Types of ventilation systems

The ventilation scheme in a house made of aerated concrete should be drawn up taking into account the characteristics of the premises. There are several options:

- in a natural way;

- coercive system;

- a combination of both methods.

Natural (passive)

With passive ventilation, air circulation occurs naturally. Air flows that come from the street into the premises rush upward and go outside again. There is constant air exchange. In order for it to pass stably, you need to place holes near the ceiling. To properly organize air exchange, special valves are used. They are placed in walls or window blocks. Some plastic frames have special devices in the window handles. However, they are too small to provide sufficient ventilation, so it is recommended to use them in addition to wall valves.

The main rule when operating ventilation ducts is their absolute cleanliness. Clogged ventilation shafts do not work efficiently, so you need to constantly monitor their condition. It is better to use modern options - special designs with holes for the influx of air flows and their exhaust. Valves are installed in each room under the ceiling for air intake and below for air outflow.

Forced air exchange system

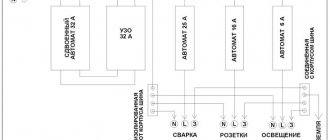

- Supply air, in which the fan is “planted” in the supply duct. Install it so that the air flows along the walls. Caps with slots are mounted on the valves, which facilitate the outflow of air along the wall surface in the desired direction.

- Exhaust. Such fans are in wide demand as they work for exhaust. They are installed in walls or a wall surface with a through hole. Devices must be selected based on performance. For example, fans with an air exchange of 60 m3 per hour are suitable for kitchens, 25 cubic meters per hour for bathrooms, and 30 for living rooms.

- Supply and exhaust. This type of ventilation system includes forced air supply into the house and the same exhaust hood. Today you can buy a complete system with air duct layouts. Special blocks help reduce heat loss by almost a third. Recuperator. Connected to a common channel, usually installed under the roof or in the attic

Mixed air exchange system

Mixed air exchange combines forced and passive ventilation. Street air flows enter naturally and exit using exhaust devices. This type is used for proper distribution of air exchangers in rooms, for example, in living rooms there is a natural system, and in sanitary and utility areas there is a forced one. For places with high humidity, you need to select a separate device with exhaust vent to the outside through a window or wall.

Ventilation schemes for aerated concrete houses

In general, ventilation systems can be divided into two main groups - natural and forced (mechanical).

The natural scheme works due to the temperature difference and the density of the air mass inside and outside the building. It is completely autonomous and operates regardless of the electricity supply. However, the closer the outside temperature is to room temperature, the worse the air exchange will be, up to a complete stop.

This is especially felt in the summer. Achieving high performance with natural ventilation is problematic. Moreover, if it is designed according to the channel principle with numerous turns and bends: the more complex the circuit, the weaker the thrust will be;

The mechanical circuit is much more powerful than the natural system. It is often equipped with additional functions of heating or cooling air, a heat saving function (recovery), and the ability to integrate into the Smart Home system. This ventilation works regardless of temperature changes.

What both types of systems have in common is that it is advisable to think through both natural and mechanical ventilation at the design stage of a house and install it immediately during its construction.

Why is it important? Because the ventilation system, in most cases, is a network of metal or plastic air ducts that must be laid from the premises and brought to the roof.

One of the most popular ways to organize duct ventilation in houses made of aerated concrete is to lay them under the upper ceiling. The system is covered with suspended or suspended ceilings so that only the grids of supply and exhaust openings are visible

If you do not immediately take into account all the nuances of installation, then installing ventilation in the future may be associated with many difficulties (punching or drilling holes in main walls and ceilings, the need to lay pipes from the premises of the first floor through the living rooms of the second, unsightly appearance, etc.).

Despite the apparent complexity, it is quite simple to understand the organizational issues in order to install ventilation in an aerated concrete house with your own hands or correctly order its installation without overpaying for equipment and work.

So, let's move on to the types of ventilation.

Subtleties of natural ventilation devices

We have already figured out that the force that makes natural ventilation work is the desire of warm air to rise upward. In order for such movement to begin, an air duct is needed to allow warm air from the room to exit to the colder street.

Air ducts are made of plastic, galvanized metal or stainless steel round pipes or profiles of square or rectangular cross-section. Ventilation ducts can also be made in the form of voids in the walls during their construction.

If the above pipes are laid in such voids, this is called lining; this method is widely used, as it eliminates leaks in the masonry and facilitates maintenance.

With natural ventilation, the air ducts are made vertical and as straight as possible, and the number of turns and horizontal (sloping) sections is minimized, as this reduces draft. Also, for better traction, you cannot narrow the diameter of the pipe.

The ventilation risers of the exhaust part of the natural type ventilation are installed above the roof to a height equal to the height of the chimneys. If the distance between the ridge and the ventilation pipe is less than 1.5 m, the pipe must rise above the ridge ridge by at least 0.5 m. This is necessary to form a stable draft

The exhaust openings are equipped with ventilation grilles. They are installed in the upper quarter of the walls or directly under the ceiling, since this is where the air rises and requires removal.

Air flow in natural ventilation schemes occurs through leaks in building structures, windows and doors, as well as through special supply openings located at the bottom of the house.

Plastic windows and safe doors practically do not allow air to pass through. Therefore, when installing natural ventilation in modern housing, the presence of inlet openings or valves is a prerequisite for the operation of the ventilation system.

The simplest solution is to install windows with ventilation valves. They will allow the flow of fresh air into the room without making additional holes.

To equip a house made of aerated concrete, it is better to buy double-glazed windows with a built-in micro-ventilation system. This way it will be possible to ensure a continuous flow of fresh air into the house without noticeable drafts

But don’t despair if the windows in your house are installed without such valves. For these cases, devices built into walls are offered on the market. They have a significantly higher throughput capacity than window ones, and can also be equipped with filters, which allows the air to be purified before it is supplied to the home.

It is worth remembering that wall valves cannot ventilate a room on their own. For them to work, the built-in exhaust or supply fan must be working. The valves simply allow air from the street to pass through them and allow you to regulate its flow by opening or closing the damper.

Wall ventilation valves are divided into supply and exhaust. Supply models are equipped with devices for air flow filtration. Among them there are models with devices for heating the flow

Natural ventilation is good because of its simplicity, low cost and energy independence. It is easy to install it yourself. It can be an excellent solution for small homes.

Nuances of organizing mechanical ventilation

The difference between a mechanical ventilation system and a natural one is that the air is driven by electric fans. Thanks to this, mechanical ventilation can have a complex and long system of ventilation ducts with both vertical and horizontal sections.

Pressure losses in duct versions of mechanical ventilation are compensated by increasing the fan power. This allows you to install air ducts in all the necessary rooms without worrying about the lack of draft.

The mechanical version of the ventilation system is completely independent of the temperature and density of the air outside the window and indoors. Its design includes fans that force air in or remove air through exhaust components

Another distinctive feature of a mechanical ventilation system is the ability to automate it. Thanks to the installation of fans with multi-stage speed control, as well as other devices that regulate the speed, direction of air flow and its temperature, mechanical ventilation allows you to achieve optimal air exchange in each room.

It is more profitable to equip a private house with a mixed ventilation system, which contains components of both gravity and forced type. In these schemes, air movement is stimulated by a fan mounted either in the supply part or in the exhaust part.

Mixed ventilation schemes use both gravitational principles and mechanical devices. Either supply or exhaust is carried out by a fan

Mechanical and mixed ventilation can be local or centralized.

With a local ventilation system , each room from which air is removed has its own fan installed. A typical example is a kitchen hood and a fan on the exhaust vent in the bathroom.

The exhaust components of both natural and mechanical ventilation systems are located at the top of the wall because contaminated warm air spontaneously moves upward

This solution is often used if for some reason the natural ventilation draft is not enough and it needs to be increased. Installing local exhaust fans is a low-cost method that you can do yourself.

Both for the natural scheme and for mechanical exhaust ventilation, it is necessary to have air flow paths through leaks, or through special supply openings or valves.

With a centralized ventilation system in the house, usually in the attic, an exhaust or supply and exhaust ventilation unit is installed. Further from this unit, ventilation ducts are laid into the necessary rooms, removing exhaust air, and if the installation is a supply and exhaust system, then supplying fresh air.

It is better to install the supply and exhaust ventilation unit outside the living space, as it can make noise during operation. Ideally, a non-residential attic should be used for its placement.

Supply and exhaust ventilation units are equipped with two fans and ensure equal amounts of incoming and outgoing air. Also, such installations can be equipped with heating and filtration systems for incoming air and automation, which allows maintaining the specified temperature and air exchange parameters.

Ventilation units with recovery are equipped with a device that increases the economic effect of using the equipment. This is a recuperator that provides the opportunity to rationally manage the energy of heating systems and save on utility bills.

With any other type of mechanical ventilation, heat is simply released from the room to the street along with the exhaust air! Savings from ventilation with recovery are especially important in winter, when a lot of thermal energy escapes into the ventilation pipe. At the same time, the cold air it receives from the street in return also needs to be heated to room temperature.

The recuperator is a heat exchanger through which warm air from the house and cold air from the street simultaneously pass. A number of recuperator models use additional plate heaters with freon or water.

In ventilation systems with a recuperator, warm air from the room is cleaned and mixed with a fresh portion captured by the fan from the street

Thus, fresh air is heated not by heating or electricity, but by previously heated air removed from the room. Heat losses when using a recuperator are minimal.

In warm weather, when it’s hot outside, the recuperator is also useful: in this case, it cools the hot air coming from the street with cooler air from the room, reducing air conditioning costs.

Recuperation is a technological process for reusing thermal energy, which can significantly reduce the cost of preparing outdoor air pumped into the premises by ventilation

Unfortunately, despite its obvious advantages, recovery has two disadvantages:

- Firstly, ventilation units with recovery are many times more expensive than similar units without a recuperator;

- Secondly, recuperators can operate stably only when the outside air temperature is not lower than – 10 °C. At colder temperatures, the plates become covered with an ice crust.

However, even with its shortcomings, the recuperator is the best solution for systems that process all rooms in the house. Among the local options, the breather is the leader.

A breather is a device for ventilation in a separate room. It consists of a ventilation duct and a housing in which are installed: an electric heater, a fan, filters, blinds and automatic control.

For ease of setup, breathers may have a remote control. Some breathers are equipped with a ceramic heat exchanger, which allows them to operate in recovery mode.

A breather is a fairly effective miniature local ventilation unit that heats and cleans the air flow

Breathers forcefully pump fresh air into the room, pre-filtering it and, if necessary, heating it. Models with a heat exchanger are capable of not only pumping air into the room, but also removing old air from it.

In a house made of aerated concrete, installing breathers and valves yourself is not difficult: you just need to drill a hole of a suitable diameter in the wall for the ventilation pipe and secure the device to the wall.

Air purification in ventilation

At the beginning of the article, it was mentioned about dust flying in the air due to improper or absent ventilation. To solve this problem, modern supply ventilation systems can be equipped with special filters to clean the air entering the room from the street.

Moreover, depending on your needs, the set of filters can be different: from coarse cleaning, which retains only large particles; to a fine cleaning that does not allow even odors and pollen to pass through.

To equip ventilation systems, filters of various levels are produced. Among them there are models for coarse and fine cleaning, holding animal hair, screening out viruses, etc.

Filters have only one drawback: they need to be changed periodically.

Chimneys of stoves and fireplaces in residential premises

If you are planning or already have a stove or fireplace in your home, then when calculating ventilation you need to keep in mind that the chimneys of stoves and fireplaces are actually also exhaust ventilation.

In a cold state, chimneys work like a regular natural exhaust, and when burning wood, this effect is enhanced significantly, since a large amount of air is consumed for combustion.

And although chimneys cannot fully perform the function of exhaust ventilation, their presence must be taken into account when determining the size of the supply openings so that they can provide the required supply of fresh air both for the operation of the main ventilation and for the operation of the heating device.

Why is ventilation needed in a house made of aerated concrete?

An example of a ventilation scheme for a house made of aerated concrete.

Houses built from aerated concrete belong to the budget construction segment.

Of their advantages, it should be noted:

- speed of construction;

- good thermal insulation.

However, due to the high hygroscopicity of the material, interior decoration prematurely loses its attractive appearance. In addition, moisture penetrating into the material not only from the outside, but also from inside the house, accumulates in the pores of aerated concrete and freezes in the cold season.

This leads to the formation of cracks and destruction of the structure. That is why ventilation installed in houses made of aerated concrete must be carried out strictly in accordance with existing standards.

Effective air outflow and supply helps normalize humidity and ensures a comfortable stay in a home made of aerated concrete.

Do-it-yourself ventilation ducts in a house made of aerated concrete: brickwork

It is best to trust the construction of ventilation systems for a private home to specialists. If you follow building codes and follow the rules of laying and installation, it is possible to install a hood yourself. First of all, it is determined which of the known methods will install the exhaust duct.

When laying channels with bricks, you need to consider:

- Location - in one of the walls of the room where moisture especially accumulates.

- The fewer channels the better. This issue is resolved geographically - the kitchen and sanitary rooms are located in close proximity to each other (“neighboring”). By the way, this requirement applies not only to ventilation, but also to sewerage and water supply systems.

- The brick structure should not come into contact with the wooden building elements of the house - the temperature of the channel will gradually destroy the wood.

- Only solid brick is used. Laying from hollow facing is also allowed, but with careful filling of the voids with mortar. Silicate, which has the ability to crumble, is not suitable for such work; it does not tolerate the temperature regime formed inside the ventilation duct.

- The channels are tied together, the separators make up ½ brick.

- The brick is laid using a single-row ligation system. When applying the solution for the next row, you must ensure that the mixture does not get inside the channel.

Important! Ventilation is not installed in a load-bearing wall made of aerated concrete, as in houses made of other materials! This is not a mandatory requirement, but experts recommend it due to the fact that, basically, load-bearing walls are located outside the building - condensation will form on them. The inner surface of the ducts, ventilation and smoke, should be as smooth as possible

Therefore, when laying bricks, excess mortar is removed from the joints, and the surface is smoothed with a trowel. Also, there should be no protrusions or depressions on the inner surface - they interfere with normal air circulation

The inner surface of the ducts, ventilation and smoke, should be as smooth as possible. Therefore, when laying bricks, excess mortar is removed from the joints, and the surface is smoothed with a trowel. Also, there should be no protrusions or depressions on the inner surface - they interfere with normal air circulation.

Particular attention is paid to the seams, which must be filled with mortar and rubbed to prevent combustion products and exhaust air from entering adjacent ducts or rooms of the house. Grouting is done after laying 2-3 rows of bricks

The process is carried out manually, with reciprocating and circular movements along the inner surface of the structure.

Important! The peculiarity of brick ventilation ducts is that they are not equipped with mechanical devices

Optimal ventilation system for an aerated concrete house

We must start again with a reminder that gas silicate blocks are highly hygroscopic. This means that the best option for constructing a ventilation system in such a house is to install vertical channels and shafts. It may not be easy to install a ventilation duct, it may take a lot of time and money, but this is the ideal option.

Installing air valves in the walls of a gas silicate house is a high probability, firstly, of reducing the load-bearing capacity of the wall, and secondly, it becomes possible for moisture to penetrate into the body of the gas blocks when warm air from the premises comes into contact with cold air outside. That is, the appearance of condensation is a real possibility. And this is again moisture that destroys aerated concrete.

Therefore, we offer three additional options that will help you avoid trouble.

- Use only the supply circuit with output through the central risers.

- Use materials to insulate air exhaust valves. By the way, many manufacturers today do just that. Their models use a cylindrical insulating material that is inserted inside the valve. It also protects the wall from condensation.

- Use only window structures as supply units.

By the way, the supply ventilation system showed itself to be much better in this situation than the exhaust system. But many craftsmen found their way out of the difficult situation. For example, to install a valve with a diameter of 100 mm, a hole with a diameter of 130-150 mm was made in the wall. the valve was installed in the wall, and the gap between it and the wall was filled with polyurethane foam. The latter is polyurethane foam with high thermal insulation characteristics.

Another option that is well suited for houses made of aerated concrete is a system with recovery or calorific heating of the incoming air. That is, cold air, before entering the interior and passing through the wall, gains heat, which naturally eliminates the formation of condensation. However, it should be noted that such ventilation systems are very expensive, and they also consume energy, so you will have to pay electricity bills all the time.

Types of ventilation systems

Ventilation in an aerated concrete house has its own characteristics. If in buildings made of traditional materials ventilation ducts are laid only in rooms with high air humidity, then here it is advisable to install them in every room.

Advice. If this is too difficult, then rooms such as the kitchen, bathroom, boiler room and basement must be equipped with a ventilation system. And in residential premises, interior doors must be equipped with ventilation grilles or a small gap must be left under them for free air circulation.

Door with ventilation grille

Ventilation of a private house can be natural, forced or mixed.

Examples of different schemes are given in the table.

| Ventilation diagram | Explanations |

| Ventilation occurs naturally through ventilation ducts leading to the roof of the house. |

| Mixed ventilation system with exhaust fans in rooms with the highest air pollution. Fans are turned on as needed, either manually or automatically at specified intervals. |

| The exhaust fan is installed in a common duct that connects all the air ducts coming from the rooms. |

| The influx of fresh air and the outflow of exhaust air is carried out forcibly using a mechanical ventilation system with a recuperator. |

Now in more detail about each type.

Natural (passive) ventilation

In order for the passive ventilation of a house made of aerated concrete to work properly, you need to make some efforts.

Namely:

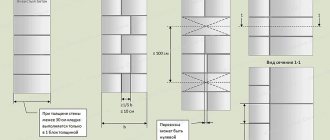

- Install channels to remove dirty and humid air from the house. In order for it to extend itself, these channels must extend to the roof of the house to a certain height. If they are one and a half meters away from the ridge, then they should be 50 cm higher than it. At a distance of up to 3 meters, the head of the channel can be flush with the ridge. And if this distance exceeds 3 meters, the top of the channel should not be below a line drawn from the ridge at an angle of 100 to the horizon. Violation of these requirements causes poor traction or even its “capsizing”.

Scheme of ventilation ducts output to the roof

Advice. It is necessary to install an umbrella at the top of the exhaust pipe to protect against precipitation or a deflector to improve the functioning of natural ventilation.

- Provide fresh air flow. Sealed plastic windows practically do not allow it into the house, but you can find a way out. For example, install window units with supply valves or ventilators built into external walls.

Advice. If the ventilators are installed directly under the windows, the air coming from the street in winter will be heated by the heat coming from the heating radiators.

Forced ventilation

Such a system will be more expensive to install and operate due to the use of electricity and special devices for forced air circulation.

But their price is compensated by greater ventilation efficiency and improved home microclimate.

- The air ducts in such a system are equipped with exhaust fans, and air from the street is supplied through its network of channels.

- To ensure that the temperature regime in the premises is not disturbed in cold weather, the ventilation system is equipped with units for heating outdoor air.

- The most economical option in this case is to use not an electric heater, but a heat recuperator. This is a heat exchanger with two fans - supply and exhaust, in which fresh air is heated from the heat of gases removed from the house.

The principle of operation of the recuperator

For reference. When using systems with a recuperator, heat loss in a heated building is reduced by 20-30%.

Typically, the recuperator is installed in the attic of a house and connected to a common duct, which combines air ducts from all ventilated rooms. Access to it must be free, as it requires maintenance - cleaning the plates when the seasons change and replacing filters.

Recovery unit in the attic

Mixed ventilation

In such a system, fresh air flows naturally, and exhaust fans are installed to remove exhaust air masses.

It can be:

- Appliances built into the exterior walls or windows of each ventilated room;

Exhaust fan in the wall

- One powerful duct fan in the attic, to which several ventilation ducts are supplied.

Duct fan

Personal installation of the ventilation system

Now on the Internet there is any information about the selection and installation of ventilation systems, which you can easily build with your own hands in a house made of aerated concrete. In a hardware store you can freely buy ventilation ducts, fans or serious ventilation units.

Various methods are used to mask ventilation ducts. The most popular location is behind a false wall or in a plasterboard box.

The only thing that is better to entrust to designers is the calculation of ventilation, because it is unlikely to be possible to do it yourself without having the knowledge.

Correct calculation is especially important if you plan to use natural ventilation, because in this case it is important to correctly select the number and cross-section of ventilation air ducts so that they provide the necessary draft and air exchange. If you plan to install mechanical ventilation, then an approximate calculation of its performance can be made based on standards, as in the example indicated at the beginning of this article

To do this, you need to calculate the standard ventilation value for your home and increase this value by 10-20% to compensate for losses when air moves through the ventilation ducts

If you plan to install mechanical ventilation, then an approximate calculation of its performance can be made based on standards, as in the example indicated at the beginning of this article. To do this, you need to calculate the standard ventilation value for your home and increase this value by 10-20% to compensate for losses when air moves through the ventilation ducts.

As for the installation of ventilation itself, for people who build a house with their own hands, this is usually nothing complicated.

Ventilation ducts are assembled like a construction set, when one part is freely inserted into another. A large number of lengths, shapes and sections of channels, as well as various bends, tees, transitions, valves, gate valves and other products allow you to assemble a ventilation duct of any configuration.

The construction of a ventilation system will be much faster if you use a set of parts designed for this purpose.

Also, thanks to standardization of sizes, ventilation ducts can be easily connected to a wide variety of supply, exhaust and supply and exhaust mechanical ventilation installations.

By the way, the choice of such installations and their manufacturers is also large: from budget ones with simple functionality to premium ones with full automation.

System installation

The assembly of the entire system can be carried out in different ways and depends on the chosen method of arranging ventilation. Thus, the installation of pipes and laying of brick channels are carried out during the construction phase of the building; the installation of fans and valves can be carried out after.

It is best to make special channels at the construction stage - in all rooms or only where high humidity is noted. Brick channels or pipes in blocks are laid along the walls and lead to the attic, combining them there and insulating them at the points of access to the roof.

Pipes are usually made of plastic with a diameter of 13 centimeters or more. They are laid in aerated concrete blocks and insulated with mortar.

Stages of assembling a horizontal ventilation duct system:

- Drawing up a diagram for installing air ducts - if there is only one system, the main line is created from one air duct laid horizontally under the ceiling.

- Calculation of the diameter of the air duct based on the calculation of the volume of air that is removed.

- Calculation of the number of fittings, straight sections and their length (according to the diagram).

- Purchase of materials.

- Making holes in each wall along the cross-section of the air duct.

- Assembly with couplings/clamps starts from the back room.

- Exit the outlet pipe (usually through the kitchen) through the wall to the street.

- Installation of exhaust windows in the air duct, covered with grilles.

When installing a duct model, it is inserted into the exhaust hole in the wall. Wall-mounted models (often used for bathrooms) are mounted indoors to the wall exactly horizontally so that the fan works correctly.

Ventilation ducts in walls made of aerated concrete blocks: engineering standards

In houses built from aerated concrete, special attention is paid to the construction of a ventilation duct. The ability of this building material to absorb moisture, gases, its fragility and inability to withstand high temperatures must be taken into account.

Therefore, ventilation ducts are performed in other ways:

- laying out the channel itself and the adjacent brick wall;

- lining with plastic, steel or asbestos-cement pipes;

- installation of a galvanized box, which is lined with aerated concrete blocks.

Ventilation ducts are installed on the roof to a certain height. Violation of the location of the pipe is fraught with poor traction or even its “tipping over”. Thus, a channel installed at a distance of 1.5 m from the ridge should exceed it by 500 mm. If it is located 3 meters from the ridge - level with it in height, more than 3 meters - no lower than an angle of 10° between the ridge and the upper edge of the pipe.

Important! It is strictly forbidden to make a “work of art” out of a ventilation duct and decorate it with devices that are not related to the ventilation system. The end of the pipe can be an umbrella or deflector, which will improve the operation of natural hood

Installation of ventilation ducts

When planning to build a ventilation system in a house made of aerated concrete with your own hands, you need to study everything carefully. Particular attention is always paid to the installation of ventilation ducts, remembering that aerated concrete is a fragile material and is afraid of sudden changes in temperature and moisture.

Craftsmen do not advise installing the system in external walls, as condensation will appear; it is better to arrange everything in separate ventilation shafts or partitions.

Methods for arranging ventilation ducts in an aerated concrete house:

- Lining of plastic and asbestos pipes

- Brick laying

- Installation of a box made of zinc-coated steel with laying out small blocks of aerated concrete

Brick ventilation ducts

Laying out brick ventilation ducts requires a certain sequence of actions, as well as the availability of the necessary materials and tools.

Sand-lime brick is not used in such masonry, as it is sensitive to high temperatures and crumbles. Mechanical devices cannot be installed in brick channels.

Lining with plastic pipes

The most effective way to install forced ventilation. For installation, plastic pipes with a cross-section of 13 centimeters or rectangular pipes with a cross-section of 150 cm2 are used.

Calculations of productivity and optimal dimensions

Only a specialist can handle calculations that take into account temperature, the number of people living, glass area and other parameters. However, every building owner is able to make a simple approximate calculation of the ventilation of his home using just a few parameters.

So, before building a ventilation duct in a load-bearing wall made of aerated concrete, it is necessary to calculate its performance. For example, let’s take: a one-story house, the area of five living rooms is 80 square meters. m, ceiling height – 2.7 m, kitchen with electric stove, combined bath and toilet, boiler room – 10 sq.m and data from SP 54.13330.2011 “Residential multi-apartment buildings”.

- Inflow – 80x2.7x1=216 cubic meters/hour.

- Required exhaust air removal: kitchen – 60 cubic meters/h; bathroom – 50 cubic meters/hour. boiler room – 100 cubic meters/hour – 60+50+100=210 cubic meters/hour.

- The calculated rate is 216 cubic meters/hour.

The height of the ventilation duct of a one-story house is 4 m. At a temperature of 25°C, the hood capacity is 58.59 cubic meters per hour, therefore, 216/58.59 = 3.69. Based on the calculated data, it is necessary to install 4 air ducts that will ensure effective ventilation of the house.

Reliable and affordable. But will the building, built in a short time, be comfortable for living? Aerated concrete has powerful absorption properties, so it quickly absorbs moisture. Its excess in residential premises reduces the heat-saving properties of walls and causes deformation of the finishing layer. Properly organized ventilation will provide a favorable atmosphere for human life and the normal functioning of a cottage made of aerated concrete. This channel system will ensure air circulation in the house, preventing it from stagnating in the rooms.

Calculation of ventilation cross-section

To correctly calculate the cross-section of the boiler room ventilation system pipeline, you will need the following data:

- The cubic capacity of the boiler room, depending on the height of the room. According to SNiP requirements, its height should not be less than 6 meters. Obviously, in the conditions of a village house such a requirement is impossible to fulfill. When calculating, it must be taken into account that when this indicator decreases by 1 meter, the amount of air required for fuel combustion must be increased by 25%;

- Air mass flow velocity (at least 1 m/s).

- Air exchange rate. The value depends on the height of the boiler room.

The result of the calculation will be the air requirement, on the basis of which, using special tables, the cross-section of the ventilation system pipeline can be determined.

The calculation is made using the relationship V = L x SX (6 - H) x 1.25 xn, where:

- V is the volume of air for fuel combustion;

- L is the length of the room;

- S is the width of the room;

- H is the height of the room;

- n is the frequency of air change in the boiler room, equal to 3.

Thus, when determining the air requirement, the actual size of the room and the increase in air turnover are taken into account. Having received the desired value, the diameter of the air duct can be selected from the table.

Table: dependence of the duct diameter on the required air flow

To ventilate rooms with gas appliances, it is advisable to install a duplicate ventilation system so that one of them works under any circumstances.

When there is a power outage, ventilation of the premises will be carried out through natural circulation channels.

What not to do

When a private house is being built and a ventilation system is created in it, it is very important to take preliminary calculations seriously and do everything in accordance with the standards. Things to remember:

Things to remember:

- Ventilation in load-bearing walls is not done to avoid a decrease in strength.

- In boiler rooms, both exhaust and supply valves are installed.

- In rooms separated from the room with the ventilation duct by two doors, both valves are also installed.

- The minimum cross-section of the channel should be 0.016 m2 (about 15 centimeters pipe diameter).

- The most effective method is lining the ventilation duct with a plastic pipe. Metal pipes will collect condensation.

- In apartment buildings, it is better to install metal-plastic windows with valves or powerful exhaust fans.

Installation of ventilation in an aerated concrete house

- The outlet is fixed in the block located near the ventilation hole and connected to the tube.

- Holes are cut out, the diameter of which is 2 cm larger than the diameter of the pipes in the blocks.

- The gap between the pipes and the walls is filled with concrete mixture.

- Pipes are insulated in unprotected areas (attic, roof).

- Air vents in the roof space are combined into a single channel, which is led to the outside space or attached to the recuperator.

The system is assembled taking into account the chosen method. The installation of pipes and channels made of bricks is carried out during the construction stages of the house, and the installation of fans and valves can be done already in the constructed building.

It is important to remember that load-bearing wall structures are not suitable for installing ventilation. In boiler rooms it is necessary to install both exhaust and supply valves

It is necessary to select pipes with a diameter of at least 15 cm. For lining, it is better to use plastic materials, since condensation forms on the metal surface.

A ventilation system in an aerated concrete house will help create a favorable microclimate and comfortable living conditions. A competent approach to its arrangement improves the performance characteristics of the building and increases its service life.

What is ventilation and why is it needed in an aerated concrete house?

Ventilation is a directed air flow that replaces and supplies fresh air from the street into the house.

Ventilation serves two main purposes:

- maintaining a comfortable level of carbon dioxide inside the house;

- removing excess moisture from interior spaces and walls.

A good ventilation system is especially important when aerated concrete walls are insulated with vapor-proof materials, such as polystyrene foam, EPS, and polyurethane foam. A sufficient flow of fresh supply air can dry aerated concrete walls without creating dampness in the room.

Key points regarding the location of natural ventilation

In general, the natural ventilation scheme is installed according to the following principles:

- Openings for air flow are located in bedrooms, living rooms and other “clean” rooms. The fresh flow is supplied through plastic or asbestos-cement pipes hidden in separate shafts or internal walls with holes for air ducts.

- Exits are installed in the kitchen, bathroom, and toilets. In the attic, they are combined into a common pipe covered with insulation and taken out beyond the roof surface, often ending the system with a special “mushroom”.

Also, ventilation ducts in a house made of aerated concrete can be made in a reinforcing belt, but this complicates the replacement or repair of pipes if such a need arises. To avoid drafts, the inlet and outlet openings are mounted at a considerable distance from each other, ideally in different rooms.

To make air exchange more efficient, you can place the ventilation duct above the stove, radiators and other heat sources. Storerooms, dressing rooms and other small rooms can be ventilated due to the gap in the doors.

Natural ventilation in a house made of aerated concrete copes well with the task in warm and cool weather, but can fail when the temperature increases or decreases significantly. In the summer heat, hot air is difficult to remove from the room, since the necessary pressure difference is not created to move the air masses. The problem is solved by turning on the air conditioners. And in winter, the temperature difference is too significant and ventilation can occur too intensely.

System installation

Many people who have just moved into a purchased house or are building it from scratch are asking a completely logical and reasonable question: how to make ventilation in the house?

Moreover, it is very important that the ventilation system fully complies with all sanitary and technical standards. They use a specialized complex, which consists of certain systems. Air ducts are made from the following materials:

Air ducts are made from the following materials:

- zinc;

- plastic;

- asbestos cement.

They are laid in all rooms

Ventilation ducts that leave the premises are combined approximately at the level of the ceiling (attic), in such situations it is very important that they are insulated in those places where they go out onto the roof

For natural pipes, take pipes with a slightly larger diameter, the difference is 2 centimeters. Next, a hole is made in the aerated concrete wall at small intervals of half a centimeter in each direction, and the air duct systems are fixed into them.

For successful completion, you need to prepare a special solution before installation, and all holes in which pipes and fans will be installed must be waterproofed.

Why choose inertial hoods

Inertia supply and exhaust structures demonstrate high efficiency, provided that the cross-sections and lengths of the channels are correctly calculated, as well as the correct location of the valves. First, a detailed diagram of the house is drawn up, taking into account the interaction of air (cold at the bottom, warm at the top), and the volume of air exchange.

Inertia hoods are quite simple in their operating principle - when air comes from the street, they close, preventing it from entering the room. When air comes from the hood, the valve lets it through, opening. By properly installing such devices, you can create an effective ventilation system.

Ventilation in a house made of aerated concrete is an issue that cannot be ignored if you plan to create comfortable and healthy conditions in your home. In addition, properly equipped ventilation will significantly increase the strength, reliability and durability of the house itself.

The need to install ventilation

Aerated concrete is highly hygroscopic, so moisture accumulates inside and fungus forms on the walls

Old air masses must be removed from the house so that fresh, oxygen-filled air can enter. Thanks to air exchange, condensation will not accumulate in the apartment, which leads to the formation of mold and fungi. Fresh air is also beneficial for the health and normal functioning of the human body.

The standards for ensuring air exchange are prescribed in SP, SanPiN and SNiP.

- Every residential building made of any material must have a ventilation system. This applies to both private and multi-apartment buildings.

- The ventilation system should help renew the air at certain intervals.

- Air exhaust is provided through exhaust ducts in the kitchen and bathroom.

- Each room has its own air exchange values that must be adhered to.

All air exchange values are specified in regulatory documents.

The need for ventilation in a private house

Wall-mounted units of various capacities are used, having a compact and productive firebox of an open or closed type. The conditions for placing equipment are less stringent than for floor-mounted types, so they are placed in the boiler room, kitchen, bathroom or utility room.

Owners sometimes doubt the need for a hood in the boiler room, considering opening the transom sufficient. Keeping the window constantly open is inconvenient in winter, and periodic ventilation does not completely solve the problem of air exchange. A forced air supply is organized, in addition to the natural inflow. In the absence of normal ventilation, the performance of a wall-mounted boiler decreases, and normal air flow ensures fuel combustion without residues, therefore the efficiency indicator increases.

The system performs the following functions:

- supplies oxygen in the volume needed for gas combustion;

- the hood removes smoke and carbon monoxide;

- removes accidental gas emissions that cause poisoning of domestic animals and humans.

Insulation of the foundation in a private house

Unfortunately, it is through the foundation of the house that the cold enters the room. Basements are often built and equipped for the residents' personal purposes (stock storage, laundry, etc.). In this case, thermal insulation is especially important.

The waterproofing of premises is also influenced to some extent by the insulation of the foundation.

You can determine the main advantages of thermal insulation of the lower part of the building:

Two insulation technologies are used: pouring the foundation and simultaneous installation of a thermal insulation layer or insulation after the concrete has completely dried. Experts prefer the first option.

This technology is expensive because it uses polystyrene foam boards. The advantage of this type of thermal insulation is that there is no need for additional insulation.

Properly executed insulation of a private house not only provides comfortable living conditions for its owners, but also extends the life of the building itself, protecting building structures from destruction.

Conclusions and useful video on the topic

The following video will introduce you to the features of the air exchange system in a house made of aerated concrete:

Properly selected and installed ventilation in a gas block house is the key to the well-being and health of household members. Natural ventilation is suitable for small houses, but for large buildings with many rooms, a mechanical system is the best solution.

You can select and install ventilation either independently or by entrusting it to builders, but in both cases it is recommended to do this at the design (planning) and construction stage of the house.

Do you want to share your own experience in installing a ventilation system in a house made of aerated concrete blocks? Please leave comments in the form below. In it you can ask questions, post photos on the topic of the article, and give useful recommendations to site visitors.