When constructing foundations, blind areas, bases for paths and roads, sidewalks and laying communications, various combinations of soil, sand, crushed stone, gravel and secondary gravel are used. In this case, the mixtures are necessarily compacted and compacted, which implies a certain compaction coefficient, which must be known to accurately calculate the material.

Typical preparation of the base for a monolithic or block foundation in section

On average, data on the compaction coefficients of the most popular materials is presented in Table 1.

| Material and its technical characteristics | Compaction factor |

| Crushed stone fraction 40-70, grade 800 fraction 70-120, grade 800 all fractions, grade 300…600 | Average 1.1 1,25…1,3 1,25…1,3 1,1…1,5 |

| Slag, depending on density | 1,3…1,5 |

| Construction sand | 1,15 |

| Soil, depending on type | 1,1…1,4 |

| PGS | 1,2 |

| Expanded clay | 1,15 |

However, these are general, average data. Let's take a closer look at where the concept of compaction coefficient comes from and how to determine it.

Materials used

For different types of foundations, it can use both local compacted soil and imported materials. Most often, local semi-rocky and sandy soils are subjected to compaction. Already loams, and even more so clayey soils, must be removed to the depth of the pit and replaced with a cushion of sand and gravel.

In this case, the base layers must be subjected to compaction, the effectiveness of which depends on the following factors:

- layer material. For crushed stone of different types, gravel, gravel-sand mixture (GSM) and sand, the compaction coefficient is very different;

- fractions of material. The larger the fragments, the more difficult it is to compact them;

- tamping method - manual, mechanized - and the force applied;

- height and total volume of the backfilled layer;

- the presence of material with a grain size less than that specified by the lower limit of this class (for example, for crushed stone of fraction 5...20, the content of stone up to 3 mm in size inclusive is about 5% - such a discrepancy will have little effect on the degree of compaction. If the percentage is ¼...1/4 volume – adjustments will have to be made);

- flakiness (for crushed stone). This parameter expresses the ratio of the content of cuboidal stones to flat ones. The lower the flakiness, the more cubic elements and the more densely the crushed stone can be compacted;

- layer moisture.

Quality standards, fractions and other parameters of crushed stone are regulated by GOST 8267-93 for crushed stone and GOST 8736-2014 for construction sand.

Accordingly, the degree of compaction of any bulk material, expressed by a dimensionless coefficient, depends on the type of material and operating conditions.

Terms and Definitions

Compaction coefficient ( Ky ) —

the ratio of the density (skeleton) of dry soil in the subgrade structure to the standard maximum density (skeleton) of dry soil determined by the Soyuzdorniy device (GOST 22733-77).

Required soil compaction coefficient ( Kmp )

- compaction coefficient (share of standard density) provided for in the work project or established in SNiP 2.05.02-85 for a specific horizon from the top of the coating.

Relative compaction coefficient ( K1 )

- the ratio of the required density (skeleton) of dry soil in the embankment, established taking into account the compaction coefficient according to table. 22 SNiP 2.05.02-85, to its density, adopted when calculating soil volumes.

Approximately K1 can be taken according to the table. 14 obligatory adj. 2 SNiP 2.05.02-85.

Required volume of excavation work ( Vp 1 )

- the product of the design geometric volume of soil in an embankment or other structural element of a road structure and the value of the relative compaction coefficient (K1)

Design geometric volume of soil ( V 2 ) -

the volume of soil determined by calculation in the project for the corresponding structural element of the roadbed or underlying layer of road pavement with the required compaction coefficient.

The average weighted density of dry soil in a quarry (reserve)

is

the ratio of the sum of the dry soil densities of individual layers multiplied by the thickness of the layers (

hi

) to the total thickness of the layers () presented in the quarry passport.

Bulk payment of sand

- the ratio of the mass of sand, dried to a constant mass, to the volume poured into a standard container with a capacity of 10 liters at natural humidity (GOST 8735-88).

What is transportation compaction factor

This name refers to the ratio of the volume of material at the time of loading the vehicle to the volume at the time of delivery.

Taking into account the fact that during transportation bulk material is inevitably compacted - road shaking plays the role of compaction - the minimum acceptable coefficient for accepting crushed stone, sand or sand-gravel mixture delivered to the site is considered to be 1.1. That is, data on the volume of the body (car, other transport capacity), multiplied by a factor of 1.1, must match the ordered volume or slightly exceed it. If the resulting figure is less than the required one by 2...5% or more, it is necessary to resolve the issue of shortage of material.

Example.

20 cubic meters of crushed stone were ordered, 18 cubic meters were delivered. (according to measurements from the inside of the body). Taking into account the coefficient 18x1.1=19.8 cubic meters. The underload is 0.2 cubic meters, that is, 1% - the error is within the permissible limit.

Important: data on the compaction of the material during transportation may be indicated, but is not required to be indicated in the accompanying documents of the cargo! To avoid misunderstandings, ask the supplier to include the data in the sales and transportation agreement.

2.1. Concepts and definitions

2.1.1. The required volume of natural sand in concentrated reserves or quarries, when, according to the transport scheme, it is used directly for the construction of structural elements of the roadbed (embankment or additional underlying layers of road pavement), should be determined by the formula

,

where is the geometric volume of soil of the constructed structural element (subgrade, additional underlying layer) in a compacted state;

relative compaction coefficient (the ratio of the required density (skeleton) of dry soil in a structural element to the density (skeleton) of dry soil at the source.

The required volume of sand, calculated in vehicles (dump trucks, railway gondola cars, etc.), when it is in a loosened state, should be calculated using the formula

,

where is the geometric volume of soil of the constructed structural element of the roadbed in a compacted state (at the required density);

— coefficient of relative compaction (the ratio of the required density of dry (skeleton) sand in a structural element to the bulk density of dry soil, determined at natural humidity in a standard 10-liter container according to GOST 8736-93.

2.1.2 The required amount of sand can be calculated by volume or mass. In the first case, measurements are carried out either by regular geodetic survey of the source of material being mined, or directly in vehicles (railway cars, cars, barges, etc.).

When calculating by weight, the shipped material in cars or cars is weighed on railway or truck scales. In accordance with GOST 11830-66, the weight is indicated in the delivery note.

The amount of sand supplied by barges or ships is determined by the draft of the latter.

2.1.3 The amount of sand is recalculated from units of mass to units of volume and vice versa based on the bulk density of the sand, determined at the moisture content of the material during shipment, in accordance with GOST 8735-88. The bulk density and moisture content of construction sand are indicated in the passports for each shipment.

2.1.4 To bring the volume of sand supplied in a surge or car to the volume in a compacted state, i.e. in a structural element, the resulting initial volume is multiplied by the relative compaction coefficient. The latter depends on the grain composition and moisture content of the material, the loading method and the hauling distance.

2.1.5 When developing design solutions, the relative compaction coefficient should be assigned depending on the required density of the material and the structural element or its corresponding horizon (SNiP 2.05.02-85, Table 22) approximately:

- when calculating volumes supplied from industrial quarries in vehicles - according to SNiP 4.02-91; 4.05-91;

- when using sands of natural density at the source - according to SNiP 2.05.02-85.

2.1.6. In cases where the PIC and PPR provide for the filling of subgrade elements and additional underlying layers in the winter (directly or through intermediate accumulated volumes - stacks), the volumes of sand calculated in vehicles must be increased by the appropriate coefficients given in this Methodology.

2.1.7 Additional volumes of soil associated with losses during transportation, depending on the method and distance of transportation in accordance with SNiP 3.02.01-87, should be taken equal

— 0.5% — for a transportation distance of up to 1 km;

— 1% — at longer range.

It is allowed to accept a higher percentage of losses with sufficient justification and a joint decision of the customer and contractor, consumer and owner of the quarry.

2.1.8. To determine the relative compaction coefficient, the following initial data are required:

— compaction coefficient and soil density of the structural element;

— standard maximum density and optimal moisture content of the material;

- bulk density.

2.1.9. In adj. 2 provides a more complete list of terms and definitions.

How is the compaction factor calculated?

This requires laboratory or, for private housing construction, home tests.

A sample of material is compacted to the extent that will be organized on the construction site, after which measurements of the compacted sample are compared with measurements before compaction.

The general principles of testing, the equipment and methods used are described in GOST 22733-2016 and GOST 8269.0-97.

For a more complete understanding of the process of checking the degree of compaction of bulk materials, we recommend watching the video.

You can also use more accurate soil density meters.

2.4. Determination of the coefficient of relative compaction of sand taking into account winter conditions

2.4.1. In winter, the shipped sand is in a granular frozen state, therefore the relative compaction coefficient should be set through the bulk density, determined according to GOST 8735-88 in the natural state of the sand.

2.4.2. The temperature of a standard container for determining bulk density must correspond to the ambient temperature.

2.4.3. The procedure for determining bulk density and calculating the relative compaction coefficient is similar to those specified in paragraphs. 2.3.8 - 2.3.13 and adj. 4.

Crushed stone compaction coefficient

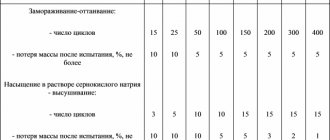

According to SNiP 3.06.03-85, the normal compaction coefficients for crushed stone are:

- 1.25...1.3 for grade 800, fractions 40-70 and 70-120;

- 1.1…1.5 for grades 300…600, depending on the fraction;

- 1.3…1.5 for slag depending on its density.

At the same time, it is impossible to obtain accurate data; even the supplier provides information on the degree of compaction with a certain tolerance.

If there is no reliable information, but it is necessary to ensure increased compaction density, SNiP recommends using wedging (that is, wedging in smaller stones):

- for fraction 40-70 crushed stone fractions 5-20, 0-20, 0-10 - gradually, with a decrease in fraction towards the surface of the layer;

- for fraction 70-120 – crushed stone 40-70.

In this case, the consumption of smaller stones should correspond to the data in the table below.

To facilitate wedging and better compaction, the mixture is spilled with water during the compaction process, at a flow rate of 15...25 / sq. m. If slag is used, the amount of water increases to 25...35 l/sq.m. at the primary stage and 10...12 l/sq.m. at the decluttering stage.

Process Features

Regardless of the rock, any soil is porous. It is permeated by microscopic voids that fill with moisture and air.

During the construction process, when the soil surface is being excavated, the voids increase, which can lead to an increase in its looseness. Therefore, it is extremely important to determine the soil compaction indicator in order to make the right decisions.

Important:

Please note that density values for compacted soil and fill rock may vary significantly. As a rule, the second one is much smaller. Therefore, it is the soil compaction coefficient that is considered as a parameter that determines the suitability of the site for the planned work. Based on this indicator, sand cushions are prepared for the foundation and its base in order to further compact the soil. If you do not pay attention to this detail in a timely manner, the structure being built may begin to collapse or deform due to soil subsidence.

Sand compaction coefficient

Here you can also rely on the supplier’s data, but it is better to check real data using test results.

The average bulk density of sand is indicated in the table.

Based on regulatory data, the average compaction coefficient of construction sand is assumed to be 1.15.

It should be remembered that for some types of work, thorough sand compaction may not be necessary, and accordingly the coefficient may be less than one.

Basic concepts of compaction factor

According to generally accepted formulations, the compaction coefficient of sand is the density value that is characteristic of a specific type of soil on a certain area of the site to the same value of the material that transfers standard compaction modes in laboratory conditions. Ultimately, it is this figure that is used to assess the quality of the final construction work. In addition to the above technical regulations, GOST 8736-93, as well as GOST 25100-95, are used to determine the compaction coefficient of sand during compaction.

At the same time, it must be remembered that in the working process and production, each type of material can have its own unique density, which affects the main technical indicators, and the sand compaction coefficient according to the SNIP table is indicated in the relevant technological regulations SNIP 2.05.02-85 in part of Table No. 22. This indicator is the most important in the calculation, and the main project documentation indicates these values, which in the range of project calculations range from 0.95 to 0.98.

Sand compaction

ASG compaction coefficient

Sand-gravel mixture (SGS) is a natural or enriched (OPGS) mixture of sand and gravel. The composition of the natural mixture is standardized by GOST 23735-2014; according to GOST, the content of gravel grains with a fraction of about 5 mm should be within 10...90%.

This material is rarely used for filling a sand and gravel cushion under the foundation; it is more often used for the production of medium and heavy concrete. Accordingly, the grain size and percentage composition of the mixture greatly influence the compaction coefficient of concrete.

The ASG group must be taken into account according to the table.

Why is it necessary to determine the soil compaction coefficient?

Determination of soil compaction coefficient - geological studies that are carried out at the pre-project stage in order to determine the suitability of the site for upcoming construction work.

Studying the density of the soil cover helps make the right design decisions.

Namely, it allows:

— Eliminate a number of problems associated with soil subsidence under the weight of the structure;

— Minimize the appearance of cracks on the walls of the structure, as well as its partial or complete destruction due to soil subsidence.