Dependence of the height of the supporting elements of the fence on the type of material

When building a fence, proper support is of particular importance. To ensure that the fence does not sag and stands for a long time without warping, several nuances are taken into account, such as material, installation method, length and width (diameter) of the posts.

In this article we will look at some characteristics of fence posts and use one example to calculate what diameter and thickness to choose.

The use of pipes in fence construction

Pipe fences are very popular due to their practicality, attractive appearance and reliability. But not all enclosing structures repeat each other, so they are divided into several groups. To determine the choice of the appropriate option, you should study a number of criteria and subtleties.

The key components of the simplest fence made of corrugated sheets are a profiled metal pipe, which is used to construct the frame, and the main sheet of corrugated sheets. Other parts are consumables and are selected taking into account the design features.

The metal pipe for the fence can have different diameters - from 40 to 150 mm, shape and overall characteristics. To obtain a stable and reliable structure, it is worth observing all technological aspects and following the sequence of actions.

Using metal pipes, you can get the following advantages:

- Reliable fixation of large fences.

- Resistance to corrosive processes.

- Easy and simple installation.

- Comfortable finishing.

- Harmonious combination with fence design.

Asbestos-cement supports

An asbestos cement pipe is concreted into the ground according to the same rules as a metal one. For the reliability of the structure, after installation is completed, it is recommended to fill the cavity in the asbestos-cement pipe with concrete; this will be more than enough to make reliable fence posts from corrugated board.

It is recommended to anchor the part located in the ground - drill holes in the pipe and insert strips of reinforcement into them. Such a simple structure, after filling the hole with concrete, will work as an anchor.

The crossbars are attached to the post using a bolted connection. Holes for bolts are drilled in the pipe for these purposes. With a span width of less than 3 meters, a 40x40 mm profile can be used as the material for the crossbars. The corrugated sheet is attached to the profile using self-tapping screws.

Types of pipes for intake: profile or round, what to choose

Experts say that round products have minimal resistance and rigidity. But in terms of ease of installation, they are much inferior to profile models. Rectangular supports and purlins are easily cut and joined using welding equipment. The flat coating ensures tight and rigid installation of all parts of the fence.

But with identical diameter and weight, the round pipe is superior to the profile version in terms of permissible bending force. Therefore, when installing round fence pipes, you can save money by using less support weight. It is also more convenient to drive the product into the soil by screwing it in with a collar.

Optimal sizes of posts and crossbars for a fence

The cross-section of fence posts is determined by its height, the presence or absence of a foundation, as well as the spaces between the supports. Due to their shape, pillars and crossbars made from profile pipes are easiest to join together, and also to attach corrugated sheets to them.

A low-cost and relatively durable structure can be obtained by using rectangular metal pipes with a cross-section of 40x20x2 or 40x25x2 mm. The distance between the pillars, as a rule, is chosen to be 2.5 m; increasing the span requires the selection of thicker-walled pipes.

For fences up to one and a half meters high without a strip foundation with spot-filled supports, profile pipes 50x50x2, 50x30x2, 60x30x2 mm for posts for corrugated sheets are best suited; crossbars 30x20x2 in this design will cope with the load perfectly.

A more solid option on a foundation base of 2 meters in height has more significant weight, the pillars will need a section of 60x60x2, you can use lighter ones 60x40x2 mm, in which case the optimal dimension for the crossbars will be 40x20x2 mm.

Round pipes are chosen with a slightly larger diameter, since with an identical cross-section their bending strength is less.

As the height of the fence increases, it is worth giving preference to fence posts and crossbars made of corrugated sheets of a larger cross-section so that the structure remains stable even under strong wind loads. The principle is also valid for materials such as wood and asbestos-cement pipes.

How to choose the right intake pipes depending on technical parameters

The performance properties of the fence are determined by the quality and characteristics of the supporting structure. Therefore, in order for the fence to be of high quality and reliable, you should familiarize yourself with its technical parameters.

Section diameter

In order for the future fence to be strong and durable, you need to take a responsible approach to choosing the cross-section of the support posts. This indicator varies from 2 to 15 cm. The thicker the product, the stronger the load it can withstand.

If you choose an insufficient diameter, the fence may collapse under the influence of heavy winds or other negative factors.

For a forged metal fence, a support with a diameter of 5 cm or more is suitable, which performs direct functions and responsibilities.

The upper parts of the pipes are welded with metal to insulate them from snow and water. If you miss this requirement, in winter the frozen liquid will negatively affect the structure and lead to its cracking.

Material

Fence posts are made from different materials. Galvanized models are securely fixed in the soil and are superior to steel or stainless steel products in terms of wind resistance. In addition, they look aesthetically pleasing and do not require additional decoration.

You can get by with simple metal pipes without spraying, but they need annual painting to protect them from corrosion and damage.

It should be borne in mind that galvanized structures are quite expensive. But this is justified by their service life and external advantages.

Pillar height

The height parameters of the supports are determined by the following characteristics:

- Soil structure. For areas located on sand or loose soil, the height of the pillar is increased by 10-15 cm. This is due to the inability of the soil to fix a short pillar in a stationary state.

- Dimensions of the enclosing structure.

- Specific gravity of the fence.

The length of the products affects such a property as the degree of windage, i.e. on the resistance of supports to strong wind gusts and hurricanes.

Numerous calculators can be found in the public domain that allow you to correctly calculate the parameters of a fence post based on the listed criteria.

Distance between pillars

The distance between the supports determines the choice of pipes. The standard parameters look like this:

- For round pipes - 2.2.5 m.

- For rectangular and square structures - 2-3 m.

In addition to the geometric shape, the type of fence is taken into account. The distance changes in inverse proportion, since the more massive and larger the system, the smaller the distance between the pillars should be. For a fence made of corrugated sheets or chain-link, a distance of 3 m is used.

But a forged steel panel is fixed on poles with a distance of 2-2.8 m. A fence made of corrugated sheets does not need reinforced support, since it does not have much weight.

Having chosen the optimal distance and other characteristics of the pillars, you can proceed to calculating the amount of materials required.

Number of support pipes

To estimate the number of parts for installing a fence, you should apply a simple formula: the length of the perimeter is divided by the distance between the supports. It is important to make sure that the distance is identical in all areas.

Wooden supports

Wooden posts are the best option for fixing sections of a wooden fence, regardless of the level of complexity. Fastening transverse elements does not require the use of complex professional equipment, and the main advantages of such supports are presented:

- mechanical strength;

- sufficient resistance to strong gusts of wind;

- aesthetic appearance;

- environmental safety and naturalness;

- affordable cost;

- ease of self-installation.

Wooden pillars with decorative elements

However, a prerequisite for using wood for a long time is additional preventive treatment of problem areas to protect them from rotting processes and insect attacks.

The method of installing wooden poles directly depends on the quality characteristics of the soil, as well as the load on the supporting elements and the dimensions of the structure being built.

Approximate prices for pipes of different sizes

A wide selection of rolled metal products is offered for sale, and the number of pipe manufacturers is constantly increasing. Therefore, before purchasing components for making a frame, you need to evaluate the market value of the product and plan a budget for the upcoming work.

Some builders calculate the cost of construction taking into account the cost of pipes per 1 linear meter of length, and not per 1 ton of weight. If you clarify the total footage of the racks and cores, you can correctly create prices.

Pipes for a rectangular metal fence with a cross-section of 40x60 mm and a thickness of 2 mm are available at prices ranging from 110 to 130 rubles. for 1 linear meter. If a more durable and powerful fence is being built, you will need to buy a stand 80x80 mm thick with 3 mm thick walls. The cost of such structures is 260-290 rubles/rm.

Square profile pipes with parameters 100x100 mm and a thickness of 3 mm are available for 360 rubles. (linear meter).

The veins to which the profile sheet is fixed have a smaller diameter than the pillars. They are intended to distribute the weight of the finishing layer with subsequent transfer of loads to the vertical supports.

When designing a fence up to 2 m high, tubular profiles with parameters 40x20 mm and walls 2 mm thick are used for purlins. The cost of such models starts from 66 rubles. for 1 pm.

For fences that are subject to increased requirements for reliability and durability, pipes with a cross section of 60x30 mm with walls of 2-2.5 mm are used. The purchase of such parts will cost 96 rubles. per linear meter.

Concrete pillars

Concrete fence posts will last no less than metal posts. The significant weight of the structure will guarantee stability on any ground.

Wrought iron fence

Positive properties include:

- The material is not afraid of moisture, rust and temperature changes;

- This fence post support is highly reliable and has a long service life;

- Its surface can be subjected to additional finishing: cladding, painting, plastering;

- Possibility of constructing a monolithic structure or using stacked pillars of various shapes and sizes;

- You can install electrical wiring into the “body” of the pole, which will allow you to install lighting sources on the top of the support;

- Easy to install and maintain.

Fence made from corrugated sheets

Cons:

- Concrete fence posts require preliminary preparation of the foundation in terms of reinforcement;

- Concrete fence posts have significant weight. To deliver products to the construction site, you will have to use special equipment, and this entails considerable costs.

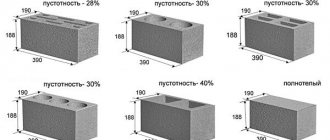

Concrete fence posts can have different shapes: round, semicircular, square, rectangular, trapezoidal.

Fence with metal posts

How to protect a product from corrosion

If anti-corrosion protection is not provided when installing the fence, the structure will become vulnerable to negative factors and will quickly lose its attractive appearance. Therefore, rust protection is an important step in the construction of pipe fencing.

Work begins with preparing the surface for the application of coloring compounds. This step is paramount as it affects the ease and efficiency of paint installation. At the preparatory stage, the coating should be cleaned of rust, oil compounds, grease and paint. In this case, it is necessary to adhere to radical and conservative methods.

The first involves removing rust with a scraper, a metal brush or a special knife. A blowtorch or acetylene torch gives good results.

Next, builders apply a primer that provides anti-corrosion protection and ensures good adhesion of the paint to the painted coating. For ferrous metals, specialized primers are selected, and for non-ferrous metals, adhesive primers are selected, since they are not subject to corrosive processes. The soil solution is distributed with a brush, sprayer or roller.

Having completed priming, you should proceed to final painting. Paintwork materials are applied with the same tools as the primer.

At the same time, experts recommend doing this in 2-3 layers, maintaining intervals for listening. In this case, you will receive uniform coloring without defects. For convenient distribution of paint, it is customary to use a sprayer, holding it at a distance of 15-20 cm from the surface.

In addition to paint and varnish materials, anti-corrosion protection is provided by installing special tops. Such decorative details perform two functions: they decorate the fence and protect it from liquid penetration into the internal voids.

In addition, people often choose pipes with a welded end that is installed into the soil. Such actions are aimed at increasing the resistance of the material to corrosion processes when interacting with moisture. If you choose an unprotected pole, you will need to organize rust protection yourself by applying primer or paint. The main thing is to do the treatment in 2 layers.

Brick pillars

A fence with brick pillars will look neat and solid. Installation of the support will be long and labor-intensive - each row will need to be reinforced with reinforcing tape. The distance between fence posts should be no more than three meters to provide the necessary rigidity and aesthetic appearance.

Brick fence posts from above must be protected from destruction by special caps that have a slope to allow precipitation to drain.

Fence with stone pillars

To concrete the supports, a monolithic strip reinforced concrete foundation is installed, the width of which is equal to the width of the pillar. Installation of such poles will require significant financial investments. But the result will be a reliable, durable fence that will not require special care and will last for many years.

An easier and faster option would be to build pillars from foam blocks.

Installation recommendations

Installing pipes for a fence is a responsible process that requires the master to study all the intricacies and step-by-step instructions. Having decided on the type and parameters of pipes and drawn up approximate drawings and diagrams, you can begin installation work. Don't forget that the key hazards for metal fencing are soil and wind. Therefore, it is recommended to fix the supporting parts in monolithic concrete.

Driving pipes into the ground for a fence or using the method of screwing in posts is not practical. Unstable soils are exposed to wetness and can quickly deform. Therefore, the concrete pad prevents the fence from losing stability or deforming its shape.

The profile pipe from which the racks are made is turned perpendicular with its wide side to the facing layer. This has a positive effect on wind stiffness and eliminates excessive windage.

Unlike solid fences made of corrugated sheets, pipe frames made of steel mesh are less vulnerable to negative factors. They are not afraid of hurricane winds, because... do not create much resistance. When installing such structures, it is necessary to ensure proper penetration into the soil and concrete the pillars to increase stability.

Installation of fence posts

If you are enclosing an area with an expensive fence, we would recommend entrusting the installation of posts and fastening of sections to specialists. But if you yourself want to “have a hand” in the new fencing of your summer cottage, garden or flower bed, you can install fence posts with your own hands. First of all, you will need to determine which fence posts are most suitable, choose the fence itself and fastenings, and also learn how to install fence posts in our article.

Basic recommendations

If you know the production of fence posts and some of its nuances, the concept of concreting fence posts and the theory of installing various elements, as well as screw fence posts, you don’t have to read further; you can already install the simplest fence without any problems. But, if these questions remain unanswered for you, then listen to our following recommendations:

- Initially, as we said above, determine the sections, posts and mounting options;

- Next, depending on the size of the sections and the parameters of the selected fence, set the correct distance between the fence posts and mark the locations of the posts;

- Now, based on the weight and materials of the fence, determine the depth for the fence posts (calculated individually for each case);

- Install the posts to the required depth, concrete the posts under the fence, install, if necessary, underground metal fasteners and arrange the dressing;

- Be sure to work with a level and tape measure, do not forget about distances and slopes;

- Once the posts have been installed and secured, you can begin installing the fence or its sections.

These few lines refer to wooden, metal and asbestos-cement columns. As for the technology for installing fence posts made of forging, brick and concrete, we definitely recommend working with professionals. You will not be able to carry out the installation on your own for many reasons: lack of practice, several assistants, special tools, equipment, and so on.

In principle, this can conclude our topic for today. All that remains is to wish you self-confidence and free time to buy fence posts, as well as install them and the fence itself in the shortest possible time.