Material characteristics

Bitumen compounds are used to treat surfaces, creating a moisture-proof coating. The work must be carried out correctly at the construction stage before the building is put into operation. The use of heated bitumen solution is not advisable due to the low elasticity of the coating and the difficulty of application.

It is optimal to use special bitumen mastics that have pronounced damage resistance properties. The qualities of strength and elasticity of the coating are achieved thanks to the component composition of bitumen mastic for foundation waterproofing:

- mineral wool;

- asbestos components;

- limestone, brick, quartz;

- combined ash;

- fibrous components;

- thickeners (peat chips, chalk).

The material is easy to apply and economical, thanks to the ability to reduce composition consumption for waterproofing coatings of large areas. Additional components in the form of polymer components increase the thermal insulation properties, moisture resistance and bending resistance of the mastic.

Technical characteristics correspond to the indicators:

- viscosity 15-30sec;

- strength 0.2-0.5 MPa;

- elongation at break 100-300%;

- adhesion strength to concrete surfaces 0.3-0.4 MPa;

- water absorption (24 hours) 0.5-1%;

- softening at a temperature of 100-130°C.

Technical indicators determine the basic properties of mastics, opening up wide application possibilities in the construction industry.

Composition and technical characteristics

Bitumen mastic is a special mixture made from astringent organic substances (oil refining waste) with the addition of mineral and artificial fillers. Additives are necessary to improve the performance characteristics of the material, such as hardness, ductility, density, resistance to low temperatures, etc.

The following components act as fillers:

- Polymers;

- Crumb rubber, rubber;

- Short fiber mineral wool;

- Talc, asbestos, quartz, brick powders;

- Waste processing products, such as ash;

- Antiseptics, etc.

The composition of bitumen mastic can be one-component or two-component . In the first case, a solvent is added to the mixture, and the material hardens under the influence of air due to the evaporation of volatile substances.

This material is supplied in sealed packaging, which prevents premature hardening. The exception is bitumen mastic with polyurethane filler. In a well-sealed package, it can retain its properties for a year. After opening the container, the mastic quickly hardens and becomes unsuitable for use.

Two-component mastic basically contains two chemically inactive components, which are packaged separately from each other, which increases its shelf life.

The advantage of using a mastic with two components is the ability to obtain a mixture of the required density by varying the ratio of solvent and base substance. However, it is possible for craftsmen with extensive experience to prepare a mixture of optimal composition.

The quality of roofing work directly depends on compliance with the mastic mixing technology and the speed of its application. In this case, preference is given to a one-component material that is ready for use immediately after opening the container.

The drying time for a 1mm thick layer is about a day. During this time, the solvent completely evaporates, and the composition becomes solid.

The consumption of waterproofing mastic is related to the type of work and the type of material on which it will be applied. For example, for gluing surfaces you will need from 0.8 to 1 kg per m2, and for arranging a 1mm waterproofing layer the figure will be 2-3 kg per m2.

Advantages and disadvantages of bitumen mastic

Bitumen mastic for foundation waterproofing is affordable. Work can be carried out even at low temperatures. The properties of the material make it possible to create a non-shrinking, pore-free coating.

The advantages of using bitumen mastics are:

- Reliable protection of surfaces of various configurations from moisture.

- Optimal adhesive properties and elasticity ensure adhesion of the waterproofing material to the base without cracks or splits.

- Can be used as an adhesive for laying rolled materials.

- Increasing the service life of structures and the building as a whole.

- Resistant to sudden temperature changes.

- Preventing corrosion on metal elements.

- After the mastic has hardened, it is possible to paint the surfaces.

It should be noted that the material is resistant not only to moisture, but also to ultraviolet radiation, which is very important for the external surfaces of structures exposed to atmospheric influences. Mastics combine an optimal set of quality characteristics and decorative properties. The material is presented in a wide range of colors.

The disadvantage of using bitumen foundation waterproofing is the need to carry out work in good weather conditions. Atmospheric precipitation and negative temperatures can have a negative impact on the quality characteristics of the material. It is important to consider that the resulting lining will not be uniform due to the strong viscosity of the composition.

Foundation waterproofing is carried out in good weather

Technical data sheet of the material

The basic requirements for production technology, technical parameters and the quality of mastic for roofing work are indicated in GOST 14791 79, 2889-80, 30693 2000. For each type of waterproofing material, an individual quality passport is required, which indicates the name, date of manufacture, specifications, batch number, volume and number of packaging units.

Following the manufacturer's recommendations and following the work technology will ensure a durable, high-quality coating with a high degree of protection against moisture penetration. The use of waterproofing bitumen mastic in roofing work will significantly reduce construction costs.

Types of bitumen mastics

Bitumen waterproofing of the foundation can be performed with various types of mastic compositions. Materials are conventionally classified according to three main characteristics: preparation method, application technology and type of polymer components.

Preparation methods involve two main types: mono-compositions and two-component mastics. One-component materials are ready for application. It is important to use the mixture immediately; the composition will harden and become unsuitable for work. When processing large areas, it is recommended to select containers with a small volume. Two-component mastics require mixing with a thickener before use, allowing you to increase the shelf life of the mixture.

Bituminous mastics are presented in various mixture options according to their component composition:

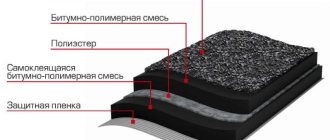

- Bitumen-polymer. The composition contains an aqueous emulsion of bitumen with modified polymers. The absence of inorganic solvents allows the material to be used for external and internal work. It has good moisture-proof, vapor barrier and adhesive properties.

- Bitumen-rubber. The mastic will reliably protect against corrosion, has the highest degree of elasticity, increasing 20 times without breaking when stretched.

- Bitumen-rubber. It is produced on the basis of oxidized petroleum bitumen with mineral components, crumb rubber, solvent and synthetic rubber. It is used in a wide temperature range, the material is resistant to mechanical stress.

- Bitumen-oil. The composition is frost-resistant and is used for buried surfaces.

- Bitumen-mineral. It consists of finely dispersed mineral powders and additives in the form of plasticizers.

- Bitumen primer. The material has a more liquid consistency than mastic. It is used as a primer for preparing surfaces before applying the base composition.

The technology of applying the material involves methods of cold and hot surface coating. Cold-applied bitumen mastic for foundation waterproofing is completely ready for use and does not require heating. Hot coating materials should be heated at high temperatures of 150-300°C, which complicates the installation process and requires compliance with safety regulations.

Cold applied mastic just needs to be stirred well before use.

Layer thickness and consumption

Using a simple calculation algorithm will help determine the amount of material to cover the surface. When waterproofing the foundation with bitumen mastic, the consumption is carried out in several stages:

- determination of the area of the treated surface;

- choice of material, taking into account the depth of the foundation, the level of soil moisture;

- calculation of the material based on the information indicated on the packaging of the composition.

It is important to consider the number of layers applied to the surface. The most expensive initial coating when filling pores and cracks. Average material consumption is 1-2 kg/sq.m. m for a horizontal plane, 0.3-0.9 kg/sq.m. vertical sections of the foundation. Deepening the foundation to 3 m requires a protective coating with a thickness of at least 2 mm. If the depth exceeds 3m, a waterproofing layer of 2-4 mm will be required.

Features of application

It is impossible to most effectively solve the problem of waterproofing without knowing the specifics of working with bitumen-based mastics.

Mastic consumption

Before starting work, you need to find out in what quantity you need to use mastic to create a waterproofing layer. To do this, first of all you need to study the manufacturer's instructions. Most often, the recommended consumption rate is given on the pack with the composition.

If there are no such instructions, but there is information about the preferred layer thickness, then you can calculate the optimal amount of waterproofing composition yourself. To do this, you need to focus on the following values, which correspond to standard consumption indicators for cold-applied mastics:

- 2−4 kg/m2 for foundation treatment;

- 3.5−6 kg/m2 when arranging the roof;

- 1−2 kg/m2 for laying roofing felt or other roll covering.

Please note that when using hot mastics, the consumption will be slightly higher, but in any case it should not exceed the maximum rate for using cold-applied material.

Application technology

To better understand how exactly surfaces are treated with bitumen-based waterproofing compounds, let’s consider the situation with applying bitumen waterproofing to the foundation.

To perform this work correctly, it is carried out in stages:

- The waterproofing compound can be applied only after the poured concrete has completely hardened.

- It is first necessary to prepare the surface to be treated and examine its condition. All detected cracks, chips and other irregularities must be eliminated.

- All debris, dust and other types of contaminants must be removed from the surface.

- After this, you need to apply a layer of primer or bitumen primer 1-2 mm thick.

- If you do not have the required type of emulsion, then you can prepare a solution for preparing the base yourself from the main mastic, for which it must be diluted with water in a 1:1 ratio.

- Now wait for the primer to dry. If you are working with hot mastic, first heat the required amount to a temperature of 160-200 degrees. Remember that the composition sets very quickly, so you should already have everything ready to quickly apply it to the surface. To avoid additional complications, it is recommended to heat not the entire mass at once, but its individual parts, which will allow you to treat only a specific area.

- Start applying the main layer of waterproofing, remembering that its thickness should not be more than 2-4 mm.

- When creating a waterproofing layer, pay attention to ensure that there are no streaks or areas of excessive saturation of the solution on the surface.

- Wait until the manufacturer's recommended drying time has passed.

- After this, you can begin applying a second additional layer, observing the same time intervals.

Keep in mind that when working with bitumen-based mastic, you can create no more than three layers. This distinguishes it from other waterproofing compounds.

Technology of work execution

When carrying out construction work on waterproofing the foundation with bitumen mastic, the processing technology must take into account the basic requirements and rules. The preparatory stage during the operation of the structure involves the creation of a trench about 1 m wide along the entire perimeter of the structure.

Proper preparation of the work area will help enhance the insulating properties of the material:

- elimination of defects, irregularities, cracks in the foundation;

- fillets are made to eliminate sharp corners;

- if necessary, grout the surface to avoid the formation of air bubbles;

- sharp protrusions are rounded;

- The surface is cleaned from dust and soil.

It is recommended to measure the moisture level of the foundation surface using a special device. The treatment area must be dry and clean. The proximity of groundwater requires the initial construction of a drainage system.

Hot applied bitumen is heated immediately before use. The preparation of two-component mastic involves mixing bitumen and polymer additives. The bitumen-polymer material should be diluted with a solvent, bringing the composition to a uniform consistency.

The mastic is applied with a brush

The mastic is applied using a brush, working the surface of the foundation from top to bottom. The next layer is applied only after the surface has dried. There is no need to wait long periods between each application. Treatment with a special sprayer will help speed up the process.

Using a special sprayer significantly speeds up the work

A foundation waterproofing coating made with bitumen mastic will provide reliable protection of the surface from moisture. Choosing the optimal coating option will improve the performance characteristics of the building structure.