Laying paving slabs: when to finish the work

09/25/2020 00:22

Paving slabs are a reliable, durable, environmentally friendly road surface that is highly decorative. A wide range of colors allows you to create original patterns, including those with a 3D effect. The paving slab covering can be easily dismantled if there is a need for excavation work on the site, and restored after its completion. The only thing that should be taken into account when laying is compliance with the deadlines for paving. Work is carried out only in the warm season

Conditions for high-quality paving with paving slabs

In order for the road surface made of paving slabs to be of high quality and durable, several conditions must be met.

- Use quality materials.

- Strictly follow technology when performing work.

- Landscaping the area during the warm season.

Not all manufacturers offer high quality materials. The desire to save money often leads to a reduction in the service life of the coating and additional costs for restoration work. produces paving slabs, which differ

- long service life;

- resistance to negative atmospheric influences;

- wide selection of shapes and colors.

With such tiles, the road surface will be pleasing to the eye and will last a long time. And these are the main requirements that customers place on the material.

Compliance with technology and work deadlines

It is recommended to invite professionals to carry out landscaping work and lay paving slabs. This requirement is due to the complexities of paving technology.

To obtain a high-quality result, you need not only to lay the paving stones in a certain order to get the desired pattern, but also to carry out serious preparation of the site, which includes

- design (geodetic work, development of a design project, execution of drawings, preparation of the foundation, drainage installation);

- calculation of the cost of materials and work;

- paving (includes delivery of materials to the site).

Qualified specialists will not undertake landscaping in sub-zero temperatures . There are several reasons for this. They relate to materials and features of preparatory work. If the tiles are laid with mortar or special glue, then their use is allowed at a temperature not lower than +2 °C. When paving on a sand cushion, the base is prepared using moisture, which freezes at sub-zero temperatures. Soil saturated with water is swollen. It is not recommended to lay paving slabs on such a base. With warming, the thawed soil will subside, and along with it, the road surface will no longer be smooth.

It is important to take into account this feature of the soil in the spring, when the air temperature is already consistently above zero, and the ground has not yet completely thawed. Paving slabs cannot be laid on such a surface, as the result will be similar to work performed in winter.

Paving in the summer is not particularly difficult. At very high temperatures, equipment may overheat. We have to stop work to cool it down. The base must be periodically watered with water, since the soil is compacted using moisture, which quickly evaporates in the heat.

Preparatory work

Before starting work, you need to purchase tiles, consumables, and tools.

How to calculate the amount of material needed

The calculation method depends on the drawing that is supposed to be posted. Complex compositions require a special approach and specific recommendations. The quantity is calculated based on the selected pattern, after drawing up a preliminary sketch plan of the entire site.

If simple shapes are chosen, it is worth remembering the school geometry course and calculating the area of a specific geometric figure that the site or its individual parts represent.

The area of all parts that need to be covered will be taken as a basis. The number of tiles per square meter is indicated by the manufacturer on the packaging, so the required number of sets to be purchased is calculated using simple mathematical operations.

Experts advise purchasing material with a reserve of one square meter for each part of the surface to be coated. This is necessary so that there are fewer joints in oblique corners.

REFERENCE. There are special online calculators that automatically calculate the number of tiles after entering parameters (area of the plot, size of the blocks). Using it, accurate calculations are made.

Additionally, a curb is purchased, which is installed to prevent the blocks from moving along the edge. Its quantity is calculated according to the length of the perimeter of the covered area.

When purchasing material and planning the size of the covering, you need to try to make calculations in such a way that there is no need to lay cut pieces along the edges. The fewer cut pieces there are in the coating, the more aesthetically pleasing it will look.

What you will need

Installing paving slabs with your own hands requires the use of special tools:

- Tamping

- Roulette.

- Rubber hammer.

- Line or cord for marking.

- Rule.

- Level.

- Grinder with discs for concrete.

- Master OK.

- Rake.

- Broom.

In addition to tools, consumables are purchased:

- Sand (for a standard area 2-3 tons).

- Cement.

Preparing the base

Careful preparation of the base is the key to quality installation. After drawing up the plan, markings are made using pegs with a thread stretched across them. The quality of the soil in various parts is preliminarily assessed, and the sides of the slope are determined. If it is located towards the house and yard buildings, a drainage system is first thought through.

The sites are carefully leveled, soil is removed to a height of 15-20 centimeters. Then the surface is compacted. At the same time, drainage and sewer pipes are being installed.

After leveling and compacting, a cushion of crushed stone is poured. For garden paths made of paving slabs with your own hands, the thickness of the layer is 10-15 centimeters; for parking areas and roadways, the thickness of the crushed stone doubles.

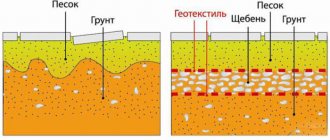

The pillow is compacted by a special machine and covered with geotextile, which will prevent sand from penetrating between the crushed stone. In areas with weak, loose soil, geotextiles are additionally laid under crushed stone.

The prepared cushion is filled with a cement-sand mixture (1X5), sand is poured on top of such a height so that the slabs are 1 cm above the surface before compaction.

ADVICE. To prepare the base, it is advisable to use guides made of boards along the height of the pillow. The foundation requires especially careful preparation if the site has soft soil. It is compacted after moistening.

The entire further process will depend on the quality of foundation preparation.

Important to avoid mistakes! If you want to know how to lay paving slabs with your own hands, watch this video of a man who decided to lay them incorrectly:

Related Posts

- What layer of adhesive is needed when laying tiles?

- Is there any benefit to using a tile leveling system? pros and cons, reviews, rules for using SVP

- Laying floor tiles - step-by-step instructions

- Seamless ceiling tiles: installation and characteristics

- How to update old tiles in the bathroom

- Features of choosing adhesive for ceramic tiles: tips

- Polymer sand paving slabs installation features

- Laying mosaic tiles in the bathroom

- The best way to glue plaster figures, means and rules for do-it-yourself restoration

- Making paving slabs with your own hands

- Density of wet sand: properties and melting point of river sand

- 8 tips on how to choose crushed stone: types, fractions, brand, application

- 9 types of heat-resistant tiles for fireplaces and stoves: choosing the best

- What and how to drill into the tiles so that they don’t crack?

- Decorating the floor in the bathroom: rules for laying ceramic tiles

- Joint between laminate and tile without threshold

- Installation of heated floor heating mats under tiles

- PVC floor tiles

- How to lay tiles in the bathroom: the whole process from surface preparation to grouting

- Technology for paving slabs around the house

- How to properly lay parquet boards on a concrete floor?

- How to lay carpet correctly

- DIY technology for laying paving slabs

- The best manufacturers of quartz vinyl tiles: rating of floor coverings

- Laying quartz vinyl tiles: step by step instructions

Read with this

- What layer of adhesive is needed when laying tiles?

- Is there any benefit to using a tile leveling system? pros and cons, reviews, rules for using SVP

- Laying floor tiles - step-by-step instructions

- Seamless ceiling tiles: installation and characteristics

- How to update old tiles in the bathroom

- Features of choosing adhesive for ceramic tiles: tips

- Polymer sand paving slabs installation features

- Laying mosaic tiles in the bathroom

- The best way to glue plaster figures, means and rules for do-it-yourself restoration

- Making paving slabs with your own hands

Is it possible to lay paving slabs in winter?

It is not always possible to reschedule landscaping work for the warm season, and then you have to lay paving slabs at sub-zero temperatures. Paving can be done, but subject to a number of conditions, and the costs will be significantly higher.

- The base is prepared before the onset of frost.

- If ice or snow appears on it by the time the work is completed, they are removed using reagents

- The sand cushion is poured before installation.

- The base is additionally heated if necessary.

- If a solution is used when laying, then special additives are added to it to prevent freezing.

- Installation of tiles and grouting of joints is carried out simultaneously with the supply of mortar so that it does not have time to cool.

All of the above actions require the use of additional equipment, materials and labor costs, which translates into a substantial amount. If possible, it is better to postpone the work to a warmer period or try to do it before the onset of cold weather.

How to lay paving slabs beautifully

To properly lay paving slabs, you need to decide what they are needed for and where we will lay them.

Depending on whether it will be a pedestrian path in the country or a parking lot, a children's playground or something else, the type of paving stones, its size, color, shape will depend.

The paving stones on the roadway should be 8-10 cm thick. For a car to enter the yard of a private house, 6 cm is enough. The thickness of the pedestrian zone is 3-4 cm.

If the pavement will be laid in a country house or in the courtyard of a private house, then it is necessary that it fits into the landscape design.

When choosing types of sidewalks, you need to get acquainted with their technical characteristics, qualities and properties. You need to find out whether the paving stones are strong enough to support the weight of a car or whether they can only support the weight of a person.

Installation of paving slabs from

While it's September outside the window, you can still do some landscaping. carries out work on laying paving slabs until November 10, 2021. The available equipment allows installation at temperatures down to –1 °C. Employees with at least seven years of experience know the technology very well and do an excellent job in the pre-winter period. Using tiles of our own production allows you to be confident in its quality.

In addition to laying paving slabs, the company sells its products year-round, and the company’s specialists provide a full range of services related to landscaping:

- laying paving stones;

- installation of a drainage system;

- preparation of sites (removal of weeds, leveling of the base);

- laying the lawn.

All work is performed at a high professional level, which is confirmed by the guarantees that the craftsmen give to clients.

provides services at reasonable prices. Contracts are concluded directly with customers (without intermediaries), which allows not to increase the cost of work. Using your own materials also has a positive effect on the price.

Didn't you have time to landscape your garden plots, local area, and walking paths in the summer? You still have time! Until November 10, he is laying paving slabs and performing related work with a quality guarantee. Hurry up! And by winter your area will be in perfect order!

Tools for getting the job done

To work with paving slabs you will need the following kit:

- shovel;

- concrete mixer (but it is quite possible to mix it manually with improvised devices);

- cement mixture;

- geotextiles;

- crushed stone;

- curbs;

- sand;

- hammer.

Performing markup

Before you begin the actual installation work, you need to make markings. This stage is extremely necessary; it allows you to calculate the required width and length of the track, as well as prevent it from moving to the side.

A schematic drawing is drawn on the site plan, taking into account existing buildings, shrubs, trees and other objects. It is important to pay attention to existing low spots to prevent water from accumulating in these areas when it rains or melts snow.

The optimal width of the path is 1-1.3 meters. This is enough to separate two passers-by. For a highway with a pedestrian area nearby, the width should be twice as wide.

When the diagram is ready, you should use a rope and pegs to transfer it to the site.

Important! It is worth adding 10 cm in each direction to the existing width of the path for subsequent installation of curbs.

Excavation

The next step is to remove the top layer of soil. Its thickness is approximately 25 cm. Sand approximately 3-5 cm in height is poured into the resulting trench, followed by compaction.

Now geotextiles are laid out. You can omit this step, but with the help of this material it will be possible to prevent plants from growing through the paving slabs, and also to prevent water from getting inside during heavy snow melting.

Drainage system

An important step in laying tiles is creating a drainage system. To do this, crushed stone 12-14 cm thick is laid out on geotextiles or compacted sand. Using this technology, it will be possible to absorb moisture. If you omit this step, then when cold weather sets in, holes and other irregularities may form on the path. The reason for this is the freezing of water that gets under the material.

Next, the crushed stone is compacted, sand is laid on top, leveled, and finally, another layer of textile base is covered.

Installation of borders

Plastic or concrete structures, which are sold individually, can serve as borders. It is desirable that their appearance be combined with the design of the tiles.

Path tiles

Garden paths

periodically deteriorate, and moving around them becomes extremely difficult. There are many reasons for this - changing weather, frequent rains, dragging heavy objects like furniture and massive equipment, in the end, just regular stress. Path tiles are sold everywhere, but you need to choose them carefully and carefully.

- First of all, you need to focus on the composition of the material from which the paving slabs are made. This will immediately help you choose the right one and weed out unnecessary options. The seller must provide you with this information.

- It is then recommended that you take a good look at the thickness and overall size of the tiles. You should not choose too large shapes, even despite the original ornament and unusual color, because the smaller the tile, the more reliable it is and the longer it will last. As for the thickness, it is better to choose a medium one - from three to four centimeters thick.

- Try to determine the quality by external data, but remember that the smoothness of the tile is not always a guarantee of its good quality.

- Take the time and effort to take a good look at each tile. If you have to buy one to check the condition of the material, don’t spare the money. It is better to make sure in advance that the purchased product meets the established standards and your wishes.

Remember, the most important thing is to follow the correct, suitable installation technique and monitor the quality of the purchased material. In this case, the tiles for the paths will serve you not even for years, but for decades.

Laying technology

Increasingly, people began to look at the option of decorating their site, as well as the adjacent territory, with paving slabs. What is this material and how should it be placed correctly?

Paving slabs - what are they?

Paving slabs are a building material that has become popular and can be used to both improve a space and make moving around it comfortable. The technology for laying it varies depending on the goals set for the finished coating, as well as on the type of tile itself.

Laying technology

A properly executed coating will last a long time - this axiom has long been entrenched among builders. Knowing the characteristics of the surfaces on which installation will be carried out, as well as exactly how the process itself should be carried out, you can make a high-quality coating.

If the technology of laying paving slabs in your dacha is important to you, you should pay attention to the planned load. The thickness and dimensions of decorative products differ from similar parameters of options that can withstand more severe and intensive use.

The technology for laying paving slabs under a car is also unique. There are certain standards that ensure long-term use of the coating. With us you will receive all the necessary knowledge, subtleties and secrets of this type of work.

It can also be installed on a concrete base. In this case, there will be some features that need to be kept in mind to create a quality solution for the long term. You should not lay tiles on concrete yourself without preparation - this is fraught with both damage to the laying material and injuries.

It is equally important to know that there is a technology for laying borders. An incorrectly laid curb spoils the appearance of the entire work and can also significantly shorten its service life. Remember that a properly secured curb can make future repairs much easier.

Conclusion

Paving slabs are good both for a summer house and as a covering for a car - this is evidenced by a considerable number of people who have managed to try this type of covering on their site. Its low cost, as well as the simplicity of its installation technology, speak in favor of this type of coating.

Having mastered this technology from us, you will be able to do the maximum to ensure that your coating lasts the stated period. Don’t put this off for too long - learn about the technology of laying paving slabs today!

Large volumes of work, as well as the need to meet construction deadlines, sometimes force paving work to be carried out in abnormally hot or too cold weather. Laying asphalt directly on snow has long been the subject of ridicule and criticism. Is it permissible to lay paving slabs in such weather and what conditions should be observed?

What is this article about?

conclusions

Winter is characterized by sudden changes in weather conditions and sub-zero temperatures, so landscaping the area and installing paving requires taking these factors into account. When laying paving sheets, it is recommended to carry out work at a constant above-zero temperature. For high-quality sealing of joints, the absence of frost is important. Compliance with the technology for landscaping the territory in winter will ensure the reliability of the coating and a long service life. The use of advanced technologies and adherence to temperature conditions make it possible to install the coating in winter. It is recommended to determine the economic feasibility of carrying out this type of work.

Large volumes of work, as well as the need to meet construction deadlines, sometimes force paving work to be carried out in abnormally hot or too cold weather. Laying asphalt directly on snow has long been the subject of ridicule and criticism. Is it permissible to lay paving slabs in such weather and what conditions should be observed?

What is this article about?

Optimal conditions for paving street surfaces

The main condition for carrying out work on paving surfaces is the presence of positive temperatures. This requirement is due to the fact that the tiles are laid on a cushion, which in turn is poured onto the prepared soil. There is a presence of moisture everywhere, even if a dry mixture is used for the substrate. When frozen, water expands and the soil swells. Is it worth putting a coating on this consistency? Of course not. When water thaws, subsidence occurs in both the soil and the soil base on which the coating was installed. It is always better to wait for normal weather and lay the tiles in normal conditions.

It is important that any such work is carried out on a non-frozen surface, even if the temperature on the thermometer is above zero. Therefore, not only the temperature regime, but its stability are important. Because sealing joints also requires the absence of frost. Otherwise, the frozen mortar will simply fall out of the seams.

There are no special restrictions for working in extremely hot conditions. The only thing worth considering is that this may not be comfortable for the performers themselves, as well as for vibration machines, which can overheat greatly during large volumes of work. If a moistened cement-sand mixture is used to create a substrate, then you need to ensure that it is sufficiently and timely moistened in order to avoid its premature drying out.

Recommendations: at what temperature can tiles be laid (video)

This kind of work is not hard enough, but the result will be excellent. In stores you can find the necessary materials at different prices, quality and a variety of colors. And following the advice of experienced specialists, you can manage it yourself in a short period of time, laying the tiles as needed according to the style of the house and yard.

The cold season is not a reason to stop construction. Thanks to modern technologies, paving slabs can be laid in winter. In order to do this, some preparatory work is needed.

Firstly, they prepare the ground for further laying the foundation. Next, a leveling layer is created before laying. In the case when the tiles are laid on a concrete base, debris, snow and ice are first removed from it, and then warmed up. In order to quickly warm up concrete, it is recommended to use a calcium chloride solution. You can also use hot sand in a layer of 5 centimeters, or special equipment, for example, an asphalt heater. After heating, the base is cleaned again, and a 2 cm thick layer of heated cement mortar with sand, at a temperature of no higher than 35 degrees, is laid on top of it. Next, lay the tiles.

The last stage of work - processing the seams between the tiles - is left for a later period; this work is more efficiently carried out in the spring. If the work needs to be completed immediately, use a heated mixture of cement and sand, which is used to fill the seams.

Builders do not recommend tiling work at temperatures below 15 degrees. Otherwise, this will lead to further deformation, cracking and destruction of the tiles. Weather conditions should also be taken into account. If precipitation is expected, it is worth stocking up on a tarpaulin or equipping a canopy, otherwise the installation will have to be stopped.

As you know, the service life of paving slabs depends on proper installation. Some builders believe that laying tiles in winter is a risky idea. Low temperatures can negatively affect the composition of the base, namely, preventing it from drying and hardening sufficiently. Therefore, there are times when you have to redo the work again.

There are some tools that allow you to install paving slabs in winter. One of them is surface waterproofing. For these purposes, the surface is created at a slope, geotextiles are used during installation, and drainage systems are installed. This will allow moisture to leave the surface.

Laying paving slabs in winter is a labor-intensive and costly process, but possible if necessary.

Is it possible to lay paving slabs in winter, what are the risks?

The appearance of a country house and the area adjacent to it can be changed by paving slabs, which have become the favorite materials of builders.

Paths made from it can not only connect functional areas (entrance, house, bathhouse, garage, gazebo), but also serve as decoration for a yard or garden. Paths and paths made of paving slabs

They will look good even at night if ground lamps are built into them.

Modern paving slabs are easy to install and pleasant to work with. Of course, for a car to enter the yard, it is better to lay 2 concrete lanes.

But for paths from the gate to the house or for paths in the garden, paving slabs have today become the ideal material. The paths, which are the main “highways” on your site, should be straight so that you can quickly get to the garage, bathhouse, woodshed, etc.

But the paths to the gazebo, summer kitchen or flower garden can be winding. Therefore, first draw up a diagram of the paths on your site, and then proceed to selecting the material for them. If paving slabs are correctly matched in shape, color and texture to the facade of the house and the surrounding landscape, then they will become a real decoration of your estate.

Laying paving slabs in winter

Time flies by very quickly and due to everyday hassles, you can miss several very important things that should have been done before the cold weather set in. This of course also applies to laying paving slabs. After all, not all specialists will undertake this type of work in winter.

But what to do when all the building materials have already been purchased and it is not recommended to store them for a long time? And if you want, after the snow melts, to see your site transformed, but there is not the slightest desire to leave this work until spring, since there is something to do during this period.

If you have the opportunity and a great desire, then you can do anything in winter. When laying paving slabs, the type of concrete VSN 15-95 is used as a basis.

There are a small number of requirements for laying tiles, and it is imperative to comply with them to obtain a positive result. Here are some of them:

- Before laying, it is best to prepare the area where the tiles will be located, as well as the base itself for the coating, before the onset of heavy frosts. But as for the leveling layer, it needs to be prepared only before work.

- If concrete was chosen for the coating, then before work it must be completely cleared of dirt, snow and ice, and then be sure to warm up. This procedure can be done using special devices and machines. You can also use heated sand, its temperature should be at least 200 degrees. But only after this layer must be removed.

- After the above procedures, it is necessary to lay heated cement mortar with sand. In this situation, the mixture should be heated to a temperature no higher than 30 degrees.

After this, you can begin the installation itself, but it is better to seal all the seams in the spring.

Of course, everyone chooses for themselves what time of year to carry out construction work. In this situation, it is best to wait until spring or contact a specialized company.

Paving slabs and water

Another characteristic that is almost always considered when choosing a hard surface option for any type of territory is its interaction with water. In this part, the laying of paving slabs is at its best.

First of all, being a fairly hard, dense and, accordingly, reliable material, tiles are able to withstand exposure to moisture for a long period without significant consequences. Experts characterize it from this point of view as quite moisture resistant. In addition to the fact that paving slabs are durable, the peculiarities of paving the surface with their help are the absence of water puddles on the surface that appear after natural precipitation, incl. melting snow.

Agree that water in front of the porch or on the paths does not look very nice, especially when you have to walk through it. However, on asphalt or concrete surfaces, the formation of puddles after rain is inevitable.

In turn, if you buy paving slabs and lay them in compliance with a drainage slope, the resulting coating will not only absorb moisture when precipitation is low, but also allow it to “leave” on its own during active rain.

In addition, a tiled surface requires the use of specially designed gutters that fit perfectly into the overall appearance of the coating and properly fulfill their functional purpose.

The decision to order paving slabs for publicly visited places - summer cafes, access areas to an office or restaurant, i.e. where dry and reliable coating is needed most and partly determines the prestige of the entire establishment.

Cozy design of your home and garden using paving slabs

You can buy paving slabs at almost any large hardware store. It is quite common in both big cities and provincial ones; tiles are widely used in a good half of private homes. It is used to cover paths, small spaces intended for barbecues, and the floors of gazebos. Your task: find, select and buy. Paving slabs should be selected carefully and with great attention: they must suit the site in all respects.

So, when choosing paving slabs, be guided by the following criteria:

1) Compatibility. In this case, we mean the relationship between the general appearance of the site and a private house with the appearance of the tile itself. It's pretty closely related. Everything should be combined in color, shape and size. 2) Aesthetics. Of course, we all want our home and everything that surrounds it to be not only cozy, but also look nice. Paving slabs are no exception. 3) Quality. The quality of the material from which the tiles are made also matters.

You can buy paving slabs either independently or by seeking help from specialists who will help you make the right choice.

How to lay tiles at sub-zero temperatures

For convenient work, a shelter with a height of 250 cm is used. A heating system is located inside to maintain a temperature of +5ºC. Paving stones are laid using a dry mixture of sand and cement or mortar. The seams are filled with fine sand, previously dried to a moisture content of 1%.

The use of grouting solutions requires compliance with the manufacturers' recommendations. After completion of the work, the shelter is moved to the next area, and a greenhouse with a height of 150 cm is installed above the equipped surface. A stable temperature of +5ºC is maintained inside.

Before laying tiles on a concrete base, the working surface is cleared of dirt, snow, ice and warmed up to operating temperature. Cleaning can be done using gas burners. A mixture of sand and cement 20 cm thick is laid on the cleaned concrete. When installing figured paving elements (FEM), mobile canopies are used. Work stops during snowfalls. Before sealing the seams, the joints are filled with a mixture preheated to a temperature of +35ºC.

Winter is characterized by sudden changes in weather conditions and sub-zero temperatures, so landscaping the area and installing paving requires taking these factors into account. When laying paving sheets, it is recommended to carry out work at a constant above-zero temperature. For high-quality sealing of joints, the absence of frost is important. Compliance with the technology for landscaping the territory in winter will ensure the reliability of the coating and a long service life. The use of advanced technologies and adherence to temperature conditions make it possible to install the coating in winter. It is recommended to determine the economic feasibility of carrying out this type of work.

Features of laying paving slabs

Considering the long service life, which is 20–30 years or more, the complexity and labor intensity of repairs, it is necessary to provide for all possible negative factors at the design stage. These conditions can affect the behavior of the paving during its service life. There are several main problems with paving.

- Soil heterogeneity: over time, the surface may sag.

- Moisture accumulation: the negative influence of climatic conditions and negative temperatures leads to rapid destruction of the surface structure.

- Different loads on the working surface: the influence of the human factor.

Ground subsidence is due to various reasons. This can be the natural processes of spilling sand or gravel, soil shrinkage due to various reasons, or the influence of the human factor.

| In cities, you can often find cars parked on paved footpaths, which leads to uneven settlement of the pavement. Is geotextile needed under paving slabs? All professionals will answer – yes! Purchasing geosynthetics and using them when performing work will avoid many problems with paving and will double its service life. |

How to lay tiles at sub-zero temperatures

For convenient work, a shelter with a height of 250 cm is used. A heating system is located inside to maintain a temperature of +5ºC. Paving stones are laid using a dry mixture of sand and cement or mortar. The seams are filled with fine sand, previously dried to a moisture content of 1%.

The use of grouting solutions requires compliance with the manufacturers' recommendations. After completion of the work, the shelter is moved to the next area, and a greenhouse with a height of 150 cm is installed above the equipped surface. A stable temperature of +5ºC is maintained inside.

Before laying tiles on a concrete base, the working surface is cleared of dirt, snow, ice and warmed up to operating temperature. Cleaning can be done using gas burners. A mixture of sand and cement 20 cm thick is laid on the cleaned concrete. When installing figured paving elements (FEM), mobile canopies are used. Work stops during snowfalls. Before sealing the seams, the joints are filled with a mixture preheated to a temperature of +35ºC.

Winter is characterized by sudden changes in weather conditions and sub-zero temperatures, so landscaping the area and installing paving requires taking these factors into account. When laying paving sheets, it is recommended to carry out work at a constant above-zero temperature. For high-quality sealing of joints, the absence of frost is important. Compliance with the technology for landscaping the territory in winter will ensure the reliability of the coating and a long service life. The use of advanced technologies and adherence to temperature conditions make it possible to install the coating in winter. It is recommended to determine the economic feasibility of carrying out this type of work.