Main directions of use of crushed stone

Cuboid crushed stone is considered the most popular, because the stones in it are the same in shape and size. Therefore, when filling, it almost does not form voids (flakiness index < 10%), it is consumed more economically and, due to good compaction, it becomes stronger in use.

The less flakiness, the higher quality the material. The maximum rate is 11%. Low flakiness of crushed stone crushed in a rotary crusher rather than in a cone crusher.

| How crushed stone is used | Description |

| Filler | Add during mixing:

Used for silicate, cellular blocks with autoclave curing. Limestone has good adhesion to cement, so the concrete is dense and provides a monolithic coating |

| Landscaping |

|

| Base |

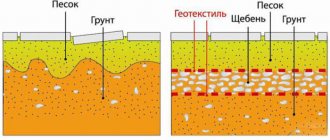

Limestone foundations require good waterproofing (ring drainage). The pillow must be above the groundwater level, because limestone is destroyed by continuous contact with moisture |

| Facing | Finish the walls of buildings as facing stones |

| Drainage |

|

| In the chemical industry | For fertilizers, obtain lime |

Crushed stone with a compaction coefficient of 1.01–1.52 tons/cubic meter is suitable for road construction. This is true for both highway cushions and ordinary sidewalks.

Limestone crushed stone is used as a cushion for the foundation

Options for using limestone in landscape design

Application of crushed limestone

Limestone crushed stone is a long-known and well-proven material in construction. It is obtained by crushing limestone rocks and has a characteristic white color that distinguishes it from other types of crushed stone. Although, depending on the rock of the particular area from which this type of crushed stone is produced, it may have other color impurities, pink, brown or yellowish.

Production of crushed limestone

The use of crushed limestone in construction is so widespread that it can be called a truly popular building material. This is due to its excellent characteristics - frost resistance, strength, environmental friendliness, availability, and ease of manufacture.

Of course, crushed limestone is in some ways inferior to granite, especially in terms of strength, but this disadvantage is compensated for. Firstly, by a significantly lower price, and secondly, by the fact that there are few places where that truly exceptional strength reserve of the older brother of limestone crushed stone is required.

The crushed limestone fraction is the main indicator that you need to know before you buy it. Lime crushed stone is the finest fraction, crushed up to 10 mm, ideal for filling paths and as admixtures for the manufacture of decorative coatings, paving slabs and facade finishing.

This is followed by a small fraction of limestone crushed stone 10-20 mm, this is the most popular brand of crushed stone in civil and industrial construction, and the production of reinforced concrete products. And, by the way, the most expensive.

Medium fractions, crushed 20-40 mm, are used in the construction of foundation cushions, substrates for walking paths and sidewalks, and in private construction.

Medium fractions, crushed 20-40 mm, are used in the construction of foundation cushions, substrates for walking paths and sidewalks, and in private construction.

Road construction, as one of the most responsible and significant construction industries, consumes crushed stone of large fractions of 40-70 mm. It is used as a substrate for road surfaces, fill, and road repair, but has limitations for the construction of roads that experience heavy loads.

The range of applications for crushed limestone is extremely wide; it is truly a versatile, inexpensive, excellent building material. But, as with the purchase of any building materials, the purchase of crushed limestone, especially in large volumes, should be a measured step, where the supplier’s reputation and product quality play an important role.

Strength of crushed limestone

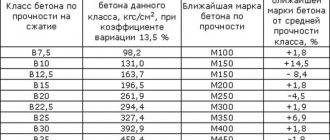

In Russia, crushed limestone of the M100 – M600 grades is more common. It can only be used for sidewalks, garden paths, driveways and when mixing lightweight concrete for thermal insulation. For use in loaded structures and on highways, high-strength crushed stone grades M800 and higher are needed, which are rare.

In this case, crushed limestone with a high dolomite content is used - its strength reaches M1400. And it can be used in highly loaded structures.

Strength

The main indicator of crushed stone strength is its crushability grade. It shows how resistant the material is to stress. The higher the number, the stronger the material.

The crushability grade of crushed limestone in the Sverdlovsk region ranges from M400 to M1200. It depends on the fraction and place of extraction of the rock. The material can withstand pressure from 0.4 to 100 MPa. For comparison, granite can withstand 90-250 MPa, and gabbro - 200-300 MPa.

Crushed limestone is not the most durable. It cannot be used in critical structures - for the foundations of multi-story buildings, roads with high traffic, engineering structures (bridges, overpasses). But in private construction it is in great demand; it is quite suitable for screeding, the foundation of one-story buildings, and filling paths and courtyards.

Use of crushed stone by fractions

The fraction of crushed stone affects the scope of its application.

| Fraction, mm | Application |

| 5–20 |

|

| 20–40 |

|

| 40–70 |

|

| 70–120 | pour pillows under the foundations of large objects |

The fraction larger than 70 mm are non-standard grains; most often they are ground or used as rubble stone. For example, for the construction of fences, gabions.

Fractions of crushed limestone

When producing crushed stone, it is sorted through specialized sieves into fractions - the size of the grains in the batch. There are three main fractions for lime material:

- Fine fraction - 5-20 mm.

- Average - 20-40 mm.

- The large fraction is limestone crushed stone (40-70 mm).

Crushed stone with grains of non-standard sizes 70-120 mm and 120-400 mm is called rubble stone. The main area of application of this material is landscape design. Rubble stone is also used to construct foundations. Rubble foundations are reliable and durable, but quite difficult to construct.

Limestone crushed stone characteristics

Limestone crushed stone today is in greater demand among other types of this material.

Its areas of application are varied:

- when laying the road surface;

- in the production of construction admixtures and mineral fertilizers;

- concrete products;

- in printing;

- glass industry;

- widely used in finishing works.

This type of crushed stone is obtained by sifting sedimentary rock and then

crushing. The quality of crushed limestone will be determined by calcium carbonate, which must be present in its composition. If the building material is of poor quality, it means that there are too many foreign impurities mixed in it.

Its strength is not very high, but it copes well with temperature changes and is not afraid of extreme cold. Another advantage of crushed limestone is its reasonable price and environmental characteristics.

Fractions of crushed limestone

This building material has several types, which are distributed among themselves according to the size of the granules. All of them are used in various fields. Let's look at the most famous ones.

Fraction 5 20

The particle size of this type of crushed stone is very small, which allowed it to find its application in the manufacture of concrete. Often used in reinforced concrete structures. This option is most suitable for laying roads and cladding various types of buildings. For the production of lime, this type of crushed stone is the main component of the resulting mixture.

Fraction 20 40

This type of crushed stone is the most popular in production; its particles are medium in size. Areas of application:

- for pouring the foundation of houses;

- for landscaping;

- also applicable in the production of concrete and medium-sized precast structures;

- successfully used to restore the proper appearance of the external sides of the building;

- for making lime.

Fraction 40 70

This version of crushed stone is least in demand in construction and other fields of activity. Its particles are very large in size.

Most often used:

- when laying tram tracks;

- for the production of pillows for highways;

- for embankments on railway tracks.

If you need to create a powerful structure made of reinforced concrete, then crushed stone of this type is best suited. Sometimes it is used for cladding the walls of buildings.

Types and scope of application of limestone crushed stone

Limestone crushed stone is limited in color; most often you can find white or brown stone, sometimes gray or yellow, and less often red.

No construction work will be carried out without the use of all kinds of bulk materials, so crushed limestone is a frequent guest at construction sites.

It is an important component in the production of concrete mortar and is used when pouring foundations for various types of structures. No road will be built without crushed limestone.

You might be interested in:

- Crushed limestone buy with delivery

Limestone crushed stone application

Limestone crushed stone is a building material often used to form the bases of road surfaces or special parking areas for vehicles with low load characteristics.

Crushed limestone, the use of which is a cheap and affordable option, has good qualities in terms of frost resistance and density.

Crushed limestone is used as a component of reinforced concrete products, as a filler. The material combines well with cement mortar and gives it additional strength properties.

The presence of different fractions of crushed limestone significantly expands the scope of its application.

Main groups of material by fraction and application:

1. Crushed limestone of fraction 5-20 mm is a necessary material for construction and repair work. Used for preparing cement mortars and dry construction mixtures. Thanks to the substances included in the material, chemical processes that affect the quality of the solution are accelerated.

2. Crushed limestone 20-40 mm has a wide range of color shades, from gray granite to ash white. Thanks to this feature, the material is widely used in landscape design. The mosaic color effect of crushed stone is widely used by designers for the original design of various objects - garden paths, platforms, flower beds and lawns.

3. Crushed limestone fraction 40-70 mm is used as a cushion and bedding material in the construction of tram and railway lines, special transport sites and roads. From this fraction, large-sized reinforced concrete products are manufactured and industrial lime is produced.

additional information

The absence of harmful substances and toxic compounds in crushed stone makes its scope of application wider and more universal. The material is in demand and popular due to its quality characteristics and environmental safety. When extracting limestone, both at the initial stage and upon completion of crushing, the products are checked for radioactivity and the presence of other harmful components.

When producing limestone crushed stone, the material is treated with special chemical compounds that improve the quality characteristics of the material and its functional properties.

You might be interested:

- Expanded clay 0-5 mm in 50 l bags

- Crushed limestone fraction 20-40

- Granite crushed stone in bags 3-10

- Crushed limestone 40-70 in bags