Advantages and other features of a monolithic concrete staircase

Monolithic concrete stairs are quite heavy structures. Therefore, such stairs are made in houses with monolithic, prefabricated or frequently ribbed reinforced concrete floors.

Concrete stairs are constructed during the construction of the house frame. They can be used for their intended purpose immediately, until the construction of the house is completed.

Stairs made of concrete have high rigidity and strength, do not creak or vibrate.

Reinforced concrete stairs are safer due to their simple design and massive steps.

The finishing and cladding of concrete stairs during repairs is easy to restore or replace.

It is difficult to make stairs of complex configuration or miniature ones from concrete.

Larch and beech

There will be no problems purchasing larch; its price will pleasantly surprise you, since it is almost two times lower than the price of oak. However, the material itself is not inferior in appearance and quality. It is quite reliable and durable, and it is ready to serve for a very long time. Finishing a concrete staircase with ash will be cheaper compared to work using oak. Among other things, this breed is very durable, and the pattern is distinguished by its natural beauty. By choosing an ash-based material, you can even choose a color that can be light or dark. Another worthy contender in the line of materials described is beech, which has a uniform structure and a pleasant shade. You won’t have to pay so much for it, and the quality of the material will be high.

Design options for concrete stairs in a private house

The design of a concrete staircase must be developed before the construction of a house begins, since it is necessary to provide embedded anchors made of reinforcing steel and other elements in the ceilings and masonry walls for fastening flights of stairs and intermediate platforms.

Reinforcement outlets are made in the ceiling or load-bearing beam, which are connected to the reinforcement of the flight of stairs.

A staircase made of monolithic reinforced concrete in a private house consists of flights of stairs and an intermediate landing between the flights.

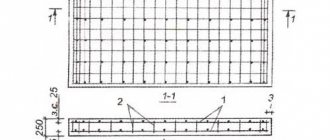

The flight of stairs is a reinforced concrete slab on which concrete steps are located.

Reinforcing frames of reinforced concrete floors, staircases and landings are connected together into a single structure. Thanks to the joint work of reinforcement and monolithic concrete, the staircase has very high rigidity and strength.

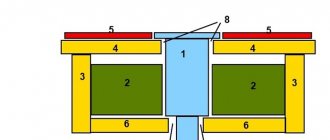

Staircase with stringer made of monolithic reinforced concrete. The stringer is located along the longitudinal axis of the flight of stairs.

The stringer here is a reinforced concrete beam with projections to support the steps. Cantilever steps are those whose ends are not supported.

The steps of a staircase on a stringer can be made of wood or monolithic concrete. Wooden steps are attached to the stringer using metal inserts.

Formwork of a monolithic staircase on a stringer with concrete steps. The reinforcement frame of the cantilever steps made of concrete is connected to the reinforcement of the stringer.

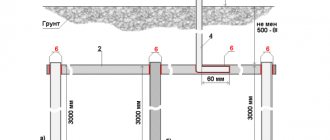

Reinforced concrete stair stringers, as well as flights of stairs, can be installed either between interfloor ceilings, or between the ceiling and the intermediate landing.

Cantilever steps made of reinforced concrete are jammed in the masonry of the wall.

A staircase is called closed if the spaces between the steps are closed with risers. Without risers, this is an open staircase.

Concrete for reinforced concrete stairs

For the manufacture of reinforced concrete stairs, concrete is used that has a compressive strength of at least 20 MPa (class B20). Freshly laid concrete in the formwork must be thoroughly compacted by vibration.

It can be advantageous to make flights of stairs and landings from architectural (decorative) concrete . The surface of the steps and landings of such a staircase will not require additional cladding or finishing. It is better to order the production and laying of architectural concrete to specialists.

Types

There are two fundamental options for installing stringers for concrete stairs to the second floor:

- Standard – when the stringer runs across the entire width of the structure. It, of course, does not add lightness to the product, which is so important in the interior of a private home.

- But the second option, when the stringer is narrow and the space under the steps is open, looks quite elegant. Streams of light penetrating through the approach openings will enhance the airiness effect, as can be seen in the photo.

Where in the house to place a concrete staircase

In order for the staircase to be comfortable, safe and “quiet”, it is necessary to successfully choose its location in the house, correctly arrange it and determine its dimensions.

Modern architecture of a private house usually does not provide special isolated staircases for staircase placement. Stairs are installed openly and are part of the interior of the living room, hall or hallway.

It must be taken into account that the staircase in the living room, as an element of the interior, places higher demands on appearance. The staircase in the living room should be more refined, and therefore more expensive, than the staircase in the hallway, hall or in an isolated staircase.

Compared to wooden ones, concrete stairs look heavier, they are simpler in shape and do not fit well into the interior of the living room.

A place near a wall is more suitable for placing a concrete staircase.

Kinds

Monolithic concrete stairs can come in different shapes and sizes, but the most common are straight single-flight ones. When constructing this type of structure, SNIP standards are taken into account, so they can be used in premises with increased safety requirements (medical institutions, schools, offices and residential buildings).

The type of staircase transition depends on two criteria: the method of formation and location in space. According to the manufacturing method, there are two types of stairs - spiral and marching. Depending on the type of installation (location), a monolithic concrete staircase can be located both indoors and outdoors. Next we will examine each of these types in more detail.

By manufacturing method

Depending on the production technology of monolithic concrete stairs, they can be either marching or spiral. Each type has its own operating characteristics. Thus, staircases with a rotation of 90 and 180 degrees (L-shaped and U-shaped, respectively) allow you to save free space in the room. That is why this kind of construction is often used in small houses or two-story apartments.

Recently, turning staircases have been increasingly used in residential construction. This design can decorate any multi-level room, and also provides a smooth rise to the second floor. In this case, the rotation is achieved through the manufacture of winder steps (compared to conventional ones, their inner side is narrower than the outer one).

Related article: Stairs to the attic: which one is better to choose and how to install it yourself?

Screw

This model of a flight of stairs can be used both indoors and outdoors. A distinctive feature of the design is its compactness and unusual appearance. However, the disadvantage can be considered the complexity of constructing and reinforcing a concrete staircase of this type. In most cases, a spiral staircase is installed with support on the nearest wall or away from it.

Difficulties in implementing such a design are associated with the need to form shaped formwork with smooth contours and planes, but with curved surfaces.

Marching

This version of a monolithic staircase is classic. Flights of stairs are the most convenient and safe to use. They are easier to manufacture, but take up much more space than screw models.

This type of interfloor transitions is divided into single-flight straight, double-flight corner with a platform and rotary structures with winder steps.

For self-production, structures resting against side walls are best suited (construction is carried out using formwork and reinforcement that are attached to the base of the wall). The ceiling of the second floor can also be used, but this method requires additional supports when installing the formwork. If you are planning to create a two-flight staircase, then it would be most reasonable to mount the steps (jointed at a selected angle with the landing) with support on the wall.

By installation type

A monolithic frame is one of the most durable and reliable structural elements. When properly manufactured, it meets all safety requirements and has unsurpassed technical and operational characteristics. There are several types of structures, but the most common are concrete models. Depending on the type of installation (installation location), they are divided into internal and external.

External

The possibility of installing external flight stairs exists only if there is a high foundation of the building. In most cases, this structural element is used to move to the second floor or attic. If we are talking about spiral staircases, then it is worth noting a special way of installing the structure - with support on the facade or only on the upper floor.

Domestic

A special feature of such structures installed indoors is the ability to redistribute the load from the foundation of the building to the walls. If there is a lack of free space, we recommend paying attention to corner spiral staircases. They look stylish and meet all safety standards.

Whatever option you choose (external or internal, spiral or marching), you will certainly need reinforcement for a monolithic staircase.

How to choose staircase sizes

Selecting the slope of the stairs

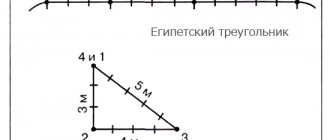

A comfortable and safe staircase should be fairly flat. Building regulations limit the steepness of stairs in a home. The slope of the stairs should not be more than 1:1.25 (the ratio of the height of the flight of stairs to its horizontal projection). In the figure below, staircase 1 has such a maximum slope of about 40° .

Two staircase options:

staircase 1 - steep with extreme slope, provides a minimum of comfort and safety, but occupies a minimum area in the house; staircase 2 - a comfortable and safe staircase with the recommended slope.

In order for the staircase in the house to be quite comfortable and not take up too much space, it is recommended to choose a slope of the flight of stairs of about 30o, which corresponds to the ratio of the height of the flight of stairs to its horizontal projection as 1: 1.75. Staircase 2 in the figure above has this slope.

The recommended slope often has to be adjusted for design reasons, taking into account the size of the space intended for installing the stairs.

Calculation of stair step sizes

After determining the slope - the height and horizontal projection of the flight of stairs, at the second stage, the optimal dimensions of the stair steps are calculated.

Optimal sizes of staircase steps in a private house. To move comfortably along the steps of the stairs, you must fulfill the condition indicated in the green frame.

Building regulations require that the height of the stair step be within the range h = 16-19 cm.

For example, let's calculate the dimensions of staircase 2 in the figure. Taking into account the requirements of the rules, for further calculations we accept the height of the steps of our stairs h = 17 cm.

Then, we find the number of steps in the flight of stairs. To do this, divide the height of the flight of stairs by the height of the step. Number of steps in a flight of stairs: 272 cm / 17 cm = 16 steps.

Building regulations limit the number of steps in one flight of stairs to no more than 18 steps. If this limitation cannot be met, then it is necessary to make two flights of stairs with an intermediate platform between them.

Knowing the number of steps, we calculate the width of the tread of the flight of stairs. To do this, divide the horizontal projection of the flight of stairs by the number of steps. For staircase 2 in the figure, the estimated width of the step will be s = 474 cm / 16 = 29 cm.

Construction rules recommend choosing a stair tread width within the range of 22 - 33 cm. For a comfortable staircase, the tread width is at least 25 cm.

On a step with a width of 29 cm, a person’s foot will feel confident and comfortable.

Finally, we check whether it will be comfortable to move up the stairs. To do this, we make a calculation using the formula indicated in the figure in the green frame: 2h+s=60-65. For our staircase 2*17 cm+29 cm=63 cm - the condition for comfortable movement is met.

What should be the height of the steps without finishing?

A comfortable staircase should have all steps of the same height. The decision on what material to decorate it with is best made before the construction of the staircase begins - this will avoid surprises in the form of height differences between individual steps.

If the floor and treads are finished with the same material or materials of identical thickness, all unfinished steps must be the same height.

If the materials have different thicknesses, the height of the first step in the open state should be matched to the thickness of the material that will cover the tread and floor on both floors. The thickness of ceramic tiles (including the adhesive layer) is approximately 2 cm, of rolled material - about 0.5 cm, of stone cladding - 3-4 cm, of wood - 4-5 cm.

Stair width

The width of a flight of stairs is the width of the passage between the stair railings, not the length of the steps. The length of the step may be different, depending on the method of fastening the railing.

Building regulations require that the width of the passage along the stairs be at least 90 cm. For the sake of comfort and ease of moving furniture, it is recommended to increase the width of the passage to 110 cm.

Step overhang

Steps on stairs are usually made with an overhang of 2-3 cm, as in the figure above. An overhang is necessary so that the vertical surface under the step (riser) is less dirty and damaged.

On reinforced concrete stairs, which are lined with wood, the overhang of the steps is achieved by increasing the width of the wooden covering.

On stairs without wood cladding, the surface under the step (riser) is made not vertical, but inclined, so that the surface of the upper step slightly overhangs the lower one.

However, for stairs made of concrete, an overhang is not necessary.

Reinforced concrete stairs look too massive and therefore require a creative approach to finishing.

On a reinforced concrete staircase, all parts of the steps need to be finished:

- horizontal planes, that is, treads;

- vertical - risers;

- as well as baseboards - sections of walls located directly above the steps.

The treads are covered with non-slippery and abrasion-resistant material, while at the same time, the risers, which we most often touch with the toes of our shoes, must be shock-resistant.

How to build a staircase

Any construction begins with a project. The main parameters according to SNiP that must be provided for when calculating a flight of stairs:

- 160-180 mm is a convenient step height for use. It is selected depending on the inclination of the staircase structure.

- From the ratio of the height of the step to the length of the span, the number of steps is calculated.

- The tread should be able to fully accommodate a person's foot. This must be taken into account when choosing the width of the tread.

- 1200 mm is the distance that is considered comfortable so that 2 people can move along the stairs towards each other. If space allows, it is better to make the width of the march no less than this value.

- The height of the railings is 90-110 cm.

- For residential premises, the correct slope of the stairs is from 24 to 37°. The width of the step and the height of the riser are determined depending on it.

- Winder steps or a turning platform with supporting posts are calculated relative to the turn of the march.

For a rotating structure, the width of the step in the widest part should be no more than 40 cm, and in the narrowest part - 10 cm.

The strength of the entire structure is determined by the reinforcement. It is advisable to have a separate diagram in which the reinforcing frame will be presented, repeating the staircase shape, indicating the cross-sectional values of the reinforcement.

The amount of concrete mixture can be calculated using online calculators. The grade of concrete required and the cement used are taken into account. The approximate mass of 1 m³ of mixture and the number of bags of cement are calculated.

It is better to do the project in 2 planes - side and top views. It needs to clearly present all the important elements separately.

How to choose finishing material?

The choice of material is influenced by the location in which the staircase is located and the method of finishing the floor on both floors. It's also worth asking yourself a few more important questions.

What shape does a flight of stairs have? The steps of straight flights can be covered with almost any finishing material. For winder steps, it is better not to choose materials that will have to be cut locally (ceramic tiles, stone cladding) - the steps will not look very aesthetically pleasing, and the material consumption will be excessively large.

Who will use the stairs? In a house where there are small children or elderly people, the stairs must be covered with a material that perfectly absorbs falls. If children often play on the steps, the facing material should also be warm (wood, carpet).

Should stairs be quiet?

Different finishing materials absorb sound differently, which can affect the comfort of using the stairs.

Carpeting and wood are good at absorbing sound, while stone and ceramic tiles sometimes increase footfall noise.

Will the staircase be damaged?

If the arrangement of the house has not yet been completed, you should take into account that when moving furniture, the stairs may be damaged. In this case, for finishing the steps you should not choose soft types of wood or carpeting that are susceptible to damage.

Classification

Staircase structures are classified according to the following criteria:

- span shape;

- installation features.

Staircase structures of various configurations are used:

- rectilinear. They can be found in buildings with increased floor space. As a rule, the appearance of such flights of stairs attracts attention due to their non-standard design. The design allows you to use the free space under the span to organize additional containers and special rooms;

- curvilinear. Saving free space is achieved thanks to the screw shape of the product. However, radius span elements are labor-intensive to manufacture and install. Production difficulties are caused by the radius formwork, the creation of which requires an increased level of costs, since it consists of individual segments;

The monolithic structure does not have elements that become loose from dynamic loads

- composite. Double-flight structures have a U-shaped configuration or are made of two parts located at right angles. They have proven themselves to be the best option for moving between floors in small spaces. They can be formed from individual elements without the use of additional platforms.

Builders use various solutions when constructing flights of stairs:

- monolithic structures. The concrete stairs are poured together with the interfloor platforms. As a result, a common power circuit is formed. To carry out concreting activities, a formwork is constructed in which a mesh of steel reinforcement is installed;

- prefabricated spans. Includes flights of stairs and interfloor landings, which are manufactured separately. They are installed in working position using lifting means. Installation is carried out on site by welding reinforcing bars.

The staircase structure is formed from various flights. They transfer the load to the walls of the building, as well as floor panels between floors.

Finishing the stairs with soft material

Another inexpensive and labor-intensive way to finish steps is to cover them with a soft material. Stairs with elastic cladding are easy to keep clean, and carpeting is warm and absorbs sound well.

The finishing material must be carefully glued to the steps: if any fragments peel off, there is a danger of tripping and falling.

The rolled material is thin and elastic. It can be laid without cutting, but the riser of a staircase finished in this way must be protected by a special profile made of metal or composite.

Products for construction and repair

⇆

If it is a solid cladding, then it will have to be cut, and each step should be laid separately.

Which roll covering is suitable for stairs?

Carpeting should be easy to clean and dry quickly: polypropylene and polyamide coatings meet these conditions. You should not choose coverings with long pile or thick backing, such as felt.

Wool coverings are not suitable for stairs as they get dirty easily and are difficult to clean. It is also better not to choose acrylic ones - they have low strength.

Carpets intended for stairs are additionally reinforced. It is better to choose those that are marked with a special pictogram.

Elastic coatings must be abrasion-resistant, non-slip and flame-retardant. Rubber coating meets these requirements. At the same time, it is better not to use vinyl coating, since it is not resistant to dents, and shoe polish can leave marks on it that are difficult to remove.

steps

In a simple sense, a staircase is a device with steps connecting floors, levels, tiers. Concrete steps for stairs are attached to supports, which can serve as side walls, bowstrings, stringers. The lower part of the staircase can rest against the floor, the upper part can rest against the opening to the next floor.

Comfortable operation of the stairs depends on the shape, thickness and size of the steps. When developing projects, designers use original solutions - mortise steps, goose step steps, asymmetrical fragments.

There are certain requirements for the size and angle of rotation of the steps that need to be taken into account:

- the optimal length is at least 80-90 cm;

- standard for the height of the concrete tread is 17-18 cm;

- width for a comfortable step (foot) – 25-30 cm;

- the number of steps in the march is no more than 18;

- the optimal angle of inclination of the stairs is 30-45º;

- the overhang should be 20-30 mm.

Related article: How to make a staircase to the basement: the main stages of manufacturing using three examples

Stairs can have different configurations, heights, and types of installation. Products made from durable concrete require detailed calculations at the house design stage. The solution needs to be given time to dry, so the construction of stairs is carried out in several stages.

On the video: the main types of monolithic stairs and the calculation of a simple flight.

Wood - for a home with soul

The wooden staircase evokes associations with the interiors of old houses. Thanks to its many advantages, it is also appreciated by owners of modern interiors.

Wood is warm to the touch, and it visually makes the room warmer. It is a springy material that absorbs falls well. Wood is readily used because of its plasticity and ease of processing: it can be adapted for steps of any shape.

Many people choose this material because of its natural color and layering pattern. But a wooden staircase can also be painted or coated with stain, thus giving it a completely different look.

Great opportunities are opened by the use of exotic wood, characterized by a rich palette of colors: from white - through yellow, red, brown, olive, green - to deep black.

Often only treads are made of wood, and the risers are left in plaster painted white. Such a staircase is made not only for reasons of economy - it looks light and less monotonous.

But it should be remembered that white risers get dirty very quickly, the plaster may fall off, and the painted surface is not so easy to clean. To avoid this, the risers must be plastered with durable cement mortar.

For painting, it is recommended to use paint that forms a smooth and water-resistant finish (for example, vinyl or acrylic).

You can also use other materials to finish risers: resin-based plaster, ceramic tiles and even steel sheets.

The risers are finished with mosaic plaster. Against its background, treads made of light oak stand out expressively

Oak boards were used for the treads, and stone or ceramic tiles were used for the risers.

Dark wood overlays protect the surface of the treads and the top of the riser

A staircase with a straight flight can be finished with almost any material. In this case, dark wood is used, contrasting with the color of the walls.

Due to the risers painted white, a staircase with wooden steps seems lighter

Ceramic tiles - for the practical

It is so diverse that it allows you to arrange a staircase for any interior. Richly decorated Southern-style tiles will create the climate of a Greek tavern, floor tiles imitating old stones will create a farmhouse atmosphere, and sparkling polished porcelain tiles will create the atmosphere of a modern residence.

Is this a good material for stairs from a practical point of view? The tiles are cold, hard and do not absorb falls. At the same time, it is easy to keep clean, cheaper than stone, and much more durable than wood. It does not burn - in the event of a fire, it does not contribute to the spread of fire between floors.

However, if all elements of the staircase are tiled, it will look too monotonous. Interesting effects are achieved by combining ceramic tiles with other materials, such as wood.

Which tiles are suitable for stairs?

Tiles that have certain parameters are suitable for stairs: they must have a high abrasion class, preferably IV or V, a hardness of at least 5-6 on the Mohs scale and anti-slip properties.

Such high requirements are imposed only on treads - risers may have lower technical parameters.

The surface of tiles intended for treads must be corrugated (corrugations are convex or concave elements on the surface of the tile) or embossed (relief is convexities on the entire surface of the tile).

The staircase can also be tiled with matte tiles with an uneven, rough structure.

For internal stairs, floor tiles, gres and clinker are used.

Mosaic ceramic tiles are used for steps and risers, as well as for flooring in staircase halls

Ceramic tiles of various colors were used to decorate the steps of the staircase, reminiscent of a multi-colored carpet.

Popular options

Reinforced concrete stairs are developed at the design stage in order to harmoniously fit the heavy structure into the interior of a house or cottage. The structures can be straight with concrete flight spans, or helical with spiral winder steps. The type of support varies - on the walls on one or both sides, in the floor and the upper ceiling.

The load-bearing capacity of the product does not depend on the installation method - “hanging” structures are as strong as structures adjacent to the walls.

Let's look at what concrete stairs to the second floor are like:

- Direct single-flight structure. Used for installation in low rooms with two levels, it simply connects the lower and upper tiers.

- Complex L-shaped stairs. They look good in spacious rooms and can contain turning steps and platforms.

- U-shaped structures for high-rise buildings. The marching spans are connected by platforms, located at an angle of 180°. An additional plus is space saving.

- Screw structures made of concrete. They are used in conditions of limited free space, characterized by curved lines and the creation of steps of unusual shape.

Interfloor transitions can be smoothly hemmed in the shape of the lower edge of the steps, with a double frame (stepped bottom) and options with bowstrings and stringers, leveling the heaviness of concrete. The weight of the structures ranges from one and a half to 2.5 tons, taking into account the reinforcement with iron rods, with the help of which the complete safety of the structure is ensured.

Screw

Spiral staircases are beautiful structures that transform the interior and interior decoration of a house. You can build them with your own hands, but the work is labor-intensive and requires a lot of time and certain skills. For individual projects, specialists will make a screw concrete structure of any configuration, knowing the dimensions of the room.

The construction process is based on the construction of formwork and pouring liquid concrete, which can take on various shapes.

The screw concrete model has undoubted advantages:

- weightlessness of the design - the staircase seems to float in the air;

- compact dimensions - the structure takes up minimal space;

- the steps are poured around a column, which serves as a support;

- serves as a connecting and reinforcing frame between levels;

- may have a different angle of rotation, the steepness of the winder steps.

Related article: Advantages of transforming staircases and their varieties (popular manufacturers)

There are no style restrictions in the decoration of spiral staircases. For the decorative design of the structure, tiles, metal inserts, wooden boards, chips, laminate, porcelain stoneware, and soft carpet are used. Facing materials must be laid on a flat surface.

A spectacular decoration of a spiral staircase is the railings, presented in a wide range, which are installed after the installation of the structure.

Marching

When the area of the room allows for the installation of a larger concrete structure, home owners give preference to marching models. They are considered safe for movement, and the size between the railings/handrails leaves enough space for lifting furniture, appliances and other bulky items to the upper tier.

Features and advantages of the concrete product:

- ease of use, variety of installation methods;

- equipping main flights with intermediate platforms;

- optimal width, height, length of steps, slight steepness;

- several types of structures - straight, U-shaped, L-shaped;

- the ability to “connect” several floors with a flight of stairs.

Products made of concrete are equipped with winder rotary steps for easy lifting, depending on the characteristics of the installation site. According to established standards for safe operation, it is necessary that the height of one flight does not exceed 3 meters. Otherwise, it is worth equipping platforms between marches.

Wood, granite, and artistic forging are best suited for cladding buildings. The space under the stairs can be used to organize storage areas.

Finishing a monolithic concrete staircase with porcelain stoneware

Steps for stairs made of porcelain stoneware are slabs specially designed for finishing the steps of concrete stairs. The porcelain stoneware slab has dimensions of 300 - 350 mm. wide and 1200-1300 mm. in length.

Porcelain stoneware steps can be with or without anti-slip notches.

Porcelain stoneware slabs can be used to cover both treads and risers.

Porcelain stoneware slabs are produced to look like wood, like marble, like natural stone, as well as steps in pure colors (monocolors) and many others.

The steps come in a straight shape with a processed front edge, as well as with a curved “nose” - in this case, the choice depends on what appearance you want to give to the concrete staircase.

Porcelain stoneware steps are very durable, do not allow moisture to pass through, are not susceptible to chemical attack, do not fade from sunlight, are environmentally friendly and do not require replacement for a long time. This is one of the best options in terms of price-quality ratio for finishing concrete stairs.

Porcelain stoneware steps as a material for finishing interfloor stairs are very diverse. Depending on your preferences, you can choose matte, lapped, embossed or polished steps for your concrete staircase as a finish.

You can finish with porcelain stoneware in the same style both the concrete staircase itself and the entire space between the stairs.

More articles on this topic

- Load-bearing, self-supporting and non-load-bearing walls - what's the difference!?

- Heating costs and heat transfer resistance

- Dry heated floor without screed in a wooden house

- Distribution boxes for electrical wiring installation

- Prefabricated monolithic frequently ribbed floors made of light stone blocks

- Calculation of a wooden attic beam

- How to make the right concrete floor in a wooden or frame house

- Installation of plastic windows at the dacha

Formwork for steps

For the steps, the formwork is made of boards with a width equal to the height of the step. They are attached depending on the structure of the flight of stairs.

For winder steps, each element must be made separately in the shape of a trapezoid, taking into account the required width of the step and the angle of rotation.

In straight marching structures, you can lay a longitudinal strip through the middle of the boards and fasten the formwork together. This will prevent the form from bending under the weight of concrete, the steps will be the same size.

If the march is located close to the wall, then the formwork for the steps is attached to it on one side using an additional block. Side 2 is attached to the side formwork.