What is a DRL lamp

The abbreviation DRL stands for “mercury arc lamp”. Sometimes the abbreviation RL is found. In some documents, the letter “L” means “luminophor”, since it is the main light source in the device. The element belongs to the category of high pressure gas discharge lamps.

The marking of a specific model contains a number indicating the power of the equipment.

DRL power 400 W

Device types

Lamps operating according to the principle described above are of the following types:

FRL – fluorescent mercury arc lamp;

Model HPL-N (Philips)

DRL lamps differ from DRL lamps in that they use a tungsten filament, which performs two functions: a light source and an electric current voltage limiter. To operate a device of this type, no special ballasts are required (throttleless electric lamp);

High pressure DRV devices (HQL), manufacturers Osram and Philips

DRLF – light sources that promote the process of photosynthesis in plants;

DRLF type device

DRUF and DRUFZ - emit in the long-wave ultraviolet spectrum;

Ultraviolet (bactericidal) electric lamp

DRT – tube-type ultraviolet light source;

Lighting source DRT

HPS - tubular lamps, in which, unlike DRL, in addition to mercury, sodium vapor is also used. The main feature is a specific shade of radiation (orange-yellow or golden-white), which requires special equipment to launch.

Mercury-sodium lamp DNAT

Advantages and disadvantages

DRL sources have long been used for street and indoor lighting. During this time, users managed to highlight the advantages and disadvantages that determine their choice:

Advantages:

- good light output;

- high power;

- relatively small body size;

- low price compared to LED;

- economical energy consumption;

- most products are capable of operating for 12,000 hours (the figure depends on the quality of the components used).

There are also disadvantages that are important to consider:

- inside the flasks there are harmful mercury vapors that can cause poisoning if leaked;

- It takes some time from switching on to reaching the rated power;

- a preheated lamp cannot be turned on until it cools down (about 15 minutes);

- sensitive to voltage surges (a 15% deviation will cause a 30% change in brightness);

- equipment does not work well at low temperatures;

- during operation there is a pulsation of light;

- low color rendering;

- the elements become very hot;

- in the circuit you need to use specialized heat-resistant components (wires, cartridges, etc.);

- the arc element requires ballasts;

- sometimes the switched-on element makes an unpleasant sound;

- in the room where the lamps operate, ventilation is required to ventilate ozone;

- Over time, the phosphor loses its properties, which leads to a weakening of the luminous flux and a change in the spectrum.

Most of the disadvantages are inherent only in cheap DRLs from dubious manufacturers and are insignificant when a powerful lighting source is needed.

Lamp design

Initially, the designs used burners with two electrodes, requiring the installation of an additional module for generating pulses when turned on. The voltage they created was much higher than the operating voltage of the lamp.

Design of the DRL element

Later, two-electrode elements were replaced by units with four electrodes. It is now possible to dispense with external equipment that generates ignition pulses.

The DRL lamp consists of the following components:

- main electrode;

- ignition electrode;

- electrode leads from the burner;

- a resistor that provides the required circuit resistance;

- inert gas;

- mercury vapor.

The main flask is made of durable glass that is resistant to high temperatures. The air is pumped out and replaced with inert gas. The main function of the inert gas is to prevent heat exchange between the heating pad and the flask. But even in this case, the equipment housing can heat up to 120 degrees Celsius during operation.

A base is provided to connect the lamp to the network. It allows you to secure the equipment in the chuck and ensures the tightest possible contact.

The inside of the flask is coated with a phosphor, which converts invisible ultraviolet radiation into a visible glow. Under the influence of UV rays, the phosphor heats up and begins to emit light. The shade of light depends on the composition of the coating.

The main luminous element inside the bulb is the electric arc between the electrodes.

Mercury in the light source

Mercury acts as a stabilizer for electron movement and in a cold device can take the form of small balls. When heated slightly, mercury turns into vapor and interacts with the internal elements of the structure.

The burner itself looks like a small tube made of glass or ceramic. Basic requirements for the material: preservation of properties at high temperatures and the ability to transmit ultraviolet rays.

Resistors in the circuit limit the current and prevent other elements from failing prematurely.

The device of a mercury arc lamp

The first burners that were used in this type of light sources had 2 electrodes; this required the presence of an additional device that generates powerful pulses to ignite the arc. The lamp burning voltages are lower than the starting voltage. The first device was PURL-220 – Mercury Lamp Starter. 220 is the operating voltage in volts. PURL-220 was short-lived, as it was based on a gas discharger. In the seventies, two-electrode lamps were discontinued. They were replaced by burners with four electrodes. They did not require an external device to run. Launching is much easier.

1 – main electrode.

2 - ignition electrode.

3 – leads of electrodes from the burner.

5 – resistor (resistance).

The work is based on two processes:

- Electric arc between electrodes.

- Luminescence process.

The outer casing is made of special heat-resistant glass. Air has been evacuated from the flask - the outer casing. Instead, nitrogen or inert gas is pumped in. Its purpose is to prevent heat exchange between the burner and the flask. However, the temperature of the cylinder can reach 120 degrees. The socket is designed to be fixed in the connection socket. The inside of the flask is covered from the inside with a phosphor layer. A phosphor is a substance that can glow in the visible spectrum when irradiated with ultraviolet light or when bombarded with electrons. In the case of DRL lamps - ultraviolet radiation. The luminous body is the electric arc between the electrodes. Due to the presence of a phosphor coating, the bulb is opaque.

When the lamp is not connected and is cold, the mercury can be either in the form of a ball or in the form of a thin layer on the walls of the burner.

The burner is a tube made of quartz glass (or special refractory transparent ceramics), as it is heat-resistant and transmits ultraviolet radiation. Inside there are strictly dosed portions of inert gas. Ultraviolet light causes the phosphor layer to glow. This is the most important part - the emitter.

Resistors are needed to limit inrush currents.

Principle of operation

Operating principle of DRL

The principle of operation of the DRL provides for the presence of a light source, a capacitor, an inductor and a fuse.

When voltage is applied to the electrodes, gas ionization occurs in the free region. A breakdown and arc discharge occurs between the electrodes. The discharge glow may be bluish or purple.

The phosphor is selected in a red shade. By mixing the spectra, the output is pure white light. The shade may change when the voltage applied to the contacts changes.

Thematic video: Design, principle of operation and operating features of DRL lamps.

Reaching the desired brightness in DRL takes approximately 8 minutes. This is due to the gradual melting and evaporation of mercury balls. It is mercury vapor that ensures the stability of processes inside the burner and improves the glow of the device. Maximum brightness appears at the moment of complete evaporation of mercury.

It is worth noting that the ambient temperature and the initial state of the lamp affect the speed at which the rated power is reached.

The choke in the circuit is a primitive ballast mechanism. With its help, the system controls the strength of the current passing through the electrodes of the structure. If you try to bypass the choke by connecting the lamp directly to the network, it will very quickly fail.

Nowadays, most electronic equipment manufacturers are moving away from the inductor as an outdated solution. Arc stabilization is carried out by electronic devices that provide the required performance even with significant voltage drops in the network.

Specifications

The main technical characteristic of sources of this type is power. It is indicated in the device labeling next to the abbreviation DRL. The remaining parameters should be considered separately. They are indicated on the box or in the equipment passport.

Technical characteristics are always indicated on the device packaging

These include:

- DRL luminous flux. Determines the efficiency of the device when lighting a specific area.

- Resource. Equipment service life if basic recommendations are followed.

- Base. Designation of the method of integrating the model into lighting equipment.

- Dimensions. A less important characteristic that determines the use of the model in specific lamps.

DRL 250

Technical characteristics of DRL 250 lamps

| Power, W | Luminous flux, Lm | Resource, h | Dimensions (length × diameter), mm | Base |

| 250 | 13 000 | 12 000 | 228 × 91 | E40 |

DRL 400

Technical characteristics of DRL 400 lamps

| Power, W | Luminous flux, Lm | Resource, h | Dimensions (length × diameter), mm | Base |

| 400 | 24000 | 15000 | 292 × 122 | E40 |

Mercury lamps DRL-70, DRL-125, DRL-250, DRL-400, DRL-700, DRL-1000

Mercury arc lamps type DRL — high-pressure gas-discharge mercury lamps, used for street lighting and lighting of large production areas.DRL lamps are used in alternating current networks with a voltage of 220 V and a frequency of 50 Hz.

DRL lamps are turned on through ballasts (ballasts).

Marking:

D - arc; P - mercury; L - lamp.

Specifications:

Name

| Lamp voltage, V | Power, V | Length, mm (L) | Diameter, mm (D) | Base type | Luminous flux, lm | Service life, hours | |

| DRL 125 | 125 | 125 | 178 | 76 | E27 | 5900 | 12000 |

| DRL 250 | 130 | 250 | 228 | 91 | E40 | 13500 | 12000 |

| DRL 400 | 135 | 400 | 292 | 123 | E40 | 24000 | 15000 |

| DRL 700 | 700 | 357 | 154 | E40 | 41 000 | 20000 | |

| DRL 1000 | 1000 | 411 | 168 | E40 | 59000 | 18000 |

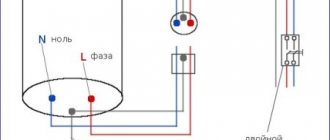

Connection diagram:

| 1. Main electrodes. 2. Ignition electrodes. 3. Electrode inputs. 4. Buffer gas (Argon - used for initial ionization and arc discharge). 5. PTC posistors (serve to limit the glow discharge current on the igniting electrodes). 6. Mercury (serves to change the potential gradient in the discharge). |

Thanks to the additional electrodes, the lamp does not require an igniter; it is connected to a network with inductive ballasts and ignites directly from a 220-volt network voltage.

The discharge occurs in an internal flask filled with argon.

The radiation spectrum consists of ultraviolet, and blue and green visible spectrum.

The components of the red region of the spectrum are completely absent.

A layer of phosphor on the inner surface of the outer bulb converts the ultraviolet component into light radiation from the red part of the spectrum.

The process of flaring up the DRL lamps after switching on lasts about seven minutes; the disappearance of voltage leads to the extinguishing of the lamp.

It is impossible to light a hot lamp; the lamp must cool completely. Advantages:

- high luminous efficiency (up to 60 lm/W)

- compactness, with high unit power

- ability to work at negative temperatures

- long service life (about 15 thousand hours)

Flaws:

- low color rendering

- light pulsation

- criticality to network voltage fluctuations

PRICES from 02.08.2017

| Name | Price | Qty. |

| Lamp HPL-N 125W base E27 Philips 871150018012430 | 281,75 | Thing |

| Lamp HPL-N 250W base E40 Philips 871150018060515 | 422,93 | Thing |

| Lamp HPL-N 400W base E40 Philips 871150018045210 | 629,72 | Thing |

| Lamp HPL-N 700W base E40 Philips 871150018391010 | — | Thing |

| Lamp HQL 125W E27 OSRAM 4050300012377 | 186,11 | Thing |

| Lamp HQL 250W E40 OSRAM 4050300015064 | 325,21 | Thing |

| Lamp HQL 400W E40 OSRAM 4050300015071 | 467,16 | Thing |

| Lamp HQL 700W E40 OSRAM 4050300015088 | — | Thing |

| Lamp HQL 80W E27 OSRAM 4050300012360 | 343,75 | Thing |

| DRL lamp-1000 W | 836,75 | Thing |

| DRL lamp-125 W | 108,17 | Thing |

| Lamp DRL 125 Phoenix (China) | — | Thing |

| DRL lamp 250 W | 133,23 | Thing |

| DRL 250 Phoenix lamp (China) | — | Thing |

| DRL lamp-400 W | 175,84 | Thing |

| Lamp DRL-400 Phoenix (China) | — | Thing |

| DRL lamp-700 W | 547,69 | Thing |

If you are interested in our products, call (mngk), 740-42-64, 973-65-17 or send a request by email

Scope of application

Street use of DRL

All DRL sources are used to illuminate large areas. Most often they are built into street lamps, road and gas station lighting systems. They often organize lighting for large warehouses and other premises where the color rendering parameter is not fundamental, as well as in exhibition complexes. The high power of the devices comes in handy.

They are not used in residential buildings and apartments, because... poor color rendering and long turn-on times make this solution ineffective.

Life time

The service life of DRL lamps directly depends on the power. The most common DRL 250 can operate for about 12,000 hours without any problems. It is important to remember that the following factors can reduce the resource:

- frequent switching on and off;

- voltage fluctuations;

- continuous use at low ambient temperatures.

All this leads to accelerated degradation of the electrodes and, as a consequence, rapid failure.

Disposal

The presence of mercury in DRLs places them in the first hazard class. In a number of countries, such devices are prohibited for use. However, compliance with the rules of operation and disposal minimizes all risks to humans and the environment.

DRL disposal area

It is prohibited to throw away such lighting sources with regular garbage. Mercury released into the environment can significantly harm the environment.

Disposal of DRLs is carried out by the same structures that work with other energy-saving lamps. The company must have a state license authorizing such work.

In large cities you can find special tanks in which spent elements are placed. You can also contact utility companies, lighting equipment manufacturers or repair companies, or hazardous waste disposal companies.

Economic advantages of mercury lamps

Cost-effectiveness of use is one of the reasons for the great commercial success of tungsten devices, not only in Russia and the CIS countries, but also in developed Western countries. The fact is that strong and powerful incandescent lamps left behind huge umbrella lamps

, replacing which, especially in large industries, is extremely costly in all respects. The costs will be as follows:

- purchasing new lighting fixtures;

- installation of fastening systems;

- installation of lighting lines.

All these expense items can be reduced by installing tungsten light sources in old lamps. These hybrid type light sources are more efficient. It is worth noting that in most cases, purchases of high-pressure mercury lamps are made specifically for DRV devices.

But there are a number of nuances. For example, their light parameters

significantly inferior to even the most inefficient DRL lamps. Why is this happening? Let's find out what the operating principle of DRV lamps is.