Nichrome is an alloy of 80% nickel and 20% chromium with a melting point close to 1400 C. It is gray in color and is resistant to corrosion. Due to its high resistance and difficult oxidation at high temperatures, it is widely used in manufacturing. Nichrome wire is a resistive material that is used to improve the high temperature performance of many materials at very high temperatures where other conductive metal elements cannot operate.

What is nichrome

Nichrome alloy has good ability to resist electron flow. These unique properties make it suitable for applications in heating elements of hair dryers and heat guns. It has high oxidation resistance, which also makes it a suitable material for heating technology. Nichrome wire is wound into coils with a specific electrical resistance of nichrome through which a current is passed to produce heat.

Nickel-chromium 90/10 alloy is used in thermocouples in combination with Ni/Al 95/5 alloy. This combination is called chromel-alumel, represents heating elements with a maximum operating temperature of 1100 C and is subject to drift in the region of 1000 C due to oxidation. This effect is eliminated by adding silicon. Commercial grades include Nicrosil (containing 14% Cr and 1.5% Si) and Nisil (containing 4.5% Si and 0.1% Mg).

What does nichrome look like?

Nickel-chromium 80/20 metal is a high-temperature corrosion-resistant alloy used for wrought and cast parts because it has better resistance to oxidation and hot corrosion than cheap iron-nickel-chromium alloys.

Properties and characteristics of the alloy

Nickel-chromium metal shows that chromium is highly soluble in nickel with a maximum of 47% at the eutectic crystallization temperature of 1145C and drops to 30% at room conditions.

The introduction of small amounts (<7%) of chromium into nickel increases the sensitivity of the nickel-chromium alloy to oxidation due to a proportional increase in the rate of oxygen diffusion. This trend is reversed, when more than 7% chromium is added, the drop continues up to 30%, after which the oxidation process stabilizes.

With increasing chromium additions, there is a noticeable increase in the electrical resistivity of the conductor. The addition level of 20% chromium is considered optimal for elements operating in heating systems. This composition combines not only good electrical properties, but also strength ones. This metal has ductility, which makes it suitable for the process of drawing nichrome wire.

Here are some basic properties of nichrome.

- Color: has a silver-gray color.

- Specific gravity: 8.4 g/cm3.

- The density of nichrome is: 8400 kg/m3.

- The melting point of this substance is: 1400 C.

- The electrical resistivity at room temperature for this substance is: 1.0 × 10 -6 to 1.5 × 10 -6 ohm (Ω).

- Specific heat capacity measures the amount of heat required to change the temperature of a substance by a certain amount, usually 1 degree. The specific heat capacity of this substance is: 450 J/(kg*K).

- The modulus of elasticity is a mathematical representation of a substance or the tendency of an object to deform when a certain force is applied to it. The elastic modulus for nichrome is: 2.2 × 10 11 Pa.

- Thermal expansion is the property of a substance due to which it changes volume when exposed to heat. The coefficient of thermal expansion of nichrome is: 14 × 10 -6 / C.

- Operating temperature is defined as the T at which a mechanical or electrical device operates. The operating temperature for nichrome is: 900 C.

- The temperature coefficient mathematically represents the relative change in the physical properties of a substance when T changes by 1 Kelvin. The temperature coefficient of resistance for nichrome is 100 ppm/C at temperatures ranging from 25 C to 100 C.

- The substance is highly resistant to corrosion and resistant to oxidation at high temperatures.

Decoding stamps

The properties and purpose of nichrome products are determined by their chemical composition. Let's look at the main ones.

- Х20Н73УМ-VI: chromium - 20%, nickel - 73%, aluminum - 3%, molybdenum - 1.5%, manganese - up to 0.3%, titanium - up to 0.05%, iron - 2%, carbon - up to 0.05%; melted using the vacuum induction method;

- ХН70У-Н: Cr - 27%, Ni - 70%, Al - 3%, Mn - up to 0.3%, Cs - up to 0.03%, Ba - up to 0.1%, Fe - up to 1.5% , C - up to 0.1%; designed for electric heating elements;

- ХН20УС: Cr - 20%, Ni - 20%, Al - 1%, Zn - up to 0.2%, Ca - up to 0.1%, Si - 2.5%, Fe - 50%, C - up to 0, 08% - for heaters of industrial furnaces.

Advantages and disadvantages

Nichrome alloys are characterized by high resistance to electric current; this property allows manufacturers to produce electric heating devices with smaller dimensions and weight. Other advantages of nichrome:

- Resistance to corrosion and aggressive environments;

- no temperature deformation;

- high ductility of the alloy, due to which it lends itself well to welding and stamping;

- lack of magnetic properties;

- high heat resistance;

- light weight;

- low specific resistance and thermal conductivity, which requires less nichrome wire for the same power;

- do not form oxides during operation;

- have an increased number of on/off cycles before destruction than other heating elements;

- high strength characteristics.

Nichrome has high heat resistance.

Among the disadvantages, one can highlight the high cost of nichrome wire due to the nickel included in the composition and the costly manufacturing method, and therefore its scrap is highly valued on the market.

Temperature coefficient of resistance for different substances

Most metals have a temperature coefficient of resistance greater than zero. This means that the resistance of metals increases with increasing temperature. This occurs as a result of electron scattering on the crystal lattice, which enhances thermal vibrations.

At temperatures close to absolute zero (-273 o C), the resistance of a large number of metals sharply drops to zero. Metals are said to go into a superconducting state.

Semiconductors that do not have impurities have a negative temperature coefficient of resistance. Their resistance decreases with increasing temperature. This occurs due to the fact that the number of electrons that move into the conduction band increases, which means that the number of holes per unit volume of the semiconductor increases.

Electrolyte solutions have. The resistance of electrolytes decreases with increasing temperature. This occurs because the increase in the number of free ions as a result of the dissociation of molecules exceeds the increase in the scattering of ions as a result of collisions with solvent molecules. It must be said that the temperature coefficient of resistance for electrolytes is a constant value only in a small temperature range.

Nichrome brands

Alloy grades are established by state standards GOST 10994-74, GOST 12766.1-90 and GOST 8803-89. The most popular alloy grades are: X20N80 and X15N60.

Explanation of nichrome alloy markings using the example of X20N80:

- X – Cr content;

- 20 – value in %;

- Н – Ni content;

- 80- in%.

The designation may contain additional letters, for example, for the X15N60-VI alloy, the letters “VI” indicate that the alloy was made using vacuum induction melting. For the X15N60-N alloy, the letter “N” indicates that it contains zirconium to increase the reliability and durability of the heater at maximum operating temperatures.

Other designations for alloy products:

- H - used for heating elements with a thickness greater than 0.2 mm;

- C - wire can be used as a resistance element in mechanical designs;

- Heating element - thread is used for dry type electric heaters.

Nichrome wire resistance

Home / Nichrome, fechral / Resistance of nichrome wireNominal resistance value of nichrome wire

| Wire diameter, mm | Tolerance | Weight 1 m Х20Н80, | Nominal value of electrical resistance of 1 meter of wire, Ohm | |||

| + mm | gram | Х20Н80 | Х15Н60 | Х23У5Т | ||

| GOST 8803-89 | ||||||

| 0,01 | Not | 0 | 16000 | not made | not made | |

| 0,01 | normi- | 0 | 13000 | not made | not made | |

| 0,01 | rushes | 0 | 10700 | not made | not made | |

| 0,01 | 0 | 9020 | not made | not made | ||

| 0,01 | 0 | 6630 | not made | not made | ||

| 0,02 | 0 | 5070 | not made | not made | ||

| 0,02 | 0 | 4010 | not made | not made | ||

| 0,02 | 0 | 0 | 3340 | not made | not made | |

| 0,02 | 0 | 2760 | not made | not made | ||

| 0,03 | 0 | 2180 | not made | not made | ||

| 0,03 | 0,01 | 1510 | not made | not made | ||

| 0,04 | 0,01 | 1050 | not made | not made | ||

| 0,04 | 0,01 | 852 | not made | not made | ||

| 0,05 | 0,02 | 546 | not made | not made | ||

| 0,06 | 0,01 | 0,02 | 379 | not made | not made | |

| 0,07 | 0,03 | 279 | not made | not made | ||

| 0,08 | 0,04 | 214 | not made | not made | ||

| 0,09 | 0,05 | 169 | not made | not made | ||

| 0,1 | 0,01 | 0,07 | 137 | 139 | not made | |

| 0,11 | 0,08 | 113 | 115 | not made | ||

| 0,12 | 0,1 | 95,1 | 96,6 | not made | ||

| 0,14 | 0,13 | 70,2 | 71,3 | not made | ||

| 0,15 | 0,15 | 61,1 | 62,2 | not made | ||

| 0,16 | 0,17 | 53,8 | 54,7 | not made | ||

| 0,18 | 0,21 | 42,5 | 43,3 | not made | ||

| 0,2 | 0,26 | 34,6 | 53,2 | not made | ||

| 0,22 | 0,32 | 28,7 | 29,1 | not made | ||

| 0,25 | 0,41 | 22,2 | 22,6 | not made | ||

| 0,28 | 0,51 | 17,7 | 18,1 | not made | ||

| 0,3 | 0,59 | 15,4 | 15,8 | not made | ||

| 0,32 | 0,67 | 13,7 | 13,9 | not made | ||

| 0,34 | 0,75 | 12,1 | 12,3 | not made | ||

| 0,36 | 0,85 | 10,8 | 11 | not made | ||

| 0,4 | 1,05 | 8,8 | 8,9 | not made | ||

| GOST 12766.1-90 | ||||||

| Diameter, | Add. | Weight | Х20Н80-Н | Х15Н60 | Х23У5Т | |

| mm | +, mm | 1 m, gr. | Х15Н60-Н | |||

| 0,1 | 0,01 | 0,07 | 138 | 141 | not made | |

| 0,11 | 0,07 | 126 | 129 | not made | ||

| 0,11 | 0,08 | 114 | 117 | not made | ||

| 0,12 | 0,09 | 104 | 107 | not made | ||

| 0,12 | 0,1 | 95,6 | 98,2 | not made | ||

| 0,13 | 0,11 | 81,2 | 83,5 | not made | ||

| 0,14 | 0,13 | 70,1 | 72,1 | not made | ||

| 0,15 | 0,15 | 61 | 62,7 | not made | ||

| 0,16 | 0,17 | 53,7 | 55,2 | not made | ||

| 0,17 | 0,19 | 47,6 | 48,9 | not made | ||

| 0,18 | 0,21 | 42,5 | 43,7 | not made | ||

| 0,19 | 0,24 | 38 | 39,1 | not made | ||

| 0,2 | 0,26 | 34,4 | 35,4 | not made | ||

| 0,21 | 0,29 | 31,2 | 32,1 | not made | ||

| 0,22 | 0,32 | 28,4 | 29,2 | not made | ||

| 0,24 | 0,38 | 23,9 | 24,6 | not made | ||

| 0,25 | 0,41 | 22 | 22,6 | not made | ||

| 0,28 | 0,51 | 17,5 | 18 | not made | ||

| 0,3 | 0,59 | 15,3 | 15,7 | 19,7 | ||

| 0,32 | 0,67 | 13,4 | 13,8 | 17,3 | ||

| 0,34 | 0,75 | 11,9 | 12,2 | 15,3 | ||

| 0,36 | 0,85 | 10,6 | 10,9 | 13,6 | ||

| 0,38 | 0,94 | 9,56 | 9,82 | 12,3 | ||

| 0,4 | 1,05 | 8,57 | 8,81 | 11 | ||

| 0,42 | 1,15 | 7,77 | 7,99 | 10 | ||

| 0,45 | 1,32 | 6,79 | 6,98 | 8,74 | ||

| 0,48 | 1,5 | 5,97 | 6,13 | 7,68 | ||

| 0,5 | 1,63 | 5,54 | 5,66 | 7,09 | ||

| 0,53 | 1,83 | 4,98 | 5,02 | 6,29 | ||

| 0,56 | 2,04 | 4,47 | 4,51 | 5,65 | ||

| 0,6 | 2,35 | 3,89 | 3,92 | 4,91 | ||

| 0,63 | 0,02 | 2,59 | 3,53 | 3,56 | 4,46 | |

| 0,67 | 2,93 | 3,12 | 3,14 | 3,94 | ||

| 0,7 | 3,2 | 2,86 | 2,88 | 3,61 | ||

| 0,75 | 3,67 | 2,49 | 2,51 | 3,14 | ||

| 0,8 | 4,17 | 2,19 | 2,21 | 2,76 | ||

| 0,85 | 4,71 | 1,94 | 1,96 | 2,45 | ||

| 0,9 | 5,28 | 1,73 | 1,75 | 2,39 | ||

| 0,95 | 5,88 | 1,55 | 1,57 | 1,96 | ||

| 1 | 6,52 | 1,4 | 1,41 | 1,77 | ||

| 1,06 | 7,32 | 1,25 | 1,26 | 1,58 | ||

| 1,1 | 7,89 | 1,16 | 1,17 | 1,46 | ||

| 1,15 | 8,63 | 1,06 | 1,07 | 1,34 | ||

| 1,2 | 9,38 | 0,97 | 0,98 | 1,23 | ||

| 1,3 | 11,04 | 0,83 | 0,84 | 1,05 | ||

| 1,4 | 12,78 | 0,71 | 0,72 | 0,9 | ||

| 1,5 | 14,69 | 0,62 | 0,63 | 0,79 | ||

| 1,6 | 16,68 | 0,55 | 0,52 | 0,69 | ||

| 1,7 | 18,84 | 0,49 | 0,49 | 0,61 | ||

| 1,8 | 21,08 | 0,43 | 0,44 | 0,55 | ||

| 1,9 | 23,57 | 0,39 | 0,39 | 0,49 | ||

| 2 | 26,06 | 0,35 | 0,35 | 0,44 | ||

| 2,1 | 28,72 | 0,32 | 0,32 | 0,4 | ||

| 2,2 | 31,54 | 0,29 | 0,29 | 0,37 | ||

| 2,4 | 37,52 | 0,24 | 0,25 | 0,31 | ||

| 2,5 | 40,75 | 0,22 | 0,23 | 0,28 | ||

| 2,6 | 44,07 | 0,21 | 0,21 | 0,26 | ||

| 2,8 | 51,13 | 0,18 | 0,18 | 0,23 | ||

| 3 | 58,68 | 0,16 | 0,16 | 0,2 | ||

| 3,2 | 0,02 | 66,73 | 0,14 | 0,14 | 0,17 | |

| 3,4 | 75,36 | 0,12 | 0,12 | 0,15 | ||

| 3,6 | 84,66 | 0,11 | 0,14 | 0,14 | ||

| 3,8 | 93,79 | 0,1 | 0,1 | 0,12 | ||

| 4 | 104,58 | 0,09 | 0,09 | 0,11 | ||

| 4,2 | 114,54 | 0,08 | 0,08 | 0,1 | ||

| 4,5 | 131,97 | 0,07 | 0,07 | 0,09 | ||

| 4,8 | 150,23 | 0,06 | 0,06 | 0,07 | ||

| 5 | 162,68 | 0,06 | 0,06 | 0,07 | ||

| 5,3 | 183,43 | 0,05 | 0,05 | 0,06 | ||

| 5,6 | 204,18 | 0,05 | 0,05 | 0,06 | ||

| 6 | 238,25 | 0,04 | 0,04 | 0,05 | ||

| 6,1 | 0,05 | 242,36 | 0,04 | 0,04 | 0,05 | |

| 6,3 | 258,96 | 0,04 | 0,04 | 0,04 | ||

| 6,7 | 292,16 | 0,03 | 0,03 | 0,04 | ||

| 7 | 319,55 | 0,03 | 0,03 | 0,04 | ||

| 7,5 | 366,86 | 0,03 | 0,03 | 0,03 | ||

| GOST 12766.3-90 | ||||||

| Diameter, | Add. | Weight | Х20Н80-Н | Х15Н60-Н | Х23У5Т | |

| mm | +, mm | 1 m, gr. | ||||

| 6 | 0,08 | 239,8 | not made | not made | 0,05 | |

| 6,1 | 245,36 | not made | not made | 0,05 | ||

| 6,3 | 258,96 | not made | not made | 0,45 | ||

| 6,5 | 278,6 | not made | not made | 0,04 | ||

| 6,7 | 292,16 | not made | not made | 0,04 | ||

| 6,9 | 313,94 | not made | not made | 0,04 | ||

| 7 | 319,55 | not made | not made | 0,04 | ||

| 7,1 | 332,4 | not made | not made | 0,04 | ||

| 7,3 | 351,39 | not made | not made | 0,03 | ||

| 7,5 | 366,86 | not made | not made | 0,03 | ||

| 7,8 | 401,18 | not made | not made | 0,03 | ||

| 8 | 422,02 | 0,02 | 0,02 | 0,03 | ||

| 8,2 | 476,42 | 0,02 | 0,02 | 0,03 | ||

| 8,5 | 476,42 | 0,02 | 0,02 | 0,02 | ||

| 8,8 | 510,64 | 0,02 | 0,02 | 0,02 | ||

| 9 | 534,11 | 0,02 | 0,02 | 0,02 | ||

| 9,2 | 558,12 | 0,02 | 0,02 | 0,02 | ||

| 9,5 | 595,11 | 0,02 | 0,02 | 0,02 | ||

| 9,8 | 633,29 | 0,02 | 0,01 | 0,02 | ||

| 10 | 659,4 | 0,01 | 0,01 | 0,02 | ||

| GOST 12766.4-90 | ||||||

| Diameter, | Add. | Weight | Х20Н80-Н | Х15Н60-Н | Х23У5Т | |

| mm | +, mm | 1 m, gr. | ||||

| 8 | 0,09 | 422,02 | 0,0207-0,0263 | 0,0207-0,0263 | 0,0250-0,0318 | |

| 9 | 534,11 | 0,0163-0,0207 | 0,0163-0,0207 | 0,0196-0,0250 | ||

| 10 | 659,4 | 0,0132-0,0168 | 0,0132-0,0168 | 0,0158-0,0203 | ||

| 11 | 797,87 | 0,0110-0,0140 | 0,0110-0,0140 | 0,0131-0,0157 | ||

| 12 | 949,54 | 0,0090-0,0110 | 0,0090-0,0110 | 0,0110-0,0140 | ||

Specific value of electrical resistance

| Brand | Specific value of electrical resistance, µOhm m |

| Х20Н80 (Х20Н80-Н) | 1,08-1,13 |

| Х15Н60 (Х10Н60-Н) | 1,11-1,12 |

| Х15У5 | 1,29 |

| Х23У5 | 1,35 |

| Х23У5Т | 1,39 |

| Х27У5Т | 1,42 |

| ХН20УС | 1,02 |

| ХН70У-Н | 1,3 |

We draw your attention to the fact that in the formula for calculating electric heating elements we use the nominal value of the electrical resistance of nichrome wire from the upper table. Calculations can also be made using the specific value of electrical resistance, but the calculation method is different. From our point of view, we have proposed the fastest and most accurate calculation method using the nominal value of the electrical resistance of nichrome wire.

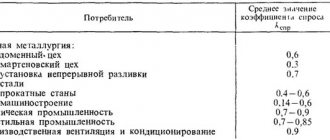

Scope of application

Based on application, the global nichrome alloy market can be segmented into architectural, automotive, electronics, aerospace and others. Nichrome alloys are used to make monel from iron and steel, to produce stainless steel. Nichrome alloys are used for architectural purposes such as lead for water pipes, roofing and windows.

Nichrome is used in gears, driveshafts, and special vehicles for operating in areas with low temperatures or heavy wear. It is also used for special engineering purposes. Nichrome alloys are primarily used for electrical resistance heating. They have high electrical resistance, good strength and ductility at operating temperatures.

Nichrome is widely used in the fireworks and explosives industry and to prepare wires for electrical ignition systems such as lighters, electric matches and electronic cigarettes.

This substance is used in ceramic works. It serves to provide internal support structure and helps keep the shapes of clay sculptures soft. Because of its resistance to high temperatures, it is used when pieces of clay are fired in kilns. Nichrome wires are used to test the flame color in unlit parts of a cationic fire for sodium, copper, potassium and calcium cations.

Nichrome is also used in microbiology laboratories and to make thermocouples.

Temperature coefficient of resistance for different substances

Most metals have a temperature coefficient of resistance greater than zero. This means that the resistance of metals increases with increasing temperature. This occurs as a result of electron scattering on the crystal lattice, which enhances thermal vibrations.

At temperatures close to absolute zero (-273 o C), the resistance of a large number of metals sharply drops to zero. Metals are said to go into a superconducting state.

Semiconductors that do not have impurities have a negative temperature coefficient of resistance. Their resistance decreases with increasing temperature. This occurs due to the fact that the number of electrons that move into the conduction band increases, which means that the number of holes per unit volume of the semiconductor increases.

Electrolyte solutions have . The resistance of electrolytes decreases with increasing temperature. This occurs because the increase in the number of free ions as a result of the dissociation of molecules exceeds the increase in the scattering of ions as a result of collisions with solvent molecules. It must be said that the temperature coefficient of resistance for electrolytes is a constant value only in a small temperature range.

Cost of nichrome

Based on geography, the global nichrome alloy market can be classified into Asia Pacific, Europe, North America, Latin America, and the Middle East and Africa. North America and Europe are the main markets for nichrome alloys, driven by the growth of the aerospace and electronics industries. Nichrome manufacturing companies in Asia Pacific and Latin America are investing heavily in nichrome research and development in Asia.

The cost of nichrome products in the form:

- Wire 0.8 mm Х20Н80 – 1,990 rub./kg;

- Wire 2.0 mm Х20Н80 -2,050 rub./kg;

- Tape #1.0x15 mm Х20Н80 – 1,990 rub./kg;

- Nichrome wire 1.5 mm X15N60 – RUB 1,590/kg.

Nichrome Bibus Metals

The major players operating in the global nichrome alloys market are American Elements, Bibus Metals, VDM Metals, Crown Alloys, Wickeder Westfalenstahl GmbH, Tri Star Metals and others. These companies constitute a significant share of the nichrome alloys and scrap market, thus the market is highly competitive.

Russian producers of nichrome: Volgograd Steel Wire Rope Plant, GRACE-1000 (Moscow), Western Ural Industrial Supply (Perm), Index-VK (Ekaterinburg), Kamensk-Uralsky Plant, Metallokomertsiya (Moscow), Prommet (Moscow), Promsnabmetall AG (Moscow ), Ural Precision Alloys Plant.