About grounding in simple words

The very concept of “grounding” comes from the word “earth”, that is, soil or soil, the purpose of which is to serve as a drain for dangerous currents flowing through a specially organized circuit. For its formation, an inextricable connection of all parts of the protective system is necessary, which starts from the point of contact of the body of the grounding element and ends with the element of the grounding device (GD) immersed in the ground.

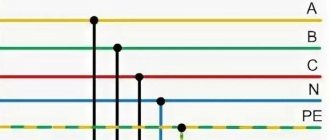

External ground loop of a private house (left). Indoor grounding (right), grounding conductor indicated by dotted line.

According to the definitions given in the technical documentation, grounding is a deliberate electrical connection of the metal housings of units with a special grounding circuit. Based on the facts considered, we can conclude that grounding is the intentional electrical contact of the protected equipment with the ground.

Differences between working and protective grounding

Working and protective grounding differ from each other primarily in purpose. If the first is necessary to ensure the correct and uninterrupted operation of electrical equipment, then the second serves to protect people from electric shock. It also protects equipment from damage in the event of a breakdown of any electrical device on the housing. If the building is equipped with a lightning rod, this type of grounding will protect the devices from overload in the event of a lightning strike.

Working grounding of electrical installations, in the event of an emergency, will play a protective role, but its main function is to ensure the correct uninterrupted operation of electrical equipment.

In its unchanged form, functional grounding is used only in industrial facilities. In residential buildings, a grounding conductor is used, which is connected to the outlet. However, there are household appliances in the house that pose a potential danger to the consumer, so it would not be superfluous to ground them using a solidly grounded neutral.

Household appliances that need to be connected to a working ground:

- Microwave.

- Oven and stove that run on electricity.

- Washing machine.

- System unit of a personal computer.

Grounding Requirements

After you have figured out what is the definition of the very concept of grounding, you can move on to those categories and norms that are introduced by current standards. According to the PUE, the grounding device is primarily subject to the following requirements:

- the purpose of the charger is to effectively drain dangerous currents into the ground, for which purpose their design includes a whole set of conductors and metal rods;

- All parts of the electrical installation, including metal switchboard doors, must be grounded;

- the total contact resistance of the contacts in the grounding system should not exceed 4-30 Ohms;

- when installing it in distributed loads, it is necessary to use a potential equalization system (its purpose is to eliminate uneven voltage distribution).

Additional information: Since the main purpose of grounding is to ensure the safety of personnel working with the equipment, during its operation special attention is paid to the reliability of operation.

The quality of its work is ensured by a whole range of preventive measures and periodically organized tests.

Purpose of functional grounding

In order to understand what is called working grounding, you should know its main purpose - to eliminate the danger of electric shock in the event of a person coming into contact with the body of an electrical installation or its live parts that are currently energized.

This protection is used in networks with a three-phase current distribution system. An insulated neutral is necessary for an electrical network where the voltage does not exceed 1 kV. In networks with voltages above 1 kV, protective grounding can be done with any neutral mode.

Why does a person get electrocuted?

In order to answer the question posed, you will need to familiarize yourself with the malfunctions that periodically occur in existing electrical equipment. The fact is that during its long-term operation, the insulation may be destroyed and the exposed power supply wire may come into contact with the body of the electrical installation.

If the equipment being operated does not have grounding, this threatens the operator working with it with an electric shock (photo on the left). A similar effect occurs when a person’s body accidentally comes into contact with conductive parts of a washing machine or bathtub, for example.

In what cases is grounding necessary?

So why do you need grounding? For clarity, it is worth considering a few examples:

1. For example, there is a dishwasher in the apartment. But for some reason, at a certain moment, a phase appeared on the case, and the case was not grounded. But the neutral of the power line, which leads to the house and provides electricity, is grounded, and taps and batteries are also grounded.

If you are wearing rubber slippers, then upon contact there will be no unpleasant sensations or even the slightest blow. But if there are no shoes, and at the same time the person also grabbed the tap, and the second hand is located on the body, then it becomes a conductor of electric current, which is supplied through the body to the person, and then into the ground to the neutral, and to the substation.

2. If the dishwasher is grounded? What will happen in such a situation? If for some reason a zero appears on the housing, the current will immediately go into the ground. Even if the person is barefoot, even if he is wearing slippers, nothing will happen, the grounding has worked , no electric shock, everyone is safe and sound. One downside, the dishwasher will need to be repaired, but it will still be cheaper and better.

3. The washing machine in the room has broken down, and the equipment body is under voltage. In this case, if the person comes into contact with the body, he will receive an electric shock. This is why grounding is needed, then the current goes into the ground and everything is fine with the person.

The fact is that the resistance of human skin is much higher than the resistance of the wire, and then the current follows the path of least resistance, enters the ground, and the person remains intact. This is one of the simplest examples, which shows why grounding is needed in a house or other building. Without such a system, the risk of receiving an electric shock increases.

Expert opinion

Evgeniy Popov

Electrician, repairman

It is worth taking one more point into account, especially for the owner of a private house this is extremely important information. Even if the structure is built from natural material, the amount of electrical wiring remains the same as in a multi-story residential building, but the natural material is highly flammable. It is on this basis that a grounding system in a private home can prevent the occurrence of unpleasant situations and harmful consequences.

The most terrible event that can happen is a fire; it occurs due to a short circuit or failure of electrical equipment. That is, if doubts and questions arise about why grounding is needed in a private home, you need to realize that such a system protects not only from fires, but also prevents each family member from electric shock.

Expert opinion

Evgeniy Popov

Electrician, repairman

The situations can be quite scary, but they are a clear example of what negligence and disregard for safety precautions can lead to. As you can see, sometimes the consequences can really be the most serious and harmful.

Grounding principle

After familiarizing yourself with the definition of grounding systems and the requirements for them, you should understand what grounding is and what it is intended for. To do this, first of all, you should know that a person’s feet through a reinforced concrete floor always have some contact with the ground.

When a person touches the body of equipment exposed to high potential, current flows through his body and legs into the ground, that is, he is a link in this chain.

Please note: Even small currents are dangerous to humans, and when they reach a value of 100 mA, death is possible.

In order to understand how the grounding system works, it should be taken into account that the housing of electrical equipment is connected to the ground (grounded) through a set of conductors and metal pins. Through this intentional connection, the human critical potential is reduced to a safe level. In this case, emergency currents “flow” through the grounded body to the ground, bypassing the human body.

Why is grounding needed?

Grounding is used to protect people from electric shock. During normal operation of an electrical appliance, its body is reliably isolated from live parts. If the device breaks down, live parts may touch the housing and then it will become energized. Anyone who touches such a device will receive an electric shock.

A circuit breaker will not help in this case, since the current flowing through a person will clearly not be enough to trigger it. But this current is quite enough to deprive a person of health and even life.

To avoid such situations, the housings of all electrical devices that can be touched by a person must be grounded, that is, electrically connected to the ground through conductors. In this case, the current from the device body, and along with it the dangerous voltage, will go into the ground without causing any harm to a person.

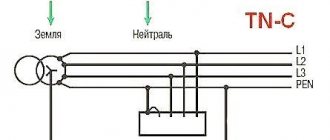

To provide such grounding, Europeans added a grounding wire to the electrical wiring of residential premises. The electrical wiring turned out to be three-wire. Two wires, as in our wiring - phase and zero, are intended to power electrical appliances, and the third is protective grounding.

Sockets of such wiring must have three contacts - neutral, phase and ground. Household appliances designed for such wiring have a three-wire cord and a plug with three contacts. Two wires of the cord are phase and zero, and the third is designed to connect the device body to the grounding of the electrical wiring. The ground contact of the socket (metal strips at the top and bottom) is connected to the protective ground of the electrical wiring. The grounding contact of the plug is connected to the body of the electrical appliance.

By plugging the plug into the socket, we connect the metal body of the device to protective grounding. Now, even when voltage appears on the device body, the entire charge will flow into the ground, and the faulty device will not receive an electric shock.

Grounding household appliances is only possible if the house has a ground loop. Unfortunately, it is not available in old houses. In those days, wiring was done with a two-core wire, one of the wires was zero and the other was phase. Sockets and plugs also had two contacts, neutral and phase. No one thought about any grounding at that time. After all, at that time people had practically no household appliances and six-amp safety plugs were quite enough in their houses. That is, if the power of all electrical receivers turned on in the apartment reached one and a half kilowatts, the plugs would burn out.

With the development of technology, more and more electrical assistants became available in people's homes. Somewhere in the mid-sixties, televisions, refrigerators, washing machines, and electric irons began to appear in homes. The nineties brought computers, automatic washing machines, dishwashers, air conditioners, etc. into our everyday life. Along with the increase in the number and power of electrical receivers, the number of cases of people being electrocuted from faulty electrical appliances began to increase. This problem had to be solved somehow, and since 1997, builders were required to equip all buildings under construction with protective grounding.

In houses of modern construction, all electrical wiring is three-wire, and there are no problems with the operation of modern equipment.

In old houses with two-wire wiring, even perfectly working equipment can receive an electric shock. The fact is that household electrical appliances are equipped with a built-in surge filter that protects the electronic circuits of the device from sudden voltage surges. The design of the filter is such that it connects the neutral and phase wires to the device body through capacitors.

If the device body is not grounded, then a voltage of 110 volts appears on it. That is, on the body of a washing machine, refrigerator, microwave, computer there is a voltage of 110 volts.

If you live in a house with old wiring without grounding and you have some knowledge of electrical engineering, try measuring the voltage on the case of your computer, refrigerator and washing machine. It is quite possible that there will be a voltage of 220 V. This statement looks like nonsense. After all, manufacturers understand perfectly well that the equipment they produce must be absolutely safe for humans and in no case be harmful to their health. But the creators of imported equipment, far from Russian reality, cannot imagine that somewhere it can work without grounding. This circumstance allows us to understand the manufacturer’s logic. The new technique is designed to allow a small amount of current to flow from the capacitors into the ground through the device body. The 110 V voltage appears on the case only if it is not connected to ground.

Despite its large magnitude, this voltage does not pose a serious danger. The small capacitance of the filter capacitors limits the amount of current so that it cannot cause serious harm to humans. You can only get an unpleasant electric shock from it if you simultaneously touch a live body and some grounded object, such as a battery or a water tap. Although this should not be done on purpose, no one can guarantee a successful outcome of such an experiment.

The situation is much worse when, due to a breakdown of the device, its body is connected to the supply wire. In this case, there will be 220 V on the device body and the current value will no longer be limited by the line filter capacitors. Touching such a device can, under unfavorable circumstances, lead to death.

Despite the fact that faulty household appliances can be a source of serious danger, most of the population of our country lives in houses without grounding and is not even aware of the dangers that await them. Almost all of us have been electrocuted, but few have experienced serious electrical injuries. What explains this current selectivity? Why does it maim and kill some, while others only slightly snap?

The effect of current on the human body is determined by its magnitude. A person can feel a current of one milliampere. A current of one to ten milliamps causes pain in a person. A current above ten milliamps causes convulsive contraction of the muscles, as a result of which a person cannot independently open his hand to break contact with the energized current-carrying part. With a current of over forty milliamps, respiratory paralysis occurs, and disruption of the heart. A current of one hundred milliamps leads to cardiac arrest and death.

The magnitude of the current flowing through the human body depends on the magnitude of the voltage applied to it and on the resistance of the circuit through which the current passes. In order to understand why, at the same voltage, a current in one case can only cause unpleasant sensations in a person without causing any harm to him, and in another case kill him, it is necessary to understand what a current circuit is and how it is created.

A current circuit is a path for current flow and this path is always closed. The current enters our house from the transformer substation via the phase wire, after which it returns to the same substation via the neutral wire. Moreover, as much current came from the substation to the house, the same amount should return from the house to the substation, no more and no less.

The current does not necessarily return to the substation only through the neutral wire. If the insulation is damaged, current may leak into the ground. In this case, part of the current will return to the substation through the ground, and part through the neutral wire. But even in this case, the total current returning to the substation will be equal to the current flowing from the substation to the consumer.

If for some reason the return of current to the substation is impossible, for example, the neutral wire at the substation has burned out, then there will be no current in the consumer’s homes. There will be voltage in the sockets, both in the phase and neutral contacts of 220 volts, but the current will not flow through the devices and they will not work.

What does the design of the grounding device consist of?

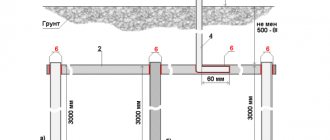

First you should get acquainted with the elements that make up its design. A typical grounding loop is a structure of three steel grounding rods driven into the ground at the corners of a trench dug to a depth of approximately 0.7-0.8 meters. Grounding conductors can be steel angles or copper-plated rods.

The length of the part of the grounding conductors immersed in the soil must be at least 2.5 meters. The exact values of these parameters are selected taking into account the nature of the soil at the location where the circuit is being constructed and the climatic conditions in the area. You can learn more about the grounding loop and its installation in our article “Grounding loop, what it is and how it works.”

Parts of steel blanks protruding from the ground by 10-15 cm are welded together with metal plates 40 mm wide (at least 4 mm thick). In the upper part of one of the vertical electrodes, a contact zone is arranged in the form of a threaded bolt welded onto it. The end of a copper bus coming from the body of the grounded device is attached to it using a nut, the cross-section of which should not be less than 6 sq. mm.

Additional information: To reduce the resistance of the emergency current flow circuit, this connection is sometimes welded.

External ground loop

Upon completion of the main work, the trench with the structure placed in it is filled with previously discarded earth, from which stones and unnecessary debris are removed.

According to the requirements of the PUE, any grounding system must comply with technical standards in terms of the maximum permissible leakage current resistance. Its value should be:

- less than 8 Ohms in industrial networks with phase voltage 220/127 Volts;

- less than 4 Ohms for linear voltages 380 Volts;

- no more than 30 Ohms in household networks (this indicator is considered the maximum permissible).

The copper core laid from the structure of the charger is fixed at its second end on a special strip mounted on the distribution panel of the facility (at home, in particular). It is called the main grounding bus (GGB), and it is intended for assembling all protective conductors in one place. Copper conductors diverge from it directly to consumers (through sockets to device housings).

How not to ground

According to paragraph 1.7.110 of the PUE, it is prohibited to use any types of pipelines as working grounding. In addition, it is prohibited to bring the grounding cable out and connect it to an unprepared contact pad on the bus. This prohibition is explained by the fact that each metal has its own individual potential. When exposed to external factors, galvanic steam is formed, which contributes to the process of electrical erosion. Corrosion can spread under the sheath of the ground wire, which increases the risk of melting when high currents are applied to the ground loop in the event of an accident. A special protective lubricant prevents the destruction of the metal, but it only works in a dry room.

The PUE also prohibits sequential grounding of electrical installations with each other, or connecting more than one cable to one grounding bus pad. If such rules are neglected, then in the event of an accident at one installation, it will interfere with the work of its neighbor. This phenomenon is called electrical incomparability. If the working ground is connected incorrectly, remedial work can be life-threatening.

Natural and artificial grounding

Natural grounding is an object or structure that has reliable contact with the ground due to the functions it performs. This category includes:

- water and heating pipes laid directly in the ground;

- any metal structures and their elements that have good contact with the soil;

- sheaths of welding and similar cables;

- metal mortgages and tongues, etc.

Worth noticing! In this case, special efforts will not be required to arrange functional grounding, since the elements of the natural grounding system are already ready for connecting grounding conductors.

Natural grounding systems

In a situation where such systems cannot be found, you have to install homemade chargers.

Artificial grounding is considered to be a deliberately organized electrical contact of two bodies, one of which is the protected device, and the second is the so-called “grounding loop”. This component is a special distributed (sometimes point) structure based on metal rods placed deep in the ground.

As a rule, steel rods with a diameter of up to 12 mm and a length of at least 2.5 meters are used as vertically driven electrodes. To arrange horizontal jumpers that ensure electrical contact between two bodies, metal corners 50x50x6 mm and 2.5-3 meters long are taken (they can be replaced with pipes with a diameter of about 6 mm or more).

Why are several ground electrodes made?

An electrical installation cannot be equipped with only one ground electrode, since the soil is a non-linear conductor. The ground resistance is strongly dependent on the voltage and area of contact with the inserted working ground pins. One ground electrode will have insufficient contact area with the soil to ensure uninterrupted operation of the electrical installation. If you install 2 ground electrodes at a distance of several meters from each other, then a sufficient contact area with the ground appears. However, it should be remembered that the metal parts of the grounding cannot be separated too far, since the connection between them will be interrupted. As a result, only two ground electrodes installed separately in the soil will remain, not connected to each other in any way. The optimal distance between two ground loops is 1-2 meters.