Lamps - class of protection against electric shock.

Lamps, like any electrical equipment, are classified according to classes of protection against electric shock according to the IEC 61140 .

Please note that the class number does not express the degree of protection of the luminaire, but only determines the method of protection against electric shock.

In this article, we do not provide an exact excerpt from the standard, trying to characterize as simply as possible how this standard applies to lamps.

Protection class 0 - a luminaire that has protection only in the form of a single layer of insulation. If the insulation is broken, electric shock through the lamp body may occur. IEC 61140 recommends that Class 0 electrical equipment be excluded from international standardization in the future.

Protection class I is a lamp that has an additional terminal - grounding (otherwise - a neutral protective conductor) - in case of a malfunction. The connection point for the protective neutral conductor must be clearly marked with either the letters PE or a combination of green and yellow.

Protection class II is a luminaire that uses double insulation to increase the degree of protection. Luminaires with protection class II must be marked with a graphic symbol located next to the information about the power source.

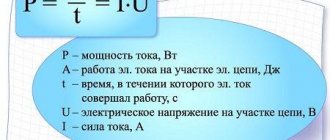

Protection class III is a protection method based on limiting voltage to ultra-low values - such luminaires are designed for a rated voltage not exceeding 50 V AC and 120 V DC. If the main insulation is damaged, the exposed conductive part cannot be exposed to dangerous voltages exceeding extra-low voltage values.

Class III electrical equipment is used in particularly hazardous environments where the potential for electric shock is extremely high. For example, portable lights used in confined spaces with conductive floors and walls, lights installed in fountains and pools, and other similar electrical equipment must be Class III.

Source

Protection classes of luminaires

Protection classes of luminairesLamps should not only be beautiful and emit high-quality light. They must also provide maximum security. Such safety can only be guaranteed if the luminaires comply with the technical requirements of international safety directives.

Electric shock protection classes

For the electrical reliability of luminaires, preventive measures are required to prevent the occurrence of voltage on accessible metal parts. The division into protection classes provides information about each such protection measure (Table 10.8).

Electric shock protection classes

Table 10.8

Protection class

| Symbol | Protection measures |

| I | Protection against breakdown is provided not only by working insulation (on all parts of the OP), but also by grounding of conductive parts accessible to touch with a flexible conductor from the supply network. This symbol indicates the terminal for connecting the protective ground |

| II | Double reinforced insulation - live parts are provided with additional (to working) protective insulation. Grounding connection is prohibited |

| III | Protection is provided by connecting the luminaire to a power system with low protective voltage (up to 42 V) |

Fire/flammability

protection classes Lighting fixtures emit heat during operation. Lamps installed directly on flammable materials are marked with the following symbols (Table 10.9).

Flame/flammability classes

Table 10.9

| Symbol | Meaning |

| Installation on normally flammable materials is allowed. The maximum permissible temperature on the mounting surface is 180″C | |

| Installation on difficult to flammable and normally flammable materials is allowed. Maximum permissible temperature on the mounting surface ZO»S | |

| Installation on materials whose flammability is unknown is allowed. The maximum permissible temperature on the mounting surface is 115″C | |

| Fixed luminaires suitable for installation only on surfaces made of non-combustible material |

Imply that the material is normally flammable

- this is a material that has an ignition temperature of at least 200 ° C, does not soften or deform before reaching this temperature.

For example,

wood and wood-based materials with a thickness of more than 2 mm.

Incombustible

material - a material that is not capable of supporting combustion: metal, gypsum, concrete, etc.

Support (mounting)

surface - part of the structure of a building, furniture and other structure in/on which a luminaire can be mounted, suspended or placed for normal use and which serves or will serve as a support.

Differences between class and degree of protection

The concept of “luminaire protection class” refers to ensuring electrical safety when fingers and tools come into contact with conductive parts. Regulated by international GOST IEC61140-2112 with general provisions on the safety of installations and equipment. It sets out the requirements for the insulation of parts exposed to current. The electrical enclosure must provide complete protection from mechanical damage, internal and external influences. This classification is provided for carrying out measures to ensure the safety of electric shock:

| Protection class | Methods of protection | Notes |

| An ordinary layer of insulation, if violated, there is a risk of electric shock from touching the lamp | Use only in a non-conductive environment or with separation of wires and housing. Plugging into an outlet using a two-pin plug | |

| I | Output of an additional neutral conductor (grounding), the connection location of which is indicated by a combination of yellow and green colors, icon No. 5019 or PE symbols | In addition to the basic insulation on metal parts, parts accessible to touch are grounded. These include industrial, street devices |

| II | Using double insulation marked No. 5172 | It is not designed for protection in electrical installations, as it does not have a grounding contact. Used for indoor lighting. Supplied with double or reinforced insulation |

| III | LED luminaires designed for the voltage range specified by the manufacturer, but not more than 50V AC and 120V DC. If the main insulation is damaged, there will be no voltage on the exposed conductive part above the extra-low voltage. Identified by numbers No. 5180 | It is used in places where there is a risk of electric shock, namely in the area of vertically falling drops, water jets, splashes, immersion in water |

Each manufacturer or selling organization is required to provide technical instructions for installation and proper use of light sources. Examples of LED lamps:

Table lamp with protection class 0

Industrial luminaire, class I

Office, class II

Pool light, class III

The wording “degree of protection for luminaires IP” means preventing the ingress of moisture and dust, which have a harmful effect on the operation of the devices. It is marked, according to international standards, in addition to the alphabetic abbreviation, with two numbers. The first of them indicates compliance with the conditions for protection from dust particles, the second - from liquids.

Marking of the degree of protection of lamps

Let's consider a table describing the existing degrees of protection of LED lamps:

Table of degrees of protection with description

Let's take lamps with IP20 protection level. Based on the data provided, we can say that they are able to prevent dust from entering, but will not be able to prevent moisture from entering. Therefore, they are used only in dry rooms, protected from exposure to steam and condensation. These include residential buildings, offices, commercial buildings, medical, cultural and educational institutions.

If we compare other options, we can draw the following conclusions:

| IP21, 22 - suitable for light industry workshops, if technological features do not require ideal cleanliness, in spaces where there is a risk of condensation formation and the presence of installations containing liquids |

|

| IP40 is a standard version of the luminaire for shopping centers and stores, which does not have a degree of protection against moisture |

|

| Devices with IP43, IP44 can be installed in a humid environment - bathrooms. Cantilever or pedestal with an optical block that prevents dirt from covering the lamp and reflector, suitable for street lighting |

|

| IP54 – used in heavy industry, places with high pollution, large amounts of dust and corrosive particles |

|

| IP53, 54, 55 – applicable in the food industry or public catering, depending on the processed products |

|

| IP65, IP66, IP67, IP68 - belong to the groups of floodlight street and industrial lighting. They withstand atmospheric influences, are not afraid of fine and coarse elements, water under pressure, and the last two categories are able to withstand immersion to depths for several minutes |

|

Designations in Latin letters are added as an auxiliary mark. Four of them, located in the column on the left, display the level of protection against contact with dangerous parts:

- A – inner side of the hand;

- B – fingers;

- C – tool;

- D – wires or wire.

Must be indicated in two cases. In the first - when the degree of protection of the lamp from the penetration of dust and solid particles has not been determined, but it is necessary to note the indicator when touched. In the second - if this parameter is not higher than the third level, and the degree of protection against contact exceeds it. Let’s say the device has a protection unit of 3. This means that an object with a diameter of more than 2.5 mm will not be able to get into the housing, except for a thin wire or a screwdriver with a narrow tip. Then the symbol C is added to the marking.

Additional images in the right column are necessary to clarify the features of objects and actions, such as:

- H – accessories for high-voltage units;

- M – testing the level of protection against water ingress during operation;

- S – at the time of the water test, the equipment was not working;

- W – availability of protection in all weather conditions.

How to choose a lamp by protection class

Frequently used degrees of IP protection for luminaires:

- IP20 – lighting devices recommended for installation in rooms with a normal environment. Such facilities should be free of pollution or humid air. Typically these include offices, shopping centers, and entertainment venues.

- IP21 , IP22 – equipment is intended for cold shops. With this protection class, moisture or condensation cannot penetrate into the device.

- IP23 . These lighting devices include devices for lighting construction sites.

- IP40 . – lighting for shops and shopping centers. Such devices are not waterproof.

- IP43 , IP44 . Outdoor luminaires for installation at low heights, where foreign bodies and water cannot enter. Often installed in baths and saunas.

- IP50 . Can be used in rooms with high concentrations of dust in the air. Such devices are sealed and easy to clean from dirt. Even with serious mechanical impact, the lamp will not be destroyed, and small elements will not fall out of it. This is especially important in food production.

Lamps in production.

- IP53 , 54 , 55 – used at food industry facilities or catering outlets. There are restrictions on the type of products. Devices marked IP54 are installed in heavy industrial facilities, as well as in places with a large number of corrosive particles and severe air pollution.

- IP67 , IP68 . These lighting devices can be used underwater - installed in fountains and pools.

In addition to the IP protection degree, lighting devices are marked with Latin letters, which act as an additional designation. Four of them, located in the left column, show the level of safety of devices when in contact with them:

- A – inner side of the hand;

- B – such lamps are protected from touching with fingers;

- C – various instruments;

- D – wires or other conductive products.

For example, the device has a unit of measurement of 3. This means that an object with a diameter exceeding 2.5 mm cannot enter the housing. Then the symbol “C” is indicated in the marking. Such devices include ordinary household lamps in chandeliers.

Household lamps in chandeliers.

In the right column of markings, additional images are indicated to clarify the features of objects and actions:

- H – relation to the class of high-voltage devices;

- M – indicates whether the level of protection against moisture ingress during operation was tested;

- S – the device did not work when tested in an aquatic environment;

- W – availability of a sufficient level of protection during operation in various weather conditions.

Thematic video: Briefly about the degree of protection of lamps

Depending on the level of protection, a lamp is selected for specific operating conditions.

Features of the classification of anti-vandal lamps

The most vulnerable parts to mechanical stress are the body and the diffuser. In public places, light sources are often subject to destruction and theft. To prevent this, special measures have been developed: manufacturing the housing from particularly durable materials, producing a diffuser from shockproof polycarbonate, and concealed fasteners.

Anti-vandal lamp

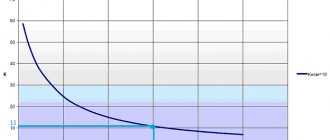

The degree of protection against vandalism is established by the IEC 62262:20020 standard and is determined by the IK code. The differences between classes are expressed in impact force and are measured in joules (SI). The highest degree 10 can withstand a load falling from a height of 40 cm and a weight of 5 kg.

| Protection class | Hammer weight | Drop height | Impact energy |

| IK01 | 0.2 kg | 7.5 cm | 0.15 J |

| IK02 | 0.2 kg | 10 cm | 0.20 J |

| IK03 | 0.2 kg | 17.5 cm | 0.35 J |

| IK04 | 0.2 kg | 25 cm | 0.50 J |

| IK05 | 0.2 kg | 35 cm | 0.70 J |

| IK06 | 0.5 kg | 20 cm | 1 J |

| IK07 | 0.5 kg | 40 cm | 2 J |

| IK08 | 1.7 kg | 29.5 cm | 5 J |

| IK09 | 5.0 kg | 20 cm | 10 J |

| IK010 | 5.0 kg | 40 cm | 20 J |

Lamps equipped with reinforced shades have a range of IK04-06. And the most durable models are those with code IK07.

Class 0

It is easy to guess that in this case there are no protective equipment. In fact, only an insulating layer can protect a person from current in this case.

This class means that the electrical circuit is in no way connected to the ground loop or other protective elements.

However, the case is not equipped with any voltage indicators that could warn a person about the danger.

If the insulating layer is damaged, only the floor covering can protect you from electric shock. If you stand on a wet floor and touch the body, you will definitely be electrocuted.

The International Electrotechnical Commission does not endorse the use of such protection in any appliance. However, the Electrical Installation Rules suggest the possibility of using luminaires with this class.

In our opinion, if you use zero protection, then only in places far from grounded conductive parts and where only employees can enter.

It is precisely because of the strict requirements for electrical safety rules that today it is impossible to use zero protection in all devices except lamps.

Fire protection

This formulation includes all surfaces on which luminaires are installed. They have the following protection classifications:

| Fastening places | Characteristics of building materials | |

| No markings | Fixation on non-flammable surfaces | Concrete, stone |

| Fixation on low flammable surfaces | Fire at temperatures above 200°C, with a slight delay | |

| Fixation on flammable surfaces | Instant combustion at temperatures less than 200°C |

All products sold in retail outlets must contain complete information on the packaging. The degrees of protection are determined by the manufacturers themselves, according to the European standard MEK-529.

How to choose the right degree of protection for LED lamps

This article will be useful to those who are thinking about purchasing electrical equipment, or more precisely, LED lamps.

In it we will tell you:

- What is the degree of IP security?

- How to choose it correctly and what to pay attention to.

- What level of protection is needed in rooms with high humidity.

- What degree will be sufficient to illuminate street areas?

- Protection for rooms with high dust levels.

Moisture protection level

This indicator in the IP marking is displayed as the second digit, and there are eight degrees of protection; the higher the number, the better the protection of the lamp from moisture. Protection from moisture is relevant if the device is installed outdoors or used in rooms with high humidity, such as bathrooms. Each number also corresponds to its own level.

| Level | Description |

| 0 | The developers have not provided any structural protection |

| 1 | Minimum level of protection, only individual drops are allowed to fall on the lamp, and strictly vertically |

| 2 | The product is protected from individual drops falling at an angle of no more than 15 degrees |

| 3 | The lamp is not afraid of drops and splashes coming from any direction. This level of protection is considered medium |

| 4 | The product can additionally withstand the impact of water jets from any angle |

| 5 | The product can additionally withstand the impact of water jets from any angle |

| 6 | The lamp is able to withstand direct exposure to jets of water, regardless of the pressure |

| 7 | You can completely immerse the lighting fixture under water, but subject to time and maximum depth restrictions. |

| 8 | Complete sealing of the lamp, allowing its operation under water |

First thing you need to know

Any electrical device has its own degree of protection - IP. It characterizes the level of protection of the device from the penetration of dust and moisture into the housing. As a rule, this parameter is the key to uninterrupted operation of the LED lamp throughout its entire period of use.

In 1976, the International Electrotechnical Commission adopted a standard that is still in force today. In short, it contains a detailed description of the tests that result in determining the level of protection of the equipment. This level is indicated by the IP sign and two numbers next to it. The first number shows the class of protection of the case against the penetration of solid particles, the second - about resistance to moisture getting inside.

IP67 - complete dust protection and moisture resistance

Levels of protection against dust and other particulate matter

This characteristic provides not only a level of protection against dust, but also other solid particles. The higher the protection class, the higher the first digit in the IP marking will be. Each of the numbers provides a certain level.

| Level | Description |

| 0 | The luminaire does not have any protection against penetration of solid elements |

| 1 | Protection is provided only from large objects measuring 50 mm or more, for example, a human hand |

| 2 | Reliable protection is provided against all objects larger than 12 mm, such as fingers |

| 3 | Provides protection against any objects thicker than 2.5 mm, for example, it cannot be reached with a screwdriver or knife |

| 4 | The product has a high degree of security, blocking the penetration of any objects except dust, while the latter leaks in volumes that do not interfere with the full and safe use of the lighting device |

| 5 | The lamp has a high degree of security, blocking the penetration of any objects except dust, while the latter leaks in volumes that do not interfere with the full and safe use of the lighting device |

| 6 | The device is completely protected from any foreign penetration, ensuring the tightness of the internal space |

How to determine the degree of IP protection for LED lamps

The safety level of an LED luminaire is determined by a test that tests how well its housing protects its internal components from the penetration of foreign objects or water. For example, checking the device for moisture resistance.

Testing LED lamps for moisture resistance IP68

An important point: as a rule, the protection class of the entire device is determined by the least protected element. But here there are two options:

- If the power supply is not isolated and has IP40 protection, then the equipment cannot have an IP higher than 40, say IP54.

- However, if the IP20 power supply is isolated and located inside the device, such as in Armstrong lamps, then the device as a whole can have IP40 protection.

Now let's take a closer look at what each number in the IPXX marking means. So, the first number:

0-6: dust resistance.

This figure characterizes the level of protection of the lighting device from the penetration of solid particles. For example, such as: a screwdriver, wire, cable or dust. They can be in the range from 0 to 6, where 0 is the minimum security level, and 6 is the maximum.

- 0 — The LED device has no protection.

- 1 - protected from objects ⌀ ≥50 mm.

- 2 — ⌀ ≥12.5 mm.

- 3 — ⌀ ≥2.5 mm.

- 4 — ⌀ ≥1 mm.

- 5 - partial dust protection.

- 6 - complete dust protection.

0-6: degrees of protection from solid particles.

Next is the designation of the second digit in the marking:

0-8: moisture resistance

This figure indicates the moisture resistance of LED equipment. It can be in the range from 0 to 8. Accordingly, 0 is the absence of protection, and 8 is the full functionality of the equipment under water.

- 0 - the lamp is not protected.

- 1 - protected from drops falling vertically.

- 2 - drops when the device is tilted up to 15° will not cause harm.

- 3 - rain resistance.

- 4 - from splashing water from any direction.

- 5 - the body of such a device can be easily washed with a stream of water.

- 6 - protection against high pressure water.

- 7 - a short immersion of the device under water of 0.15 - 1.00 m is allowed, but without using it.

- 8 - operating equipment in water for more than 30 minutes.

0-8: device waterproof levels

Another important point. It happens that the security class is indicated in the product passport or on the box, for example, IPX7. What does it mean? In general, according to GOST, the letter X indicates that there is no need to standardize this parameter. To put it simply, the manufacturer says that for certain reasons the device will not be exposed to such effects. At the same time, IPX7 provides us with absolute moisture resistance, which also guarantees resistance to dust.

International approach to classifying the degree of protection against electricity

There is a special marking - IP. This is an international approach to classifying electrical protection equipment. After the marking there are two numbers, the first means:

- 0—no protection.

- 1 - particles up to 5 mm will not enter.

- 2 - particle isolation up to 12 mm.

- 3 - up to 2.5 mm.

- 4 - up to 1 mm.

- 5 - partial protection from dust.

- 6 - dust penetration is impossible.

Designation of the second digit:

- 0 - only for dry conditions, no protection.

- 1 - protection against droplets falling almost vertically.

- 3 - protection against droplets falling on the device at an angle of 15°.

- 3 - 60°, suitable for working in the rain.

- 4 - for working in very heavy rain.

- 5 - protection against jets of water.

- 6 - from a strong jet.

- 7 - work is allowed when immersed in water (not for long).

- 8 - complete isolation from water.

Additional letters may also be used:

- A - protection against contact with the back of the hand.

- B - from touching with a finger.

- C - protection against contact with other machines.

- D - from connection with the conductor.

- H - high-voltage equipment.

- K - the device can be washed under pressure.

- M - the device is protected from water penetration (tests were carried out).

- S - the device did not work when tested with protection against moisture penetration.

- W - the device can be used in adverse conditions.

It is extremely important to study all equipment parameters, since operator safety depends on them. The information provided is enough to understand how many classes hand-held power tools are produced in.

Source

What IP LED lamps are most common?

For clarity, here are a few of the most popular security classes, so that the difference between them is better visible:

1. IP20 . As a rule, they are used in interior lighting - dry and well-heated offices, shops and some industrial premises. We do not recommend using it outdoors, even under a canopy - LED equipment may not work out its stated lifespan.

LED lamps IP20 in the interior

2.IP54 . _ Typically used in clean rooms where higher demands are placed on the lighting system. As a rule, these are medical institutions - hospitals, dentists, rehabilitation centers, etc.

IP54 LED equipment in a hospital

3. IP65 - IP66 . They are completely dustproof and have a sufficient level of moisture resistance. Well suited for lighting production facilities, gas stations, washing complexes and other objects with high dust levels and moisture levels. Among LED devices in this category, street lighting devices are often found. That is, for lighting roads, local areas or courtyards, you can safely use lamps with IP65 and higher, up to IP68.

IP65 devices in a car wash

4. IP67 . A characteristic feature is that they can be completely immersed in water and this will not affect their performance. Accordingly, these LED devices can be installed in all rooms with high humidity, be it a swimming pool or a sauna. Also, equipment of this class is often used in street lighting.

LED devices IP67 in the pool

Source

Connecting electrical equipment of protection class II

Today is a fairly easy topic in which we will discuss connecting electrical equipment that has protection class II. Despite the fact that everything is quite simple here, we will try to look at it all from a slightly different angle.

It is no secret that there are 4 classes of protection of electrical equipment from electric shock.

First, let's look at GOST R IEC 61140-2000 (Protection against electric shock. General provisions for safety provided by electrical equipment and electrical installations in their interrelation):

7.1 Electrical equipment of protection class 0 ELECTRICAL EQUIPMENT with BASIC INSULATION as a measure for BASIC PROTECTION, without providing PROTECTION IN THE PRESENCE OF A FAULT.

7.2 Electrical equipment of protection class I ELECTRICAL EQUIPMENT with BASIC INSULATION as a measure of BASIC PROTECTION and POTENTIAL BASIS as PROTECTION IN THE PRESENCE OF A FAULT.

7.3 Electrical equipment class II ELECTRICAL EQUIPMENT using:

— BASIC INSULATION as a measure of BASIC PROTECTION and

— SUPPLEMENTARY INSULATION as a PROTECTION MEASURE IN THE PRESENCE OF A FAULT, or in which:

— BASIC PROTECTION and FAULT PROTECTION are provided by REINFORCED INSULATION.

7.4 Electrical equipment of protection class III ELECTRICAL EQUIPMENT, which is based on limiting the voltage to ultra-low values as a BASIC PROTECTION measure, and not as a PROTECTION measure IN THE PRESENCE OF A FAULT.

Application of electrical equipment in an electrical installation

In general, electrical equipment of protection class II has double or reinforced insulation and does not require the connection of a protective grounding conductor PE. These products do not have a grounding terminal. We can say that connecting current equipment will cost less, because... You can save on one cable core.

However, when I was at one site that I had to do, I had a discussion with the energy engineer. The electrical installation was almost completed and I needed to sketch everything and reflect it in the project. Protection class II LED lamps were installed in the sales area. I was surprised when the power engineer said that a three-wire cable was needed to connect these lamps. At first I thought it was nonsense, but then I understood his point.

It turns out that the PE conductor is necessary to protect the cable itself, so that protective devices work correctly if the insulation is damaged. For example, the insulation was damaged - a current leak occurred, the RCD tripped. But, the most interesting thing is that a general fire protection RCD was not installed at this facility; there were automatic switches on the group lighting lines. According to the energy industry in the USA, a non-insulated PE core is used for these purposes. Is this true? But, our PE conductor has its own insulation and the likelihood that the external insulation of the cable and the insulation of the conductors will be damaged in one place at the same time is not so great. The phase conductor may be damaged, but the PE conductor will be insulated and no current leakage will occur. Therefore, in our conditions this is not very relevant.

At the same time, I would like to say hello to the “6th Element” organization in Gomel. In appearance they seemed like a decent organization, but when it came down to it, they simply said that they no longer needed my project, arguing that they could no longer wait for the project, while they did not sign the contract (accordingly, we did not receive an advance), plans for work They didn’t provide it, but I was waiting for them. I only managed to sketch everything they had done and make diagrams of the electrical panels. I wasted my time and got nothing. Even though the store was quite large, I planned to make it in 2 days. Now someone will have to sketch everything out again, they think it will work out faster... By the way, at this site the PVS and SHVVP wire again showed its worth.

Such is the fate of the designer - they throw everything and everywhere

Question (Electrical Engineering News): Expert's comment: “make single-phase group lines three-wire, regardless of the protection class of the lamps (SP 256.1325800.2016, clause 10.1).” Design solution: lamps of class II protection against electric shock were used. In my opinion, the requirement of clause 10.1 of SP 256.1325800.2016 is general and does not apply to all cases, including the specified design solution. In normal mode, main insulation protects lamps from electric shock; in case of damage to the main insulation, double insulation protects them, because lamps belong to class II (base: PUE, clauses 1.7.50, 1.7.51). The use of three-wire lines is not justified. An example of non-compliance with clause 10.1 is, for example, the power supply of a three-phase asynchronous electric motor (electric drive of a residential building elevator) with a four-wire line (L1, L2, L3, PE), although clause 10.1 states that three-phase lines must be five-wire. Who is right? Answer: Alexander Shalygin.

Let me start with the fact that the concept of a “three-wire line” consisting of L, N and PE conductors, adopted in Chapter 1.7 of the PUE, 7th edition, is in principle incorrect and contradicts current national and international standards. Such a line is defined as two-wire by the number of working conductors, and the PE wire is not taken into account. Norm SP 256.1325800.2016 was borrowed from SP 31-110-2003 and has not been updated, although the question of its clarification has been repeatedly raised before. As one of the developers of the joint venture, I will explain why the norm was adopted in this formulation. In residential premises and a number of public buildings, in most cases the class of luminaires is not determined during design, so we decided to use three-core cables as a universal solution “for all occasions”. This standard does not reflect the fact that there are places where the use of class II lamps is normatively defined, for example, zone 2 bathrooms. In this case, the use of a three-core cable with a PE conductor is not only unnecessary, but also dangerous.

I recommend reading:

Amendment No. 7 to SNiP II-35-76

#20 Connecting instantaneous water heaters (analysis of comments)

Regulatory documents for the preparation of electrical drawings

Symbols of switches and sockets

Electrical safety classes

The classification of electrical safety levels of luminaires is established by the state standard GOST R IEC 60598-1-2011. It describes 4 main classes of protection for users from electric shock:

0 class

The electrical safety of the device is ensured only by a single layer of insulation. If it is damaged, there is a risk of electrical injury to the user as a result of contact with the lamp. Devices of this class can only be used in a non-conductive environment or if the wires and the housing are separated. The lamp may only be plugged into an outlet using a two-pin plug.

I class

In addition to the main insulating layer, the device is equipped with a neutral conductor (grounded). The conductor connection point is marked with the symbols “No. 5019”, the letter index PE or a graphic icon combining yellow and green colors. All metal elements of luminaires accessible to the touch of users must be grounded. Devices with this level of electrical protection are used outdoors, as well as in industrial enterprises.

II class

The design of the device does not provide for an additional grounding contact, but the insulation of this class is two-layer or reinforced (marked with the symbols “No. 5172”). These lamps cannot be used in electrical installations; they are intended for indoor use.

III class

Device protection is designed to operate from low voltage networks (no more than 50 V AC and no more than 120 V DC). The devices are designed in such a way that even if the insulating layer is damaged, it is impossible to get electrical injuries - the voltage on the conductive elements is ultra-low. Such lamps are allowed to be used, including in areas where they may be exposed to splashes and jets of water falling vertically. Equipment with an appropriate degree of moisture protection can also be submerged under water. Class III devices can be identified by the marking “No. 5180”.

Electrical safety classes according to GOST

LED lamps, for all their advantages, remain electrical devices. They pose a certain danger to humans. This aspect is regulated by current regulations. For example, there are several degrees of protection against electric shock, which are established by GOST R IEC 60598-1-2011.

Let's consider the existing electrical safety classes of lamps.

- Class 0. Basic insulation is the main protection of a luminaire with this class. The design does not involve the connection of conductive elements that can be touched. The outer shell is the main insulation.

- Class I. To increase electrical safety, the design of the luminaire includes both basic insulation and connection of conductive parts through which no current passes to the grounding of stationary wiring. And even if these parts are damaged, they should not become live.

- Class II. Such luminaires provide basic and reinforced insulation. The design does not imply the presence of a protective grounding device or special means in the electrical installation.

- Class III. The luminaires use low supply voltage. It is maintained at a safe level. The design does not have grounding clamps. In the internal circuits of lamps, the voltage does not exceed 50 V AC and 120 V DC.

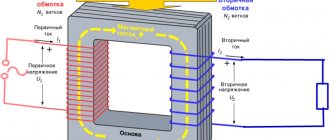

If a converter or transformer is used as a power source, its windings should not be electrically connected, but reinforced insulation should be provided between them.

Additional classification

There are other electrical safety classes according to GOST. The protection of LED lamps from touching their live parts is designated as IP-XY, where instead of X and Y the numbers corresponding to the degree of protection from solid particles and water are indicated:

- “0” – no protection;

- “1” – barrier against contact with objects (parts of the body) with a diameter of over 50 mm;

- “2” – protection against penetration of objects (fingers) with a diameter of more than 12 mm;

- “3” – barrier against contact with objects (screwdrivers) with a diameter of over 2.5 mm;

- “4” – protection against access by elements (wire) with a diameter of more than 1 mm;

- “5” and “6” – a barrier against dust penetration and complete protection of people.

Hand-held lamps must be equipped with a handle made of insulating material. The products have a thick wire grille that prevents the adverse effects of lamps after mechanical impact.

Taking into account the specified electrical safety class for a specific LED lamp contributes to its safe and efficient use, therefore not only specialists at production enterprises, but also ordinary consumers should be familiar with such information. This will improve culture and reduce the risks of using electrical products.