Many years have passed since the creation of electric motors. It is difficult to imagine enterprises that would not use electric motors. Electric motors have found their application everywhere, from small household appliances and devices to powerful industrial electric motors that perform heavy work.

Electric motors are produced in three types:

- Asynchronous electric motors

- Synchronous electric motors

- DC motors

Asynchronous electric motors are divided into two types:

- Asynchronous electric motor with squirrel cage rotor

- Asynchronous electric motor with wound rotor

The most commonly used electric motors in industry are asynchronous electric motors with a squirrel-cage rotor. For long-term heavy loads, synchronous electric motors are used. Where it is necessary to change the rotation speed of an electric motor, according to technological requirements, asynchronous electric motors with a wound rotor and DC electric motors are used.

Regardless of the type of electric motors, their installation and proper operation are required. When installing and servicing electric motors, safety precautions must be observed.

Safety precautions when installing electric motors.

To install an electric motor, a clear design is required. The project indicates the installation location of the electric motor, indicates in conjunction with which unit it will work, calculation of wires, loads. It is more convenient to turn to specialized design workshops for design, as this increases safety.

To install the electric motor at the installation site, it is necessary to hire professional installers who have been working for several years. Electric motors of low power (up to 10 kW), light weight (up to 50 kg) can be installed independently, after installation by inviting a team of installers to check.

The cross-section of the wires is selected according to formulas, taking into account that a copper wire with a cross-section of 2.5 mm2 can withstand loads of up to 30 Amperes.

The power calculation formula for a three-phase circuit is P= 1.7*U*Y. Where U is voltage, Y is current, and 1.7 is the square root of 3. By redoing the formula, we get the calculation of the current for an electric motor with a power of 10 kW, Y = 10000 W / (1.7 * 380 Volt) = 15 amperes. The proportion is 2.5 mm2-30 Ampere Xmm2-15 Ampere X = (15 Ampere * 2.5 mm2) / 30 Ampere = 1.25 mm2 There is no such cross-section of wires in the standard range, so select a wire with a cross-section of 1.5 mm2.

When installing yourself, you need to be extremely careful. Even a small electric motor can cause injury to installers. Whenever possible, work should be done using tried and tested lifting mechanisms. Use levers, work in protective equipment: a helmet, safety glasses, overalls, mittens, special shoes.

Explain to employees how to work safely. When lifting the electric motor from the floor to a height of more than 1 meter, you must not approach the electric motor; you can level it and direct the electric motor to the installation site only after the motor is at a height of several centimeters from the floor.

When moving and lowering, do not hold the electric motor by the lower part. When connecting the power cable to the electric motor, work is performed with the voltage removed. The circuit breaker is turned off, and a sign “Do not turn on!” is hung on the handle. People are working." The outgoing cable wires are uncoupled from the circuit breaker, having first checked that there is no voltage at the contacts.

After installing, securing, and connecting the electric motor, first start the electric motor without load, that is, without connecting it to the unit. After checking, check the electric motor in conjunction with the unit by applying a load.

Safety rules when performing work on servicing electric motors.

6.4.1. When work involves touching live parts of the electric motor or rotating parts of the electric motor and the mechanism driven by it, it is necessary to stop “Do not turn on!” sign on its starter or control key. People are working."

6.4.2. When working on an electric motor with a voltage higher than 1000 V or a mechanism driven by it, which involves touching live or rotating parts, the voltage must be removed from the electric motor...

When working on an electric motor, grounding is installed on the cable (with or without disconnecting it from the electric motor) or at its connection in the switchgear.

..

6.4.3. Before allowing pumps, smoke exhausters and fans to operate on electric motors, if rotation of the electric motors from the mechanisms connected to them is possible, the valves of these mechanisms must be closed and locked , and measures must be taken to slow down the rotors of the electric motors.

6.4.6. A single-person operator or a trained person with group III assigned for this purpose is allowed to service the brush apparatus of a running electric motor. In this case, the following safety precautions must be observed:

- work in a hat and buttoned-up overalls, being careful not to get caught by the rotating parts of the machine ;

use dielectric shoes or rubber mats ;

- do not touch live parts of two poles or live and grounded parts with your hands at the same time.

Rotor rings may only be ground on a rotating electric motor using pads made of insulating material and safety glasses .

6.4.9. On electric motors of the same type or similar in size, installed next to the one on which work is being carried out, posters “Stop! Voltage" regardless of whether they are in operation or in reserve.

6.4.10. Testing of electric drives together with the actuator should be carried out with the permission of the shift supervisor of the technological workshop in which they are installed.

An entry about the issuance of a permit is made in the operational journal of the technological workshop, and about the receipt of this permit - in the operational journal of the workshop (site) conducting the testing.

6.4.12. The electric motor is turned on for testing until the work is completed after the team has left the workplace.

TICKET No. 14

Joule-Lenz law.

Work and power of electric current. Joule-Lenz law.

| Work and power of electric current. | |

| Work of electric current: A=I*U*t=I2*R*t=U2*R*t | A=I*U*t=I2*R*t=U2*R*t |

| Electric current power (work per unit time): P=A/t=I*U=I2*R=U2/R | P=A/t=I*U=I2*R=U2/R |

| Sometimes an off-system unit of electric current work is used - kW⋅h (kilowatt-hour). | 1kWh=3.6⋅106J |

| Joule-Lenz law. | |

| In an electrical circuit, the energy of the ordered movement of charged particles is converted into heat. According to the law of conservation of energy, the work done by the current is equal to the amount of heat released. The amount of heat released when an electric current passes through a conductor is directly proportional to the square of the current, the resistance of the conductor and the time during which the current flowed: Q=I2Rt | Q=I2Rt |

Safety precautions when operating electrical machines.

When operating electric motors, basic safety rules must be observed. Do not touch the rotating, moving parts of electric motors and the devices connected to them during their operation. You cannot check with your hands which direction of rotation the electric motor is turned on. Do not push objects through the holes on the motor impeller housing. You should not be near an electric motor with flying clothes. Clothing must be buttoned. Do not allow water, oils, or other liquids to come into contact with a running electric motor. It is prohibited to open the Brno cover (the cover of the box in which the cable is connected to the EM contacts) of the electric motor while it is running. You cannot stand on a running electric motor.

The couplings of the electric motor and the unit must be covered with a protective casing to prevent various foreign objects, animals and people from getting on them. It is recommended to cover the electric motor itself with visors if production processes involve the transfer of liquids. Do not throw various objects towards a running electric motor. It is prohibited to disassemble or carry out repair work on a running electric motor. All repair work is carried out only with the electric motor switched off and de-energized.

27. Labor protection when performing work on electric motors.

27.1. If work on an electric motor or a mechanism driven by it involves touching live and rotating parts, the electric motor must be turned off and the technical measures provided for in the Rules must be taken to prevent it from being switched on by mistake. In this case, both power circuits of the stator windings must be disconnected and disassembled for a two-speed electric motor.

Work that does not involve touching live or rotating parts of the electric motor and the mechanism driven by it is permitted to be carried out with the electric motor running.

It is prohibited to remove guards on rotating parts of a running electric motor and mechanism.

27.2. When working on an electric motor, it is legal to install grounding on any section of the cable line connecting the electric motor to the switchgear section, panel, or assembly.

If work on the electric motor is designed for a long period of time, is not performed or is interrupted for several days, then the cable cable disconnected from it must also be grounded on the electric motor side.

In cases where the cross-section of the cable cores does not allow the use of portable grounding, for electric motors with voltages up to 1000 V, it is allowed to ground the cable line with a copper conductor with a cross-section not less than the cross-section of the cable core, or to connect the cable cores together and insulate them. Such grounding or connection of cable cores should be taken into account in operational documentation along with portable grounding.

27.3. Before permission to work on electric motors capable of rotation due to mechanisms connected to them (smoke exhausters, fans, pumps), the shut-off valve steering wheels (latches, valves, dampers) must be locked. In addition, measures must be taken to slow down the rotors of electric motors or disengage the couplings.

Necessary operations with shut-off valves must be agreed upon with the shift supervisor of the technological workshop or area with an entry in the operational log.

27.4. The voltage must be removed from the circuits for manual remote and automatic control of electric drives of shut-off valves and guide vanes.

Posters “Do not open! People are working,” and on keys and control buttons for electric drives of shut-off valves - “Do not turn on! People are working."

27.5. On electric motors of the same type or similar in size, installed next to the engine on which work is to be performed, a poster “Stop! Voltage" regardless of whether they are in operation or stopped.

27.6. Work one at a time on electric motors of the same voltage, units, technological lines, and installations taken out for repair can be carried out under the conditions provided for in paragraph 6.9 of the Rules. Admission to all pre-prepared workplaces is permitted at the same time; registration of transfer from one workplace to another is not required. In this case, it is prohibited to test or put into operation any of the electric motors listed in the work order until the work on the other electric motors has been completed.

27.7. The procedure for turning on the electric motor for testing should be as follows:

- the work manager removes the team from the work site, formalizes the completion of the work and hands over the work order to the operational personnel;

- Operating personnel remove installed grounding connections, posters, and assemble the circuit.

After testing, if it is necessary to continue working on the electric motor, the operating personnel again prepares the workplace and the crew is re-allowed to work on the electric motor.

27.8. Work on a rotating electric motor without contact with live and rotating parts is permitted by order.

27.9. Servicing of the brush apparatus while the electric motor is running may be carried out by order of a group III worker trained for this purpose, subject to the following precautions:

- work using face and eye protection, wearing protective clothing that is buttoned up, being careful not to get caught in the rotating parts of the electric motor;

- use dielectric galoshes and carpets;

- Do not touch live parts of two poles or live and grounded parts with your hands at the same time.

Rotor rings may only be ground on a rotating electric motor using pads made of insulating material.

27.10. The labor safety instructions of the relevant organizations must set out in detail the requirements for preparing the workplace and organizing safe work on electric motors, taking into account the types of electrical machines used, the features of ballasts, the specifics of mechanisms, and technological diagrams.

Source

Safety rules when working on an electric motor.

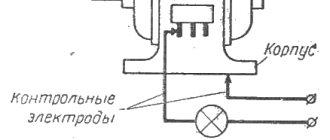

The working electric motor must be grounded; grounding is installed when installing the electric motor. A series connection of groundings is not allowed, that is, there should be no grounding according to the following scheme: electric motor - metal motor control box - grounding loop. The metal box and the electric motor are connected separately to the ground loop.

When the electric motor is running, do not wash it with water or other liquids, do not clean it with a brush, or wipe it with a rag. You cannot check the stability and reliability of the electric motor mounts using a crowbar or a mounting tool. Do not perform any work while standing on the electric motor itself. The place where the electric motor is installed must be well lit. No strangers or animals are allowed near the electric motor. The area around the electric motor must be clean; there should be no flammable substances or objects nearby that block access to the electric motor. There should be no spilled oils or other slippery substances or objects on the floor. It is not allowed to store propane and oxygen cylinders near electric motors. Do not cover the electric motor with fabrics or mineral wool. If necessary, you can cover the electric motor with screens made of non-flammable material to prevent the ingress of water and various small objects.

Safety precautions when repairing electrical machines.

When starting to repair electrical units, the first step is to de-energize them. They will turn off circuit breakers, hang up prohibiting posters after first checking that there is no voltage, install portable grounding connections, and limit the access of unauthorized persons to the electrical equipment being repaired by installing fences. Repair work should only be carried out by qualified personnel.

Repair cases of electrical equipment are:

- Strong heating of cases

- Increased hum

- Sparking during operation.

- Loud noise in the motor bearings.

- Loosening fasteners

- Strong vibration

- Arbitrary stop of the electric motor with protection triggered

- Electric motor fire (!)

If an electric motor catches fire, it is immediately de-energized, firefighters are called, and they begin to extinguish it with carbon dioxide fire extinguishers.

You should not try to extinguish a burning electric motor without turning off the power to it. If necessary, replace the electric motor with a new one. By following the instructions described above, you can protect people from accidents and injuries.