Strengthening foundations with cementation is a common, effective method of strengthening them. The technology is used to improve the load-bearing characteristics of the soil before construction and to repair the existing foundation. In the latter case, not only the foundation is strengthened, but also the soil under its sole. Under the influence of various factors, the support under the building may become deformed. This is often accompanied by the appearance of cracks on the walls of the building. To stop the process of destruction and extend the life of the structure, it is imperative to carry out strengthening. A preliminary inspection of the structure is carried out to identify the cause of the process.

The essence of the cementation method

Foundation cementation is the process of compacting it by introducing cement mortar inside. The soil near the base is also often affected. The solution is delivered by a pump (under pressure) to the desired location through drilled wells. At the same time, existing voids are filled, problem areas are strengthened, because the adhesion of structural elements improves. As a result, the integrity of the support is restored.

Cement mortar under the base

Cementing of foundation structures must be carried out in the following cases:

- if natural wear of the base occurs during its operation;

- if it is necessary to strengthen unstable soils during construction or under an operating structure;

- when cracks (even minor ones) appear on the surface of the foundation;

- when the base is deformed;

- in cases of an increase in the effective load on the supporting structure due to the completion of the building;

- if voids have formed in the soil under the foundation base as a result of the action of groundwater, or the soil has become loose because of this.

Cementing services are provided by construction organizations. Prices for its implementation start from various contractors at approximately 4,000 rubles per linear meter. The final cost is determined after calculations by estimators.

You cannot strengthen the foundation yourself using the cementation method, because the work requires special equipment, as well as skills in handling it and relevant experience.

How to understand that the foundation needs to be strengthened

In addition to many external factors, rapid destruction of the foundation can be caused by errors during its installation - for example, a solution of the wrong density was used or several solutions were mixed, low-quality materials were used, markings were carried out incorrectly, etc.

An important role is played by waterproofing concrete, as well as compacting the soil before pouring it; Ignoring these measures will lead to rapid displacement of the foundation, especially on heaving soil. As a result, the concrete surface becomes covered with cracks; if the foundation sag under the building, these cracks will increase and soon appear on the walls. The appearance of such damage is the first sign that the foundation needs repair.

You can determine the speed at which destruction occurs using paper tape, attaching it to the surface of the wall across the crack. If it does not break within a week, the faults have stopped expanding, or are expanding very slowly; If the tape breaks within a few days, it’s time to sound the alarm.

Causes of base deformation

The reasons for the destruction of the foundation and walls of a building are various. Before strengthening the condition, they must be accurately determined in order to obtain the desired result.

Destruction of walls and foundation

The most common reasons causing deformation of the base, as well as the appearance of defects on its surface and inside, are:

- poor waterproofing (low quality);

- location of the building on a site that has a slope;

- change in the load-bearing properties of the soil under the building (after its construction) due to waterlogging, heaving or rising groundwater levels;

- carrying out extensive excavation work near the building;

- foundation design errors;

- incorrect calculation of the effective load;

- an increase in the mass of the building due to redevelopment or reconstruction of the building with an increase in the number of floors or the use of heavier building materials;

- constant or one-time vibrations of the earth under and near the structure, caused by the location of a railway nearby, underground workings, or an earthquake;

- use of low-quality materials for construction;

- improper operation: lack of scheduled repairs;

- severe soil freezing;

- flooding of the building site, for example, due to floods, heavy rainfall, floods;

- deviation from technology during construction work.

The table below shows various types of building deformations and their possible causes.

| Shrinkage of the central part of the structure | Settlement of the structure at the edges | Wall deformation |

| formation of voids in the ground under the middle section of the building | weak foundation at any angle of the building | exposure to loads from existing guy wires attached to the structure |

| soil subsidence | digging trenches or pits near a collapsing building | earthquakes |

| weakening at the center of the foundation | soil problems, landslides | loads from working equipment located inside the building |

Each reason for its elimination, in addition to restoring the strength of the foundation, also requires a whole range of related work. This may include dewatering the area, installing a drainage system, conducting research into changes that have occurred in the soil, and other activities. All this is reflected in the final estimate.

Strengthening the foundation by cementation

The foundation is the support of the building. Its task is to withstand the weight of the external structure, preventing negative consequences: deformation of the walls, subsidence, swelling, etc.

In order for the foundation to withstand constant loads and not deform, the foundation is strengthened, in particular, the foundation is strengthened by cementation.

Read about the foundation cementation method in this article.

Foundation cementation technique

Cementation – compaction of the foundation by introducing cement mortars. It is carried out using the method of drilling a ditch in the foundation and pouring a cement mixture using a pump. Filled injections into the problematic area of the structure strengthen the bonds between the concrete elements and make it monolithic.

Methods of strengthening the foundation by cementation

To strengthen the foundation by cementation, the following measures are carried out:

- Wells are drilled in the concrete covering of the structure to a immersion depth not reaching the base by 30 cm.

- They dig a similar well, but through the base of the foundation, deepening it into the soil by 0.5 m, filling the voids under the structure. The idea is to strengthen the sole to transfer the statistical and mechanical impact of the building to the sandy base (if the drainage pad has settled), as well as to increase the volume of the non-heaving seal.

Procedure for cementation

Strengthening the foundation by cementing involves identifying the factors that led to the violation of the integrity of the structure. They study the main characteristics: dimensions, base, stability, installation depth, waterproofing system, adhesion of soil rocks, materials for making the foundation.

To do this, they dig holes to a depth less than the level of the foundation base. Test pits can be dug in the form of trenches or wells in sandy and clayey soils. They have a rectangular shape measuring 1.5 by 3 m. The pits are dug in a checkerboard pattern, inside and outside the foundation. The larger side of the trench is adjacent to the base. A thorough examination of the surface of the structure will help identify flaws that require repair.

After 25-50 cm, holes with a width of 4 to 11 cm are dug in the body of the foundation at an angle. The main condition: the drill (a cutting tool for making holes in solid materials - concrete, stone, brick) should not reach the structure by 3 cm.

The pump pumps up the liquid solution and fills the dug wells.

Prepare concrete solution:

- Preparation of a liquid mixture of water-cement in a ratio of 0.9-1. Sand: fine and medium fraction, bentonite sand, expanded perlite or calcined diatomaceous earth sand, perlite or plamilon.

- First 10 min. they fill the recess under a pressure of 0.2 MPa to capacity - the consumption of the concrete mixture will decrease to 3.5-4 liters per minute.

- Then it’s a matter of more viscous water-cement mortars with a ratio of 0.8...0.7 to 1.

- Cementation is carried out until complete filling - immersion up to 5 liters per minute. Pressure - 0.3 MPa;

It will take 2 days to dry the mixture.

If a week after applying the alabaster mortar the problem area (gap, crack) increases in size, this means that the structure of the foundation is damaged.

The fact that the gaps are increasing is established using beacons (special guide rails for leveling the plane). The slats are mounted across cracks on the surface of the room. Outwardly, they resemble a bridge with a length of 30, a width of 5...7 and a height of 1.5...2 cm. The place where the lighthouse is attached is cleaned down to the concrete base. Two slats are fixed at the gaps: the first one is at the point of maximum magnification, the other is at its beginning. If after three weeks no cracks have formed on the lighthouses, it means that the deformation of the structure has returned to normal. Lighthouses are made of plaster, metal or glass.

Ground cover assessment

Studying the surrounding area helps determine the cause of the defects. Incorrect calculation and installation of the drainage system, close proximity of reservoirs, filled-in ravines - all this can lead to damage to the structure of the foundation.

| Type and external manifestation of deformations | Causes of deformities |

| 1. Shrinkage of the middle part of the building | Weak foundation in the middle part of the building; Shrinkage of the base; Voids in the middle of the structure. |

| 2. Settlement of the edges of the house | Weak foundation under the extreme part of the building; Uneven soil shrinkage; karst voids; Digging a trench near the house; Basement flooding. |

| 3. Buckling and deformation of walls | Tension from guy wires attached to the building; Dynamic action of equipment located in the building; |

Uneven loads on the soil foundation, changes in soil structure or incorrect calculations during construction are the main causes of destruction. Cementation of the foundation as a method of strengthening it is effective in eliminating the influence of negative factors on the foundation.

Practical implementation of technology

Work begins with a preliminary inspection of the structure being repaired. This allows you to determine the volume of work to be done, as well as the associated costs of materials and financial resources.

Inspection can be of 2 types:

- underground, designed to determine the dimensions of the foundation, operational characteristics (for example, strength), materials used in its creation, the structure and condition of the soil;

- external, which allows you to determine the dimensions of the building, the condition of its walls, the presence and nature of cracks, and calculate the load on the foundation.

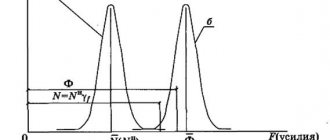

Schematic representation of the cementation process.

Proper inspection followed by analysis of the data obtained helps to determine the cause of deformation. A site survey also helps to create an accurate estimate.

To find out whether the shrinkage of the building has stopped, beacons are installed across the existing cracks. One is mounted in the widest possible place, and the other at the beginning of the gap. If after a month the slats do not fall off or are not deformed, it means that the shrinkage of the building has ended. Beacons can be used to monitor the progress of the process.

Strengthening the base and the soil underneath is carried out in 2 ways:

- traditional;

- jet.

Cementation work using various methods is carried out using different technologies. The mixtures used may consist of different materials.

Jet method

Using the jet method, the load-bearing properties of the soil under the existing foundation or on the site for a new building are improved. The essence of the technology is that cement mortar is supplied into the well under pressure. The energy of the jet causes destruction of the soil structure. As a result of this, it becomes stronger, and its resistance to multidirectional shears and deformation increases. The working mixture is mixed with the soil mass on site. The result of the process is the formation of soil-cement piles with a cross-section from 30 cm to 2.5 m, which are considered as a single mass with soil.

Jet method

The differences between the jet method and the classic cementing option are as follows:

- it is possible to strengthen almost all types of soil;

- the diameter of the working holes is 30-250 cm, and with traditional technology it does not exceed 25-30 mm.

The working process for the jet cementation method goes through the following stages:

- creation of a well of the depth required by the project (direct stroke);

- lifting the drilling part of the equipment with its simultaneous rotation and supply of a jet of working solution under high pressure;

- reinforcement of soil concrete pile.

The advantage of the jet method is the high cementing speed and predictable quality result. Installation of reinforcement bars is carried out if this is included in the estimate document.

III. ORGANIZATION AND TECHNOLOGY OF WORK EXECUTION

3.1. In accordance with SP 48.13330.2001 “Construction organization. Updated version of SNiP 12-01-2004” before the start of construction and installation work at the site, the Contractor is obliged, in the prescribed manner, to obtain from the Customer design documentation and a permit (order) to perform construction and installation work. Carrying out work without permission (warrant) is prohibited.

3.2. General requirements

3.2.1.

Soil consolidation is the artificial transformation of the construction properties of soils by physical and mechanical methods in the conditions of their natural occurrence to increase strength or cohesion and impart water resistance. As a result of soil consolidation, the bearing capacity of structure foundations increases.

3.2.2.

Consolidation of soils is carried out by injecting binders and chemical solutions into the soil, as well as by exposing the soil to electric current, heating and cooling the soil.

3.2.3.

Depending on the type of means used, the following methods of soil consolidation are distinguished:

– cementation;

– claying;

– bituminization;

– silicatization;

– smolization;

– thermal and electrochemical methods.

3.2.4.

The limits of applicability of each method of fixing soils are determined by the requirements for the fixed soil and the properties of the soils themselves:

– water permeability;

– filtration flow rate;

– soil homogeneity, etc.

These requirements are laid down in the detailed design, and one of the methods for securing soils is proposed.

3.2.5.

Work on consolidating soils must be carried out strictly according to the design, allowing changes and deviations from it only in agreement with the design organization. The project for artificial soil stabilization specifies:

– plan of the building foundations, profile and volume of the soil mass to be fixed;

– layout of injectors and electrodes in plan and sections, driving depth, as well as the number of stops and their location in depth;

– data on the scope of work and control workings;

– data on the amount of chemical solutions for one stop and the entire scope of work, on the mode of injection of solutions and the mode of soil treatment with electric current;

– requirements for fixed soil: strength, solidity, water resistance, water resistance and non-subsidence, fixing radius;

– data on the time required to complete the process and its complexity.

3.2.6.

The simplest and most reliable methods of strengthening soils are cementation, silicatization and electrosilicatization.

3.2.7.

Silication of

soils is carried out with single-solution (sodium silicate - liquid glass, sodium aluminate) or two-solution (liquid glass and calcium chloride) compositions pumped through injectors (perforated pipes with a diameter of 19.38 mm and a length of 1 m) under a pressure of 0.3. 0.6 MPa (3.6 atm). Silication fixes fine and silty sands, quicksand and loess. The radius of soil fixation around one injector is approximately 0.3. 1m.

3.2.8.

Electrosilication

is

used to consolidate clay soils with a filtration coefficient of less than 0.1 m/day. The essence of the method is that the solution penetrates into the soil simultaneously under the influence of pressure and direct electric current. The soil is strengthened as a result of an electrochemical reaction.

Cementation

The difference between cementation (injection) is that with it, hollow tubes are installed in the base cavity. As a rule, this method is used for rubble base, which has many voids. The accessibility of the technique is achieved due to the fact that the cavities between the rubble and bricks are filled with cement mortar, and minor cracks are covered up. Hollow tubes are installed in such a way that they extend beyond the holder by more than 40 cm and must be fixed with a solution.

To fill the cavities of the tubes, cement of a lesser density is poured into them than for the holder. The work must be carried out in the established order: first you need to make a clip, two days later, when it hardens, you need to fill the tubes placed in advance. Cementation is possible only when the base has retained its load-bearing capacity.

Causes of damage to the foundation of a house

In addition to the critical mistakes that were made during the construction of the house, the cause of the destruction of the foundation may be improper laying of the foundation or a change in the characteristics of the soil. For example, a structure can be built on one type of soil, and over time it changes its properties, for example, through an increase in the level or quantity of groundwater.

This fact cannot but be reflected in the foundation of the building. In addition, the foundation of the house can be damaged as a result of laying new communications next to it or carrying out excavation work, radical redevelopment (see photo), which changes the load points, or vibration, which is obtained, for example, from the passage of tram tracks next to the building or frequent passage large-sized transport.

Standard strengthening method

Today, the construction market uses a variety of methods to strengthen the foundation. But two of them are most often used. The first method is the standard strengthening method, as in the video. Its popularity is primarily due to its low cost and ease of implementation. The essence of this method is that a new foundation is laid around the structure, which thus allows the creation of auxiliary fixation points.

Strengthening the building begins from the corners (see photo). To do this, holes are made that expose the old foundation. Moreover, they must have a width of at least a meter and a depth that will exceed the depth of the old foundation by about half a meter. After this, the frame is erected. To create it, reinforcement with cell dimensions of 20x20x20 centimeters is used. When the grate is ready, it is lowered into the hole and filled with concrete. All this must be done as quickly as possible, since all this time the old foundation is open, which makes its subsidence even greater.

Strengthening the foundation of a house with drilled injection piles

Adherents of the most modern strengthening methods are trying to strengthen the foundation with drilled injection piles. You most likely won’t be able to do this with your own hands, since special equipment is required to implement this method. In addition, strengthening with drilled injection piles is not a cheap pleasure. But at the same time, this method is the most reliable.

https://youtube.com/watch?v=4zYIOTom-bI

Its essence is that inclined wells with a diameter of 16 to 24 centimeters are drilled into the existing foundation of the house on both sides, depending on the situation (see video). Cement mortar or concrete is poured into them, after which a frame of reinforcement is laid. After the mixture has completely dried, the result is a structure that sits on an impressive number of reinforced concrete piles. Wells are usually drilled to a depth, which will largely depend on the properties of the existing soil. Most often, in order to strengthen a building, wells are drilled until the drill reaches solid ground (see photo).

Sometimes it happens that the time when it was possible to simply strengthen the foundation is lost. In this case, it is necessary to partially or completely replace the foundation of the building. To do this, the most favorable plot of land near the building is selected, a hole about 2 meters long is dug until the old foundation is reached, after which supports are placed and it is removed. Then a new solution is poured into the vacant space.

Ways to strengthen the foundation of a house

Foundation depth for a two-story house

Builders have a wide range of tools and methods to strengthen the foundation of an old house. At the same time, time-tested methods do not lose their relevance. To choose the most optimal one, it is necessary to understand the advantages and disadvantages of each of them in relation to a specific case.

Ways to strengthen the foundation

Strengthening the strip foundation

The foundation of most private houses is a strip foundation. The characteristics of such foundations have the technical possibility of locally exceeding the normative loads. This type of foundation may experience local soil heaving. All types of foundations are built on bedded stone

When it draws down, it is important to stop this process in a timely manner.

Strengthening strip foundations

To do this, a hole is dug at an angle of 35 degrees in close proximity to the foundation. Its depth should reach the level of laying the bed stone. Then a pipe with a diameter of 150-200 mm is placed in the resulting hole. With its help, a thin concrete solution is poured, which is continued until the soil is completely saturated with it. At this stage, it is necessary to suspend all work for a couple of hours. At this time, observation should be made of the behavior of the soil in terms of saturation with the solution.

If the solution leaves, then continue filling the hole after a few days.

As practice shows, to completely saturate the soil, the procedure must be repeated two or three times. Control over the situation is carried out by beacons. In case of a slight change in their position, they move on to the next stage.

A ditch with a width of 200-350 mm is dug along the contour of the foundation. At its bottom and on the outside, a structure similar to formwork is constructed from boards. Pins are driven into the foundation, and a reinforcing mesh is attached to them. The resulting reinforcement is filled with concrete mortar filled with fine gravel and crushed stone. Such a structure will make it possible to significantly strengthen this corner of the house and evenly distribute the loads in the horizontal plane, which will stop the process of subsidence of the house.

Restoration of a foundation with cracks

Crack formation in the base and distortion of load-bearing structures can be of a different nature. Therefore, the first priority is to find out the nature of the processes taking place in order to find an adequate way to strengthen the foundation of the house.

Restoration of a foundation with cracks

If there is destruction along the perimeter of the foundation due to increased loads or exposure to moisture, a trench is dug that follows its contours. After this, the surface is thoroughly cleaned to remove the layer of plaster and adhering dirt. Next, the metal mesh is fixed with anchors driven into the base. Finally, the concrete solution is poured layer-by-layer with careful compaction.

If the foundation material is rubble stone, a monolithic slab of concrete or combinations of concrete-based materials, then a widened reinforced concrete frame is used. In this case, it is necessary to carry out reliable fixation, using through anchoring, with the old masonry material. The idea of building such a structure is that the old and new foundations work as a single whole.

Partial foundation replacement

If the foundation fails completely, it becomes necessary to replace it. To accomplish this task, it is completely unloaded, and at the same time the stability of the structure is preserved.

Unloading

This activity can be accomplished by installing so-called chairs, which are made of wood. Their installation occurs perpendicular to the foundation tracks. To secure the building, pillars placed under the walls can be used. The use of braces to hold the base and transmit forces at an angle to the ground is not excluded.

Before starting repair and restoration work, beacons should be installed. This is necessary so that the likely deformation process during this work can be detected. After this, they begin directly to implement the planned activities, which begin with digging a pit. The foundation is laid in sections, the length of which should not exceed two meters.

During excavation work, walls must be reinforced with struts. Next, a dig is made under the foundation and the soil is removed. Then the formwork and base for the foundation being constructed are installed. The sole is cleaned and, where required, dismantled. The old and new masonry are fixed together using rigid cement mortar and crushed stone. Having completed the foundation in one place, it can be continued in another.

How to strengthen the foundation under a house without causing it to collapse prematurely

To begin with, we note that experts recommend working sequentially and gradually, in sections of 2.5-3 m. Until restoration work is completed in one section, it is not recommended to begin another. Otherwise, you can get deformations and unpredictable redistribution of loads.

Working with a brick foundation

The reasons for the weakening in this case, as a rule, lie in the deterioration of the properties of the fastening solution. In this case, a trench is dug along the perimeter of the building, to the depth of the foundation. Its width should provide you with comfortable work, as a rule, it is 1-2 m.

The surface of the foundation masonry is cleared of soil and other debris. Notches about 15 mm thick are applied to the brick. Then, a layer of concrete mortar is applied to the surface of the masonry, preferably under pressure using a concrete gun. Thanks to the notches, the adhesion of concrete to masonry will increase, which will increase the efficiency of work.

Working with a brick house

To identify problem areas, it is necessary to hang special beacons (paper, for example) around the perimeter of the house, which will show where exactly the foundation is sagging or cracking.

Opposite the indicated place, at some distance from the house, a hole is being dug. The point is that it digs downhill in such a way that its end goes under the foundation. An asbestos-cement pipe is inserted into the pit, through which concrete solution is supplied until it stops going under the foundation.

After a couple of days, check the condition of the hole - if the solution has completely gone into the space under the object, the procedure must be repeated.

What is soil cementation? Technology

Jet cementation of soils is a physical and chemical consolidation with the aim of creating a petrified base. Simply put, this technology allows you to create, strengthen or level foundations without digging pits or unearthing existing structures.

Soil-cement pile

Jet grouting (jet grouting technology) allows you to lay the foundation during construction near other buildings, when digging a pit is impossible.

Also, with the help of this technology, it is possible to strengthen the foundations of existing buildings without causing them any harm.

Work can be carried out in various conditions, with sesmically active soils, close proximity of natural waters, etc.

Basic Concepts

Jet grouting of soils (translated as jet grouting) is the oldest technology that allows for such consolidation of soil.

They began to use it to strengthen loose, coarse-sandy, coarse-clastic soils. The fact is that digging a pit in the sand is generally a thankless task.

In conditions of coarse rocky soils, an attempt to violate the integrity of the soil (especially in mountainous areas) can generally lead to catastrophic consequences, such as landslides.

Using the jet grouting method to secure the foundation

This state of affairs would hardly please the developers, so they had to invent a method that would allow for consolidation without compromising the integrity of the soil.

Jet grouting technology consists in the fact that special tube injectors (a pipe with holes with a diameter of 2-4 mm) are vertically inserted into the soil, (cement laitance) is supplied under high pressure

Water under pressure hydraulically fractures the ground, filling the cracks with a cement mixture.

Excess water is gradually squeezed out to the surface. The solution gradually hardens and forms a strong, indelible mixture with the soil - soil concrete.

The result of the work performed to consolidate the foundation soil using jet technology after excavation

If the soil is consolidated at a shallow depth, the injector is driven into the ground. When working at great depths, it is immersed in a pre-drilled well.

Positive and negative sides

This method is well known among professional developers and architects. It has many positive features. As for its negative aspects, they are more related to the impossibility of using it in the domestic sphere.

Advantages of jet grouting

- This technology allows for consolidation of soils practically without violating their integrity and without dynamic impact on them. Thanks to this, jet grouting can be used to strengthen mountainous areas, reconstruct old buildings, and carry out work in dense urban areas.

- It has a combined effect on the ground.

Firstly, new interparticle bonds arise and old interparticle bonds become denser. Secondly, the base is compacted under high pressure. Thirdly, high-strength vertical soil concrete piles are laid in the ground at a given distance, and chaotic soil concrete horizontal layers also appear. - Fastening the base in this way allows you to achieve its high strength.

- This technology makes it possible to almost completely prevent soil subsidence.

- Makes it possible to correct the tilt of high-rise buildings.

- Work can be carried out on any soil, both above and below groundwater.

- Cementation allows work to be carried out without any waste.

Therefore, it can be used to create or strengthen sarcophagi of highly toxic or radioactive waste without their release to the surface, as well as with minimal contact with workers.

Cons of cementation

Previously, the disadvantages of jet grouting included the inability to perform work on high-density soils. However, new technologies using micro-hydraulic fracturing make it possible to consolidate absolutely any soil.

Soil cementation is carried out only with special equipment

Therefore, the only disadvantage can be attributed to the fact that this method cannot be used in everyday conditions, at least independently. Cementation requires special equipment, skills, financial and time expenditures, as well as preliminary seismic exploration. The pressure and composition of the supplied liquid depend on the characteristics of the soil.

Work order

The technology of jet cementation of soils, as mentioned earlier, allows for the consolidation of any soil in any conditions.

The diameter of soil concrete piles, depending on the characteristics of the soil and the needs of the developer, can range from 60 cm to 2 meters.

Let's take a closer look at the order of work:

- At the first stage, you need to load the injector into the ground. If the soil structure and cementation depth allow it, the injector is driven in without drilling a well. If not, a well with a diameter of 112 mm and a depth corresponding to the design elevation is drilled.

- When the injector is lifted upward, a cement suspension is supplied through the holes in the cone nozzle under a pressure of up to 600 atmospheres. The mixing proportions of cement and water range from 1:0.4 to 1:10, depending on the degree of water absorption of the soil.

- Cement laitance, coming out under high pressure from nozzles (holes) in the injector with a diameter of 2-4 mm, will not only fill the natural pores of the soil, but also produce small hydraulic fractures, which allows you to secure a larger space and prevent further subsidence of the building.

- Immediately after pouring cement-concrete piles, if necessary, they are reinforced. Depending on the purpose, metal or reinforced concrete pillars are pressed into the mixture.

The strength of a soil concrete foundation created using jet grouting technology is influenced by the type of soil and the amount of cement used.

Scheme of soil cementation work

Maximum strength is achieved when working in sandy and gravelly soils, minimum strength in clayey soils.

Application area

The scope of application of jet grouting technology is very wide: from urban construction of houses to preventing landslides and filling mine openings.

- fencing pits with intersecting soil-concrete piles, acting as both a vertical and an impervious curtain;

- strengthening of any types of foundations: strip, pile, reinforced concrete monolithic slabs to increase the deformation characteristics of soil foundations;

- installation of drilled combined piles by driving metal or reinforced concrete elements into a soil-cement mixture;

- creation of separation walls that resist the destruction of existing buildings during the construction of new ones;

- filling of mountain, mine workings and karst voids;

- carrying out anti-landslide measures;

- cementation is used to consolidate weak soils during road and transport construction, construction of tunnels and bridges;

Drilling rig for soil cementation

Technological equipment

As mentioned earlier, to carry out jet grouting of foundations you need serious professional equipment.

- Drilling rigs. They can be large-sized (for drilling to a depth of up to 50 meters) and small-sized (allowing work to be carried out at a depth of 2 meters in tight buildings and a small working space).

- High-pressure pumping units that allow supplying cement suspension under pressure from 450 to 600 atmospheres. Such equipment supplies from 150 to 420 liters of suspension into the well in one minute.

- Mixing installations for the preparation of water-cement suspension.

Soil jet cementation technology (video)

Source: https://PoPenobloky.ru/beton/cementaciya-grunta.html