We'll tell you how to calculate the cable cross-section and power by diameter - our tables and formulas will help you carry out the calculations yourself. In order to understand which wire you will need in different situations, you should distinguish the diameter of the cable cross-section. The table of values can tell amateur electricians how to choose the right cable depending on its purpose in the future - connecting powerful household appliances, large equipment, or carrying electrical wiring into the house.

To carry out the measurement procedure yourself, it will be easiest to use special instruments: for example, using a micrometer you can get the most accurate result, which cannot be achieved with a regular ruler, although it can be used for such purposes. It should be remembered that the use of improvised means requires great precision and knowledge of calculation formulas.

General information about cable and wire

When working with conductors, it is necessary to understand their designation. There are wires and cables that differ from each other in their internal structure and technical characteristics. However, many people often confuse these concepts.

A wire is a conductor that has in its design one wire or a group of wires woven together and a thin common insulating layer.

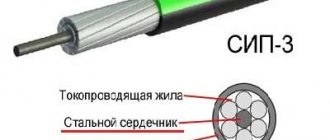

A cable is a core or a group of cores that has both its own insulation and a common insulating layer (sheath).

Each type of conductor will have its own methods for determining cross sections, which are almost similar.

Conductor materials

The amount of energy that a conductor transmits depends on a number of factors, the main one of which is the material of the current-carrying conductors.

- The following non-ferrous metals can be used as the core material of wires and cables:

- Aluminum. Cheap and lightweight conductors, which is their advantage. They are characterized by such negative qualities as low electrical conductivity, a tendency to mechanical damage, high transient electrical resistance of oxidized surfaces;

- Copper. The most popular conductors, which have a high cost compared to other options. However, they are characterized by low electrical and transition resistance at the contacts, fairly high elasticity and strength, and ease of soldering and welding;

- Aluminum copper. Cable products with aluminum cores coated with copper. They are characterized by slightly lower electrical conductivity than their copper counterparts. They are also characterized by lightness, average resistance and relative cheapness.

How and with what to measure the diameter of a wire (wire)

To measure the diameter of the wire, a caliper or micrometer of any type (mechanical or electronic) is suitable. It’s easier to work with electronic ones, but not everyone has them. You need to measure the core itself without insulation, so first move it aside or remove a small piece. This can be done if the seller allows it. If not, buy a small piece to test and take measurements on it.

On a conductor stripped of insulation, measure the diameter, after which you can determine the actual cross-section of the wire from the found dimensions. Which measuring device is better in this case? If we talk about mechanical models, then a micrometer. Its measurement accuracy is higher. If we talk about electronic options, then for our purposes they both give quite reliable results.

If you don't have a caliper or micrometer, take a screwdriver and a ruler with you. You'll have to strip a fairly decent piece of conductor, so you'll hardly be able to do without buying a test sample this time. So, remove the insulation from a 5-10 cm piece of wire.

Wind the wire around the cylindrical part of the screwdriver. Lay the coils close to each other, without a gap. All turns must be complete, that is, the “tails” of the wire must stick out in one direction - up or down, for example.

The number of turns is not important - about 10. You can have more or less, it’s just easier to divide by 10. Count the turns, then apply the resulting winding to the ruler, aligning the beginning of the first turn with the zero mark (as in the photo). Measure the length of the section occupied by the wire, then divide it by the number of turns. You get the diameter of the wire. It's that simple.

For example, let's calculate the size of the wire shown in the photo above. The number of turns in this case is 11, they occupy 7.5 mm. Divide 7.5 by 11, we get 0.68 mm. This will be the diameter of this wire. Next, you can look for the cross section of this conductor.

Measurement process

To measure the thickness of an electrical wire or cable, you must have a caliper or micrometer of any type. Measurements are made by removing a piece of insulation, although sellers do not always allow this to be done. There are cases when sellers warn buyers that the cross-section, although slightly, is underestimated. Often this is uncritical, and sometimes it is critical. By measuring the thickness of the wire (diameter), it is easy to determine the cross-section using the formula.

If we talk about accuracy, then a micrometer is a more accurate device. If you use modern electronic instruments, then both a caliper and a micrometer have acceptable characteristics.

If there are no such devices, then you can get by with a regular ruler and a regular screwdriver. To carry out measurements, you will have to strip a decent length of wire, ridding it of insulation. After removing the insulation, 10 turns of wire are wound around the screwdriver. Why 10? Yes, because it will be easier to count. The wire is wound tightly turn to turn, without gaps.

After winding 10 turns on a cylindrical base, take a ruler and measure the width of the winding, after which the resulting result is divided by 10. Simple and convenient, and at the same time accurate.

Determining wire diameter using a ruler

For example, you can calculate the diameter of a conductor wound around a cylindrical base, shown in the image above. In this case, 11 turns of wire are wound without insulation. Using a ruler, it was determined that the winding length was 7.5 mm. After this, 7.5 mm is divided by 11 (the number of turns). The result is 0.68 mm, which corresponds to the diameter of the wire core.

What kind of cable is needed for the sockets? How to find out the cable cross-section by diameter? Cable according to GOST and TU

Methods for measuring conductor diameter

When selecting an electrical cable or wire to check the cross-section of the core, it is necessary to measure its diameter. There are several ways to do this. You can use measuring instruments such as calipers or micrometers. They measure the size of the exposed part of the conductor.

The device is simply attached to the core, clamped between the jaws, and the result is displayed on the scale. For private use, the measurements are quite accurate, with a small error. Especially if the devices are electronic.

For the second method, you only need a ruler and some kind of even rod. But in this case, you still have to do calculations, albeit very simple ones. More on this method later.

Ruler+rod

If there are no measuring instruments on the farm, you can get by with a regular ruler and any rod of the same diameter. This method has a high error, but if you try it will be quite accurate. Take a piece of wire about 10-20 cm long and remove the insulation.

We wind the bare copper or aluminum wire onto a rod of the same diameter (any screwdriver, pencil, pen, etc. will do). We lay the coils carefully, close to one another. The number of turns is 5-10-15. We count the number of full turns, take a ruler and measure the distance that the wound wire occupies on the rod. Then divide this distance by the number of turns. As a result, we obtain the diameter of the conductor.

For example, we wound 10 turns (it’s easier to count), they took up 3.8 cm (or 38 mm) on the rod. Next, we divide the distance by the number of turns, 38/10 = 3.8 mm, we get that the diameter of the wound wire is 3.8 mm.

As you can see, there is an error here. Firstly, you can lay the wire loosely. Secondly, it is not enough to take accurate measurements. But if you do everything carefully, the discrepancies with the actual sizes will not be so large.

Application of measuring instruments

To determine the diameter of the cores of wires and cables, various measuring instruments are widely used, showing the most accurate results. Basically, the use of micrometers and calipers is practiced for these purposes. Despite their high efficiency, a significant drawback of these devices is their high cost, which is of great importance if the tool is planned to be used only 1-2 times.

As a rule, professional electricians who are constantly engaged in electrical installation work use special devices. With the right approach, it becomes possible to measure the diameter of wire cores even on working lines.

Why do you need to specify cable cross-sections?

On most wires and cables, the manufacturer is required to apply markings indicating their type, the number of conductors and their cross-section. If the wire is marked as 3x2.5, this means that the diameter of the wire is 2.5 mm². Actual values may differ from those indicated by approximately 30%, because some types of wiring (in particular PUNP) are produced according to outdated standards, which allow an error of the indicated number of percent and generally it appears on the smaller side. As a result, if you use a cable with a smaller cross-section than the calculated one, then the effect for the wire will be approximately the same if a thin polyethylene hose were connected to a fire hydrant. This can lead to dangerous consequences: overheating of the electrical wiring, melting of the insulation, and changes in the properties of the metal. Therefore, before making a purchase, it is imperative to check that the cross-sectional area of the conductor does not differ from that declared by the manufacturer.

Ways to find out the real diameter of the wire

The easiest and most accurate method to measure the diameter of a wire strand is to use special tools such as a caliper or micrometer (electronic or mechanical). In order for the measurement to be accurate, the wire being measured must be cleared of insulation so that the tool does not cling to it. You also need to inspect the tip of the wire so that it is free of kinks - sometimes they appear if the wire is cut through with blunt pliers. Once the diameter is measured, you can begin to calculate the cross-sectional area of the wire core.

A micrometer will give a more reliable reading than a caliper.

If you don’t have an accurate measuring tool at hand, there is another way to find out the cross-section - you will need a screwdriver (pencil or any tube) and a measuring ruler. You will also have to buy at least one meter of wire (50 cm is enough, if they sell that much) and remove the insulation from it. Next, the wire is wound tightly, without gaps, onto the tip of a screwdriver and the length of the wound section is measured with a ruler. The resulting winding width is divided by the number of turns and the result will be the required diameter of the wire, by which you can already search for the cross-section.

How to take measurements is shown in detail in this video:

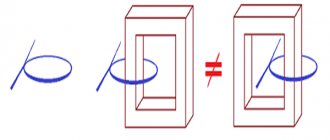

What formulas should you use?

What such a cross-section of a wire is known from the basics of geometry or drawing is the intersection of a three-dimensional figure with an imaginary plane. At the points of their contact, a flat figure is formed, the area of which is calculated by suitable formulas. The wire core is most often cylindrical in shape and has a circle in cross-section; accordingly, the cross-section of the conductor can be calculated using the formula:

S = ϖ R²

R – radius of the circle, equal to half the diameter;

ϖ = 3.14

There are wires with flat conductors, but there are few of them and it is much easier to find the cross-sectional area of them - just multiply the sides.

To get a more accurate result you need to keep in mind:

- The more turns (there should be at least 15) screwed onto the screwdriver, the more accurate the result will be;

- There should be no distance between the turns; due to the gap, the error will be higher;

- You need to take several measurements, changing its beginning each time. The more there are, the higher the accuracy of the calculations.

The disadvantage of this method is that thin conductors can be used for measurements; it will be difficult to wind a thick cable.

Determine the wire cross-section using the table

Using formulas does not give a guaranteed result, and as luck would have it, they are forgotten at the most necessary moment. Therefore, it is better to determine the cross section according to the table where the calculation results are summarized. If you manage to measure the diameter of the core, then the cross-sectional area of the wire can be viewed in the corresponding column of the table:

If you need to find the total diameter of a stranded cable core, you will have to separately calculate the diameter of each wire and add the resulting values. Then everything is done in the same way as with a single-wire conductor - the result is found using a formula or table.

When measuring the cross-section of a wire, its core is carefully cleaned of insulation, since it is possible that its thickness will be greater than the standard. If for any reason there is doubt about the accuracy of the calculations, then it is better to choose cables or wires with a power reserve.

To approximately find out the cross-section of the wire that will be purchased, you need to add up the power of the electrical equipment that will be connected to it. Power consumption must be indicated in the device passport. Based on the known power, the total current that will flow through the conductor is calculated, and based on it, the cross-section is selected.

About choosing a cable brand for home wiring

Making apartment electrical wiring from aluminum wires at first glance seems cheaper, but operating costs due to low reliability of contacts over time will be many times higher than the costs of electrical wiring made from copper.

It is recommended to make wiring exclusively from copper wires! Aluminum wires are indispensable when laying overhead electrical wiring, as they are light and cheap and, when properly connected, serve reliably for a long time.

Which wire is better to use when installing electrical wiring, single-core or stranded? From the point of view of the ability to conduct current per unit of cross-section and installation, single-core is better. So for home wiring you only need to use solid wire.

Stranded allows multiple bends, and the thinner the conductors in it, the more flexible and durable it is. Therefore, stranded wire is used to connect non-stationary electrical appliances to the electrical network, such as an electric hair dryer, an electric razor, an electric iron and all the others.

After deciding on the cross-section of the wire, the question arises about the brand of cable for electrical wiring. The choice here is not great and is represented by only a few brands of cables: PUNP, VVGng and NYM.

PUNP cable since 1990, in accordance with the decision of Glavgosenergonadzor “On the ban on the use of wires such as APVN, PPBN, PEN, PUNP, etc., produced according to TU 16-505. 610-74 instead of APV, APPV, PV and PPV wires according to GOST 6323-79*" is prohibited for use.

Cable VVG and VVGng - copper wires in double polyvinyl chloride insulation, flat shape. Designed for operation at ambient temperatures from −50°С to +50°С, for wiring inside buildings, outdoors, in the ground when laid in tubes. Service life up to 30 years.

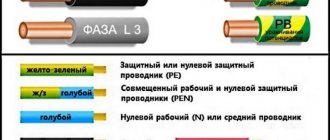

The letters “ng” in the brand designation indicate the non-flammability of the wire insulation. Two-, three- and four-core wires are available with core cross-sections from 1.5 to 35.0 mm2. If in the cable designation there is a letter A (AVVG) before VVG, then the conductors in the wire are aluminum.

The NYM cable (its Russian analogue is the VVG cable) with round copper cores with non-flammable insulation, complies with the German standard VDE 0250. Technical characteristics and scope of application are almost the same as the VVG cable. Two-, three- and four-core wires are available with core cross-sections from 1.5 to 4.0 mm2.

As you can see, the choice for laying electrical wiring is not large and is determined depending on what shape the cable is more suitable for installation, round or flat. A round-shaped cable is more convenient to lay through walls, especially if the connection is made from the street into the room. You will need to drill a hole slightly larger than the diameter of the cable, and with a larger wall thickness this becomes relevant. For internal wiring, it is more convenient to use a VVG flat cable.

Why do you need to calculate the cable cross-section?

Calculating the current cross-section of the wire allows you to correctly calculate the load. Otherwise, the electrical equipment will fail. When connecting to the network, you need to select the right wire material:

- copper;

- aluminum.

Important! Copper is considered an excellent conductor, and aluminum demonstrates flexibility.

Aluminum wiring

Dependence of current, power and core cross-section

It is not enough to measure and calculate the cross-sectional area of the cable based on the diameter of the core. Before installing wiring or other types of electrical networks, it is also necessary to know the capacity of the cable products.

- When choosing a cable, you must be guided by several criteria:

- the strength of the electric current that the cable will pass;

- consumer power;

- current load exerted on the cable.

Power

The most important parameter during electrical installation work (in particular, cable laying) is throughput. The maximum power of electricity transmitted through it depends on the cross-section of the conductor. Therefore, it is extremely important to know the total power of the energy consumption sources that will be connected to the wire.

Typically, manufacturers of household appliances, appliances and other electrical products indicate on the label and in the documentation accompanying them the maximum and average power consumption.

For example, a washing machine can consume electricity ranging from tens of W/h during rinsing mode to 2.7 kW/h when heating water.

Accordingly, a wire with a cross-section that is sufficient to transmit electricity of maximum power must be connected to it. If two or more consumers are connected to the cable, then the total power is determined by adding the limit values of each of them.

The average power of all electrical appliances and lighting devices in an apartment rarely exceeds 7500 W for a single-phase network. Accordingly, the cable cross-sections in the electrical wiring must be selected to this value.

It is recommended to round the cross-section towards higher power due to a possible increase in power consumption in the future. Typically, the next largest cross-sectional area from the calculated value is taken. So, for a total power of 7.5 kW, it is necessary to use a copper cable with a core cross-section of 4 mm2, which is capable of transmitting about 8.3 kW. The cross-section of the conductor with an aluminum core in this case must be at least 6 mm2, passing a current power of 7.9 kW.

In individual residential buildings, a three-phase power supply system of 380 V is often used. However, most equipment is not designed for such electrical voltage. A voltage of 220 V is created by connecting them to the network through a neutral cable with an even distribution of the current load across all phases.

Electric current

Often the power of electrical equipment and equipment may not be known to the owner due to the absence of this characteristic in the documentation or completely lost documents and labels. There is only one way out in such a situation - to calculate using the formula yourself.

Power is determined by the formula:

P = U*I

- Where:

- P – power, measured in watts (W);

- I – electric current strength, measured in amperes (A);

- U is the applied electrical voltage, measured in volts (V).

- When the strength of the electric current is unknown, it can be measured using instrumentation:

- ammeter;

- multimeter;

- current clamps.

After determining the power consumption and electric current, you can use the table below to find out the required cable cross-section.

Load

Calculation of the cross-section of cable products based on current load must be carried out to further protect them from overheating. When too much electric current passes through conductors for their cross-section, destruction and melting of the insulating layer can occur.

The maximum permissible long-term current load is the quantitative value of the electric current that can pass the cable for a long time without overheating. To determine this indicator, it is initially necessary to sum up the powers of all energy consumers.

After this, calculate the current load using the formulas:

single-phase network: I = P∑*Ki/U

three-phase network: I = P∑*Ki/(√3*U)

- Where:

- P∑ – total power of energy consumers;

- Ki – coefficient equal to 0.75;

- U – electrical voltage in the network.

Dependence of cross-sectional dimensions on load currents

In order not to carry out complex calculations each time to determine the required wire cross-section, unified tables were compiled. They are called “Permissible current loads on the cable”. Sometimes it is enough to know that for equipment of sockets it is better to use a copper cable with a cross-section of 1.5-2.5 mm², and for installation of lighting - 1.0-1.5 mm²; to enter a standard apartment (40-80 m²) a single-phase wire is sufficient so that its cross-section is equal to 6.0 mm².

To roughly calculate the required cross-section, many professional electricians believe that a copper electrical wire with a cross-section of 1 mm² passes an electric current of 10 A, therefore, a wire with a cross-section of 2.5 mm² passes 25 A, and with a cross-section of 4.0 mm² - 40 A, and so on. This technique is quite suitable for approximate calculations, but only for wires with a cross-section of no more than 6.0 mm².

Below you can see a brief table of the dependence of the cross-section of an electrical wire up to 35 mm² on current loads. The total power of electrical equipment for single-phase (220 V) and three-phase (380 V) consumption is also shown here. It should be noted that when laying an electrical wire in a pipe (and in other enclosed spaces), the probable current loads on it should be lower than when laying the same electrical wire openly (in the air). This happens because the electrical wire heats up during operation, and heat transfer both in the ground and in the wall is much worse than in the open air.

Table 1.

Selecting the cross-section of the electrical wire when laying in a pipe and in an open way

Note.

The parameters indicated in Table 1 are given for a core with a single installation of electrical wires. Core temperature +65ºС, ground +15°С, air +25°С.

↑ Return to contents

Stranded wire

The PVS cable for connecting power tools and electrical appliances is made flexible, since all the cores are stranded. Measuring the diameter of the harness at the same time will give an incorrect result, since there are air gaps inside. The correct calculation principle is the same as for cable.

The core should be fluffed up, count how many wires are in it, and then measure the diameter of one of them. Knowing their total number in the vein, you can calculate the total cross-section using the previous formula. It’s best to take measurements using a micrometer. It is more convenient to use, since the caliper easily presses through thin wires.

How to calculate the cross-section of a stranded wire

Stranded wire, or as it is also called stranded or flexible, is a single-core wire twisted together. To calculate the cross-section of a stranded wire, you must first calculate the cross-section of one wire, and then multiply the resulting result by their number.

Let's look at an example. There is a multi-core flexible wire, in which there are 15 cores with a diameter of 0.5 mm. The cross-section of one core is 0.5 mm × 0.5 mm × 0.785 = 0.19625 mm2, after rounding we get 0.2 mm2. Since we have 15 wires in the wire, to determine the cable cross-section we need to multiply these numbers. 0.2 mm2×15=3 mm2. It remains to determine from the table that such a stranded wire will withstand a current of 20 A.

You can estimate the load capacity of a stranded wire without measuring the diameter of an individual conductor by measuring the total diameter of all twisted wires. But since the wires are round, there are air gaps between them. To eliminate the gap area, you need to multiply the result of the wire cross-section obtained from the formula by a factor of 0.91. When measuring the diameter, you need to make sure that the stranded wire does not flatten.

Let's look at an example. As a result of measurements, the stranded wire has a diameter of 2.0 mm. Let's calculate its cross-section: 2.0 mm × 2.0 mm × 0.785 × 0.91 = 2.9 mm2. Using the table (see below), we determine that this stranded wire will withstand a current of up to 20 A.

Determination of cross-sectional area

Here's how to determine the wire cross-section. In general, this is a problem from elementary geometry, but school knowledge is quickly forgotten and has to be remembered. Since a wire is one or more round wires, the cross-sectional area is expressed

formula:

where n is the number of wires, d is the wire diameter in mm. As a result of the transformations, instead of the numbers π and 4, we get a coefficient of 0.785. The result is obtained in square millimeters. If there is only one wire, then n = 1 and you can forget about it.

For example, we measured the diameter of the wire with a micrometer and it turned out to be 1.02 mm. Then we square this number: 1.02 * 1.02 = 1.0404 and multiply by 0.785. We get: S = 0.817 mm.sq. For practice, we can consider this result quite accurate. For stranded cores, the result must be additionally multiplied by n.

The diameter of the wire should be measured with a caliper, preferably a micrometer. But if there are no such instruments, you can measure the diameter of the wire with an ordinary millimeter ruler using the following trick (ham radio method): as many turns of wire are tightly wound onto a pencil or even solid rod as are convenient to hold together.

Then the winding width is measured with a ruler with an accuracy of 1 mm and divided by the number of turns. When measuring, it is important to avoid gaps between turns and overlap of turns! This will have a bad effect on accuracy.

TIP The cross-section of a stranded wire (more precisely, stranded) can be approximately estimated by its diameter if it is neatly twisted, as in insulation. The correction factor for the void between the wires is 0.91.

Undersized wire cross-section - what is the danger?

So, let's consider the dangers that await us when using low-quality wires in everyday life. It is clear that the current characteristics of current-carrying conductors decrease in direct proportion to the decrease in their cross-section. The load capacity of the wire decreases due to the reduced cross-section. According to the standards, the current that the wire can pass through is calculated. It will not collapse if less current passes through it.

The resistance between the cores decreases if the insulation layer is thinner than required. Then, in an emergency situation, when the supply voltage increases, a breakdown may occur in the insulation. If, along with this, the core itself has a reduced cross-section, that is, it cannot pass the current that, according to standards, it should pass, the thin insulation begins to gradually melt.

All these factors will inevitably lead to a short circuit and then to a fire. A fire occurs from sparks that appear during a short circuit. Let me give you an example: a three-core copper wire (for example, with a cross-section of 2.5 2), according to regulatory documentation, can pass 27 A for a long time, usually 25 A is considered.

But the wires that come into my hands, produced in accordance with the specifications, actually have a cross-section from 1.8 mm2 to 2 mm2 (this is with the declared 2.5 mm2). Based on the regulatory documentation, a wire with a cross-section of 2 mm2 can carry a current of 19 A for a long time.

Therefore, if a situation occurs when a current designed for such a cross-section flows through the wire you have chosen, which supposedly has a cross-section of 2.5 mm2, the wire will overheat. And with prolonged exposure, the insulation will melt, followed by a short circuit.

Contact connections (for example, in a socket) will collapse very quickly if such overloads occur regularly. Therefore, the socket itself, as well as the plugs of household appliances, may also be subject to melting.

Now imagine the consequences of all this! It’s especially disappointing when a beautiful renovation has been made, new appliances have been installed, for example, an air conditioner, an electric oven, a hob, a washing machine, an electric kettle, a microwave oven. And so you put the buns in the oven to bake, started the washing machine, turned on the kettle, and even the air conditioner, since it became hot.

These switched on devices are enough to cause smoke to come out of junction boxes and sockets. Then you will hear a pop, which is accompanied by a flash. And after that the electricity will disappear. It will still end well if you have circuit breakers.

What if they are of low quality? Then you won't get away with a bang and a flash. A fire will start, accompanied by sparks from the wiring burning in the wall. The wiring will burn in any case, even if it is tightly walled under the tile.

The picture I described makes it clear how responsibly you need to choose wires. After all, you will use them in your home. This is what it means to follow not GOSTs, but TUs.

Calculation of the cross-section of electrical wiring according to the power of connected electrical appliances

To select the cross-section of cable wire cores when laying electrical wiring in an apartment or house, you need to analyze the fleet of existing electrical household appliances from the point of view of their simultaneous use. The table provides a list of popular household electrical appliances indicating the current consumption depending on the power.

You can find out the power consumption of your models yourself from the labels on the products themselves or data sheets; often the parameters are indicated on the packaging. If the current consumed by an electrical appliance is not known, it can be measured using an ammeter.

Table of power consumption and current for household electrical appliances at a supply voltage of 220 V

Typically, the power consumption of electrical appliances is indicated on the housing in watts (W or VA) or kilowatts (kW or kVA). 1 kW=1000 W.

Table of power/current consumption of household electrical appliances

| electrical appliance | Power consumption, W | Current strength, A |

| Washing machine | 2000 – 2500 | 9,0 – 11,4 |

| Jacuzzi | 2000 – 2500 | 9,0 – 11,4 |

| Electric floor heating | 800 – 1400 | 3,6 – 6,4 |

| Stationary electric stove | 4500 – 8500 | 20,5 – 38,6 |

| microwave | 900 – 1300 | 4,1 – 5,9 |

| Dishwasher | 2000 – 2500 | 9,0 – 11,4 |

| Freezers, refrigerators | 140 – 300 | 0,6 – 1,4 |

| Electric meat grinder | 1100 – 1200 | 5,0 – 5,5 |

| Electric kettle | 1850 – 2000 | 8,4 – 9,0 |

| Electric coffee maker | 630 – 1200 | 3,0 – 5,5 |

| Juicer | 240 – 360 | 1,1 – 1,6 |

| Toaster | 640 – 1100 | 2,9 – 5,0 |

| Mixer | 250 – 400 | 1,1 – 1,8 |

| Hairdryer | 400 – 1600 | 1,8 – 7,3 |

| Iron | 900 –1700 | 4,1 – 7,7 |

| Vacuum cleaner | 680 – 1400 | 3,1 – 6,4 |

| Fan | 250 – 400 | 1,0 – 1,8 |

| TV | 125 – 180 | 0,6 – 0,8 |

| Radio equipment | 70 – 100 | 0,3 – 0,5 |

| Lighting devices | 20 – 100 | 0,1 – 0,4 |

Current is also consumed by the refrigerator, lighting fixtures, radiotelephone, chargers, and TV in standby mode. But in total this power is no more than 100 W and can be ignored in calculations.

If you turn on all the electrical appliances in the house at the same time, you will need to select a wire cross-section capable of passing a current of 160 A. You will need a finger-thick wire! But such a case is unlikely. It’s hard to imagine that someone is capable of grinding meat, ironing, vacuuming and drying hair at the same time.

Calculation example. You got up in the morning, turned on the electric kettle, microwave, toaster and coffee maker. The current consumption will accordingly be:

7 A + 8 A + 3 A + 4 A = 22 A

Taking into account the switched on lighting, refrigerator and, in addition, for example, a TV, the current consumption can reach 25 A.

Selecting a wire cross-section for connecting electrical appliances to a three-phase 380 V network

When operating electrical appliances, for example, an electric motor, connected to a three-phase network, the consumed current no longer flows through two wires, but through three and, therefore, the amount of current flowing in each individual wire is somewhat less. This allows you to use a smaller cross-section wire to connect electrical appliances to a three-phase network.

To connect electrical appliances to a three-phase network with a voltage of 380 V, for example an electric motor, the wire cross-section for each phase is taken 1.75 times less than for connecting to a single-phase 220 V network. Attention, when choosing the wire cross-section for connecting an electric motor by power, you should take into account that The motor nameplate indicates the maximum mechanical power that the motor can produce at the shaft, not the electrical power consumed.

The electrical power consumed by the electric motor, taking into account efficiency and cos φ, is approximately two times greater than that created on the shaft, which must be taken into account when choosing the wire cross-section based on the motor power indicated on the plate.

For example, you need to connect an electric motor that consumes power from a 2.0 kW network. The total current consumption of an electric motor of such power in three phases is 5.2 A. According to the table, it turns out that a wire with a cross-section of 1.0 mm2 is needed, taking into account the above 1.0 / 1.75 = 0.5 mm2. Therefore, to connect a 2.0 kW electric motor to a three-phase 380 V network, you will need a three-core copper cable with a cross-section of each core of 0.5 mm2.

It is much easier to choose the wire cross-section for connecting a three-phase motor based on the current consumption, which is always indicated on the nameplate. For example, the current consumption of a 0.25 kW motor for each phase at a supply voltage of 220 V (the motor windings are connected in a delta configuration) is 1.2 A, and at a voltage of 380 V (the motor windings are connected in a star configuration) it is only 0.7 A.

Taking the current strength indicated on the nameplate, according to the table for selecting the wire cross-section for apartment electrical wiring, we select a wire with a cross-section of 0.35 mm2 when connecting the electric motor windings in a “triangle” pattern or 0.15 mm2 when connecting in a “star” pattern.

Formula for calculating cable cross-section by power

Allows you to select the cross section based on power consumption and voltage.

For single-phase electrical networks (220 V):

I = (P × K and ) / (U × cos (φ) )

Where:

- cos (φ) - for household appliances, equals 1

- U - phase voltage, can range from 210 V to 240 V

- I - current strength

- P - total power of all electrical appliances

- K and - simultaneity coefficient, for calculations the value is taken as 0.75

For 380 in three-phase networks:

I = P / (√3 × U × cos (φ))

Where:

- Cos φ—phase angle

- P is the sum of the power of all electrical appliances

- I is the current strength by which the cross-sectional area of the wire is selected

- U - phase voltage, 220V

Continuously permissible currents

This value differs depending on the selected cable and the current-carrying cores used. Any wire has a certain long-term temperature Td, which is indicated in its passport. At this temperature, prolonged operation of the conductor cores is permissible, and any damage is excluded.

To calculate the continuous permissible current, use the formula:

- Id = √((Td*S*Kt)/R),

Where:

- Ktp - heat transfer coefficient;

- R - resistance;

- S - core section.

In practice, you can use PUE tables.

Cable cross-section by diameter table

Knowing the diameter of the wire, you can determine its cross-section using a ready-made dependence table. The table for calculating the cable cross-section by core diameter looks like this:

Table of cross-section versus diameter

| Conductor diameter, mm | Conductor cross-section, mm2 |

| 0,8 | 0,5 |

| 1 | 0,75 |

| 1,1 | 1 |

| 1,.2 | 1,2 |

| 1,.4 | 1,5 |

| 1,6 | 2 |

| 1,8 | 2,5 |

| 2 | 3 |

| 2,3 | 4 |

| 2,5 | 5 |

| 2,.8 | 6 |

| 3,2 | 8 |

| 3,6 | 10 |

| 4,5 | 16 |

Options by definition

There are several ways to determine the cable cross-section. The need for this usually arises during electrical installation work, when it is necessary to check the existing conductor for compliance with the application standards for a particular area. For example, a person may be doing wiring that requires a cable with a cross-section of at least 1.5 mm. He will need to check his wire for compliance with these conditions, since otherwise, overheating of cables and connections, failure of household appliances and even a fire are possible.

Before measuring, remove the insulating layer

Important! If the conductor has one core, then measurements are made directly on it. It is necessary to untangle one wire from the wire coil, clean it of insulation, and only then take measurements.

Circle area formula

To calculate the cross-sectional area of a round wire through the radius, you need to multiply its square by the number Pi. In practice, it is much easier to determine the diameter and divide it by 2. Based on the measurement methods, the following methods for calculating the cross-section can be distinguished.

By diameter using a caliper or micrometer

The most popular measurement method is to determine the diameter using a caliper or micrometer. Such devices allow you to measure the diameter as accurately as possible, and then multiply half of it by the number Pi.

To operate, you only need a wire and the device itself. The process looks like this:

- Move the micrometer lock to the “Open” position.

- Unscrew the handle of the device to a distance that will be sufficient to insert the conductor between the probes.

- Insert the wire into the probes and twist it with a special hand-held device until a cracking sound is characteristic of the device.

- Record the diameter readings on the appropriate scale.

- Unscrew the handle and remove the wire.

A significant advantage of this measurement method is that it allows you to determine the diameter and, as a consequence, the cross-section of any round conductor. Moreover, it can be connected to the network and actively work in one or another electrical device.

Using the caliper is very convenient

Note! The disadvantage of this method is that the devices are quite expensive, and there is no point in buying them for one or two uses.

By diameter using a pencil or pen

This method is based on the use of any ton object on which a wire core can be wound. Typically, a pen, pencil or felt-tip pen is used as such an object. The wire is wound around it in the form of a spiral with the rings compressed as tightly as possible. To eliminate inaccuracies, the insulation is removed along the entire length of the conductor under test.

You may be interested in this Features of the NShVI tip

All windings have the same width and thickness, so it is necessary to compress them as much as possible and determine the total length using a ruler or centimeter. Next, this value is simply divided by the number of winding rings. The more turns there are, the more accurate the result will be in the end.

The advantage of this approach is that its application does not require any special measuring tools at all, except for a regular ruler. If we talk about the disadvantages, they consist in the low accuracy of measurements and the longer process of preparation for them.

Wrapping around a pencil

Important! If in the previous case everything could be done in a couple of seconds, then here you will have to ensure maximum adherence of all turns to each other. This also only works for thin copper wires. This is not suitable for aluminum.

By diameter using a ruler

This method is suitable for thick wires. The thinner the core, the less accurate the result will be in the end. The diameter can be determined using thread or paper. The second method is more accurate.

Step-by-step measurement process:

- Tear off a small piece of plain paper and fold it over on one side. It's best to take a thin one.

- Take a piece of paper and attach it to the conductor.

- Wrap the sheet around it until the two ends of the paper touch each other.

- Bend the other end at the junction.

- Attach the leaf to the ruler and measure the distance from one curved edge to the other.

- Calculate the diameter using the resulting circumference divided by two Pi numbers.

- Apply standard formula.

You can find the diameter using a ruler.

The method is suitable for aluminum conductors of sufficient thickness that are difficult to bend. The disadvantage is the very low measurement accuracy.

By diameter using the table

Some are interested in how to determine the cable cross-section by diameter using a table. This approach is used for cables and wires of standard cross-section. For example, a person learned the diameter using any of the methods described above. It is not at all necessary to use formulas. It is enough to look at the table presented and determine the cross section without calculations.

Relation of diameter and sections

By power or current

If a person knows the conductive properties of the wire, then with their help it is also possible to determine the cross-section. To do this, you need to find out either the current or power. Next, it remains to find the value in the table and match the section to it.

You may be interested in this Features of heat-resistant cables

Table for determining cross section based on current and power

Important! It is worth remembering that the result will be different for copper and aluminum conductors.

By formulas

As already mentioned, there are a number of simple formulas that allow you to determine the cross-section of the conductor. More precisely, this is one formula, but in one case the radius of a round wire is used, and in the second - the diameter. To determine it is necessary:

- Measure the diameter of the wire (its thickness) using any of the methods described above. It is recommended to use a caliper.

- Record the resulting diameter value.

- Calculate the cross-sectional area using the formula: S = π × R², where R is the radius (half the diameter), π is the number Pi, which is approximately equal to 3.1415.

A similar table for copper conductors

. Important! You can also use another formula, where instead of the radius, half the diameter (D/2) appears, which is squared. The result will be similar, so it is better to divide the diameter by 2 in advance.

Wire cross-section and power table

When the cross-section is known, it is possible to determine the permissible power and current values for copper or aluminum wire. In this way, it will be possible to find out what load parameters the current-carrying core is designed for. To do this, you will need a table of the dependence of the cross section on the maximum current and power.

Table of power and current values from the cross-section for hidden wiring with a single-phase 220 V connection diagram

| Wire core cross-section, mm2 | Conductor core diameter, mm | Copper conductors | Aluminum conductors | ||

| Current, A | Power, W | Current, A | Power, W | ||

| 0.5 | 0.8 | 6 | 1300 | ||

| 0.75 | 0.98 | 10 | 2200 | ||

| 1 | 1.13 | 14 | 3100 | ||

| 1.5 | 1.38 | 15 | 3300 | 10 | 2200 |

| 2 | 1.6 | 19 | 4200 | 14 | 3100 |

| 2.5 | 1.78 | 21 | 4600 | 16 | 3500 |

| 4 | 2.26 | 27 | 5900 | 21 | 4600 |

| 6 | 2.76 | 34 | 7500 | 26 | 5700 |

| 10 | 3.57 | 50 | 11000 | 38 | 8400 |

| 16 | 4.51 | 80 | 17600 | 55 | 12100 |

| 25 | 5.64 | 100 | 22000 | 65 | 14300 |

As we can see from the table, the cross-section of the cores depends, in addition to the load, on the material from which the wire is made.

Table of power and current values from the cross-section for hidden wiring with a three-phase connection diagram of 380 V

| Wire core cross-section, mm2 | Conductor core diameter, mm | Copper conductors | Aluminum conductors | ||

| Current, A | Power, W | Current, A | Power, W | ||

| 0.5 | 0.8 | 6 | 2250 | ||

| 0.75 | 0.98 | 10 | 3800 | ||

| 1 | 1.13 | 14 | 5300 | ||

| 1.5 | 1.38 | 15 | 5700 | 10 | 3800 |

| 2 | 1.6 | 19 | 7200 | 14 | 5300 |

| 2.5 | 1.78 | 21 | 7900 | 16 | 6000 |

| 4 | 2.26 | 27 | 10000 | 21 | 7900 |

| 6 | 2.76 | 34 | 12000 | 26 | 9800 |

| 10 | 3.57 | 50 | 19000 | 38 | 14000 |

| 16 | 4.51 | 80 | 30000 | 55 | 20000 |

| 25 | 5.64 | 100 | 38000 | 65 | 24000 |

Parallel connection of electrical wiring wires

There are hopeless situations when you urgently need to lay wiring, but there is no wire of the required cross-section available. In this case, if there is a wire with a smaller cross-section than necessary, then the wiring can be made from two or more wires, connecting them in parallel. The main thing is that the sum of the sections of each of them is not less than the calculated one.

For example, there are three wires with a cross section of 2, 3 and 5 mm2, but according to calculations, 10 mm2 is needed. Connect them all in parallel and the wiring will handle up to 50 amps. Yes, you yourself have repeatedly seen the parallel connection of a large number of thin conductors to transmit large currents.

For example, welding uses a current of up to 150 A and in order for the welder to control the electrode, a flexible wire is needed. It is made from hundreds of thin copper wires connected in parallel. In a car, the battery is also connected to the on-board network using the same flexible stranded wire, since when starting the engine, the starter consumes a current of up to 100 A from the battery.

And when installing and removing the battery, it is necessary to move the wires to the side, that is, the wire must be flexible enough. The method of increasing the cross-section of an electrical wire by connecting several wires of different diameters in parallel can be used only as a last resort. When laying home electrical wiring, it is permissible to connect in parallel only wires of the same cross-section taken from the same reel.

Author: Sergey Vladimirovich, electrical engineer. More about the author.