Selecting wire diameter and fuse repair

Well, now let's move on to the main issue of our article - the choice of diameter and the repair itself. Let's start with the first one.

Conductor diameter selection

The diameter of the conductor in the fuses is clearly calculated. If you are replacing, you must install a conductor of the same diameter. Otherwise, your fuse will not perform its function of protecting the electrical network.

- There are several ways to do this. The easiest way is to take the wire cross-section for the fuse, and a table of standard values will allow you to make a choice. To do this, just measure the diameter of the wire.

- The diameter of the wire can be measured using a caliper or even a regular ruler. If the diameter of the fuse wire is too small, then measurements can be made as follows. We wrap the wire around any small object - a lighter, a pencil, a pen.

- It is advisable to make 10-20 turns for greater measurement accuracy. We make the coils as dense as possible to eliminate the space between them. Then we measure the diameter of all turns. We divide the resulting value by the number of turns. Here is the diameter of the wire for the fuse.

Note! With this method of measuring diameter, you will probably have a small error due to insufficient density of turns. Therefore, we round the resulting number to the nearest smaller number.

- Calculation of a copper wire fuse can also be made for values not indicated in the table. To do this, we need to know the required fuse-link current and wire material.

- In order to calculate the diameter of the copper wire for a fuse up to 7A, we should use the formula below. In this formula, d is the calculated diameter, Ipl is the required fuse-link current, k is a coefficient taking into account the wire material. For copper it is 0.034.

- If you want to calculate the diameter of the wire for an insert with a rating above 7A with your own hands, then you should use the formula given below. In this formula, m is a coefficient that takes into account the wire material. For copper it is 80.

- If the thickness of the wire for the fuse, as a result of calculation or selection from the table, turns out to be one that is not available. Then you can achieve the required diameter by connecting several wires of different sections. Although this option is somewhat worse.

Fuse repair

Installing a wire instead of a calibrated fuse in a fuse is popularly called installing a “bug”. Any “bug,” according to the PUE standards, is unacceptable, since it is not always capable of properly protecting the electrical installation.

Nevertheless, this method of repairing fuses is resorted to quite often. Especially when there is no spare fuse at hand.

- Installing a bug instead of a fuse depends on its type. If this is a tubular fuse with a high rated current, then such products usually have a collapsible design, as in the video.

- That is, the fuse can be untwisted. Remove the burnt-out fuse-link and replace it with a fuse made of copper wire.

- With products of lower denominations everything is a little more complicated. Usually they are made non-separable, and therefore you have to tinker.

- If you have a glass or ceramic type tubular fuse, they usually have metal ends. To install the “bug” they need to be drilled on both sides and our conductor inserted into the resulting cavity. It is advisable to then solder the hole together with the conductor.

- Do-it-yourself repairs with knife fuses are somewhat more difficult. It will not be possible to drill a hole here, since the wire must be attached to the knives, which are hidden under the body. In this case, the wire cross-section of a 10 A fuse or another rating is attached directly to the knives in front of the housing. And then install the fuse.

Note! This method is much more dangerous. Since when a wire burns out, it may splash onto neighboring equipment. This may not lead to a fire, but it can damage the equipment.

- It is for these reasons that our instructions do not recommend winding wire directly onto the fuse holder contacts. The same applies to winding the wire on top of the tubular fuse housing.

How to calculate a fuse by current

Fuse links always blow at the wrong time. So what are we doing? Certainly! We make a “bug” out of it. If done incorrectly, you can get yourself into trouble. In order to correctly and safely restore the fuse link, you just need to select the correct diameter of the wire used. Below is the calculation of the wire diameter for fuse links according to the table.

| Melting current, A | Diameter, mm | |||||

| Copper | Aluminum | Nikelin | Iron | Tin | Lead | |

| 0,5 | 0,03 | 0,04 | 0,05 | 0,06 | 0,11 | 0.13 |

| 0,05 | 0,07 | 0,08 | 0,12 | 0,18 | 0,21 | |

| 0,09 | 0,1 | 0,13 | 0,19 | 0,29 | 0,33 | |

| 0,11 | 0,14 | 0,18 | 0,25 | 0,38 | 0,43 | |

| 0,14 | 0,17 | 0,22 | 0,3 | 0,46 | 0,52 | |

| 0,16 | 0,19 | 0,25 | 0,35 | 0,53 | 0,6 | |

| 0,18 | 0,22 | 0,28 | 0,4 | 0,6 | 0,68 | |

| 0,2 | 0,25 | 0,32 | 0,45 | 0,66 | 0,75 | |

| 0,22 | 0,27 | 0,34 | 0,48 | 0,73 | 0,82 | |

| 0,24 | 0,29 | 0,37 | 0,52 | 0,79 | 0,89 | |

| 0,25 | 0,31 | 0,39 | 0,55 | 0,85 | 0,95 | |

| 0,32 | 0,4 | 0,52 | 0,72 | 1,12 | 1,25 | |

| 0,39 | 0,48 | 0,62 | 0,87 | 1,35 | 1,52 | |

| 0,46 | 0,56 | 0,73 | 1,56 | 1,75 | ||

| 0,52 | 0,64 | 0,81 | 1,15 | 1,77 | 1,98 | |

| 0,58 | 0,7 | 0,91 | 1,26 | 1,95 | 2,2 | |

| 0,63 | 0,77 | 0,99 | 1,38 | 2,14 | 2,44 | |

| 0,68 | 0,83 | 1,08 | 1,5 | 2,3 | 2,65 | |

| 0,73 | 0,89 | 1,15 | 1,6 | 2,45 | 2,78 | |

| 0,82 | 1,3 | 1,8 | 2,80 | 3,15 | ||

| 0,91 | 1,1 | 1,43 | 3,1 | 3,5 | ||

| 1,22 | 1,57 | 2,2 | 3,4 | 3,8 | ||

| 1,08 | 1,32 | 1,69 | 2,38 | 3,64 | 4,1 | |

| 1,15 | 1,42 | 1,82 | 2,55 | 3,9 | 4,4 | |

| 1,31 | 1,6 | 2,05 | 2,85 | 4,45 | ||

| 1,45 | 1,78 | 2,28 | 3,18 | 4,92 | 5,5 | |

| 1,59 | 1,94 | 2,48 | 3,46 | 5,38 | ||

| 1,72 | 2,10 | 2,69 | 3,75 | 5,82 | 6,5 | |

| 1,84 | 2,25 | 2,89 | 4,05 | 6,2 | ||

| 1,99 | 2,45 | 3,15 | 4,4 | 6,75 | 7,6 | |

| 2,14 | 2,6 | 3,35 | 4,7 | 7,25 | 8,1 | |

| 2,2 | 2,8 | 3,55 | 7,7 | 8,7 | ||

| 2,4 | 2,95 | 3,78 | 5,3 | 8,2 | 9,2 |

The diameter of the fuse link is selected depending on the fusing current. The melting current is usually taken to be a current value twice the rated current. Those. if your device consumes a current of 1A, the melting current is assumed to be 2A. And according to it we select the diameter of the wire. In this case, copper is 0.09mm or aluminum is 0.1mm.

The fuse link does not burn out instantly; this requires some time, even if it is very short. Therefore, short-term overloads (for example, inrush currents) do not cause destruction of the fuse-link.

A fuse link, even of a small diameter, only 0.2 mm thick, can shatter into small pieces if it burns out. Some of the metal evaporates, some is sprayed into molten drops. Flying parts of a fuse link have a temperature close to the melting point of the material from which they are made and can cause harm to equipment or nearby people. Therefore, the fuse link must be in a housing that can withstand the effects of destruction of the fuse link. Depending on the rating of the fuse links, the housings are made of plastic, glass, and ceramics.

Calculator for calculating wire diameter for fuse links

The role of the conductor in the fuse is performed by a fuse-link, which ensures sufficient conductivity at normal operating current. But, if this parameter is exceeded excessively, overheating occurs with further burnout of the fuse-link.

The fuse-link is selected both according to the type of load being protected and in accordance with the rated current. Its main parameter is the cross section, which can be calculated in the following way.

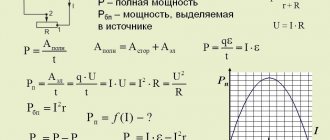

The heat released when the wire burns out is calculated by the formula:

where I is the current strength in the conductor, R is the resistance, t is the flow time (usually selected from 0.2 to 2 seconds, depending on the equipment being protected).

Also, the amount of heat can be released through the mass of the conductor, while:

where λ is the specific heat of fusion (selected from Table 1), and m is the mass of the wire.

| Metal | Specific heat of fusion | Metal | Specific heat of fusion | ||

| kJ/kg | cal/g | kJ/kg | cal/g | ||

| Aluminum | 393 | 94 | Platinum | 113 | 27 |

| Tungsten | 184 | 44 | Mercury | 12 | 2,8 |

| Iron | 270 | 64,5 | Lead | 24,3 | 5,8 |

| Gold | 67 | 16 | Silver | 87 | 21 |

| Magnesium | 370 | 89 | Steel | 84 | 20 |

| Copper | 213 | 51 | Tantalum | 174 | 41 |

| Sodium | 113 | 27 | Zinc | 112,2 | 26,8 |

| Tin | 59 | 14 | Cast iron | 96-140 | 23-33 |

From these formulas we can derive the equality:

The mass of round wire can be calculated using the formula:

where, π – constant, d – wire diameter, l – wire length, ρ – metal density

If we substitute the mass value and derive the diameter, we get the following formula:

if we assume that R = (ρ * l) / s, where s is the cross-section of the conductor, then we get:

To avoid tedious calculations and exhausting work with tables to calculate the diameter of the fuse link, it is much more convenient to use an online calculator. In which you need to indicate the wire material and the permissible current value.

Source

Conclusion

The diameter of the fuse wire depends on the rated current of the product and the material of the wire used. Selecting or calculating this diameter is not so difficult. But such a repair is only a temporary measure.

It is not for nothing that the PUE requires the use of only calibrated inserts, and as for non-separable fuses with a small rated current, their price is not so high as to risk expensive equipment. Therefore, at the first opportunity, be sure to replace the “bug” with a normal fuse or calibrated insert.

Source

Examples of selecting fuses and circuit breakers

Example 1. The main power line of an industrial enterprise with a voltage of 380/220 V powers a group of electric motors. The line is laid indoors using an armored three-core cable with aluminum conductors and paper insulation at an ambient temperature of 25°C. The long-term design current of the line is 100 A, and the short-term current when starting motors is 500 A. Starting is easy. It is necessary to determine the rated current of fuse links of the PN2 type protecting the line, and select the cable cross-section for the following conditions:

a) the production premises are non-explosive and non-fire hazardous, the line must be protected from overload;

b) the premises are fire hazardous, the line must be protected from overload;

c) the line must be protected only from short-circuit currents.

Solution. We determine the rated current of the fuse links protecting the line by long-term current: I inst = 100 A, in short-term current: I inst = 500/2.5 = 200 A. Fuse type PN2-250 with a 200 A fuse link.

1. For a paper-insulated cable, protected from overload and passing in a non-explosive and non-fire hazardous room, the value of the protection factor k z = 1. In this case, the long-term permissible current load on the cable I add = k z I z = 1x200 = 200 A.