Dowels for aerated concrete - what are their features

The dowel for aerated concrete is designed for fastening weights on walls made of loose and soft material. Standard screws and self-tapping screws are not suitable here, since the wall material crumbles and the fasteners fall out.

For load-bearing structures made of aerated concrete, self-tapping screws of a special design are used. Fasteners for foam blocks and gas blocks look like spiral bushings made of metal or plastic. During screwing, the ribs of the sleeve become wider and are firmly attached to the loose surface of the foam block. This mount can withstand a load of up to 20 kg.

What type of dowel for aerated concrete can be?

Figure 1. Dowel for aerated concrete

The construction trade network offers various types of dowels designed for fastening in a porous product. Their main difference is in the material of manufacture. When choosing a specific fastener, you need to be guided by what type of structure needs to be fixed to the aerated concrete wall.

Metal

This type of construction hardware is found more often than other parts. Typically, such fasteners are made of zinc-coated steel. Such elements are fire-safe, which is why they are recommended for use in rooms that are dangerous from this perspective. Metal dowels for aerated concrete are perfect for performing the following actions:

- install guides for fastening plasterboard sheets;

- fasten equipment and pieces of furniture that have an impressive mass;

- fix any pipelines.

The fastening contains a locking element. It prevents the risk of the dowel turning and falling inside the cellular base. The only drawback is that the part is susceptible to rust. Galvanized fasteners are expensive, but they have many positive characteristics. It can be reused whenever the need arises.

Plastic dowel for aerated concrete

This type of fastener is made of polyethylene or polypropylene. Plastic parts are convenient because they do not rust. Typically, such clamps are equipped with ribs arranged in a spiral. They provide the strongest possible adhesion between the part and the cellular base.

The peculiarity of such elements is environmental safety. They are also not afraid of aggressive environments. Along with their low cost, such characteristics have allowed plastic parts to become indispensable when working with aerated concrete surfaces. You just need to take into account that it is unacceptable to use such dowels when fastening them to the facade of a building, since they are not able to withstand low temperatures - with the onset of frost, the plastic bursts.

Nylon

Nylon dowels for aerated concrete are also plastic. They are good because they are also corrosion resistant. But such fasteners are more wear-resistant, so they can also be used for fastening parts on the facade. Nylon elements are much stronger than propylene or polyethylene parts. They have not gained popularity among consumers because they are more expensive than other modifications. But the product's characteristics fully justify the rather high price. Among the nylon models there are those that are convenient for performing the following work:

- fasten door and window frames;

- install mirrors and lighting fixtures.

Chemical anchor

If you need to securely attach a heavy object to the wall, it is most practical to use a chemical anchor for aerated concrete. It acts similarly to a metal element, but is mounted into the hole using special glue. This procedure allows you to tightly connect any structures to an aerated concrete surface.

Universal

These elements are allowed to be used on any concrete surfaces. Their distinctive feature is the special structure of the spacer. When the piece is immersed inside solid concrete, it acts like a regular dowel. In a hollow material, such a fastener is rolled up, forming a persistent knot that ensures tight fixation. Installation of such fasteners occurs by analogy with the usual option of hanging objects on the wall. The load-bearing capacity of any universal dowels is significantly lower than that of spacers, but their cost is high.

Nail dowel for aerated concrete

Figure 2. Nail dowel for aerated concrete

Special nails have been developed that are ideal when it is necessary to perform mass fastening. The sleeve of such a part is the simplest - it has 2 spacers, there are no more teeth or antennae. When fastening, a nail is inserted into the dowel instead of a screw element. Because of this, it is necessary to install a sleeve in order to prevent scrolling. The price of nail dowels is lower than that of other types of fasteners, although they have less ability to withstand significant loads. Installation of nail fasteners is easy, according to many experts in this field.

Frame dowel for aerated concrete

Such fasteners are made of metal or plastic. Its main difference is its pancake-like structure. Thanks to this, the fasteners can significantly reduce the load on aerated concrete. At the same time, the fastening strength parameter improves. It is advisable to use frame-type elements when installing window blocks, doorways, and guide structures.

Thermal insulation dowel for aerated concrete

This fastening option is recommended for any concrete foundations. It can also be used on brick. Since thermal insulation dowels are lightweight, they can be mounted even on soft surfaces, but it is recommended to fasten only light objects - thermal insulation materials.

The main types of dowels, which fasteners are best to use

Commercially available dowels are divided into:

- metal;

- plastic or nylon;

- chemical;

- nails;

- frame;

- thermal insulation;

- universal.

Metal

The material for the manufacture of metal anchors is galvanized steel. Dowels for metal foam blocks are fire-resistant and durable, but are much more expensive than their non-metallic counterparts. It is not recommended to use metal dowels in places of high humidity and for outdoor work. The fastener is equipped with a cuff or retaining flange that prevents it from falling into the wall.

Plastic

A plastic dowel is cheaper, but is used one time. These hardware are lightweight, corrosion resistant, and have a spiral cut. A type of plastic dowel is a nylon fastener. It is stronger than a standard non-metallic anchor, so it is used for installation of systems with variable loads.

Chemical

This type of fastening is used almost everywhere. Externally, the anchor looks like a tube containing chemical components. Such anchors provide reliable fastening due to adhesion forces. Connections made using chemical anchors are much more reliable than standard fastenings.

Nail dowels

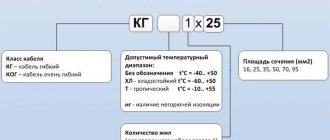

A nail anchor is used to fasten aerated concrete blocks. The anchor is held by spreading the lamellas when driving the element into the supporting structure. The thread of the spacer element is asymmetrical. The material for making the sleeve is plastic (nylon or polyamide). The helical screw is made of high carbon steel. Basically, dowels and nails for aerated concrete are used for domestic needs and outdoor work. It is chosen because:

- the cost is 15-20% lower than the price of other types of fasteners;

- ease of use;

- reliability within the stated characteristics.

Frame dowels

A metal frame anchor is a good fastener for door and window frames made of aluminum or plastic. This fastener is used when installing and connecting wooden elements to a load-bearing surface. The frame dowel for gas silicate blocks is entirely made of galvanized steel. Some of the hardware has a galvanic coating, which reliably protects the anchor from corrosion.

Frame screws for aerated concrete are used due to:

- ability to withstand high lateral loads;

- Possibility of application during installation of multi-profile structures;

Thermal insulation fasteners

Designed for installation of loose thermal insulation materials. It is made from copolymer materials and looks like a long hollow tube with a wide cap at the end, which is why this fastener is also called a mushroom dowel. The rod is plastic or metal. The perforated surface of the cap facilitates final finishing and reliably hides the thermal insulation under a layer of plaster.

Thermal insulating hardware is also used when installing roofs. In this case, one should count on their continuous operation for several years under the influence of atmospheric conditions. An incorrect choice of material or length of the product can trigger the start of corrosion processes with further destruction of the fasteners for the gas block and the collapse of the structure.

Chemical anchor

Chemical fasteners in aerated concrete are used:

- during the construction of multi-storey buildings;

- when working with the foundation in conditions of high humidity;

- for the construction of bridges;

- when laying concrete floors;

- for the construction of reinforcement outlets.

Chemical anchors are absolutely safe for humans. Their widespread use is hampered by the high cost and relatively long curing time of the adhesive composition - from several hours to a day.

Universal anchors

Universal hardware can serve as an anchor for standard load-bearing structures made of brick or concrete. It is also used as fasteners for aerated concrete blocks. The secret of its strength is in the special cutting of the sleeve, which reacts differently to contact with different materials. Thanks to its specific shape, such an anchor can be screwed into various load-bearing surfaces:

- In dense concrete or brick, the anchor is held in place by frictional forces.

- In a hollow material, hardware does not encounter resistance, therefore, depending on the shape, it behaves differently. In the first case, the dowel is screwed onto a self-tapping screw. This forms a tight knot, ensuring reliable fastening. In the second case, when the rod is screwed in, the sleeve changes its shape, turning into a persistent bolt.

What types of dowels are there?

All dowels differ in the shape of the ribs for fixation and the installation method. Dowels can be driven or screwed into the base. Screwing dowels into aerated concrete is considered the most reliable method. Let's look at the main types of fasteners that can be found on sale:

- Metal. For their production, galvanized steel is mainly used. The fasteners are highly fire resistant, can withstand heavy loads and are used for installing various pipelines. Metal dowels have a special collar that prevents rotation. The main disadvantage of metal dowels is the risk of corrosion. For aerated concrete, a metal dowel is suitable.

- Plastic. Made from durable materials that will not rust over the years. Mostly plastic products have ribs in the form of spirals. They provide a reliable connection to porous materials. Plastic dowels are environmentally friendly and can guarantee a strong fastening. Plastic is not exposed to aggressive factors, so dowels are quite common. The cost of plastic fasteners is an order of magnitude cheaper than their metal counterparts. Experts do not recommend plastic dowels for outdoor use due to their instability to temperature changes.

- Nylon. Such dowels, as well as plastic versions, are not subject to corrosion. The advantage of choosing nylon will be its strength and durability. Due to the relatively high cost, the demand for them is not so great. Most often, nylon dowels are used when installing doors, windows, and mirrors.

- Chemical. A special dowel for aerated concrete, which is used for installing large and heavy objects. Chemical anchors come to the rescue in cases where standard metal fasteners cannot cope with the task. When installing a chemical anchor, it is installed in the pilot hole with a special adhesive applied for more reliable fixation.

- Universal. Suitable for all types of surfaces, including porous aerated concrete. The design includes a spacer part. When immersing hardware, the universal dowel fixes it according to the principle of a standard expansion-type dowel.

- Gvozdeva. It is also called a dowel-nail. The structure provides for two struts without a toothed covering. When installing a nail dowel, you need to install a sleeve. It will prevent the hardware from scrolling. Anchor nails are budget fasteners designed for objects of insignificant weight. The main advantage is considered to be simple installation.

- Frame. There are models made of plastic and metal. Frame dowels are great for loose surfaces because they correctly distribute the load, which is mostly placed on the fastener itself.

- Thermal insulation. Most often used for fixing insulation. Suitable for working with concrete, brick and softer surfaces.

Varieties by method of application

A variety of fastening features allows you to use plastic and metal dowels for aerated concrete for specific tasks. Which ones make different anchor designs and how to use them?

Frame fasteners

The use of frame dowels for sibit, foam concrete and other non-solid surfaces is necessary during the construction of buildings in the period preceding the stage of finishing work. Before installation, the surface is cleaned of dirt and dust and holes are drilled that are comparable to the length and thickness of the dowel itself. The holes are chamfered so that the anchor head does not protrude above the surface. The dowel is inserted into the hole using a hammer. The fastener is driven in until it stops and then tightened.

The frame dowel can be used to install swivel consoles, wall cabinets, heating radiators, sinks and more.

When installing, do not overtighten the screw: the maximum load should not exceed 5 Nm.

Thermal insulation fasteners

There are two types of thermal insulation hardware available for sale:

- A dowel with a plastic rod is used for attaching thermal insulation (foam plastic, etc.) to enclosing structures and facades. The material for the fastening base is class B25 concrete, hollow brick or natural stone.

- The thermal insulation dowel for gas silicate is equipped with a galvanized steel screw. Unlike its universal analogues, such an anchor does not destroy the load-bearing surface, but reliably fastens the thermal insulation.

Instructions for using thermal insulation fasteners look like this:

- marking places for installing fasteners;

- drill holes with a diameter of 10 mm with a depth margin of 5-10 mm;

- We position the dowel and press it all the way (so that the perforated cap is pressed tightly against the load-bearing surface;

- insert a metal rod and hammer it in until the insulating material is completely fixed.

When installing the thermal plug, using a hammer is strictly prohibited!

How to use a chemical anchor

To perform fastening with a chemical anchor, you must:

- drill a hole of the required diameter and depth (information on the packaging);

- blow out the hole with air and clean it with a wire brush;

- cut off the clip from the anchor package or cartridge;

- Screw on the mixer and squeeze out a small amount of adhesive so that it fills 2/3 of the depth of the hole;

- screw the pin until it stops;

- maintain the time indicated in the instructions.

When using a chemical anchor, you should not rush and apply the load before the set time.

Features of fastening in gas silicate blocks

Published: October 25, 2014 at 09:51 pm

Author: Admin

Category: All about fasteners

Today I wanted to talk about the peculiarities of fastening in gas silicate blocks . It was not by chance that I touched on this topic. The material itself has become an integral part of our lives. And there are several reasons for this: speed, energy saving, ease of processing, accessibility. But having started construction from gas silicate blocks, many are not aware of the difficulties of fastening into this material. Unfortunately, as often happens, all medals have a downside: low density (which is often aggravated by the seller’s desire to earn more by passing off a low-quality product as a more expensive one). And at a certain point in time, the question of attachment to gas silicate blocks arises. The attached material itself can be of different weights, which further complicates installation.

There are several basic questions that most often have to be answered. Fastening the Mauerlat, fastening the ventilated facade, installing ventilation air conditioners, and in interior decoration in everyday life.

First, let's understand the concepts:

- Mauerlat is an element of the roofing system, essentially a beam or log laid on top along the perimeter of the load-bearing wall. Serves as the extreme lower support for the rafters. Traditionally made of wood, however, when constructing a metal roofing frame, a channel, I-beam, etc. can be used. The purpose is to tie the roof to the walls of the house.

- A suspended ventilated façade is a façade technology, a system consisting of facing materials that are attached to a galvanized steel, stainless steel or aluminum frame to the load-bearing layer of the wall or to a monolithic ceiling. Air circulates freely through the gap between the cladding and the wall, which removes condensation and moisture from the structures.

To select the right fasteners, you need to know the dimensions of the timber; we at Centrmetiz have developed a special table that will help with the choice

| Beam thickness | Screw length | Dowel length (plug) |

| 100mm | 12x260 | 16x200 |

| 150mm | 12x300 | 16x240 |

| 200mm | 12x400 | 16x240 |

I would especially like to note about the installation itself: the plug is pre-installed into a gas silicate block, in turn, marks are made on the beam, then holes are drilled. The beam is laid on top of the plugs on gas silicate blocks, and the screw is inserted into pre-prepared holes in the beam and pulled to the wall. If this installation is not suitable for you for some reason, you can contact us Tsentrmetiz, and we will be able to select other options for fastening the Mauerlat: using chemical anchors or perforated corners

As for the hinged ventilated facade, I would like to immediately note that it is attached to specially designed anchors. These anchors are presented in great variety on the Russian market, but not all of them are equally good for installation in gas silicate blocks. And don’t be misled by the various “wings” and “antennae”. In fact, they are designed to prevent the dowel from turning in the hole when the steel part of the anchor is screwed in, and they do not have much effect on the load characteristics of the anchor. The entire secret of the anchor, as a rule, is hidden inside the dowel, these are the so-called spacer zones. And here you need to pay attention to the following:

- The spacer zone should be as long as possible. For example, for an anchor 10x100 should not be less than 70mm

- There should be a cut at the end of the anchor that is not connected to the main expansion zone. At the moment of complete twisting of the metal part, this cut will allow the anchor to unfold in the form of a dovetail and fit tightly into the hole

- Protruding spacer elements should be hidden along the spacer part, which will open when the metal part of the anchor is tightened

- The anchor must be made of nylon, but the use of nylon is not a guarantee of quality, unfortunately, nylon is different from nylon. A high-quality anchor has a sleeve made of highly purified polyamide - nylon 6.6. This gives the anchor maximum elasticity. Since the installation is carried out in a low-density material, elasticity will allow the original dimensions of the hole to be preserved as much as possible. Which is not unimportant for increasing loads, and not losing them from increasing the hole due to the rigidity of the material. You should also not forget about the climatic conditions in which we live at low temperatures, the material becomes harder and more brittle, and as a result, you will not get a expansion in the wall, but a burst bushing. The elastic sleeve will also increase the speed of installation at the time of tightening, which is important, since the number of holes during installation can reach several tens of thousands of holes.

- Protection is provided in the form of a collar against electrochemical corrosion in the event of dissimilar materials of the spacer element and bracket

- Spacer with hex head and press washer has a Torx 40 slot

Having extensive experience in testing various anchors at Tsentrmetiz, and the experience is really large, the results can be viewed in the gallery of our objects. We settled on two types of anchors: EFA 10x100F from ELEMENTA and FUR10x100FUS from FISHER. But the fisher anchor is inferior to the elementa anchor: firstly, in terms of price, and secondly, it does not have a dovetail-shaped spacer zone at the end, and the lamellas in the main spacer zone are smaller than those of the elementa anchor

Gas silicate block, fastening

If you were deceived or you did not have the opportunity to buy high-density gas silicate blocks, then a GBS punch is suitable for increasing the loads

Unlike drills, the punch compacts the inner surface of the hole, which leads to increased load characteristics for the EFA façade anchor dowel. An important condition for ease of use is the placement of the SDS under the hammer drill. And has the length for a façade anchor

| type | size | anchor |

| G.B.S. | 10x85 | EFA10x85 |

| G.B.S. | 10x100 | EFA10x100 |

| G.B.S. | 10x115 | EFA10x115 |

| G.B.S. | 10x135 | EFA10x135 |

| G.B.S. | 10×160 | EFA10x160 |

If this installation is not suitable for you for some reason, you can contact us at Tsentrmetiz, and we will be able to select other options for fastening a suspended ventilated facade: using chemical anchors

Installation of ventilation systems is carried out in a similar way as for a suspended ventilated facade in the case of fastening brackets.

In the case of fastening engineering systems, as well as in everyday life, you can use dowels: MUD, GB, EX (the advantage of this dowel is the ability to use metric fasteners: bolts, screws, threaded rods), UX

You can select more precisely the size and type of fasteners for engineering systems by contacting us at Tsentrmetiz.

In conclusion, I would like to note several important points: when installing in gas silicate blocks, you cannot use metal expansion anchors and dowels.

Gas silicate blocks are a low-density material; metal anchors easily compact them and, at the moment of expansion, disrupt the structure of the material, resulting in a backlash or complete removal of the anchor from the base material. As for attaching support brackets for a suspended ventilated facade, installation can only be carried out after full-scale testing, since this type of construction and subsequent operation are associated with the safety of people. Tests can be carried out by contacting Centermetiz; they are carried out free of charge, at a pre-agreed time. When installing ventilation or engineering systems, you can use a catalog with load calculations, which you can receive free of charge from Tsentrmetiz, or order a calculation from our engineers. When using chemical anchors, you should remember that chemical anchors are divided into the base fastening material, as well as climatic conditions. There are strict requirements for installation using chemical anchors: for drilling holes, for the use of different sleeves, for the type of chemical anchor. If you violate them, you will not get the desired result. And the loads may be lower than when using standard fastening methods.

Fastening during construction

Facade work or roof installation is necessarily accompanied by the installation of thermal and waterproofing. For such work, a thermal insulation mount in an aerated concrete wall with a wide head is suitable.

Arrangement of the foundation or construction of structures intended for operation in difficult conditions cannot be done without universal or chemical dowels. The former reduce construction costs, and the latter can be used where it is really needed.