Scope of use of Wago terminal blocks

When installing electrical wiring on the scale of large objects and small rooms, it becomes necessary to connect sections of power cables at nodal points. To do this, distribution boards and junction boxes are installed, into which the ends of the wires are inserted and switched there in the required order.

Weak, poor contact will over time cause the joint to overheat, prematurely oxidize and fail. This is fraught not only with disconnecting the consumer from the power supply, but also with the danger of fire with smoke and fire.

Therefore, special attention is paid to connecting parts of electrical wiring. One method is twisting, followed by soldering and winding a layer of insulating tape. The method is reliable, but labor-intensive and time-consuming. To speed up this process without losing the quality of the connection, various types of connectors, also called terminal blocks, were invented. Most often these are screw-clamping structures in a non-conducting polymer housing.

Wago has come up with a different mechanism and offers a wide range of mounting elements for industrial and domestic facilities:

- terminals for DIN rail mounting;

- installation terminals for distribution boxes;

- removable connectors;

- terminals for field mounting.

For work on wiring an electrical network with a voltage of up to 380 V, with a circuit load of up to 7 kW and a current of up to 32 A, it is convenient to use Vago clamps with the ability to connect wires with a diameter of 0.75 mm to 4 mm. Recently, clamps for wiring with a core cross-section of up to 6 mm have appeared.

Wago terminal blocks are used in various fields.

Varieties of series

By the first three numbers in the terminal block markings you can find out which series they belong to. They differ from each other not only in appearance. Their technical characteristics are also different, which should definitely be taken into account.

The connection is considered the most vulnerable and sensitive area in the electrical wiring. After all, if the contact is poor, this will lead to heating of the wiring and its sparking. The result is electrical wiring failure or fire. It is the connector that connects the cables through which electric current passes.

WAGO terminal blocks are reliable connectors for wiring cores. Their technology does not use screw connections. The connection occurs by spring force. And depending on the spring that is used, the terminals are divided into the following types:

- flat spring clamp (fasteners under spring plates);

- CAGE CLAMP clamps (flat clamp fastening);

- FIT-CLAMP clamps.

Note: not all vago terminal blocks can connect aluminum wiring. If the wiring contacts are coated with Al-plus paste, then they can be connected with similar devices.

Terminal blocks with flat spring clamp

Used for quick wiring installation. A popular model of this type is WAGO 773. There are two options: without paste for combining copper wires and for connecting wires made of aluminum or a mixture of aluminum and copper. The wires are connected using clamping mechanisms that are completely invisible from the outside. Thanks to this, it is not possible to remove the conductive core back.

Dimensions of vag 773 series:

As for the technical characteristics, they are as follows:

WAGO 773 terminal blocks are used to minimize voltage losses in long-length wiring, to connect a socket located in parallel, as well as for power electrical installations. The video below explains in more detail what this type of terminal is:

Today, this series has been replaced by the more modern 2273, which allows you to connect wires with a small cross-section (from 0.5 to 2.5 mm2). The appearance of WAGO 2273, as well as their main parameters, are presented in the video review below:

CAGE CLAMP

Their use does not require lugs for multi-core cables. Terminal blocks are used to connect chandeliers and in distribution boxes. Their main advantage is simplicity and reliability of installation.

Popular models of this type: WAGO 222 and 224 (reusable). Connect copper wiring with a cross-section from 0.08 to 35 mm2. Self-clamping terminals with lever clamp series 222 are produced without paste and are used when connecting wires of one or several cores with a cross-section of up to 4 mm2 and voltage up to 380V. If you need to connect aluminum wiring, then the paste must be purchased separately.

Video review of connectors of this type:

WAGO 221 terminal blocks (pictured below) are considered analogues of the 222 series. These are universal spring terminal blocks with levers that will fit any copper conductor. The operating conditions for the Vago 221 connector are significantly simplified, since their dimensions are compact. Designed for voltage up to 450V. Used for wires with a cross section of 0.14–4 mm2 and for lugs 002–4 mm2.

A comparison of the 221 and 222 series of cars is demonstrated in the video:

Terminal blocks 224 – single-core connectors. Allows you to quickly connect lighting fixtures without the use of tools.

FIT-CLAMP

The use of such clamps allows the connection to be made without stripping the insulation. They use a mortise contact. This is one of WAGO's new developments and it significantly speeds up and simplifies installation. Representatives of this type of terminal blocks include the 280 and 285 series, as well as 862, which are designed for installation on a DIN rail.

Internal organization

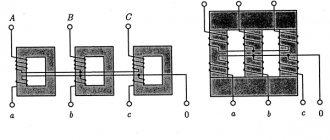

“Vago” terminal blocks are a series of terminals for wires located in one housing and connected by a common conductive busbar. The number of clamps corresponds to the number of cables that the terminal block can provide contact between. In detachable ones there can be from 2 to 5, and in one-piece ones - from 2 to 8.

The design is a steel spring mechanism with a two-part copper contact, the flat part of which is adjacent to the inserted end of the wire, stripped of insulation, and the forked part covers it around the circumference with force. The contact feed regulator ensures the same connection density for all cable diameters indicated on the marking.

The connector body is made of non-flammable polymer dielectrics, which provides the necessary level of fire and electrical protection. In almost all models, the part of the body where the wiring strand is clamped is made transparent for visual inspection.

Installation and removal of terminals 773 / 2273

Terminals of the 773 and 2273 series are easy to install and do not require special training or equipment. To connect the wires, they must be stripped to 12-14 mm

Figure 6. Installation procedure for transparent terminals

- insert the stripped conductor into the terminal hole;

- install the terminal block in the distribution box;

- fix the terminals in a convenient position in the box.

You can leave some of the holes without conductors, this does not affect the electrical capabilities of the terminal

Dismantling rules

Terminals of the 773 and 2273 series are mistakenly called disposable by some, but this is not entirely true. The possibility of dismantling and reuse is declared by the manufacturer and can be easily implemented if simple conditions are met:

- Uses copper (not aluminum) single-core wires, without additional attachments (for example, ferrules)

- The number of connections of 1 wire to the terminal does not exceed 2-3 times

- It is recommended to cut the end of the wire and strip a new section when reconnecting multiple times.

To remove the wire from terminal 773/2273, it is necessary to combine the pulling force with the rotation elements.

Features of application and installation of Wago

- If the loads and operating conditions provided for by the design exceed those indicated in the table, the Vago cannot be used.

- For cables with an aluminum core, use only Wago clamps filled with special paste. The paste removes the layer of existing oxide and prevents its appearance in the future. Without this mixture, the contact point will begin to overheat over time, which will lead to the destruction of the conductor.

Installation of Wago terminal blocks.

Specifications

The terminal blocks of the 773 and 2273 series are very similar to each other, but they also have some differences. The main thing is the sizes. The 2273 line is more modern and miniature. Also, the terminals differ in the number of connected conductors and the possible cross-section. More details in the table:

| Characteristic | Episode 773 | Episode 2273 |

| Permissible cross-sections of single-wire wires | 0.75 – 2.5 sq.mm (18 – 12 AWG) / up to 6 sq.mm for 773-173 | 0.04-2.5 sq. mm (18 - 12 AWG) |

| Number of contacts | 2,3,4,6,8 | 2,3,4,5 |

| Type of contact group | PUSH WIRE | |

| Plastic material | Polyamide 6.6 | |

| Contact material | Brass H62 | |

| Maximum operating current at specified voltage (according to test standard) | 20A at 600 V (UL listed, CSA) 24 A at 400 V in accordance with PUE 7th ed. Ch. 1.8 clause 1.8.37, clause 1.8.40, GOST R 50571.16-2007, 612.3 | |

| Maximum long-term operating temperature | 105°C (cr. Up to +180°C) in accordance with the test report | |

Technical parameters are identical to similar models of terminals Wago-773, Wago-2273. The color of the plastic insert and the dimensions of the terminals depend on the series and number of contacts for which the block is designed

Advantages and disadvantages

Using Vago terminals when installing electrical wiring has its advantages compared to other methods.

- High speed of operation due to the simplicity and ease of installation of terminal blocks;

- Reliable fixation of the contact point of the connected cables;

- There is no need for additional insulation of the connection;

- Small sizes allow you to save and organize space in the distribution box;

- When using reusable connectors, it is possible to quickly remake the connection.

However, “Vago” also has disadvantages, which include:

- high cost of the product, which especially affects costs for large volumes of work;

- according to the rules for operating electrical installations, free access must be provided to all points where Vagos are installed;

- abundance of cheap low-quality fakes.

Advantages and disadvantages

Advantages of Vago terminal blocks:

- no special tools are required to connect the wires;

- switching of cores made of dissimilar metals (for example, aluminum and copper) is allowed;

- The clamp design allows you to connect wiring of different diameters;

- it is possible to remove the device for reuse (in some models);

- a lubricant is applied to the contact plates to prevent the formation of oxides (applies to some modifications);

- each wire uses its own clamp to connect;

- due to their reduced dimensions, the clamps take up little space in the distribution box;

- The plastic housing provides insulation of the electrical wiring cores.

Flaws:

- According to the operating rules for electrical installations, when using Wago products, it is necessary to provide access to distribution boxes.

- It is not allowed to install aluminum wires without applying quartz vaseline paste to the contacting surfaces.

- There are a large number of fakes on the market that do not correspond to the declared characteristics.

An additional disadvantage of the products is the increased resistance of the joint, which is 1.5 times higher than the same parameter for standard twisted metal cores. An increase in resistance leads to an increase in heat generation and overheating of the clamp.

Due to the increased temperature of the plates, the connector body is destroyed, leading to short circuits. When using Wago elements, you should take into account the power of the connected devices and avoid overloading the electrical circuits.

Popular types of terminal blocks

Wago produces and constantly improves terminals for different types of connections. The most popular among masters:

- one-piece (disposable) Push Wire. Series 773 and 2273. There are modifications filled with special paste for connections like aluminum-copper and aluminum-aluminum, and dry ones for copper-copper connections. You can purchase the paste separately and fill the terminal block yourself;

- detachable (reusable) Cage Clamp. Series 222 and 221. Made in the form of clips, where the wire is clamped using an external lever. Before installing the wire, it rises, providing access for the wire to the contact, after which the lever lowers, fixing the cable. Terminals of the 221st series differ from the 222nd in their dimensions reduced by 40%;

- detachable (reusable) Fit Clamp. Series 224. The clamp is designed so that it pierces the wire insulation during installation.

For lighting equipment

To connect lamps and other attached removable equipment, it is convenient to use 224 series clamps, since they do not require preliminary stripping of the insulation from the end of the cable. With their help, you can connect single-core and stranded wires, including thin ones. There is no need to use additional tools with them. This is convenient when working at height from a stepladder.

Types of WAGO terminal blocks, their properties and design features

When installing power electrical circuits, it is necessary to make numerous connections of two or more sections of cables and wires. In this case, the connection can be permanent (for example, the well-known twist) or detachable - using a plug and socket. Traditionally permanent connections, made taking into account all the necessary requirements, are more reliable and can withstand high current loads. Detachable connections are used only as a last resort due to poor weight and size properties. Their main advantages are high functional flexibility and convenient operation of electrical appliances.

Features of Vago terminals

Wago terminals were developed in Germany in the middle of the 20th century. Initially, this type of terminals was conceived as an alternative to classic connectors. Indeed, Vagos are often considered a semi-permanent connection type because they combine the advantages of both removable and permanent connectors.

The advantages of Wago include:

- quick and easy installation; — the ability to connect copper and aluminum cores; — ease of secondary installation in cases where it is necessary to carry out alterations.

It is worth noting that high reliability of Vago connections is ensured only at currents up to 32 Amperes. This is enough for most household consumers. An important requirement when operating connections made using Vago terminals is easy access to them for maintenance. For this reason, the terminals are placed in a junction box.

Wago design features

In the manufacture of Vago terminals, components made using clamping, lever and wedge-shaped designs are used. The latter fixes the cable core in the socket due to the frictional force and the fact that the wedge cuts into its surface. All this increases the reliability of the connection. In addition, there are terminal blocks based on mortise contacts. Popular models include from 2 to 6 installation sockets, making it possible to make both connections and line branches.

Depending on the application, products are available with or without viscous paste filling. The paste prevents air from entering the contact area, which prevents corrosion. Some elements are enclosed in a transparent case. This makes it convenient to visually control the insertion of conductors.

On the plastic case of some elements there is a socket with which you can easily connect a phase probe or tester. The manufacturer produces both small-sized models and products for installation on a DIN rail.

Wago terminal models

All Vago terminals can be divided into the following groups:

— terminals with flat spring contacts for sections from 0.5 to 2.5 sq. mm; — CAGE CLAMP, used for stranded conductors with a cross-section from 0.1 to 35 square meters. mm; — FIT CLAMP with mortise or IDC contact, which does not require stripping of wire insulation.

So, Wago produces a wide range of connection terminals that can withstand current loads of up to 32 Amps. They are great for household wiring. Their main advantages are ease of installation and operation.

![Turboloan [CPS] RU March](https://dush-pol.ru/wp-content/uploads/turbozajm-cps-ru-mart-330x140.jpg)