Features of strength gain of concrete structures

To clarify at what air temperature the cement mixture can be poured, you need to understand the hardening process. In the finished solution, a reaction occurs between the components of cement and water - hydration. The process takes place in two stages:

- setting with the participation of SZA aluminates. Inside the concrete, needle crystals are generated that bond with each other. After 6-10 hours, a kind of skeleton of the mixture is formed;

- hardening with the participation of clinker minerals C3S and C2S. During concrete hardening, a silicate finely porous mass of small crystals is formed.

Interesting to know! At low temperatures, the water in the foundation becomes ice, which leads to the end of hardening and setting.

The danger of the influence of sub-zero temperatures on the state of the mixture

The rate of hydration reactions and strength gain of concrete is tied to the ambient temperature. When it is lowered from +20 to +5 degrees, the hardening time increases 5 times. The hardening process is even slower if it gets cold outside.

Freezing water at subzero temperatures causes it to expand. Next, there is an increase in pressure inside the mixture, which causes the disintegration of the crystal lattice. The consequence of the reaction is the destruction of the foundation and deterioration of solidity properties due to the enveloping of aggregates in ice.

Important! After the liquid thaws, the hardening process is restored, but the quality of the concrete will be worse - the reinforcement peels off and the monolith cracks.

What air temperature is acceptable for the solution?

Experts have found out at what optimal air temperature it is necessary and possible to pour ready-made concrete. It is better to carry out foundation construction work in the range from +5 to +15°. Outdoor temperature conditions ranging from +5 to minus 3° stipulate that freshly laid M200 concrete weighing 240 g/m3 should not be lower than +5 degrees.

On a note! When using less cement, the optimal internal temperature of the composition is +10°.

Properties of pouring concrete: the influence of seasonal conditions on the process

The main use of concrete is pouring the foundations of construction projects. At the final stage of installation - setting and hardening of the solution, thermometer readings play a huge role. The time range of the final result and the service life of the resulting bay depend on them.

Favorable positive temperatures for pouring are in the range of 3-25 degrees. In this regard, construction of objects is popular in spring or summer.

At low or negative temperatures, i.e. in the autumn and winter, concreting is carried out the same way, but during the actions special technologies are used that maintain the required level of heat.

Options for increasing the temperature of the concrete mixture in winter:

- Water heating;

- Introduction of frost-resistant impurities;

- Using electric heating;

- Use of heat guns with fencing of concrete mixture;

- Method of steaming concrete structures using special autoclaves to achieve a strength of 80-85%;

- Heating of reinforcement, if it is present in the concrete admixture, by electrical heating.

The influence of frost-resistant admixtures on pouring concrete in winter

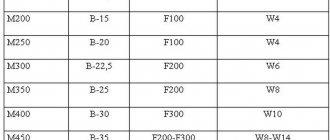

The speed at which the solution hardens depends on the brand of cement and the additive to it.

Let's look at the most common frost-resistant modifiers and take the average indicator of concrete aging for any brand of cement at sub-zero temperatures:

- Chloride salts: at -5 degrees - about 4 days, at -10 - up to 7 days, at -15 - up to 2 weeks.

- Sodium nitrite: at -5 degrees - up to 6 days, at -10 - about 9 days, at -15 - up to 10 calendar days.

- Potash: at -5 degrees - 2 days, at -10 - about 5 days, at -15 - 8 calendar days, at -20 - 9 days, at -25 - up to 12 days.

The purpose of chemical admixtures is to reduce the freezing point of the liquid in the concrete mixture.

Using potash as an example, let’s look at how to calculate the introduction of a chemical into liquid concrete at sub-zero temperatures.

If the temperature of the concrete is 10-15 degrees with a minus sign, then the required amount of poshat is 10 percent of the mass; if the readings (minus) are 21-25 degrees, take 15 percent.

The question of at what temperature concrete can be poured is irrelevant in cold times, since during the day it can vary within 5-15 degrees below zero, and constant freezing/thawing is dangerous for concreting.

If the concrete freezes, the consistency stops hardening as the water turns into ice. Such casting will have to be redone, due to the fact that even if it is possible to warm up the base, frozen water increases in volume and breaks the bonds in the concrete, which leads to heterogeneity of the poured surface.

Therefore, before starting work, it is necessary to study all the intricacies of the cold pouring process. This includes: the choice of high-quality cement and frost-resistant additives to it, as well as proper care of the concrete surface.

Temperature regime of the concrete mixture: influence of weather conditions

Here is a list of optimal concrete temperatures at which the highest quality structures are obtained:

- Favorable (with a “+”) in the range of 5-15 degrees;

- Boundary indicators: minus 20 and +45 degrees;

- Not lower than +5 degrees - with outside air readings from +5 to -3 for M200+ cement grades, and with lower markings - the mixture should be from +10 degrees.

The temperature of pouring concrete in summer at +30 degrees reduces the strength of the surface. In this regard, the flooded area is treated with water (humidification process).

Taking this fact into account, in summer the concrete is diluted to a more liquid consistency. With numerical readings of 5-15 degrees with a “+” sign, the concrete, due to heat transfer to the environment, cools on its own.

During the rainy season, damp weather combined with coolness is the most optimal: concrete sets evenly and it is possible to increase its resistance to water with special cement. Covering the working area with polyethylene will prevent the solution from washing away.

At what temperature can you cement outside in the winter or autumn season, when the thermometer goes below zero?

As stated above, concrete can be poured in any frost, but to do this, use one of the heating methods. The most popular and budget-friendly method is the advance heating of the necessary materials for the solution, which should be 35-40 degrees when pouring.

The essence of the process:

- Sand and crushed stone are heated to 60 degrees;

- Water up to 90 degrees;

- The cement is placed in a warm room for a while. It should come to room temperature;

- All components are mixed.

Technology and features of pouring in autumn

At what average summer temperature should construction begin? The warm season - from +15 to +30 degrees is suitable for construction work. Pouring concrete in summer is acceptable. The only condition is to protect the freshly laid monolith from rain.

Choosing the right time

In the fall, the weather is unpredictable, so it is important to know at what temperature you can pour concrete in the fall.

The optimal air temperature is from +20 to +5°, so it is recommended to start laying the foundation in September-October before frost. In the process of arranging the foundation, it is important to consider to what point on the thermometer the work needs to be completed before the cold snap. It should be +10 degrees Celsius. The concrete mass gains strength within 1 month. Before frost, it is recommended to make a shelter, and in the first two days, protect the mixture with film from rain.

Advice! Before pouring your foundation in the fall, check the weather forecast.

Factors influencing dough setting in autumn

Pouring a monolith will be of high quality if you take into account several points:

- air temperature. At what temperatures can concrete be poured in the fall to start building a house? The normal value is plus 16°. During this period, the solution hardens slowly, which ensures the quality of construction. Frosts occur at the end of October, so it is better to start construction in mid-September;

- humidity characteristics. Damp weather and wet soil promote the curing process. Freshly laid mortar does not need to be regularly sprayed with water, and slow drying ensures increased strength;

- presence of precipitation. If you have figured out the optimal temperatures at which you can pour the foundation, then you need to take into account the presence of rain. Overmoistening of the monolith leads to the leaching of cement laitance;

- ground water level. In swampy areas there is less water in the fall, which makes it possible to make a pile foundation. You can check whether the water has risen by digging a trench. If water has risen in it, the foundation cannot be poured.

Important! If at least one factor does not comply, the structure will lose strength.

What to do if it’s frosty outside and you need to pour the foundation?

At what temperature can concrete be poured? How to properly protect the structure in cold weather? Once the answers to these questions are found, concreting can be carried out regardless of weather conditions.

You can simply abandon construction for the winter period. Preserving the foundation for the winter is one of the most popular options, but situations vary.

Frosts do not always occur in winter; sometimes even in early winter or late spring, the readings on the thermometer drop sharply. Single frosts will not cause as much harm as temperature fluctuations. The foundation takes more than one day to harden; the best option would be positive weather within 14 days after pouring. But even after this time you need to be careful.

But what should those who are running out of deadlines and urgently need to carry out concreting do? At what temperature can concrete be poured in the fall or winter?

In fact, thanks to modern technologies, today it is possible to build a foundation even in cold weather. There are several solutions to the problem:

- adding plasticizers or increasing the amount of cement;

- heating of concrete;

- installation of greenhouses.

Each method is designed for a specific temperature regime. The first is considered one of the simplest and most accessible, but the last is complex, but most effective.

Let's look at each of the methods in more detail to decide at what temperature you can pour concrete in the fall and how to protect the structure.

Is it possible to artificially increase the frost resistance of a solution?

To speed up the work and prevent destruction of the foundation, it is allowed to use anti-freeze agents, warm up the concrete or insulate it.

Types of additives

If the dosages of special products are observed, it is easy to predict at what extreme negative temperature the construction should be completed. It is permissible to continue work down to -25 degrees. Products are classified depending on their effect on the mixture.

Additives

Special liquid products for solution hydration in sub-zero temperatures. Used in conjunction with heating to accelerate hardening and setting reactions.

Antifreeze

Means that increase the activity of cement paste in any conditions:

- potash or substances based on salts of monocarboxylic acids. They increase the temperature range for working with concrete composition to -30 degrees, accelerating the hardening of the composition. The reinforcing frame is not subject to corrosion, there is no efflorescence on the surface of the monolith;

- sodium chloride - used to plasticize the Portland cement mixture, preventing thickening. Steel reinforcement may rust;

- sodium nitrite - suitable for all types of cements, except alumina. After adding the product, the mixture can be worked at low temperatures, but up to -15 degrees;

- sodium formate - involves the use of plasticizers. Without them, voids appear in the monolith due to the accumulation of salts.

On a note! Antifreeze prevents heating of the structure.

Setting accelerators

They are distinguished by the rapid release of heat, so the water temperature remains stable and the monolith heats itself.

Important! If the dosage of substances is not observed, there is a risk of corrosion of the reinforcing frame.

Heating methods

Warming up concrete is relevant if it requires pouring the foundation of a low-rise building. If you are wondering to what maximum level the temperature can be increased, this figure is 15-20 degrees. Antifreeze mixtures begin to be introduced at temperatures from -15 degrees. Now we will briefly consider options for electrical heating of concrete:

- A frame made of wooden beams is installed across the entire area of the building, on which a film tent is organized. Gas or electric guns are installed inside the structure. After the temperature rises, the devices maintain it throughout the concrete hardening cycle;

- wrapping the reinforcing frame with a heating cable before you start pouring the foundation. The electrics are turned on after the mixture is laid. In addition to the cable, you can use nichrome spirals or heating elements.

Important! In conditions of severe cold and soil freezing, the technique is ineffective.

Features of shelter and insulation

Using this method, once the outside temperature reaches 3–7 degrees, you can pour concrete.