Motor rated power

This is the engine power with which it could operate in nominal mode - the mode of efficient operation for a long time (at least several hours). Rated power is measured in W (kW) or horsepower (hp) and is indicated on the electrical panel along with other main characteristics.

motor rated power

At loads less than Pnom, the engine power is fully developed. When the engine is loaded to rated power for a relatively short period of time, it can be considered that it is not being used to its full potential. In such a situation, it may be advisable to briefly overload it, the limit of which is determined by the overload power of the engine.

In the electric motor passport, the manufacturer always indicates the rated values of power Pnom, voltage Unom, power factor cosϕnom, rated angular speed of the motor ωnom.

Rated power calculation

Equivalent current method

It is applicable for calculating the rated power, subject to obligatory observance during operation of the invariance of power loss indicators in the motor windings, consisting of constant and variable power values, resistance of the rotor and stator windings, and mechanical friction losses. Knowing the rated power factor, equivalent current and rated voltage, it is possible to calculate the rated power of the electric motor:

Pnom ≥ Iek ∙ Unom ∙cosϕnom,

where Iek is the equivalent current indicator,

Unom – rated voltage,

cosϕnom is the rated power factor, which increases with increasing power and rated angular speed of the rotor, and also depends on the load. For most electric motors it is 0.8-0.9.

Equivalent moment method

Electric motors of any type have a torque proportional to the product of the current and the magnitude of the magnetic flux. The equivalent torque method for calculating rated power is used in cases where the applied load conditions directly determine the torque required from the motor, rather than the current. For synchronous and asynchronous AC machines, the power factor cosϕ is approximately taken as a constant value:

Pnom = Mvr ∙ ωnom,

where Mvr is the torque value,

ωnom – rated angular speed of the motor.

Determination of rated power experimentally

The rated power indicated in the passport or plate of the device will be equal to this value only at the optimal load on the shaft, determined by the manufacturer for the rated mode. What to look for if for some reason your passport has not been preserved or the inscriptions on the plate have been erased?

Practical measurements will help:

- It is necessary to completely turn off all other sources of electricity consumption: lighting, electrical appliances, etc.

- If you use an electronic meter, you should connect the engine under load for 5-6 minutes, the electronic display will display the load value in kW.

The disk meter measures in kWh. You should record the latest readings and turn on the engine for 10 minutes, accurate to the second. After stopping the electric machine, subtract the recorded readings from the obtained value and multiply by 6. The resulting number will be the active mechanical power of the engine.

When using this method, it is important to select the load correctly, since if it is insufficient or overloaded, the determined indicator will be far from the rated power of the electric motor.

Write comments, additions to the article, maybe I missed something. Take a look at the site map, I will be glad if you find anything else useful on mine. All the best.

This is the engine power with which it could operate in nominal mode - the mode of efficient operation for a long time (at least several hours). Rated power is measured in W (kW) or horsepower (hp) and is indicated on the electrical panel along with other main characteristics.

At loads less than Pnom, the engine power is fully developed. When the engine is loaded to rated power for a relatively short period of time, it can be considered that it is not being used to its full potential. In such a situation, it may be advisable to briefly overload it, the limit of which is determined by the overload power of the engine.

In the electric motor passport, the manufacturer always indicates the rated values of power P nom, voltage U nom, power factor cosϕ nom, rated angular speed of the motor ω nom.

Engine types

DC and AC motors

Depending on the electric current used, motors are divided into two groups:

- DC drives;

- AC drives.

DC motors are not used as often today as they used to be. They have practically been replaced by asynchronous motors with squirrel-cage rotors.

The main disadvantage of DC electric motors is that they can only be operated with a DC source or an AC-to-DC converter. In modern industrial production, ensuring this condition requires additional financial costs.

However, with significant disadvantages, this type of motor is characterized by a high starting torque and stable operation under conditions of high overloads. Drives of this type are most often used in metallurgy and machine tool construction and are installed on electric vehicles.

The operating principle of AC electric motors is based on electromagnetic induction that occurs during the movement of a conducting medium in a magnetic field. To create a magnetic field, windings flowing around currents or permanent magnets are used.

AC electric motors are divided into synchronous and asynchronous. Each subgroup has its own design and operational features.

Synchronous electric motors

Synchronous motors are the optimal solution for equipment with constant operating speed: DC generators, compressors, pumps, etc.

The technical characteristics of synchronous electric motors of different models differ. The rotation speed ranges from 125 to 1000 rpm, the power can reach 10 thousand kW.

The design of the drives includes a short-circuited winding on the rotor. Its presence allows for asynchronous engine starting. The advantages of equipment of this type include high efficiency and small dimensions. The operation of synchronous electric motors allows you to reduce electricity losses in the network to a minimum.

Asynchronous electric motors

Asynchronous AC motors are most widely used in industrial production. A feature of these drives is a higher frequency of rotation of the magnetic field compared to the speed of rotation of the rotor.

Modern engines use aluminum to make the rotor. The light weight of this material makes it possible to reduce the weight of the electric motor and reduce the cost of its production.

The efficiency of an asynchronous motor drops almost by half when operating at low loads - up to 30-50 percent of the nominal value. Another disadvantage of such electric drives is that the starting current parameters are almost three times higher than the operating parameters. To reduce the starting current of an asynchronous motor, frequency converters or soft starters are used.

Asynchronous motors meet the requirements of various industrial applications:

- For elevators and other equipment requiring stepwise speed changes, multi-speed asynchronous drives are produced.

- When operating winches and metalworking machines, electric motors with an electromagnetic braking system are used. This is due to the need to stop the drive and fix the shaft in case of power outages or disappearance.

- In processes with a pulsating load or in intermittent modes, asynchronous electric motors with increased sliding parameters can be used.

Valve motors

The group of valve electric motors includes drives in which the operating mode is controlled by means of valve converters.

The advantages of this equipment include:

- High service life.

- Easy maintenance due to contactless control.

- High overload capacity, which is five times the starting torque.

- Wide speed control range, which is almost twice the range of asynchronous electric motors.

- High efficiency at any load - more than 90 percent.

- Small dimensions.

- Fast payback.

Rated power

(GOST 23262-88)

- an artificial value, it leaves freedom of choice to the manufacturer. The designer is free to specify the rated power value that corresponds to the most advantageous value of nonlinear distortion. Typically, the indicated power was adjusted to the GOST requirements for the complexity class with the best combination of measured characteristics. Indicated for both speakers and amplifiers.

Sometimes this led to paradoxes - with step-type distortion occurring in class AB amplifiers at low volume levels, the level of distortion could decrease when the signal output power was increased to the nominal one. In this way, record rated characteristics were achieved in the amplifier data sheets, with an extremely low level of distortion at a high rated power of the amplifier. Whereas the highest statistical density of a musical signal lies in the amplitude range of 5-15% of the maximum power of the amplifier. This is probably why Russian amplifiers were noticeably inferior in hearing to Western amplifiers, whose optimum distortion could be at medium volume levels, while in the USSR there was a race for a minimum of harmonic and sometimes intermodulation distortion at any cost at one nominal (almost maximum) power level.

Example

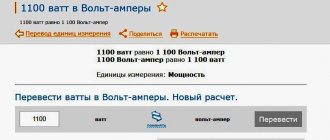

Let's say we have a generator with a power rating of 3 kVA and cos φ equal to 0.8. In this case, the rated power of this installation will be equal to:

3 kVA x 0.8=2.4 (kW)

Now you can understand why power can be indicated in certain units of measurement, in watts (W) or Volt Amperes (VA). Some manufacturers, in order to save the consumer from the need to carry out calculations, simply indicate in the accompanying documentation both power values - nominal and maximum. There are also options when the manufacturer indicates only one of the capacities and gives the value of the power factor. Some unscrupulous companies may hide the power factor from the consumer. This is done in order to pass off the generator as a more powerful unit than it actually is.

What is rated power?

We come across the term “rated power” almost every day. Whether we choose an electric kettle or an incandescent lamp, this value is indicated everywhere. The unit of measurement is watts or kilowatts. It would seem - what could be simpler in this matter? After all, even from a school physics course, everyone knows that to determine power (P) it is enough to multiply the values of current and voltage. But what is hidden behind the words “rated power”? The term “nominal” refers to a certain value of something that does not take into account external corrective factors. Thus, the rated power is the value specified by the manufacturer, which can only be obtained with the specified design parameters. This is a general concept. In each specific case, it is necessary to take into account its specific features. Let's take an example with an incandescent lamp. Its glass bulb is marked: 230 V, 100 W. That is, 100 W can only be achieved at a voltage of 230 V. The rated power is those same 100 W. Its value decreases with decreasing voltage and increases with increasing voltage since these parameters are directly dependent on each other (P=I*U).

Typically, most electrical appliances have an upper limit, usually 5-10%. In other words, operation at 230 V + 23 V = 253 V is acceptable. The lower limit may not be specified, as in the case of a lamp. More complex equipment is limited by design parameters both above and below. For example, how do we understand the term “rated engine power”? There are two equivalent definitions - one from an electrical point of view, and the other based on the calculated mechanical load on the shaft. Although they are directly related, the second one is easier to understand. We'll give both. The rating plate always shows the power value. It is numerically equal to that consumed from the electrical network at the calculated mechanical load, and the temperature of the housing must be within acceptable limits (implies long-term operation). That is, we can assume that the passport value is equal to the nominal value. If the electric drive operates in intermittent mode (duty cycle is not equal to 100%), then this correspondence is not fulfilled, since the operating time is not enough to transition to a steady state, when the increase in heating is compensated by the ambient temperature. In this case, a load diagram will be required: the rated power will be equal to the product of the passport value P and the square root of the coefficient selected from the schedule. All of the above is true for the electrical component.

Types of electric motors

Commutator motors

A commutator machine is a rotating electrical machine in which at least one of the windings involved in the main energy conversion process is connected to a collector [1]. In a commutator motor, the brush-commutator assembly serves as a rotor position sensor and a current switch in the windings.

Universal electric motor

DC brushed motor

- With permanent magnets

- With field winding

Brushless motors

Brushless motors may have slip rings with brushes, so there is no need to confuse brushless and brushless motors.

A brushless machine is a rotating electrical machine in which all electrical connections of the windings involved in the main energy conversion process are carried out without sliding electrical contacts [1].

Asynchronous electric motor

- Single phase

- Two-phase

- Three-phase

Synchronous electric motor

- With field winding

- With permanent magnets

- Reactive

- Hysteresis

- Reactive-hysteresis

- Stepper

Electric motor label

Having examined any electric motor, with rare exceptions, you can find a plate screwed onto bolts, screws or rivets. What is written on this piece of metal? Let's take a nameplate, replacing the serial number on it with the name of the site.

By the way, it rarely happens that a plate for electrical equipment is in such almost perfect condition. Often the data is faded or covered with paint, because the task is for the maintenance personnel to paint the engine, and not to paint the engine, leaving the plate untouched. But we were lucky. Let's go in order.

First line

- number of phases and type of current (3

), serial number, network frequency, design and installation form, insulation class

Second line

— type of electric motor, cosine phi, possible connection diagrams, rated speed

Third line

- possible rated voltages, rated power, IP - degree of protection of the electric motor, weight, operating mode of the electric motor (S1).

Fourth line

- rated currents depending on the winding connection circuit, then which guest the ed corresponds to.

Let's look at the individual parameters in more detail.

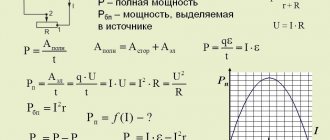

Electric motor power: total, active and shaft

Formula for calculating the power of a three-phase asynchronous motor:

S1 - total power consumed by the motor from the network

P1 - active power consumed by the electric motor from the network (indicated on the nameplate)

P is the active power on the EM shaft.

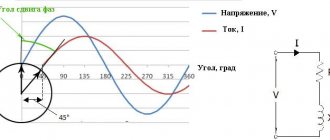

cosf - cosine phi, power factor - phase angle between active (P) and total power (S).

In the formulas above, the power value is obtained in W, the total power value in VA. To convert to kilowatts, you need to divide the resulting value by a thousand. The value of current and voltage, respectively, in the formula above is in amperes and volts.

I1 and U1 are linear values of current and voltage, they are also called phase-to-phase. Not to be confused with phase ones. Linear ones are AB, BC, SA (380); phase - AO, VO, SO (220). If we express the power formulas in terms of the phase values of current and voltage, then instead of the root of three there will initially be a coefficient of 3. This coefficient is determined visually through the vector diagram of the three-phase voltage.

For DC motors, the formula will simply be the voltage at the motor terminals multiplied by the current drawn by the motor from the network.

Power consumption p1 is greater than the power on the EM shaft due to losses that arise when converting electrical energy into mechanical energy.

Star/Delta and 220/380, 380/660

See all the values in order as they go through the fraction. That is, it is written on the nameplate Y/D (triangle/star), which means that the currents and voltages will accordingly be first for Y, and after the fraction for the star. The only caveat is that at 220/380 the triangle will be 220, and at 380/660 the triangle will be 380. That is, to say that 380 is always a star is incorrect.

Rated power calculation

Equivalent current method

It is applicable for calculating the rated power, subject to obligatory observance during operation of the invariance of power loss indicators in the motor windings, consisting of constant and variable power values, resistance of the rotor and stator windings, and mechanical friction losses. Knowing the rated power factor, equivalent current and rated voltage, it is possible to calculate the rated power of the electric motor:

P nom ≥ I eq ∙ U nom ∙cosϕ nom,

where I eq is the equivalent current indicator,

U nom – rated voltage,

cosϕ nom – rated power factor, increasing with increasing power and rated angular speed of rotor rotation, and also depending on the load. For most electric motors it is 0.8-0.9.

Equivalent moment method

Electric motors of any type have a torque proportional to the product of the current and the magnitude of the magnetic flux. The equivalent torque method for calculating rated power is used in cases where the applied load conditions directly determine the torque required from the motor, rather than the current. For synchronous and asynchronous AC machines, the power factor cosϕ is approximately taken as a constant value:

P nom = M time ∙ ω nom,

where M wr is the value of the torque,

ω nom – rated angular speed of the motor.

Determination of rated power experimentally

The rated power indicated in the passport or plate of the device will be equal to this value only at the optimal load on the shaft, determined by the manufacturer for the rated mode. What to look for if for some reason your passport has not been preserved or the inscriptions on the plate have been erased?

Practical measurements and an electricity meter will help:

It is necessary to completely turn off all other sources of electricity consumption: lighting, electrical appliances, etc.

If you use an electronic meter, you should connect the engine under load for 5-6 minutes, the electronic display will display the load value in kW.

The disk meter measures in kWh. You should record the latest readings and turn on the engine for 10 minutes, accurate to the second. After stopping the electric machine, subtract the recorded readings from the obtained value and multiply by 6. The resulting number will be the active mechanical power of the engine.

- For low-power engines, you can calculate the number of revolutions of the counter disk, for each of which the value of full revolutions in power units is indicated. Simple calculations will help determine the required power value.

When using this method, it is important to select the load correctly, since if it is insufficient or overloaded, the determined indicator will be far from the rated power of the electric motor.

Rated active power of the electric drive

(

)

– this is the power consumed from the network at the rated load of the electric drive, at which it must operate for a long time in a steady state without exceeding the permissible temperature.

For long-term operation of the electric drive

equal to the passport value

:

.

For receivers operating in intermittent mode, the rated power is determined from the nameplate power by bringing it to a long-term operating mode (PV = 1) in accordance with the formulas:

Or

,

Where

nameplate value, p.u.;

– switching factor, calculated from the ED load graph, see formula (2.1).

For electric motors, the power consumed from the network is called connected power

and is determined by the expression:

,

where is the rated power developed on the motor shaft, kW;

– nominal efficiency of the electric motor, p.u.

Rated reactive power of the electric unit

(

) – reactive power consumed by it from the network at rated active power and rated voltage.

For an electric device operating in a long-term mode, the value is calculated using the formula

,

Where

corresponds to nominal

EP (

– passport value).

For an electric generator operating in intermittent mode, the value

calculated by the formula

.

Nominal apparent power

.

Basic parameters of the electric motor

- Motor power

- Rated speed

- Efficiency

- Motor torque

- Rotor moment of inertia

- Rated voltage

- Electrical time constant

Motor power

Motor power is the useful mechanical power at the motor shaft.

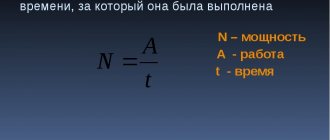

Mechanical power

Power is a physical quantity that shows how much work a mechanism does per unit of time.

- where P

– power,

W

, - A

– work,

J

, - t

—time,

s

Work is a scalar physical quantity equal to the product of the projection of force and direction F

and the path

s

traversed by the point of application of the force.

- where s

– distance,

m

For rotational movement

- where θ – angle, rad

- where ω – angular frequency, rad/s

,

In this way, you can calculate the value of mechanical power on the shaft of a rotating electric motor

Rotation frequency

- where n

is the rotation speed of the electric motor,

rpm

Rotor moment of inertia

The moment of inertia is a scalar physical quantity, which is a measure of the inertia of a body in rotational motion around an axis, equal to the sum of the products of the masses of material points by the squares of their distances from the axis

Power standards (DIN, RMS, PMPO)

The variety of standards used to measure amplifier output power and speaker power can be confusing for anyone. Here is a block amplifier from a reputable company with 35 W per channel, and here is a cheap music center with a 1000 W sticker. Such a comparison will clearly cause confusion among a potential buyer. It's time to turn to standards...

In Russia, two power parameters are used - nominal and sinusoidal. This is reflected in the names of speaker systems and speaker designations. Moreover, if previously the rated power was mainly used, now more often it is sinusoidal. For example, 35AC speakers were subsequently designated S-90 (nominal power 35 W, sine wave power 90 W)

Rated power - power at the middle position of the amplifier volume control, at which other parameters of the device correspond to those stated in the technical description.

Sine wave power is the power at which an amplifier or speaker can be operated for an extended period of time with a real music signal without physical damage. Usually 2 - 3 times higher than nominal.

Western standards are broader, typically using DIN, RMS and PMPO.

DIN - Roughly equivalent to sine wave power - the power at which an amplifier or speaker can be operated for an extended period of time with a pink noise signal without physical damage.

RMS (Rated Maximum Sinusoidal) - Maximum (limit) sinusoidal power - the power at which an amplifier or speaker can operate for one hour with a real music signal without physical damage. Typically 20 - 25 percent higher than DIN.

PMPO (Peak Music Power Output) - Musical power (exorbitant :-)) - the power that the speaker speaker can withstand for 1-2 seconds on a low frequency signal (about 200 Hz) without physical damage. Typically 10 - 20 times higher than DIN.

As a rule, serious Western manufacturers indicate the power of their products in DIN, and manufacturers of cheap music centers and computer speakers in PMPO.

100 W (PMPO) = 2 x 3 W (DIN)

Don't forget about speaker impedance. Mostly on the market there are speakers with a resistance of 4, 6, 8 ohms, 2 and 16 ohms are less common. The amplifier power will vary when connecting speakers of different impedances. The amplifier's instructions usually indicate what speaker impedance it is designed for, or the power for different speaker impedances. If the amplifier allows operation with speakers of different impedances, then its power increases as the impedance decreases. If you use speakers with an impedance lower than that specified for the amplifier, this may cause it to overheat and fail; if it is higher, then the specified output power will not be achieved. Of course, the volume of the acoustics is affected not only by the output power of the amplifier, but also by the sensitivity of the speakers, but more on that next time. The main thing is not to forget that power is only one of the parameters, and not the most important one for obtaining good sound.

Variations of electric motors according to climate control

When selecting an electric motor, you need to know what climatic conditions this motor will be used in.

The designations for different climate versions are listed below:

- U – Temperate climate;

- HL - Cold climate;

- TC – Tropical Dry climate;

- TV – Tropical Humid Climate;

- T – Tropical climate (generalized);

- M – Maritime climate;

The digital value after the letter designation of the brand indicates the type of its placement:

- 1 – work on the “street”;

- 2 – work on the “street”, but under a canopy;

- 3 – work indoors;