Electricity is a serious and dangerous matter, but many jobs do not require high qualifications and can be done independently without the involvement of specialists. For example, you can connect an electric stove with only a vague understanding of electricity. Especially if the outlet is already installed. All that remains is to install a plug on the cord and connect it correctly to the connectors of the stove. The situation is worse if it is necessary to pull the line from the shield, but even here you can cope without help. Just remember that all work is carried out with the power supply turned off.

Connection diagram and methods

Electric household stoves are powerful equipment; the current they consume is about 40-50 A. This means that the electric stove must be connected to a dedicated power line. It must be powered directly from the apartment or house panel. Power is supplied through an RCD and a circuit breaker. The stove itself can be connected via a socket and plug (special power ones) and a terminal box. Also, the line from the machine can be directly connected to the input terminals on the rear wall.

A more reliable connection is directly to the input terminals of the plate. In this case, there is a minimum number of contact points, which increases reliability. But this method is not entirely convenient: you can only turn off the power automatically. About the same problem occurs when using a terminal box, the only difference being that there are more connection points.

The most commonly used connection is a socket and plug. It's more convenient and familiar. Since the equipment is powerful, they use not ordinary household devices, but special ones, which are also called power devices - for their ability to withstand significant current loads.

Please note that when connecting powerful electrical equipment, grounding is required. Without it, you will be denied warranty repairs, and its absence is life-threatening, so it’s better not to take risks.

Electrical parameters and ratings of circuit breakers

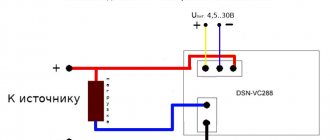

As we found out, there should be separate RCDs and a circuit breaker in the electrical panel. Through them the phase is supplied to the socket. This pair can be replaced with a difavtomat. These are the same two devices, but in one case. The negative is taken from the common bus, passes through the RCD, and the grounding is taken from the corresponding bus.

The rating of the machine is selected based on the maximum current consumption. This data is in the electric stove's passport and is usually in the range of 40-50 A. In this range, the ratings come in large increments - 40 A, 50 A, 63 A. It is better to choose the nearest larger one - this way there is less chance of a false shutdown when operating at full power . That is, if the declared maximum current consumption is 42-43 A, still take a 50 A machine.

On the other hand, you may never turn on all the burners and oven, and even at full power, and more powerful machines are significantly more expensive. It's up to you to choose.

The rating of the RCD is taken one step higher than that of the machine. If you decide to install a 50 A machine, then the RCD is required at 63 A, the leakage current is 30 mA.

Wire and its parameters

In recent years, when laying electrical wiring and connecting household appliances, copper conductors are most often used. Although they cost much more, they are more convenient to work with, and besides, copper requires a much smaller core diameter than when using aluminum conductors.

The conductor cross-section is selected depending on the type of network - 220 V or 380 V, the type of wiring (open/closed) as well as the current consumption or power of the equipment. Typically, copper conductors with a core of 4 mm (for line lengths up to 12 m) or 6 mm are used.

When choosing the type of cable to lay from the panel to the outlet, it is better to choose single-core conductors. Although they are more rigid, they are more reliable. To connect the stove itself (to which you will need to connect the power plug), you can choose a flexible stranded wire: a single-core wire in this case will be too inconvenient.

Connecting the hob is described here.

Wire parameters

In recent years, when laying electrical wiring and connecting household appliances, copper conductors are most often used. Despite the fact that they cost much more, it is more convenient to work with them, and besides, the diameter of the conductors required for copper is much smaller than when using aluminum conductors.

As a rule, the cross-section of the conductors is chosen based on the type of network - 220 V or 380 V, the type of wiring, which can be open or closed, as well as on the current consumption or power of the equipment. Typically, copper conductors with a core of 4 mm (for line lengths up to 12 m) or 6 mm are used.

Conductor cross-section selection table

When choosing the type of cable to lay from the panel to the outlet, it is better to choose single-core conductors. Such conductors, although more rigid, are much more reliable. To connect the stove itself (to which you will need to connect the power plug), you can choose a flexible stranded wire: a single-core wire in this case will be too inconvenient.

The diagrams given above were specifically for a single-phase 220 V network. To connect you will need:

- three-core cable,

- three-pin power socket and plug with a rated current of at least 32 A.

It must be said that connecting equipment from different brands is fundamentally no different. It doesn’t matter which stove you purchased - Electrolux, Gorenje, Bosh or Beko. The brand does not matter when installing and connecting an electric stove. The only difference is the different design of the covers that cover the terminal box on the housing and different methods of fastening it. Everything else is the same.

How to connect an electric stove to a 220 V network

All the above diagrams were specifically for a single-phase 220 V network. To connect, you will need a three-wire cable, a three-pin power socket and a plug with a rated current of at least 32 A. Let’s say right away that connecting equipment from different brands is fundamentally no different. It doesn’t matter which stove you purchased - Electrolux, Gorenje, Bosh, Beko. Doesn't matter. The only difference is the different design of the covers that cover the terminal box on the housing and different methods of fastening it. Everything else is the same.

Connecting the cable to the electric stove

First, the cable selected for connection must be connected to the electric stove. On the rear panel, usually at the bottom left there is a terminal block to which the conductors are routed.

Nearby are connection diagrams for different networks.

With a 220 V network, the diagram is on the far right. On the plate, contacts 1,2,3 should be connected by one jumper - this will be the phase (red or brown conductors), the second - contacts 4 and 5 - this is neutral or zero (blue or blue), the sixth contact is ground (green or yellow -green). Electrical plates usually come from the store with jumpers already installed, but it doesn’t hurt to check.

It is more correct and reliable to crimp the conductors with contact plates, and then connect them. This connection is more reliable, but often the conductors are simply twisted around the clamping screw and then tightened. In any case, it is better to follow the color coding - this way there is less chance of making a mistake.

Plug installation

Next, a plug is connected to the cable. The power plug is collapsible. Unscrew the two mounting screws and remove the cover with contacts. The fixing bar holding the cable is also removed. The protective insulation is removed from the edge of the flexible cable (about 5-6 cm), the conductors are straightened, their ends are also stripped of insulation by about 1.5-2 cm. The cut end of the cable is inserted into the plug body.

The clamping screws on the contacts are loosened, the conductors, if they are multi-core, are twisted into a bundle. These flagella are twisted around the contacts and tightened with clamping screws.

The distribution of conductors matters and they must be connected carefully. The top contact of the plug is usually labeled - the “ground” wire (green) is connected here. When connecting a socket, you need to apply ground to a similar connector.

The other two contacts are “phase” and “zero”. Where to apply which one is not important, but when connecting the socket, the “phase” must fall on the “phase”, the “zero” must fall on the “zero”. Otherwise there will be a short circuit. So before turning it on, be sure to double-check that the wires (phase and neutral) are screwed in correctly.

How to determine the phase in an installed socket

If you already had an electric stove before, and there is a socket, you need to find in it where the grounding, phase and neutral are located and connect the wires in the plug accordingly. The easiest way to determine this is to use a voltage indicator in the form of a screwdriver. It works simply - install the indicator in the place of the expected phase, and look at the LED mounted in the housing. If it lights up, then there is voltage and this is a phase. If there is no voltage, the LED does not light up, and this is zero.

The ground is even easier to determine: is the contact at the top or bottom.

Options for connecting an electric stove to the network

Since an electric stove consumes quite a lot of electricity, it must be connected to the electrical network with a separate cable coming directly from the distribution panel. Most modern apartments, especially in new buildings, have a separate power line for the electric stove. If such a line is not provided in the house, then it must be laid. A 25-40 Ampere safety circuit breaker must be installed on the line.

Connection to a single-phase power supply

This connection is the most common option and is most often used in apartments in multi-storey buildings. To connect the stove to a single-phase network, a three-core cable is used. Each cable core has its own color: red indicates phase, blue indicates neutral, and yellow-green indicates ground. The cable is connected to the contacts of the electric stove located under the protective cover.

Each of the plate contacts has its own designation. The letter L marks all phase terminals, no matter how many there are, the letter N stands for zero, of which there can also be several, the letters PE stands for grounding and usually this is only one terminal. If there are several terminals marked with the letter L, then when connecting the stove to a single-phase network, you must use the jumpers that are supplied with the stove.

When connecting a kitchen stove, first connect the ground wire to the PE terminal, then the zero wire to the N terminal. If there are several zero terminals on the stove, they are first connected to each other by jumpers, and then a cable wire in blue insulation is connected to one of them. The last phase is connected. All terminals with the letter L are also connected with a jumper, and then the phase wire of the cable is connected.

Two-phase connection

This connection method is quite rare. In this case, a cable with four cores is used, two of which are phases, and the other two are neutral and ground. The connection is made as follows: first connect the ground wire, then use a jumper for the neutral terminals to connect the neutral wire. If the plate has three phase terminals, then two of them are connected with a jumper and the phase conductor of the cable is connected to one of the terminals, and the second phase conductor is connected to the remaining third terminal.

Three-phase connection

Connecting the stove to a three-phase power supply has many advantages. Firstly, with this connection, the burners heat up faster. Secondly, there is less load on the wiring, and thirdly, there is almost no voltage drop even when the stove is operating at full load. The main disadvantage of such a connection is the cost, which is an order of magnitude higher compared to a single-phase connection. In addition, it should be noted that there is a certain complexity in establishing such a connection and the requirements for the person using such a network.

To connect an electric stove to a three-phase network, a cable with five cores is required. Three wires of this cable are phases, and the other two are neutral and ground. First, ground and zero are also connected, having previously connected the zero terminals with a jumper. One phase wire of the cable is connected to the three phase terminals of the plate. The color of the phase wires may vary, but the neutral wire is always blue, and the ground wire is yellow-green.

As for the connection diagram of the stove, it is identical for electrical networks with any number of phases. The stove is connected from the input machine through a separate group machine. Sometimes, as protection, it is additionally equipped with an RCD automatic device.

Requirements for the electric stove connection diagram:

- when connecting to a single-phase network, the input circuit breaker for the apartment must be designed for a rated current of 40 Amperes. When connected to a three-phase (two-phase) network, the rated current of the input circuit breaker is determined by the technical conditions;

- To power the electric stove, a separate group must be organized, which must be powered by a group circuit breaker with a rated current of 25 Amperes. This only applies to connections to a single-phase network;

- Electrical wiring for an electric stove must comply with the rules of the PUE for brick, concrete and reinforced concrete premises and must be carried out in a hidden way. Open wiring for an electric stove is allowed only in rooms made of flammable materials;

- The socket for an electric stove must be designed for a rated current of 25 Amps. The socket must be equipped with a grounding contact.

Connection to a three-phase 380 V network

In this case, an automatic machine and an RCD for a three-phase network are purchased; the wires must be five-core (the cross-section is determined using the same table, only the value must be looked at in the 380 V column). The plug and socket must also have five contacts.

The connection process itself will not differ in anything, only in the number of wires. The difference will be when connecting the wire to the output terminals of the electric stove. Only one jumper will be installed - on pins 5 and 6. All others are connected with separate conductors.

It is also necessary to monitor the position of “ground” and “neutral” (or they also say “zero”). The color matching of the conductors on the phases is not critical, but it is more convenient if they also match.

stroychik.ru

Types of electric stoves

Modern household electric stoves are divided into two categories, each of which is characterized by the type of hob:

- products with enameled countertops and cast iron burners;

- models with glass-ceramic hobs.

The disadvantages of any models outside their category include some thermal inertia - their cooking surfaces slowly reach operating temperature and also cool slowly. Therefore, setting the desired temperature can be quite difficult. Because of this, budget options provide a fixed adjustment of thermal power - three...6 positions.

The undoubted advantage of products with cast iron burners is their more affordable price. Models with a glass-ceramic surface have a flat cooking surface. The heating elements of these products can be tape, halogen or induction devices, which are much easier to adjust the power.

Therefore, cheap glass-ceramic electric stoves have a simple rotary control, while expensive models can be equipped with electronic or touch controls. In addition, the design of hotplates evolved decades ago and today is determined by the type and size of the heating elements. The appearance of stoves with glass-ceramic hobs is constantly being improved; they have a more stylish appearance and greater ergonomics.

The disadvantages of glass-ceramic models include the discrepancy between the size of the hob and the bottom of the cookware. However, this disadvantage is compensated by the use of several individual heating elements.

Of course, the quality of operation of any product, regardless of the brand, depends on compliance with operating rules. Moreover, the correct connection affects not only the performance characteristics, but also the safety of use.

You should know that electric stoves are available with a supply voltage of both 220.0 volts and 380.0 volts. For a city apartment, you should choose products of the first category. If a person lives in a private house and has a three-phase supply, then preference should be given to electric stoves designed for a voltage of 380.0 volts.

Rules for installing electric stoves

The stove should be connected by a person who has minimal electrical skills and has a general understanding of the rules for operating electrical installations and safety precautions when working with electrical appliances.

In addition, most dealer companies and service centers may refuse warranty repairs if the installation was not carried out by specialists from the company through which the product was purchased.

The tool you will need:

- pliers with insulated handles;

- side cutters (nippers) with insulated handles;

- Screwdriver Set;

- indicator screwdriver;

- multimeter with a maximum AC current measurement limit of 500.0...1000.0 volts.

After this, it is necessary to draw a separate electrical line through which only the electric stove will be powered. The type of power line depends on the method of power supply to the electric stove. Plates designed for a voltage of 220.0 volts are connected using a single-phase circuit; models designed for 380.0 volts can be connected using three-phase or rather rare, two-phase connection schemes.

In addition, when connecting an electric stove, the following requirements must be met:

- power supply is carried out by a copper cable, the number of cores of which depends on the connection diagram;

- in the circuit it is necessary to provide for the installation of a separate circuit breaker and a residual current device;

- The stove body must be grounded - grounding through water pipes is not allowed.

Straw house

You can often hear electrical networks called three-phase, two-phase, or less often single-phase, but sometimes these concepts do not mean the same thing. In order not to get confused, let's figure out how these networks differ and what they mean when they talk, for example, about the differences between three-phase and single-phase current

.

| Single-phase networks | Two-phase networks | Three-phase networks |

| The passage of current is possible in a closed circuit. Therefore, the current must first be supplied to the load and then returned back. With alternating current, the wire supplying the current is a phase. Its circuit designation is L1 (A). The second one is called zero. Designation - N. This means that to transmit single-phase current you need to use two wires. They are called phase and zero, respectively. Between these wires the voltage is 220 V. | There is a transmission of two alternating currents. The voltage of these currents is phase shifted by 90 degrees. They transmit currents through two wires: two phase and two neutral. It is expensive. Therefore, now it is not generated at power plants and is not transmitted via power lines. | Three alternating currents are transmitted. In phase, their voltages shift by 120 degrees. It would seem that six wires had to be used to transmit current, but using a “star” connection of sources, three are used (the type of circuit is similar to the Latin letter Y). Three wires are phase, one is neutral. Economical. Current is easily transmitted over long distances. Any pair of phase wires has a voltage of 380 V. Pair of phase wire and neutral - voltage 220 V. |

Thus, the power supply to our houses and apartments can be single-phase or three-phase.

Single phase power supply

Single-phase current is connected in two ways

: 2-wire and 3-wire.

- The first (two-wire) uses two wires. One carries phase current, the other is intended for the neutral wire. In a similar way, power supply is supplied to almost all old houses built in the former USSR.

- In the second case, another wire is added. It is called grounding (PE). Its purpose is to save human life and devices from breakdown.

Three-phase power supply

Distributing three-phase power throughout the house is done in two ways

: 4-wire and 5-wire.

- A four-wire connection is made with three phase and one neutral wire. After the electrical panel, two wires are used to power sockets and switches - one of the phases and zero. The voltage between these wires is 220V.

- Five-wire connection - a protective grounding wire (PE) is added.

In a three-phase network, the phases should be loaded as evenly as possible. Otherwise, phase imbalance will occur. The result of this phenomenon is very disastrous and unpredictable for human life and technology.

What kind of electrical wiring in the house depends on what electrical equipment can be included in it.

For example, grounding, and therefore sockets with a grounding contact, are required when the following are connected to the network:

- high-power appliances - refrigerators, ovens, heaters,

- electronic household appliances - computers, televisions (it is necessary to remove static electricity),

- water-related devices - Jacuzzis, showers (water is a current conductor).

And to power the motors (relevant for a private home), three-phase current is needed.

How much does it cost to connect single-phase and three-phase electricity?

Costs for consumables and equipment installation are also planned based on the most preferred connection. And if it’s difficult to predict the cost of sockets, switches, and lamps (it all depends on the whims of your imagination and the designer’s), then the prices for installation work are approximately the same

. On average this is:

- assembly of an electrical panel in which circuit breakers (12 groups) and a meter are installed costs from $80

- installation of switches and sockets $2-6

- installation of spotlights $1.5-5 per unit.

***

Personally, I also thought about solar panels - I did a little research on https://220volt.com.ua, now I’m trying to structure my thoughts on how and what to do with their connection...

Connecting an electric stove using various schemes

Most modern manufacturers of electric stoves supply their products to the retail chain without a power cord. This is due to modern electrical safety requirements, which imply connecting high-power devices without a socket - using special terminal blocks.

This method has two main advantages:

- the power cord can be selected to any length;

- It is possible to replace an individual circuit breaker with a fuse (insert).

If the length of the cord does not exceed 6.0 meters, then the electrical cross-section of each core can be taken equal to 4.0 square millimeters. For longer lengths, the minimum cross-section increases to 6.0 square millimeters and the installation of a fuse link is prohibited, and power is supplied only through a circuit breaker.

In principle, an electrical appliance can be connected using a special “plug-socket” pair. However, these electrical fittings must be rated for a current of at least 32.0 amperes, and the use of ordinary household plugs is prohibited.

Single-phase connection

Single-phase connection (Fig. 1) is most common in urban apartments of multi-storey buildings. To implement it, it is necessary to install jumpers in the terminal box (located on the rear panel) of the electric stove accordingly. All modern models are equipped with jumpers of the required cross-section. If there are no jumpers, they must be purchased at an electrical goods store or cut from a copper core yourself. The minimum electrical cross-section of the jumper is 6.0 square millimeters.

Fig.1

According to the diagram, for a single-phase connection you need:

- Connect terminals 1-2-3 with jumpers and connect to the phase wire (brown, gray or black) of the power cable;

- connect terminals 4-5 to each other and connect to the neutral core (usually painted blue);

- connect terminal 6 to the grounding conductor of the cable - for a single-phase network with a voltage of 220.0 volts, this wire usually has a smaller cross-section and is painted yellow or green.

When making all connections (wires to terminals and jumpers between terminals), reliable electrical contact must be ensured, for which the nuts in the terminal box must be tightened well. If the contact is poor, the connection will heat up and spark, which will lead at a minimum to burnout of the insulation of the terminal box, and at most to a fire.

We connect the power cable to the plug as follows:

- the phase wire is connected to the plug (terminal) “L”;

- zero – to plug “N”;

- grounding - to the plug marked with a conventional grounding symbol (in some products the grounding contact is marked “earth” or “PE”).

Two-phase connection

A two-phase connection (Fig. 2) is used quite rarely and can only be done in residential premises if they have a three-phase network. In this case, the electric burners will be connected to two phase wires, and one phase will remain unloaded.

Fig.2

The procedure for installing jumpers, connecting the cable to the plate and connecting it to the plug is as follows:

- connect terminals 1-2 or 2-3 with a jumper and connect to the first phase wire;

- connect the free phase terminal (3 or 2 depending on how the jumper is installed) to the second phase wire);

- installation of jumpers (4-5) and connection of neutral and ground wires is carried out similarly to a single-phase circuit.

To plug in an electric stove using a two-phase scheme, you must purchase a “plug-socket” kit to power three-phase equipment, while one plug of the plug will be unused.

Three-phase connection

Three-phase connection (Fig. 3) requires a three-phase network and is mainly used in individual houses. As is known from the course of general electrical engineering, the voltage between phases will be equal to 380.0 volts, and between any phase and zero - 220.0 volts. To implement it you will need a four to five core cable.

The cables connected to the terminal box are as follows:

- jumpers are not placed between the phase terminals (1-2-32), but each terminal is connected to a phase wire;

- installation of jumpers (4-5) and connection of neutral and ground wires is carried out similarly to a single-phase circuit.

Fig.3

When performing electrical installation work yourself, you should be aware that some models do not have a terminal box, and the connection is made to the contacts located on the rear panel.

Connection diagrams for electric stoves

Before proceeding with the actual installation of the device, study the existing device connection diagrams.

Single-phase connection

The most common option. Most often found in apartments of multi-storey buildings.

With a single-phase connection, the connection block will look like this (see diagram).

Single-phase connection

Terminals 1-2-3, as well as 4-5, are connected by copper jumpers with a cross-section of 6 mm2. If you bought a modern stove, the necessary jumpers will be included in the kit.

The phase conductor (can be gray, brown or black) is connected to terminal number 1, 2 or 3.

The neutral wire (usually blue) is connected to the 4th or 5th terminal. The ground wire (yellow-green in the diagram) is connected to the 6th terminal.

The terminal bolts must be tightened until they stop. If the connection is poor, the terminals may burn, resulting in a fire.

In the case of using a socket connection, we feed the phase conductor in the plug and socket to terminal L, the neutral conductor goes to the terminal marked N, and the grounding wire is connected to the corresponding terminal (marked with a grounding pattern, the letters PE, or the word earth).

Two-phase connection

Two-phase circuit

Rarely, but still there is a two-phase connection. For example, phases A and C may be present, but phase B will not be present.

With this connection, terminals 1 and 2 need to be connected with a jumper and phase A must be connected through it. Phase C goes to the 3rd terminal. The further connection procedure remains similar to the previous methods.

Three-phase connection

Three-phase circuit

Owners of private houses most often encounter three-phase power. The supply wire in such a situation will consist of 4 or 5 cores. In this case, the voltage between zero and phases will be 220 V, and between the phases themselves - 380 V.

In such conditions, the electric stove will be connected according to the appropriate circuit. Phases A, B and C will go to the corresponding terminals 1, 2 and 3.

The connection of terminals 4, 5 and 6 is similar to a single-phase connection.

Electric stove connection cost

Before connecting the electric stove yourself, you should call the service center and ask how much this work performed by a specialist will cost. At the same time, the owner of household appliances gets rid of a lot of problems associated with both time expenditure and the performance of sometimes unfamiliar work.

For example, in Moscow, when performing the entire range of work, standard prices are as follows:

- purchase of necessary materials and components (excluding their cost) – 350.0 rubles per hour of time spent;

- installation and connection of an electrical outlet - 450.0...750.0 rubles per unit (depending on the type of connection);

- installation of electrical wiring with connection to the panel 150.0...350.0 rubles per linear meter;

- installation of an electric stove – 1000.0 rubles.

There are companies that offer to complete the entire range of work on a turnkey basis, without intervention from the owner, for 20.0...50.0 North American dollars. At the same time, the higher price applies to equipment with a glass-ceramic hob.

In the provinces, prices are somewhat cheaper. In Krasnoyarsk and Novosibirsk, the cost of electrical installation and installation starts from 800.0 rubles. In other regional centers, in the Central regions of Russia, many companies offer their services for similar work in the range of 400.0...500.0 rubles.

househill.ru

Calculation of network parameters

Let's say we mean an apartment where the network is single-phase . Before purchasing an electric stove, you will need to calculate what its power (current consumption) may be, relative to the introductory circuit breaker and other household appliances.

Since the values of the input rated current are not indicated on all electrical appliances, you will have to sum up their power. You need to start with those that are most likely to work simultaneously with the electric stove: refrigerator, air conditioner, lighting.

You can introduce a rule not to start cleaning, washing, ironing and bathing while cooking - a vacuum cleaner, washing machine, iron and boiler consume a lot of electricity. The total current consumed by existing household appliances is calculated using the formula:

Ib.t= Pb.t/ U (A),

where Pb.t is the total power of household electrical appliances.

Knowing the rated current In of the input circuit breaker, you need to calculate the maximum permissible rated current value of the future electric stove: Iep = In - Ib.t. In other words, if there is a 16 A circuit breaker at the input, then the maximum possible power of the stove is 3.5 kW, provided that all other electrical appliances are completely turned off.

If it turns out that the electric stove was given as a gift without delving into the details of the energy supply, then you will need to contact the appropriate authorities to increase the rating of the introductory machine.

Dedicated line for electric stove

If the input machine allows you to connect the electric stove you like in the catalogue, you should not rush to order it. First, you need to decide whether the purchase is worth laying an additional cable in the apartment along with minor repairs associated with electrical installation.

The fact is that, according to the requirements of the PUE and additional standards, the connection of household electric stoves must be carried out with a separate that runs inextricably from the input panel, with copper conductors with a cross-section of at least 4-6mm².

Ignoring this rule can have dire consequences due to the fire of household electrical wiring that cannot withstand the load.

Also, this dedicated line must be protected by an automatic circuit breaker according to the load. If there is an intermediate panel in an apartment or private house, then power can be supplied to it, provided that the cable included in the panel is designed for the total load. Select the cable cross-section by power or current, based on the table:

Judging by the values, it is clear that for electric stoves with a power below 7.7 kW, a cable cross-section value smaller than that specified in the PUE (4mm²) is suitable. But these standards were developed based on increased electrical safety requirements for such electric heating devices, so they should not be ignored.

An approximate diagram of a single-phase home network should look like this:

Cable selection

Very often you can observe the following situation: a cable in a store has one price, but somewhere around the corner, with the same characteristics, wires cost half as much.

This difference in price is not due to a management feature, but to the fact that a non-certified cable has deviations in the cross-section of the conductors, the quality of the metal and the thickness of the insulation.

Therefore, when choosing a cable, you should check its quality certificate, and if you have a caliper or micrometer, you should take it with you to check the correspondence of the actual diameters of the cores to the cross-sectional values indicated in the catalog.

For stationary installations, wiring of the first and second classes is accepted, but if increased flexibility is required, the class is increased. This nuance will be important if the electric stove is connected directly, without an outlet, and sometimes the stove will have to be moved away for general cleaning, repairing walls or the heating device itself.

For a single-phase network you will need a cable with crown cores, and for a three-phase network with five, brand VVG or PPV.

Selection of protective devices

The circuit breaker is selected based on the power of the electric stove (connecting other electrical appliances to this line is highly undesirable). There are tables to make this choice easier:

Time-current characteristic of the circuit breaker: B or C. You should also use a separate protective device (RCD) with a leakage current of no more than 30 mA, and a rated current one step higher than that of the circuit breaker.

This precaution will protect against electric shock in the event of a breakdown of the electric stove and breakdown of the insulation. To save space in the panel, it is possible to use a difautomatic device that combines an RCD and a circuit breaker.

Connection method

After meeting the above conditions, you can decide how to connect the electric stove. For this purpose, there are two ways - connecting through an outlet, or directly to the electrical wiring.

Each option has its own advantages and disadvantages. Direct connection eliminates heat generation at the outlet contacts, which increases fire safety, but in the case of kitchen remodeling, the length (usually 1-2 m) of the wire protruding from the wall (placed in a corrugation) may not be enough to relocate the electric stove.

The use of a socket improves mobility and simplifies dismantling, but will require additional costs for the purchase of a connecting flexible multi-core cable, lugs for it, a specific power socket and a high-reliability plug.

Wire connections

Let's say you have chosen the option of connecting through a power outlet that can withstand heavy loads - the use of ordinary outlets is not allowed. The plug connection (plug and socket) must correspond to the rated current, otherwise the contacts will heat up and burn.

Connect the wires to this socket and plug as follows:

The plug connection can be of a different type, the main thing is that the contacts on the socket and plug match.

For three-phase connection:

An electric stove is usually three-phase; to connect it to a single-phase network, inputs L1, L2, L3 are connected by jumpers.

The jumper should come with the electric stove, or it can be made independently from a piece of wire to be connected. Connecting the electric stove and plug to a stranded wire should be done using lugs:

When connecting directly to a solid wire, lugs are not required. The appearance of the terminals may be different, but the principle remains the same: phase wire to the jumpers between the phases, neutral wire N to the zero terminal (the installed zero jumper cannot be touched), PE conductor to the corresponding contact.

To connect to a three-phase network, the jumpers between the phases must be removed and each phase wire connected to the corresponding terminal.

It very rarely happens that only two phases enter a house. In this case, a jumper is placed between the two input phase terminals of the electric stove.

The screw terminals must be clamped as securely as possible; in case of poor contact, the wires will become charred.

Compliance with all the above recommendations will allow you to independently calculate the parameters of the cable and protection, connect the electric stove yourself, and also make its choice according to the existing network conditions.

infoelectrik.ru

Single-phase network 220 V

This case applies mainly to apartments in which the owner decided that during renovations or just because it is worth installing an induction hob instead of a classic gas stove. What does this have to do with repairs? Of course, this is not a necessary condition, but in most cases the 220 V network is not ready to accept such an energy-intensive consumer, and it will be necessary to lay an additional cable from the switchgear to the induction hob and slightly modernize the distribution board.

Connecting an induction hob in a single-phase installation without first preparing and checking the existing network is risky! An induction hob is not a refrigerator! Induction consumes a lot of electricity, more than any device in the apartment. You need to be sure that the power grid will be able to withstand such a load.

The instructions for some stoves state that the protection must be at least 30 A and the cable with a cross-section of 4 mm2. However, to improve wiring safety, it is better to use 25 A protection (such as a B25 switch).

Let's move on to the options for connecting the stove. The following diagrams are prepared based on the connection methods for individual models selected by the manufacturer. Always check the instructions before connecting your model.

Connecting the plate to the outgoing cable

In this case, the plate is a closed box from which a cable, most often 5-wire, is brought out. The most common are:

See examples of drawings from the instructions for the induction panel above.

When the power cord has an inappropriate cross-section

If the power cord has a cross-section of 2.5 mm2, it must be protected using a switch with a lower current rating, such as B16. In this case, it is worth buying an induction hob with limited energy consumption so that the maximum current switch does not trip when using 3 or 4 heating fields.

There are opinions that each induction hob has a controller that takes into account that the network is single-phase and does not allow half heating at full power or intelligently switches them if they are all working at once, that is, the consumption of 7.2 kW in a single-phase installation is only on paper.

However, not every induction cooker, when you connect it to single-phase weak wiring, automatically reduces energy consumption. If the manufacturer does not include such information in the instruction manual, it should be assumed that if 4 burners are turned to the maximum heat level, the induction hob will consume approximately 7200 W of energy in total.

How are three phases different from one?

In both types of power there is a working neutral conductor (ZERO). I talked in detail about protective grounding here; it is a broad topic. In relation to zero in all three phases - the voltage is 220 Volts. But in relation to these three phases to each other, they have 380 Volts.

This happens because the voltages (with active load, and current) on the three phase wires differ by a third of the cycle, i.e. at 120°.

You can read more in the electrical engineering textbook - about voltage and current in a three-phase network, and also see vector diagrams.

It turns out that if we have three-phase voltage, then we have three phase voltages of 220 V each. And single-phase consumers (and there are almost 100% of them in our homes) can be connected to any phase and zero. You just need to do this in such a way that the consumption in each phase is approximately the same, otherwise phase imbalance is possible.

Read more about phase imbalance and what causes it - here.

And it is best to protect yourself from phase imbalance using a voltage relay, for example Barrier or FiF EuroAutomatika.

In addition, it will be difficult for the overly loaded phase and it will be offensive that others are “resting”)

Comparison with single-phase power supply

The advantage of two-phase electrical power over single-phase was that it allowed the use of simple self-starting electric motors. In the early days of electrical engineering, it was easier to analyze and design two-phase systems in which the phases were completely separated. It was not until the invention of the symmetrical component method in 1918 that polyphase power systems had a convenient mathematical tool for describing unbalanced load cases. The rotating magnetic field created by the two-phase system allowed electric motors to provide torque from zero motor speed, which was not possible with a single-phase induction motor (without additional starting aids). Induction motors designed for two-phase operation use a winding configuration similar to that of single-phase capacitor-start motors. However, in a two-phase induction motor, the impedances of the two windings are identical.

Two-phase circuits also have the advantage of constant combined power to the ideal load, whereas the power in a single-phase circuit pulsates at twice the mains frequency due to voltage and current zero crossings.

Advantages and disadvantages

Both power systems have their pros and cons, which change places or become insignificant when the power passes the 10 kW threshold. I'll try to list.

Single-phase network 220 V, advantages

- Simplicity

- Cheapness

- Below dangerous voltage

Single-phase network 220 V, cons

- Limited consumer power

Three-phase network 380 V, advantages

- Power is limited only by wire cross-section

- Savings with three-phase consumption

- Power supply for industrial equipment

- Possibility of switching a single-phase load to a “good” phase in case of deterioration in quality or power failure

Three-phase network 380 V, cons

- More expensive equipment

- More dangerous voltage

- Limits the maximum power of single-phase loads

When is it 380 and when is it 220?

So why do we have a voltage of 220 V in our apartments and not 380? The fact is that, as a rule, consumers with a power of less than 10 kW are connected to one phase. This means that one phase and a neutral (zero) conductor are introduced into the house. This is exactly what happens in 99% of apartments and houses.

However, if you plan to consume power more than 10 kW, then a three-phase input is better. And if you have equipment with three-phase power supply (containing three-phase motors), then I strongly recommend introducing a three-phase input into the house with a linear voltage of 380 V. This will save on wire cross-section, on safety, and on electricity.

Despite the fact that there are ways to connect a three-phase load to a single-phase network, such modifications sharply reduce the efficiency of motors, and sometimes, all other things being equal, you can pay 2 times more for 220 V than for 380.

Single-phase voltage is used in the private sector, where power consumption, as a rule, does not exceed 10 kW. In this case, a cable with wires with a cross section of 4-6 mm² is used at the input. The current consumption is limited by the input circuit breaker, the rated protection current of which is no more than 40 A.

I already wrote about choosing a circuit breaker here. And about the choice of wire cross-section - here. There are also heated discussions of issues.

And if you are at all interested in what I write about, subscribe to receive new articles and join the group on VK!

But if the consumer’s power is 15 kW or higher, then three-phase power must be used. Even if there are no three-phase consumers in this building, for example, electric motors. In this case, the power is divided into phases, and the electrical equipment (input cable, switching) does not bear the same load as if the same power was taken from one phase.

For example, 15 kW is about 70A for one phase; you need a copper wire with a cross-section of at least 10 mm². The cost of a cable with such cores will be significant. But I have never seen single-phase (single-pole) circuit breakers with a current greater than 63 A on a DIN rail.

Therefore, in offices, stores, and especially in enterprises, only three-phase power is used. And, accordingly, three-phase meters, which come in direct connection and transformer connection (with current transformers).

And at the input (in front of the counter) there are approximately the following “boxes”:

A significant disadvantage of a three-phase input (noted above) is the limitation on the voltage of single-phase loads. For example, the allocated power of three-phase voltage is 15 kW. This means that for each phase - a maximum of 5 kW. This means that the maximum current in each phase is no more than 22 A (practically 25). And you have to spin, distributing the load.

I hope it is now clear what three-phase voltage 380 V and single-phase voltage 220 V are?

Story

The idea of using two-phase current to create torque was first proposed by Dominic Arago in 1827. The practical application was described by Nikola Tesla in his patents from 1888, around the same time he developed the design of a corresponding electric motor. These patents were then sold to the Westinghouse company, which began developing two-phase networks in the United States. Later, these networks were supplanted by three-phase networks, the theory of which was developed by the Russian engineer Mikhail Osipovich Dolivo-Dobrovolsky, who worked in Germany at the AEG company. However, due to the fact that Tesla's patents contained general ideas for the use of polyphase circuits, the Westinghouse company was able to hold back their development for some time through patent litigation.

Advantages

The advantage of two-phase networks was that they allowed simple, soft starting of electric motors. In the early days of electrical engineering, these networks with two separate phases were easier to analyze and design. At that time, the method of symmetrical components had not yet been created (it was invented in 1918), which subsequently gave engineers convenient mathematical tools for analyzing asymmetrical load modes of multiphase electrical systems.

The rotating magnetic field created in two-phase systems allowed electric motors to create torque from zero motor speed, which was not possible in single-phase asynchronous electric motors (without special starting means). Induction motors designed for two-phase systems have the same winding configuration as single-phase capacitor starting motors.

A three-phase electrical network requires lines with a smaller mass of conductive materials (usually metals) at the same voltage and greater transmitted power, compared to a two-phase four-wire system. Two-phase lines have been replaced by three-phase lines in electrical distribution networks, but they are still used in some control systems.

The transmitted instantaneous active power in three-phase and two-phase electrical networks is constant with a symmetrical load. However, in single-phase networks, instantaneous active power fluctuates with a frequency that is twice the frequency of the line voltage. These power pulsations lead to increased noise and mechanical vibrations in electrical equipment with magnetizable materials due to the magnetostrictive effect, as well as rotational vibrations of electric motor shafts.

Two-phase circuits typically use two separate pairs of current-carrying conductors. Three conductors can be used, however, the vector sum of phase currents flows through the common wire, and therefore the common wire must have a larger diameter. In contrast, in three-phase networks with a symmetrical load, the vector sum of the phase currents is zero, and therefore in these networks it is possible to use three lines of the same diameter. For electrical distribution networks, the requirement of three conductor lines is better than the requirement of four, since this results in significant savings in the cost of conductor lines and in installation costs.

Two-phase voltage can be obtained from a three-phase source by connecting single-phase transformers according to the so-called Scott circuit. A symmetrical load in such a three-phase system is exactly equivalent to a symmetrical three-phase load.

You can often hear electrical networks called three-phase, two-phase, or less often single-phase, but sometimes these concepts do not mean the same thing. In order not to get confused, let's figure out how these networks differ and what they mean when they talk, for example, about the differences between three-phase and single-phase current

.

With alternating current, the wire supplying the current is a phase. Its circuit designation is L1 (A).

The second one is called zero. Designation - N.

This means that to transmit single-phase current you need to use two wires. They are called phase and zero, respectively.

Between these wires the voltage is 220 V.

| There is a transmission of two alternating currents. The voltage of these currents is phase shifted by 90 degrees. They transmit currents through two wires: two phase and two neutral. It is expensive. Therefore, now it is not generated at power plants and is not transmitted via power lines. |

Star and Delta circuits in a three-phase network

There are various variations for connecting a load with an operating voltage of 220 and 380 Volts to a three-phase network. These patterns are called “Star” and “Triangle”.

When the load is designed for a voltage of 220V, it is connected to a three-phase network according to the “Star” circuit , that is, to phase voltage. In this case, all load groups are distributed so that the powers in the phases are approximately equal. The zeros of all groups are connected together and connected to the neutral wire of the three-phase input.

All our apartments and houses with single-phase input are connected to Zvezda; another example is the connection of heating elements in powerful heaters and convection ovens.

When the load has a voltage of 380V, it is switched on according to the “Triangle” circuit, that is, to linear voltage. This phase distribution is most typical for electric motors and other loads where all three parts of the load belong to a single device.

Connecting an RCD in a three-phase network

Protection of devices powered by three phases at once is carried out according to a similar principle, with the difference that the RCD is selected for four outputs. An example of connection is shown in the figure below:

Rice. 5: Connecting an RCD in a three-phase system

As you can see, in this case, the protective device is also connected after the electric meter and the introductory packet. Individual circuit breakers that respond to phase short circuits are already connected behind it, and, if necessary, more sensitive RCDs are connected to create selective operation for certain groups of consumers.

Since installing a separate device for each phase is too expensive, group RCDs are used in three-phase circuits, which work with all elements of the line at once.

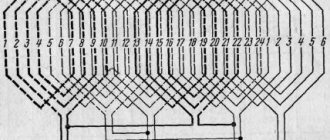

Power distribution system

Initially, the voltage is always three-phase. By “initially” I mean a generator at a power plant (thermal, gas, nuclear), from which a voltage of many thousands of volts is supplied to step-down transformers, which form several voltage stages. The last transformer lowers the voltage to a level of 0.4 kV and supplies it to end consumers - you and me, apartment buildings and the private residential sector.

Large enterprises with power consumption of more than 100 kW usually have their own 10/0.4 kV substations.

Visually:

The figure shows in a simplified way how from generator G a voltage (everywhere we are talking about three-phase) 110 kV (can be 220 kV, 330 kV or another) is supplied to the first transformer substation TP1, which lowers the voltage for the first time to 10 kV. One such transformer substation is installed to power a city or region and can have a capacity of the order of a few to hundreds of megawatts (MW).

Next, the voltage is supplied to the second stage transformer TP2, at the output of which the end-user voltage is 0.4 kV (380V). The power of transformers TP2 is from hundreds to thousands of kW. From TP2, voltage is supplied to us - to several apartment buildings, to the private sector, etc.

Such voltage level conversion stages are necessary in order to reduce losses during the transportation of electricity. Read more about losses in cable lines in my other article.

The circuit is simplified, there may be several steps, the voltage and power may be different, but the essence does not change. There is only one final voltage of consumers - 380 V.