Thermoelectric temperature sensors (thermocouples)

The operating principle of this group of sensors is based on the fact that an electric current arises in closed circuits of conductors or semiconductors if the soldering points differ in temperature. To measure temperature, one end of the thermocouple is placed in the measuring medium, and the other is used to read the values. The only significant drawback of this type of meters is their rather large error, which is unacceptable for many technological processes.

An example of such a sensor is the TSP Metran-246 sensor, which is designed to measure the temperature of solids.

It is used in metalworking and serves to control the temperature of bearings. The measurement range is from -50 to +120 degrees Celsius, the output signal for reading is analog.

Watch a video about temperature sensors below:

How does a temperature sensor work?

How does a temperature sensor work?

The temperature sensor is quite small, but very important. First of all, drivers pay attention to its indicators in winter. How engine temperature sensors work, where they are located and whether they can be repaired - every car owner needs to know this.

How does the engine temperature sensor work?

As in many similar devices, the operating principle is based on the properties of certain materials to change their resistance when heated. Therefore, coolant temperature sensors consist of a housing made of non-ferrous metal, which easily conducts heat, and a thermistor, which is pressed tightly to the outer shell. The signal is transmitted through wires either to the thermometer on the front panel or directly to the control unit.

Engine temperature sensors are immersed in antifreeze. When the coolant heats up, the sensor also heats up. This also increases the resistance of the thermistor. The control unit sends a signal to the thermistor and measures the voltage of the returned signal. The measurement result is compared with a reference table in the device’s memory, and the engine temperature is displayed on the screen.

Types of sensors that monitor coolant temperature

Engine temperature sensors are available in two versions:

- Digital.

- Mechanical.

Digital - modern devices that work in tandem with an electronic control unit. They do not have a separate display for displaying results - they are registered and processed by the block itself. Therefore, such temperature sensors are a capsule made of metal and wire.

Mechanical ones are used in older car models. Their readings are displayed on a regular thermometer.

Location of temperature sensors

Engine temperature sensors are placed as close to the cylinders as possible. Most often, they are either included in the car thermostat kit or installed in the exhaust manifold.

Diagnostics of vehicle temperature sensors

Any device tends to break down. Coolant temperature sensors are no exception. They need to be checked and changed periodically.

Possible faults

Most often, temperature sensors can break down due to:

- physical damage - the thread broke, the housing cracked, the thermistor burned out;

- problems with the electrical part - short circuit, broken wires;

- lack of antifreeze.

Problems with the sensor can be determined by engine operation and incorrect readings. If there is any doubt about its operation, it needs to be removed and tested. To do this, the sensor is immersed in antifreeze, heated and the resistance is measured in the process. If the experimental results differ from the standard, the sensor is faulty.

If the coolant temperature sensor is faulty. Consequences

Problems with the device will definitely affect the engine. If in old models this could be neglected - well, the thermometer does not work, and okay, then in new ones this will not work. The control unit, relying on incorrect sensor data, will perform its job poorly. As a result, the engine may malfunction, may not start, and the fuel will not burn completely. The results can be sad - wear of parts, carbon deposits in the cylinders, repairs.

Engine temperature sensors are small parts of one large device. But without them it would have been difficult. No wonder they have been used for a very long time. It is better to monitor the proper operation of these devices carefully, test them periodically and change them on time.

Previous news

How to check the temperature sensor

Next news

Engine temperature sensor

Comments

Thermistor sensors

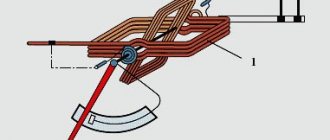

As the name suggests, this type of sensor works on the principle that the resistance of a conductor changes as its temperature changes. Due to their simple and reliable design, sensors of this type are widely used in electronics and mechanical engineering. The undeniable advantage of these meters is their high accuracy, sensitivity and simple reading devices.

An example of a thermistor sensor is model 700-101BAA-B00, which has an initial resistance of 100 Ohms and a measurement range from -70 C° to +500 C°.

It is made using a platinum plate and nickel contacts. Widely used in electronics and industrial machines.

Resistive temperature sensors (RTDs)

RTDs, also known as RTDs, are perhaps the easiest temperature sensors to understand. RTDs are similar to thermistors because their resistance changes with temperature. However, instead of using a special material that is sensitive to changes in temperature (as in thermistors), RTDs use a coil of wire wrapped around a ceramic or glass core.

The wire in an RTD is made of a pure material, typically platinum, nickel or copper, and this material has a precise resistance-temperature relationship that is used to determine the temperature being measured.

Semiconductor thermal sensors

This type of sensor works on the principle of changing the characteristics of a pn junction under the influence of temperature. Since the dependence of the voltage on the transistor on temperature is always proportional, it is possible to make a sensor with high measurement accuracy. The undoubted advantages of this solution are low cost, high data accuracy, and linearity of characteristics over the entire measurement range. In addition, they can be mounted directly on a semiconductor substrate, which makes this type of sensor indispensable for the microelectronics industry.

An example of such a device would be the LM75A sensor . Temperature range - from -55 C° to +150 C° , measurement error - ±2 C°. The measurement step is only 0.125 C°. supply voltage is from 2.5 to 5.5 V, and signal conversion time is up to 0.1 second.

How to choose

To decide which temperature sensor you need, it is worth considering a number of parameters. With proper selection, it will be possible to ensure comfortable operation of the device. Worthy of attention:

- Working temperature. Devices of a specific type are focused on use in a certain temperature range. This takes into account the error with which the results are determined. For small differences, you can use thermistors. If the operation will be carried out in fairly harsh conditions, it is worth choosing noise-type devices;

- Conditions for taking measurements. The connection diagram may vary. Some devices allow you to place the thermometer inside the material, while others allow measurements only from the outside. Radiation models will allow you to take readings through an obstacle. In the presence of an aggressive environment, models in a corrosion-resistant housing or remote non-contact sensors are preferable;

- Time until replacement or calibration. Depends on working conditions. The air temperature sensor can be used under normal conditions, with high humidity, fire hazard, and in an oxidizing environment. If calibration is not possible, the device will have to be replaced;

- The magnitude of the output signal. Its parameters must be correlated with the capabilities of electrical appliances and take into account the order of further processing. The parameters of the output signal depend on the temperature indicators, which will later be converted into energy.

- Error. It will take more time to measure with high accuracy. Digital models of sensors that measure indoor air temperature have the greatest accuracy. A bimetallic thermometer using the NQR principle allows you to take readings faster than other analogues;

- Permission. Affects the accuracy of the measurements taken. When operating in low mode 0.5 °C, in maximum mode - 0.625 °C;

- Voltage. The resistance of the resistor significantly affects the output voltage. The latter can be linear or nonlinear. The temperature of the object affects the reference values set at the thermometer terminals of each sensor;

- Operation time. Affects the speed of obtaining measurements. Quick measurements are obtained with a large error. If accuracy is required, the response time will have to be neglected.

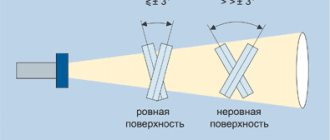

Pyrometers (thermal imagers)

A non-contact type of thermal sensors that read radiation that comes from heated bodies. This type of device allows you to measure temperature remotely, without getting close to the environment in which the measurements are taken. This allows you to work with high temperatures and very hot objects without dangerous proximity.

All pyrometers, based on their operating principle, are divided into interferometric, fluorescent, and sensors based on solutions that change color depending on temperature.

Wireless outdoor temperature sensor

When optimizing the operation of a heating system, it is worth paying attention not only to the selection of suitable controllers - additional elements are equally important to ensure the best operation of the heating system. One popular topic is the use of an outside temperature sensor and its optimal placement. For the most optimal use of thermal energy, it is worth considering the choice of a sensor, which is a device that allows you to save many costs.

An external temperature sensor, thanks to the built-in regulator, based on the heating curve, can accurately calculate what temperature the water should have, which is necessary to set the most optimal temperature for heating selected areas. Thanks to this, the temperature of the water in the heating system constantly changes depending on the temperature outside the building.

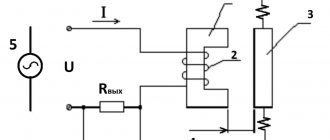

Piezoelectric temperature sensors

All sensors of this type operate using a quartz piezoresonator. The whole essence of the work is the direct piezoelectric effect, that is, a change in the linear dimensions of the piezoelectric element under the influence of electric current. When a different-phase current with a certain frequency is alternately supplied, the piezoresonator oscillates, and the frequency of its oscillations depends on the temperature. Knowing this dependence, you can easily convert data on the resonator oscillation frequency into temperature.

Another video about the types of temperature sensors:

Due to their wide measurement range and high accuracy, such sensors are used mainly in research and experiments where high reliability and durability are required.

Analog thermometer microcircuits

Instead of using a thermistor with a fixed resistor in the voltage divider, an alternative solution is an analog low temperature sensor such as the TMP36 from Analog Devices. Unlike a thermistor, this analog IC provides an output voltage that is nearly linear; The slope is 10 mV/°C over a temperature range of -40 to +125°C, and its accuracy is ±2°C. See Figure 6 below.

Figure 6 – Graph of TMP36 output voltage versus temperature from the technical description

Although these devices are extremely easy to use, they are significantly more expensive than a thermistor-plus-resistor combination.