Electric kettles are quite common today. However, to a greater extent, equipment is used whose price does not exceed 5,000 rubles. There is no doubt that we are talking about Chinese-made teapots. This means that their quality is very specific.

It is not difficult to buy a heating element for a kettle on the Grepan website. Often, it is in purchasing a suitable heating element that the problem of repairing an electric kettle lies; if it is solved, then restoring household equipment remains a matter of time.

What tools are needed to perform electrical repairs?

Below is the required instrumental set:

- suitable screwdriver;

- nailfile;

- tester (multimeter).

If the kettle stops turning on, many people immediately begin to think that the heating element has burned out. In fact, this is not always what happens. You must first complete the following steps.

It is very likely that the socket burned out due to the high electrical load. Try connecting the kettle to a different outlet and turning it on. If the kettle does not work in another room, we can say with confidence that the cause of the malfunction lies there.

We continue to systematically discard areas where the fault may be hidden - we check the base of the kettle. We call it using a multimeter - contacts and plug. If no break is detected, the technical malfunction is hidden directly in the electric kettle itself (the likelihood of the heating element burning out increases).

Checking the heating element of the kettle indiscriminately

Indeed, using a multimeter you can check an electric kettle without disassembling it. It is enough just to check the outgoing contacts (they go to the base).

The multimeter should show some resistance - 150-170 Ohms often. If the device shows infinity on the screen, the heating element is burnt out and requires replacement. However, this is not possible in every electric kettle design.

Dismantle the heating element only if you have found a similar one for replacement. But very often the heating element is intact (absolutely working). The reason for the malfunction is hidden in the control contact. It is he who turns off the electric kettle when the water in it boils.

Due to the passage of high amplitude current through it, it becomes charred. Simply clean the contact with a nail file and the kettle will work again.

The video clearly demonstrates the process of repairing an electric kettle:

Traditional electric kettles are made like those that are installed on gas burners and have a wide bottom with a heater located under it. Electric boilers are made in the shape of a jug with a larger height. The devices require proper handling as their power ranges from 500-2500 watts. Due to high loads and frequent use, the device sometimes fails, after which it requires repair. The kettle can be repaired without any problems, since the device is quite simple.

Add a link to a discussion of the article on the forum

RadioKot >Schemes >Digital devices >Household appliances >

| Article tags: | Add a tag |

Rainbow teapot

Author: Allhimed Published 12/08/2015 Created using KotoEd.

They once gave me an electric kettle. He himself is all beautiful, made of tempered glass and backlit. True, the backlight is bright blue, which is more associated with ice than with hot tea. And I wanted to make an “intelligent” backlight so that its color would match the water temperature. Cold kettle - blue backlight, hot - red, intermediate temperatures - other colors. The first task is choosing a temperature sensor. The main requirements for it are the range 0...100 degrees. C and low inertia. Special accuracy and linearity are not required. The choice fell on the ST1-19 thermistor, which is a glass bead with long leads. At a temperature of +150 degrees. Its resistance is 6.8 kOhm.

The experimental dependence of resistance on temperature is given in the table. The selected backlight color and its decomposition into RGB components are also indicated here.

| t, deg. WITH | Rt, kOhm | Color | R | G | B |

| 30 | violet | 100 | 0 | 170 | |

| 40 | 770 | blue | 0 | 0 | 170 |

| 50 | 476 | blue | 0 | 70 | 43 |

| 60 | 285 | green | 0 | 84 | 0 |

| 70 | 184 | yellow | 255 | 55 | 0 |

| 80 | 127 | orange | 255 | 31 | 0 |

| 90 | 80 | red | 255 | 0 | 0 |

| 100 | 54 | red | 255 | 0 | 0 |

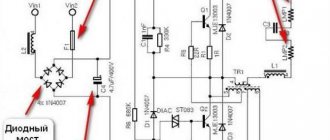

The schematic diagram is not original.

The PIC16F676 microcontroller was selected (available). The light source is an RGB LED strip of type 5050, controlled via a ULN2003AN stepper motor driver.

The voltage from the divider R1R2 is supplied to the input of the ADC controller. The most significant 8 bits of the conversion result are used. Next, the RGB component values are selected from the 3 x 256 array. Finally, the corresponding LEDs are illuminated using software PWM.

A compact 12V 0.4A power supply from some device was used as a power source.

The design is shown in the photo.

1 - LED strip, 2 - thermistor, 3 - power supply.

The power supply, LED strip and thermistor assembly are installed at the bottom of the kettle. The latter is pressed to the bottom of the heating element and lubricated with KTP-8 thermal paste. The LED strip is laid along the contour of the tank and secured with glue. The installation was carried out using fluoroplastic insulated wire (it’s hot!). The microcontroller unit is installed in the handle of the kettle. No printed circuit board was developed.

Capacitor C2 suppresses 50 Hz interference to the high-resistance thermistor circuit. The thermistor can be replaced with a similar one, for example, from a portable medical thermometer. In this case, the value of the load resistor R2 should be approximately equal to the resistance of the thermistor at a temperature of +60 degrees. C. The frequency of the ZQ1 resonator must be at least 12 MHz, otherwise the PWM frame rate will decrease and LED blinking will become noticeable. The ULN2003AN driver can be replaced with discrete KT815 transistors with 1 kOhm resistors in the base circuit.

Video of a working kettle:

The attachment contains the source code of the MicroS program and the HEX file of the controller firmware.

Files:

Firmware

All questions in the Forum.

| What do you think of this article? | Did this device work for you? | |

| 117 | 4 | 4 |

| 0 | 0 |

Operating principle

Despite the wide variety of models, the principle of operation is common for all. The water is heated by an electric heater connected to the network. It is inserted through a waterproof seal.

The electric kettle is equipped with a thermostat connected to the power supply and turning off the device when the water boils. It is triggered when a stream of steam hits a bimetallic plate through a tube or small hole, which bends when heated, pressing the switch. The device contains thermal fuses that turn off the power if it overheats due to the lack of water inside or its level falling below the permissible level. The downside is that once it cools down, power is supplied to the heater again. In some models, the thermal fuse is connected to a switch that completely turns off the kettle if it overheats.

An indicator LED or neon light bulb with a load is connected to the external circuit. The presence of an indication is convenient for monitoring the switched on state of the kettle, as well as turning it off when the water boils. In addition, if it is on, but the kettle does not heat, the cause of the malfunction is immediately clear, which is unreliable contact of the electric heater terminals or burnout of its coil. LED is usually used to illuminate water. It is not intended for direct connection to the network and a driver is installed for it. Electricity is supplied to the heater from an outlet through a cord connected to a power strip attached to the housing. Cordless devices are often used with pads on the bottom of the kettles, connected to a base-stand connected to the mains.

Electric kettle repair

Despite the apparent simplicity of the design, the service life of an electric kettle is not eternal. Sooner or later there comes a time when, having turned it on, the user discovers that the device has stopped working.

Common faults

A list of common malfunctions and the causes that cause them are given in the table.

| Malfunction | Faulty element | Possible reason |

| The kettle is turned on and does not heat the water. | heating element | Ÿ Scale formation; |

Ÿ The heating element has failed.

Ÿ damage to button parts.

Ÿ burnout of contact pads;

Ÿ power plug failure.

Ÿ the sealing elements have become unusable (in the presence of an open-type heating element).

Ÿ The steam channel is clogged with scale.

When starting repairs, the kettle must be disassembled, which is sometimes more difficult than repairing.

How to disassemble an electric kettle

Disassembling the electric kettle and/or its stand is not particularly difficult. To do this, it is enough to prepare only a set of screwdrivers: Phillips, flat and possibly Spanne (two-pronged fork).

Attention! Before you begin disassembling the electric kettle, you must unplug the power cord from the power outlet.

- Removing the bottom cover of the electric kettle. Disassembling the electric kettle begins by removing the bottom cover (bottom). To do this, you need to unscrew all the screws there. Typically, the bottom cover is secured with self-tapping screws (self-tapping screws) with a cross-shaped head. However, you can sometimes find screws with a Spanne head. This is how electric kettle manufacturers try to protect the device from self-repair. If you do not have a similar screwdriver, such screws can be carefully unscrewed with tweezers or side cutters.

In addition, the screw heads can be covered with decorative plugs, which can be easily removed using a sharp object. Once all the screws are removed, the bottom cover should come off easily. If this does not happen, then it is additionally secured with plastic latches. They need to be carefully pressed out using a flat-head screwdriver. The bottom cover of the stand is removed in a similar way.

Removing the switch. This is one of the most difficult operations that have to be performed when repairing an electric kettle. It is placed at the top of the handle (key) or at its base (plate or lever). To dismantle the switch, you need to carefully remove the plastic cover and unscrew the screws that opened underneath it. This will allow you to separate the handle with the lid from the body and remove the part. In addition, this allows access to thermal protection elements.

Repair scheme

The sequence of operations to eliminate the reasons why the kettle stopped working is almost the same for all modern models . The order is as follows:

- make sure that the power cord is in good condition and that the stand is working;

- check if the heating element is working;

- start checking the switch (thermostat).

The work at each stage must be completed by eliminating the defects found, some of which are described below.

The kettle does not turn on

The fact that the electric kettle does not turn on is indicated by the LED indicator, which does not light up when the corresponding key (lever) is pressed. There may be several reasons that can cause this defect.

- Malfunction of the power plug or power cord is determined by checking with a tester, for which it is enough to remove the bottom cover of the stand. If a break is found in the cord, it is replaced.

- Carbon deposits on the contacts of the connecting device of the stand and the kettle can be eliminated by cleaning the contacts with fine-grained sandpaper until they shine. If the contacts and union terminals are completely burnt, then they are replaced. However, this is quite a painstaking job that requires skills in electrical installation work. In addition, you will have to remove the bottom lids of the kettle and stands.

The kettle is on, but the water is not heating

The fact that the kettle is turned on is indicated by the LED lighting up after pressing the key (lever). The defect associated with the fact that the light is on and the kettle does not heat the water can be caused by two reasons:

- poor contact with the heating element;

- heating element burnout.

To gain access to the heating element, the electric kettle must be disassembled. First, check the functionality of the contact connections. If they are charred, and the wires from the slip-on terminals have fallen off, then it is necessary to restore the connections (replace the terminals, clean the contacts, etc.). In addition, on the Internet you can find quite a lot of video materials devoted to the modification and restoration of contacts welded to the heating element. Only after the electrical connection has been completely restored can you begin to check the integrity of the heating element (continuity test).

They check the heating element by measuring the resistance between its output contacts with a tester. If the device shows the presence of resistance, then the heating element is working. Otherwise, the heating element's coil will burn out.

Important! Only the open type heating element can be replaced. Replacing the disk heating element is impossible, since it is mounted into the bottom of the housing.

The kettle is leaking

There can be several reasons for water leakage. For example, if the kettle is equipped with an open heating element, then water leakage can be caused by:

- loosening the heater fastening - the defect can be eliminated by carefully tightening the existing fasteners;

- violation of the tightness of the seal - the leak is eliminated by replacing the sealing rings.

Operating rules

Filling your kettle with water is very easy.

It is important to follow the basic rules, violation of which leads to device failure and accidents.

The kettle only fills when the power is turned off or removed from the base. Each device must have minimum and maximum water level marks. If there are none, the water must cover the heater. Underfilling leads to burnout of the heater, and overfilling leads to premature shutdown and water splashing out of the spout.

Procedure for checking and repairing the electrical part

Before you start repairing an electric kettle, you need to familiarize yourself with the principle of its operation, structure and circuit diagram of the device. The simplest diagram looks like this:

Troubleshooting and repairing an electric kettle with your own hands is carried out in the following sequence.

- If there is no power, you should first inspect the panel to see if the circuit breaker or RCD has tripped. Check that the plug is plugged into the socket, that the contacts are secure, and that the kettle is installed correctly on the base. The power cord is tested with a multimeter. If the fuse located inside the housing blows, it should be replaced.

- The stand is disassembled and checked. If the contacts come off, they are soldered or fastened. If the plastic around the contact group melts, repair is no longer possible.

- The base cover is unscrewed and the serviceability of the contacts is checked.

- The fastening screws in the upper and lower parts of the handle are unscrewed. Then it is removed along with the plastic rocker located above the switch. If the switch is broken, it should be replaced. Often its contacts oxidize, which should be cleaned. The switch must be disassembled carefully so as not to damage the plastic parts, LED and contacts located inside.

- The heating element (heating element) is pressed tightly to the bottom with a metal disk, and flat contacts are welded to its ends, onto which slip-on terminals are placed. Its findings are tested with a multimeter to check the serviceability of the built-in spiral. If it burns out, the heating element should be replaced. It makes no sense to send a kettle for service repair if the heater is burnt out, since it is expensive and, in general, the costs will exceed the price of a new device. The heating element is easy to replace with your own hands, and if it is an integral part of the body or is not on sale, it is better to buy a new kettle.

- The kettle does not turn off due to a poorly closed lid or when the steam supply hole for automatic shutdown is clogged. The lid should be tightly closed, but first the kettle is turned off and the water is allowed to cool slightly. If the steam outlet is blocked by lime deposits, it must be cleaned. As soon as the boiling stops, the kettle can be removed from the base or the plug from the socket. Another reason for the continuous operation of the kettle is the breakdown of the bimetallic plate or pusher of the thermoautomatic machine. In this case, the faulty part must be replaced.

How to fix the lid of a Philips kettle? (Option No. 1)

For repairs you will need a small piece of monolithic polycarbonate 3 - 4 mm thick, a round needle file, sandpaper and metal scissors.

First, you need to disassemble the lid of the kettle by unscrewing 5 screws with a figured screwdriver.

The upper part is removed along with the gasket and transparent insert. The lower part remains in place. By attaching the damaged insert to the polycarbonate, we make a sketch.

Descaling

If the kettle turns off without boiling water or takes a long time to heat up, it should be thoroughly cleaned inside to remove deposits.

To prevent it from accumulating in large quantities, the kettle is periodically washed with a proprietary product. In this case, you should make sure that it does not damage the plastic housing. Scale impairs heat transfer from the heater to the water. In this case, the spiral overheats and quickly fails.

Important! When purchasing anti-scale products, you should read the instructions for their use.

Common descaling technology:

- the kettle is filled halfway with water, which should be boiled;

- the plug is removed from the socket and the recommended descaling agent is added to the water;

- after the formation of bubbles stops, the water is drained and new water is poured in;

- The water is boiled, then drained and the kettle is thoroughly rinsed.

If a lot of deposits have accumulated, the cleaning procedure is repeated.

The mesh filter is removed and cleaned of scale and other contaminants. If deposits are not removed, they are soaked in an anti-scale solution for several hours, after which the filter is washed with water.

Fixing a leaking kettle

If a new kettle leaks, you can wait a while for the scale to fill the microcracks. If the warranty is still valid, the device should be taken to a service center. Leaks can be caused by cracks. In this case, you won’t be able to repair the kettle: you need to buy a new one. The heating element may become loose. Leakage is eliminated by tightening the nuts or screws. Leakage occurs as a result of damage or aging of the gasket, which must be replaced. The use of sealants does not help here.

Question: how to repair an electric kettle if some parts that are not commercially broken are usually solved by purchasing a new device.

Some kettles contain a level indicator in the form of a transparent plastic tube. If cracks appear in it or it is broken at the junction with the kettle, the hole must be plugged using a screw with a nut, washers and seal. Such repairs spoil the appearance of the device, but you can boil water in it. It is necessary to use a plug made of stainless steel or with an anti-corrosion metal coating. To check for leaks, the kettle is filled with water and placed on a paper towel.

For what kind of breakdowns can you return an electric kettle under warranty?

High-quality household appliances are expensive, so the warranty on the device allows you to get your money back if the unit breaks down. But not with any malfunction you can return the kettle back to the store. Under warranty, they will accept a device that has significant defects. These include:

- Faults that cannot be corrected.

- Constant breakdowns of the same unit.

- A breakdown that is very expensive to repair.

- A malfunction that cannot be quickly corrected.

- Serious mechanical damage to the housing.

- Poor gasket quality causing leaks.

- Failure of the heating element during proper operation.

To return an electric kettle to the store, you must submit a written complaint. It indicates the reason for the return - a breakdown that is associated with expensive or time-consuming repairs, or other serious damage. The store administration will suggest contacting the manufacturer's service center. After the 20-day period, the breakdown must be repaired. If this does not happen, the buyer is refunded the money or offered another electric kettle in exchange.

The seller (store) can pay for an examination of the product to determine the cause of the malfunction - the buyer’s fault or a manufacturing defect. If a defect in an electrical appliance is caused by the fault of the manufacturer, the consumer has the right to demand compensation for moral damages, but in court.

Electric kettles have become an integral part of kitchen equipment. Convenient, compact devices boil water quickly, take up little space and attract attention with their beautiful design. You can’t do without a kettle, and to ensure it lasts a long time, you need to choose quality products.

Checking the heating element of the kettle indiscriminately

Indeed, using a multimeter you can check an electric kettle without disassembling it. It is enough just to check the outgoing contacts (they go to the base).

The multimeter should show some resistance - 150-170 Ohms often. If the device shows infinity on the screen, the heating element is burnt out and requires replacement. However, this is not possible in every electric kettle design.

Dismantle the heating element only if you have found a similar one for replacement. But very often the heating element is intact (absolutely working). The reason for the malfunction is hidden in the control contact. It is he who turns off the electric kettle when the water in it boils.

Due to the passage of high amplitude current through it, it becomes charred. Simply clean the contact with a nail file and the kettle will work again.

The video clearly demonstrates the process of repairing an electric kettle:

one of the solid-iron chrome-plated outside Chinese automatic teapots with backlight died here, a TEN horseshoe heater made of an incomprehensible alloy of roofing felts with zinc or with aluminum SOLDERED TO THE BOTTOM OF THE KETTLE OUTSIDE - there is a recess in the bottom, a tinned copper plate is soldered to it and to it a TEN TEN similar I have a dead one, along with the bottom from a plastic kettle, I want to re-solder, but the 200W solder broke off, even at 260V from LATR the solder does not melt (it is similar to the one with which the central contacts of Soviet light bulbs were soldered) WHO KNOWS WHAT SOLDER IS THERE, WHAT TO REPLACE, WHICH FLUX is better (borax will work??) and most importantly, WHAT TO MELT IT, WHAT POWER AND TEMPERATURE IS NEEDED. Yes, there is still a problem: a plastic transparent plug is inserted into the bottom (fused?) or a transparent plastic plug is glued into it, there are 2 LED backlights, this rubbish can probably melt?? It’s unclear how the Chinese collect them. PS DO NOT suggest throwing it out, I will ALWAYS have time to do that.

Yes-ah-ah. Well, if you need it, there are also irons, electric burners and gas for bottom heating. if there is solder, not welding.

PS: it’s good to soak condoms in fairy before washing, and darn socks with floss. suddenly it will come in handy.

trash

:

PS DO NOT suggest throwing it out, I will ALWAYS have time to do that.

Then take it to the master who will do everything

trash

:

200W soldering even at 260V from LATR does not melt the solder.

Have you tried mixing low-melting solder?

Don't torture your ass. The crab keeps hinting and hinting at you, but you don’t intervene. The heating element is WELDED. If you really want to make this teapot, then break out the heating element by biting it, and put another one in its place. You will no longer achieve the required density of contact between the heating element and the bottom of the kettle and, accordingly, the heating area. Conclusion: 1. Is it a shame to throw it away? 2. Send a complaint to Chinland.

If it were plastic, I wouldn’t even think about taking it apart - it would ring and if it broke, I’d throw it away, but it’s a pity that it’s shiny chrome. I'll try the gas, it won't work, I'll throw it away. There’s nothing to lose, and at the same time I’ll find out if it’s welded or soldered with REFRACTORY SOLDER.

try a gas welder (small ones that run on lighter gas). first remove the plastic lamp. If it starts to melt, then remove the solder centimeter by centimeter; if not, then alas, welding.

If space allows, try using screws and a bracket to screw a new heating element on top of the burnt one.

trash

:

brilliant pathetic.

Well, the raven is also drawn to shiny things.

trash

:

brilliant pathetic.

Then tell us how many cubic meters of gas you burned. Is there a counter?

Recently I threw away the chrome plated Bork.

Selector

:

Conclusion: 1. Is it a pity to throw it away?

2. Send a complaint to Chinland. - I’ll also tell you a way - I went to the ASC to see guys I knew - they offered - I took 5 pieces of stainless steel teapots for 2 bucks each from the pre-trade, almost from complaints with a diagnosis of “leakage in the level sensor”. business for 10 minutes, and the heating element, kettle sole - for pennies. and the relatives are happy. and so that “soar your brains with this approach. well, fuck it.

trash

:

I find out it’s welded or soldered with REFRACTORY SOLDER

- will you drink from it YOURSELF after the repair?

Radio Forum is a site dedicated to discussing electronics, computers and related topics.

An electric kettle has become an indispensable appliance in any kitchen. It heats water quickly and consumes little electricity. However, like any other device, sooner or later it may fail. There are many reasons for this situation, but most often they come down to the fact that the device does not work due to damage to the heating element. Therefore, many are interested in the question of how to ring the heating element in a kettle and, if necessary, change it?

Principle of operation

To understand what could cause a malfunction, you need to understand the principle of operation of this device. Regardless of the model and its cost, electric kettles operate on the same principle: the main heating element is installed in the lower part - a heating element, which is connected to a thermostat. When the device is connected to the network, the heating element heats up, gives off its heat to the water and brings it to a boil. When the water temperature approaches 100°C, steam is produced. It passes through the channel and reaches the thermostat, after which the kettle turns off.

Operating principle of an electric kettle

Despite the fact that the operating principle of the device is quite simple, its repair will be easy only for an experienced technician. But those who encounter a similar problem for the first time do not know how to change the heating element in a kettle. Only a few prefer to fix the problem themselves, while others go to the store in search of a new device for boiling water.

Disassembly nuances taking into account the model

Before troubleshooting, you need to check the obvious points - connecting the device to the network, pressing the power button, the state of the power connector, the correct position of the unit on the stand. If this is not the cause of the breakdown, the components must be dismantled and the problem must be accurately determined.

How to disassemble an electric kettle with a closed heating element:

- Remove the cover from the bottom. In old-style units, the fasteners are located at the top.

- In modern models, first remove the top trim, secured in two grooves at the base of the handle.

- The grooves are carefully released to gain access to the bolts, and the fasteners are unscrewed. Sometimes the top handle is removed with the lid.

- Turn the kettle over and unscrew three more fasteners from the bottom of the device; some models may have more.

- There are locking teeth along the perimeter of the bottom - they need to be snapped off step by step by lightly pressing a screwdriver.

- When the bottom is removed, access to the heating element opens, the functionality of which must be checked with a tester.

In disc electric kettles, the heating element does not come into direct contact with water. A ringing of the electrical circuit tester already at this stage of disassembling the unit will indicate the serviceability of the heating element or its failure as a result of a break in the spiral in the tube.

To check the thermostat, unscrew the screw at the bottom of the handle and carefully remove it. There is a screw under the button that needs to be unscrewed. All thermostat connection points ring. After this, the assembly itself is disassembled. First, remove the cover, check the part, and, if possible, replace it with a new one. To remove the cover, you need to press it with your fingers and push it forward, and then clean the contacts.

Stages of disassembling an old model electric kettle:

- Unscrew the screws located on the bottom of the device.

- The side panel is removed, which opens access to the heating element and thermostat.

- Unscrew the screws to get to the main components.

- If the button is located on top, the kettle must be completely disassembled.

- To check an open heating element, first remove the cover.

If the cause of the malfunction is not a broken heating element, you should check the stand. The kettle is disconnected from the network and removed from the base. Turn the stand over and unscrew the mounting bolts. Disk models have three screws that can be easily unscrewed with a Phillips screwdriver. Remove the lower part of the stand, allowing access to all elements. This system is easy to disconnect from the kettle body.

The device is disassembled slowly, since some manufacturers install special plastic latches to improve the quality of joining the parts. To avoid breaking them, first check for the presence of additional fasteners, and then disconnect the structural elements.

Removing the lid of the kettle

Unwinding the kettle

How to remove the handle

Removing the housing

Case bottom

Private breakdowns

There are a number of typical problems that are directly related to deviations in the operation of the heating element. Among them it is necessary to highlight:

- Slow water heating. This malfunction is associated with the heating element, since there is a significant layer of scale on it. Deposits are formed due to insufficient maintenance of equipment. Scale is fossilized minerals and salts found in tap water. During use of the device, they harden and deposit on the walls, including the spiral. If the scale is not removed in time, the heating element may burn out. For the same reason, damage to the contact rods of the heating element occurs. Not everyone knows how to ring an electric kettle and determine the cause of the malfunction at home. Therefore, repairs should be entrusted to experienced professionals.

- The electric kettle turns off prematurely. The reason is quite simple - scale formed on the heating element. The heating element has a fuse that trips when it overheats. For repairs, it is necessary to clean the device from plaque.

- The kettle does not turn on due to a broken spiral thread. The breakdown occurred due to scale on the heating element or turning on the device without liquid. The spiral can also burn out due to low-quality parts that were used in the manufacture of the heating device.

Possible reasons

Sometimes a breakdown actually happens because of the owner. This happens with improper care. But just clean your electric kettle regularly and the problem can be avoided.

Without cleaning, scale will form on the walls of the appliance. It interferes with heat transfer. The coil heats up, but does not transfer heat to the liquid. Then the heating element breaks down and burns out.

Important! If the kettle starts to switch off prematurely, it is worth checking its walls. It is possible that scale has formed on them. The plaque should be removed immediately, otherwise other elements will break.

Also, you cannot connect an electrical appliance to the network if there is no water in it. This leads to combustion. The heating element cannot cope with voltage surges, so the device fails.

Other causes of breakdowns:

- Service life has expired. With prolonged use, the plastic becomes deformed. This can be seen in the place where the heating coil is attached. This is how the device begins to leak.

- Traction is frayed. This element is needed to transmit power from the switch, which is located on top of the device. Because of this, the power button breaks. It can also fail due to the fact that the contacts are burned out or oxidized.

The more complex the electric kettle is, the more possible causes of failure. Therefore, it is not recommended to buy devices with a thermostat. The part leads to burnout of contacts and wear of the product.

Checking with a multimeter

Most people who repair equipment have such devices. To do this, you need to turn on the multimeter (tester) in resistance measurement mode, and then touch the contact rod with one end of the measuring device. If the thread inside the heating tube is broken, an incorrect value will appear on the tester screen. The operating resistance for a kettle with a power of 2000 W will be 25 Ohms. If no deviations are found inside the tube, then one of the taps needs to touch the contact rod, and the other to the metal tube. If there is no short circuit, then the screen will show an infinite resistance value. And if it is, then it will be fixed and such a heating element cannot be repaired.

Test using power supply

Testing using a heating element power source is done as follows: a battery (-) must be connected to one of the heating element rods, and an LED light bulb is connected to the (+) pole, the second output of which is connected to the other rod of the heating element. If the light bulb lights up, the spiral is intact.

Checking with an indicator

Checking the operation of the heating element

This verification method is dangerous because it must be done while the device is connected to the network. You need to act very carefully. In the socket you need to determine where the phase is located. After this, the contact rod must be connected with a piece of wire to the phase. If you touch the opposite rod with the tip of a special screwdriver, the lamp will light up. And if you lean the indicator against the handset, it will not light up. This means that the integrity of the spiral is broken.

How to replace the heating element in an electric kettle

To replace the heating element in an electric kettle, you need to completely disassemble it:

- remove the cover. To do this you will need a Phillips screwdriver. Raise the cover and unscrew all the screws;

- remove the handle - you need to unscrew the screws at the bottom of the kettle, then unclip the handle. Depending on the model, the mechanism may be located at the bottom of the device or directly on the handle itself;

- to dismantle the heating element, you need to remove the on/off button of the device, then unscrew the screws that were hidden under the handle;

- After this, the heating element can be freely removed. Then install a new heating element and put all the parts back together.

Replacing the heating element in a kettle

After completing the repair, do not forget to check the functionality of the device. Replacing the heating element is a quick and easy process that anyone can handle. When repairing an electric kettle, you must follow safety precautions, especially when checking the device.

Conclusion on electric kettle repair

As readers understand, this is one of the cheap models of Chinese teapots, made to order from a certain company. The maintainability of the product is zero. Difficult to disassemble, even more difficult to assemble. By picking, it is easy to spoil the presentation and functionality. The bottom got dressed quite simply, with considerable effort and threatening clicks. The lid caused a lot of trouble. Skillful use of a hairdryer will help. With only a screwdriver, disassembly will be difficult.

We recommend evaluating the assembly in the store. How difficult will it be to disassemble the device in order to repair the electric kettle with your own hands? If the product is disposable, this is not very encouraging, and if, in addition, it is dangerous... no comment.

We hope that after such a detailed review, readers will be able to repair Tefal electric kettles and repair Scarlet electric kettles. After all, most products are made in China. We want to say goodbye, look at the pictures, evaluate, study. If the bimetallic strip is inserted the wrong way, the electric kettle will stop turning off when it boils! Although the click is heard.