included in compositions for road surfaces and is used in brick production.

Coarse-grained sand has a neutral, unobtrusive color; it is excellent for arranging the design of personal plots.

Large

Coarse sand differs from coarse river sand. It is extracted from rocks by splitting stones using specialized crushing and grinding equipment. Its particle size module can be up to 5 mm.

Factions

River sand is divided into the following types:

- dusty;

- coarse-grained;

- medium grain;

- clayey

Sand is sorted by grain size, sifting it through special sieves.

river sand

River sand used by builders has its own fractional and chemical composition; it is the most popular material among its analogues.

Washed sand

Uniformly colored (yellow or gray) grains of sand with a perfectly smooth surface are found at the very bottom of the river. This sand contains oxides of iron and silicon. In river sand there is practically no presence of clay impurities and other foreign debris, because this type of sand is washed in its natural environment. The size of each grain of sand is small; it is generally considered to be average.

Washed river sand

Coarse river sand

In the construction industry, however, the coarse-grained type of river sand is considered more valuable. Such material is extremely rare, which is why it is expensive. Sand can be found in any dry river bed. This type of sand is successfully used for masonry, finishing, and design work. It is included in highway coating compositions and used to make bricks.

Coarse-grained river sand has an unobtrusive , neutral color; it is perfect for decoration used in a personal plot.

Coarse river sand

Coarse river sand

This type of sand is usually extracted from rocks found in rivers. The boulders are split using specialized equipment, and the resulting pieces are subsequently crushed and split. The largest grain of sand can reach 5 millimeters in diameter.

Factions

River sand is known in the following fractions:

- Dust-like.

- Medium grain.

- Coarse-grained.

- Clayey.

The sand is calibrated according to its grain size using a special sieve with cells of different diameters.

Sand mining

River sand is usually extracted using a dredge, which in turn is secured to a barge. The dredger has specialized mechanical equipment, which includes:

- Powerful pumps.

- Tanks for sand collection.

- Sita.

Extraction of river sand

Buying advice

The purchase of river sand should definitely begin with viewing its passport and certificate, in which the characteristics will have to meet GOST - 8736-93.

Areas of application of river sand

This material is usually used for:

- Production of concrete and concrete products (sand helps maintain their strength over a long period of time and increases their frost resistance).

- Production of dry construction mixtures.

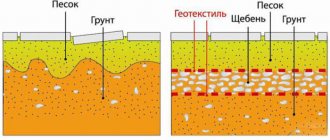

- Creation of foundation pillows.

- Production of solutions necessary for masonry and plastering work.

- Room decorations.

- Filling aquariums.

- Arrangement of playgrounds for children and so on.

Benefits of river sand

- Environmentally friendly product.

- Has high moisture permeability.

- Ideal soundproofing material.

- Does not rot over time.

- Meets most technical requirements.

Differences and features of river sand

River sand differs from other types of sand primarily in its natural purity; it does not contain clay particles, small pebbles and other impurities. Its second difference is fractional homogeneity. Dry mixtures for construction work are made from river sand.

It is used as a filler for floor screeds; it is the main component for the production of asphalt concrete. With its help, drainage is installed and used as a filter at treatment plants. Sand perfectly purifies water from mechanical impurities. In household plots, the soil is mixed with river sand to make it lighter and more crumbly.

More details in the video:

Difference from sea

River sand is almost no different from sea sand. Sea sand has high quality characteristics and does not contain natural impurities, since during extraction it undergoes a two-stage enrichment. Therefore, concrete mixtures and solutions are prepared from it.

Difference from career

Which sand is better - quarry or river - depends on the characteristics of the further scope of their application. Quarry sand, as the name implies, is mined in quarries or crushed gravel and other rocks using special devices. It usually contains large amounts of stones and clay.

Quarry sand is easy to extract and is of high quality, but due to the organic impurities it contains, the sand often behaves unpredictably, reacting with chemical additives in the solution. Quarry sand is also not suitable for filtration; washed quarry sand is more often used for concrete.

Application of sand

The material is in demand in construction of varying complexity . It is used to produce plaster and masonry mixtures, dry PC mixtures, and added to compositions for self-leveling floors.

Fine mineral sand acts as a raw material for the production of blocks . At the same time, the material gives the finished product high strength and frost resistance. The use of sand reduces the consumption of binder material by partially filling the resulting voids.

It is important to take into account the surfaces of products . If they are smooth and even, the grip will be worse. Therefore, the sand in the prepared solution must be stirred systematically. This will prevent small particles from settling at the bottom of the solution.

Coarse and medium sand are well suited for concrete products. To save money, you can add quarry sand. In the manufacture of masonry materials, clay is added, which makes the mortar more plastic, making it easier to work with the material. Fine sand is often needed by producers of dry mixes.

Extraction of sand from water with a brief description of the process

Sand is extracted from deep rivers using a dredge, which is secured to a barge. Such dredgers are equipped with special hydromechanical equipment, with powerful pumps, tanks and sieves for dividing sand by composition.

Rippers lowered to the river bottom mechanically suck in sand. The sand is transported through a slurry pipeline to the surface and deposited on a barge platform called a hydraulic dump. It has a device for draining water. The sand is then dry-cleaned and loaded onto another barge.

Extraction of river sand from dry river beds is similar to quarrying. All sand received must have a certificate of conformity.

In the video: an amphibious excavator dredger washing up sand at 400 m:

Application area of river sand

River sand today is used for various purposes in construction, as well as for landscaping private areas. Just like quarry sand, it can be used to prepare various solutions, as well as to level the terrain. However, the most common reason for purchasing this material is the preparation of various building mixtures. Since sand is included in almost all types of building mixtures that are used during repairs and construction of new structures, this material is quite in demand.

The advantage of river sand compared to quarry sand is the absence of unnecessary impurities. This allows this material to be used for preparing high-quality concrete mixtures, as well as for bricklaying and other construction purposes.

Technical characteristics and properties

When purchasing river sand, you must require a passport and a certificate for it. The characteristics of river sand must comply with GOST - 8736-93.

Basic properties of river sand

| Specifications | Indicators |

| Density (dry), kg/cub.m. | 1,5 |

| Density in a state of natural humidity, g/cm3 | 1,45 |

| Contains clay, silt and dust particles (by weight), % | 0,7 |

| Specific gravity, g/cm3 | 2,6 |

| Humidity, % | 4 |

| Contaminants, % | 0,05 |

| Filtration coefficient, m/day | From 5 – 7 |

| Size modulus, mm | From 1.37 to 2.3 |

River sand particles have different sizes. According to them, this material is classified into the following groups:

- fine sand with grains up to 2 mm in size;

- medium sand - from 2 to 2.5 mm;

- coarse sand - over 2.5 mm.

For construction sand, there are two types of specific gravity - bulk and true. Volumetric weight (density) is the amount of material placed in a unit volume. Due to its high flowability, determining the mass of sand per cubic meter is very difficult.

True specific gravity is calculated in laboratories; in practice, its values are usually not used. In practice, they use bulk specific density, this is the amount of sand that goes into a container measuring 1 cubic meter.

Properties and advantages of river sand

- natural purity: does not contain impurities and contaminants;

- high water throughput and filtration coefficient (approximately 5.5-6 meters of water per day);

- uniform, homogeneous grain size (on average approximately 2 mm);

- environmental safety: has class 1 radioactivity, does not cause allergic reactions, does not emit toxic substances, is safe for health;

- resistance to decay processes;

- fire safety;

- high noise insulation;

- durability.

Most often, river sand is compared with quarry sand. The main difference between the materials lies in the method of their extraction: quarry sand is mined in quarries by crushing rock. Therefore, such sand has a large number of various impurities and contaminants, due to the presence of which it is rarely used in the preparation of building mixtures, unlike river sand.

Application of river sand

The areas in which river sand can be successfully used are not limited.

It is used:

- For the production of concrete products, sand increases their strength and frost resistance;

- For the production of dry mixtures;

- To form foundation cushions

- In the production of mortars for plastering and masonry work

- When screeding and laying;

- For room decoration

- For landscaping

- In landscape work

- For arranging children's playgrounds.

- Sand for making concrete

River sand is indispensable in construction; it is used to produce concrete, from which various products are made. You can’t do without it in finishing work. River sand meets all construction requirements, but builders who prepare mortars do not like it because it settles very quickly, so it has to be constantly mixed.

Photo of river sand

For sandbox

The best option for a children's sandbox is river sand. It does not contain sulfites, sulfur, and other harmful particles that can harm the baby. It is better to take medium sand for the sandbox.

For aquariums

To constantly clean the water in the aquarium, you need to pour river sand into it. It is better to take coarser sand of a dark color, since light sand causes discomfort to the fish living in the aquarium.

Is it possible to paint river sand?

Multi-colored river sand can often be seen in decorative works. To do this, it is specially painted: with gouache, tempera powder or food coloring. Pour the finished paints into jars and pour sifted sand into them. After some time, it is taken out and dried. In addition to all of the above, sand can easily be given any color using ordinary multi-colored crayons.

How to paint river sand using crayons can be seen in the video:

Area of use of river sand

River sand is used in many branches of human activity. The main areas of application include:

- Production of concrete structures and mixtures. Due to the sand in the composition, the level of strength and frost resistance of the product increases;

- Creation of dry mixtures in agriculture;

- Creating a foundation in construction;

- Production of mortars for plastering and masonry processes;

- Creation of screeds and masonry;

- As interior elements (both inside the object and outside);

- Landscape design and territory development;

- Production of fertilizer for plant crops;

- As a filter (for example, in an aquarium);

- Improvement of children's playgrounds, etc.

For certain purposes, it is worth choosing the most suitable type of river sand, which will have the necessary properties.

Advantages and disadvantages

River sand has no disadvantages, except for the high cost of this natural material.

But there are a lot of positive qualities:

- ecologically pure;

- not afraid of exposure to aggressive components;

- has high moisture resistance;

- it is an excellent soundproofing material;

- sand does not rot;

- meets high technical and aesthetic requirements.

The list of its advantages can be endless, so users give this natural material the highest ratings.