The most effective way to reduce the cost of adhesive waterproofing is to use relatively thin polymer films, primarily polyethylene, the range of which is quite wide. However, it was necessary to seriously study the issue of the durability of film waterproofing.

The durability of polymer films has been proven by direct experiments and confirmed by field observations, as well as experimental and theoretical predictions and justification of the estimated service life of film coatings in various conditions.

The durability of polymer films has become especially important due to their widespread use for impervious screening of reservoirs and other hydraulic structures. Field observations of polymer films under various conditions for 15-20 years have shown that films made of stabilized high-density polyethylene with a thickness of more than 200 microns age very slowly and their durability in ground and underwater conditions exceeds 150 years; unstabilized and polyvinyl chloride films have significantly lower durability, but increasing their thickness to 0.6-1.2 mm greatly increases it.

Construction moisture-proofing films made of polyethylene stand out among the traditionally accepted insulators in the form of roofing felt and mastic.

Film insulation is impermeable to water vapor and is a waterproofing layer to protect a building (foundation, walls, floor, etc.) from waterlogging.

The disadvantages of film materials include the possibility of their damage during construction, for which reason various measures are taken.

Thickness of polyethylene film for waterproofing

You should know that for waterproofing foundations you cannot use a polymer film thinner than 0.4 mm. Film with a thickness of 0.2 mm can only be used in floor structures on the ground.

Waterproofing film for floor

Polyethylene film is used:

- to provide a moisture-proofing layer under the floor (including at ground level), floor covering;

- for the installation of a protective layer against moisture, heat and sound insulation;

- to provide a sliding layer in various designs.

A wide range of possible sizes allows the film to be used without the need for mechanical connection of the film sheets.

Advantages

- waterproof;

- elastic, easy to style;

- strong enough to break.

At the stage of construction of buildings and structures, it is necessary to protect individual structures from moisture. Polyethylene film for waterproofing is an inexpensive, resistant to repeated deformation, easy-to-use material that protects buildings from the destructive effects of water and other aggressive liquids.

Waterproofing polyethylene film ↑

Technical characteristics and types ↑

According to the technical specifications of GOST 10354-82, waterproofing film is produced on the basis of low-density polyethylene with various additives (stabilizers, dyes, modifiers). It is also made from high-density polyethylene (GOST 16338-85). In construction, film marked T (stabilized or unstabilized) with a thickness of up to 0.5 mm is used. The material is produced in the form of canvas, sleeves, half-sleeves in rolls of various widths and lengths. Operating temperature from -50 °C to +60 °C.

Waterproofing film for foundation ↑

Groundwater and melt water cause saturation of foundation elements with moisture, which leads to excessive dampness and the development of mold fungi that penetrate higher up the load-bearing structures of the building. At subzero temperatures, the water that has saturated the concrete freezes - ice crystals destroy the structure of the building material and reduce its strength. Moisture seeping into the concrete causes corrosion (rusting) of steel reinforcement. To extend the life of buildings and structures, reliable waterproofing is required during the construction phase.

Important: polyethylene film is used as an additional element to protect the foundation from moisture.

Strip foundation waterproofing technology ↑

Strip foundations are more often used in individual construction. Protection from moisture is carried out according to a certain scheme. After preparing the trench and installing the formwork, they begin to lay the film sheet. The strips are overlapped (20–35 cm), the joints are sealed with special tape or glue. The edges of the canvas must protrude beyond the edge of the formwork by at least 10 centimeters. Carefully, so as not to damage the polyethylene, perform reinforcement, then pour the concrete solution. The film will retain moisture in the concrete for a long time, promoting uniform hardening. In the future, it will serve as protection against capillary waterlogging. After the concrete has hardened (after a few days), carefully remove the formwork, otherwise damage (punctures, cuts) in the future will lead to saturation of foundation areas with moisture.

Slab foundation waterproofing technology ↑

Horizontal waterproofing of the upper part of the foundation is carried out in a certain sequence:

- They clean the surface of the foundation from dust and sand, eliminate irregularities that could damage the polyethylene during installation, and cut off protruding reinforcement.

- The first option: moisten the foundation with water and apply a layer of cement mortar. Second option: the surface is impregnated with a primer.

- A polyethylene sheet is laid on top, leaving an allowance

5 cm on each side. Film strips are joined along their length with an overlap

35 cm. The joint is glued or sealed with tape.

- The laid canvas is poured with a layer of cement mortar and leveled, protecting the film from accidental damage.

Waterproofing under concrete screed ↑

Performed in cases where a concrete slab serves as both the foundation of the building and the floor of the first floor. In such projects, it is necessary to protect the concrete from both groundwater and leaks inside the building.

Horizontal waterproofing of foundation under concrete screed

Such waterproofing is most often performed on a slab foundation, when a monolithic concrete slab serves both as the foundation of the building and as the floor of the lower floor. In this case, it is necessary to waterproof the foundation not only from groundwater, but also from leaks of pipes and plumbing fixtures. If polyethylene film is used as a waterproofing material, then a concrete screed is placed on top of it.

- Pour the slab foundation and wait for the concrete to fully mature. You can determine the readiness of the concrete this way: cover the foundation area with polyethylene at night, and if condensation forms on the film by morning, the concrete is not sufficiently dried. After the concrete has fully matured, you can begin building walls and waterproofing rooms with high humidity. If necessary, level the surface: remove protrusions, cut off protruding reinforcement, rub sinks in concrete with a cement-sand mixture.

Pouring a slab foundation - A layer of non-woven geotextile is laid on the concrete, and a polyethylene film is placed on top of it. Geotextiles create a soft substrate that protects the film from damage. The overlap of the strips of material is at least 20 cm, the joints are glued using mounting tape. If waterproofing is carried out in separate rooms, the film is folded onto the walls to a height of at least 10-15 cm. A damper tape must be laid between the film and the wall.

A layer of geotextile and polyethylene film are laid on the foundation - A concrete screed is placed on top of the polyethylene film, using ready-made mixtures for making the subfloor. After the screed has dried, you can begin finishing work.

Film for floor waterproofing ↑

The use of polyethylene not only ensures moisture insulation of the floor, but also protects the heat and sound insulation layers. The film is laid on a flat, clean surface. For reliable protection from moisture, bitumen mastic is first applied. It is advisable to use a single piece of canvas over the entire area. If it is necessary to connect the strips, they are glued together with an overlap

20 cm using tape or glue. Leave an allowance at the walls for height

10 cm. Heat and sound insulation is installed following the manufacturer’s recommendations. If a subfloor is provided, then polyethylene is again laid on top of it.

Video: educational program on construction films ↑

Polyethylene film has long been used in construction to protect various structures from moisture. Modern waterproofing materials are superior to polyethylene in many respects. Therefore, the film is used mainly in individual construction, and as additional protection. When choosing an inexpensive polyethylene sheet as the main waterproofing, you should take into account all the risks associated with the insufficient strength of the material.

Waterproofing film is a polyethylene material or membrane used to protect buildings from the negative effects of moisture (steam, snow, rain, etc.). In the article we will tell you why the material is used and what types of waterproof films there are.

Why do we need films in a roof or frame wall?

To understand this, you need to add a little theory.

Let me remind you that the purpose of this article is to explain “at a glance” what is happening, without delving into physical processes, partial pressure, molecular physics, etc. So I apologize in advance to those who got an A in physics? In addition, I’ll immediately make a reservation that in reality all the processes described below are much more complicated and have a lot of nuances. But the main thing for us is to understand the essence.

Nature has decreed that steam in a house always flows in the direction from warm to cold. Russia, a country with a cold climate, has an average heating period of 210-220 days out of 365 per year. If you add to it the days and nights when it’s colder outside than in the house, then even more.

We suggest you familiarize yourself with Cleaning a chimney from soot with your own hands

Therefore, we can say that most of the time, the vector of steam movement is directed from inside the house, out. It doesn’t matter what we are talking about - walls, roofing or lower floors. Let's call all these things in one word - enclosing structures

In homogeneous structures, the problem usually does not arise. Because the vapor permeability of a homogeneous wall is the same. The steam easily passes through the wall and exits into the atmosphere. But as soon as we have a multilayer structure consisting of materials with different vapor permeability, everything becomes not so simple.

Moreover, if we talk about walls, then we are not necessarily talking about a frame wall. Any multi-layer wall, even brick or aerated concrete with external insulation, will make you think.

You've probably heard that in a multilayer structure, the vapor permeability of the layers should increase as the steam moves.

What will happen then? Steam enters the structure and moves through it from layer to layer. At the same time, the vapor permeability of each subsequent layer is higher and higher. That is, from each subsequent layer, steam will come out faster than from the previous one.

Thus, we do not form an area where the saturation of steam reaches the value when, at a certain temperature, it can condense into real moisture (dew point).

In this case, we will not have any problems. The difficulty is that achieving this in a real situation is not easy.

Why do you need a waterproofing film, what is waterproofing

Waterproofing is work performed to protect buildings from water, evaporation and high humidity. The use of waterproofing materials significantly increases the service life of structures.

If you do not use film for waterproofing in the construction of a house, this can lead to negative consequences:

- disruption of heat supply;

- rotting of the material;

- collapse of the flooring.

The film is used as a barrier to moisture penetration. It is needed as additional protection not only for the roof, but also for the interior decoration of the walls and ceiling, and allows you to maintain the temperature inside the premises.

How can I replace vapor barrier film?

In order to make your home cozy and comfortable, first of all you need to take care of the correct temperature and acceptable humidity. Warm weather at home can be achieved with good heating and insulation, but controlling humidity can sometimes be very difficult. Plus, if there is excess humidity in the room, then all your efforts for comfort may be useless. This problem is especially acute in wooden structures. In order to extend the life of your wooden house and ensure comfortable living in it, it is necessary to make unwanted exposure to moisture as low as possible.

Wooden floor vapor barrier diagram.

And vapor barrier of a wooden floor, walls and roof can help you with this.

Moisture has a negative impact on all wooden buildings. Steam is released from washing, mopping, cooking, showering and bathing, and then escapes beyond these premises. The steam pressure will be greater than atmospheric pressure, and it will press on the floor, walls and ceiling. And the difference in temperatures will lead to the formation of condensation, and then the water will gradually penetrate the tree and destroy it. In this case, the materials will begin to rot, fungus will form and the entire structure will begin to deteriorate. Very often the floor in such a house is laid directly on the ground, and this will serve as an even greater cause for destruction. To avoid all these problems, it is necessary to make a vapor barrier layer that will protect the wood and insulation from moisture and will not stop allowing air to pass through.

Where is waterproofing film used?

Film material is widely used at various stages of construction of houses (including wooden ones), country residential buildings, summer houses, bathhouses, and for insulating balconies in high-rise buildings.

The film insulates from moisture:

- Roofing;

- Walls of wooden houses;

- Thermal insulation materials;

- Interior decoration;

- Bathrooms, showers, rooms with high humidity levels.

In addition to the house, the material is used for extensions and structures. A bathhouse, a sauna, a veranda and even an attic - during construction it is necessary to install a waterproof film. This will help avoid excess moisture and extend the durability of the insulation.

Types of films for waterproofing

For proper use, you need to distinguish between the types of waterproofing materials. This will help improve efficiency and avoid installation errors.

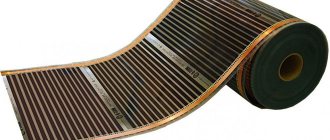

Polyethylene film for waterproofing

Polyethylene film is the most economical option, which is used for waterproofing floors, foundations and horizontal moisture insulation of walls.

- Moisture insulation;

- Sound insulation;

- Sliding layer.

The film layer ensures tightness, strength and ease of use. Its service life in conditions of being in the ground and under water exceeds 150 years. One of the disadvantages of polyethylene waterproofing is the possibility of its damage during installation.

For waterproofing foundations, polyethylene with a thickness of 400 microns (0.4 mm) is used, for floors - 200-400 microns.

It is recommended to lay a single piece of canvas over the entire surface of the room. If this is not possible, then an overlap of 20-30 cm should be made at the joints, along the walls the film should be folded 10 cm above the floor.

Film waterproofing membranes

A waterproofing membrane (also called polymer film fiber) is a material for protecting construction objects from moisture, consisting of many layers of polymer films.

Polyethylene film for foundation waterproofing

Polyethylene film for foundation construction ensures structural strength and stability under external influences. Waterproofing with such a film provides reliable resistance to moisture, but is extremely sensitive to sunlight and mechanical damage. Therefore, it is usually hidden underground. But here the second question arises - if the film is damaged, it will lose its water-repellent abilities. Therefore, the material is made from a special film that can withstand moderate loads. When pouring concrete, it often crumples and collapses, which requires special attention from a person when laying PVC film on the soil layer.

Polyethylene film

Foundation waterproofing film can provide high strength and reliability of the structure. If the work order is carried out correctly, the necessary strength can be guaranteed. Nowadays there are many types of waterproofing materials on the construction market.

How to choose a waterproofing film, requirements for it

Before purchasing, it is useful to familiarize yourself with the characteristics, study the advantages and disadvantages of a particular type of waterproofing film.

Manufacturers offer different options for foundations, walls, roofs, and floors. Special mention can be made of universal coatings. The material must meet the requirements and be in the middle price category. An incorrectly selected hydrobarrier film will lead to disastrous consequences and affect the service life of the structure.

It is preferable to purchase materials from manufacturers from Turkey, America and Germany. The cost is rarely inflated due to the brand; more often, a high cost indicates a long service life and excellent characteristics.

Read more about the manufacturer of waterproofing films here.

Installation features

Before starting work, you should prepare a complete set of tools:

- metal brackets that are useful for securing the rafters;

- self-tapping screws;

- sealant;

- construction knife;

- hacksaw;

- and a stapler.

- To simplify the process, it is recommended to use a low-speed drill.

The film is unpacked and rolled out. It is better to cut so that the insulation layer is at the bottom. Horizontal sheets are laid evenly overlapping each other. The canvas is fixed using a stapler on the rafters.

Important! During fastening, there must be some sagging in the material, but no more than two centimeters.

Where the sheets are laid overlapping, they are reinforced with polyurethane foam. Wooden boards are laid on top. To avoid negative consequences, they are treated with antiseptic solutions. The joints of the sheets must be pressed with slats to ensure maximum protection. The counter-lattice structure is placed on top, and the roofing material is placed on top.

If the question arises which side to lay the waterproofing film on, then the answer depends on its type. Basically, the material is laid so that its smooth side is adjacent to the insulation, with the pile facing outward. Under no circumstances should you confuse the side of installation. Most often, the manufacturer will mark the front side with a tape in a bright contrasting color.

Wood floor vapor barrier

Basically, the floors of a wooden house are placed directly on the ground. It is best to start creating a vapor barrier layer immediately during the construction of a house, so that you do not have to carry out major repairs.

Return to contents

Preparatory work

Before starting, you need to remove the old covering, clean floor and thermal insulation, only then can you begin laying the floor vapor barrier.

If the house is just starting to be built, then there will be fewer problems. First of all, all floor boards must be treated with a spray against rotting, fungus and all kinds of insects. This is especially significant for subfloors, which are closest to the ground. It is also necessary to lay this same floor; thermal insulation and vapor barrier will be laid on it.

If you have a wooden floor that has been lying around for a long time and you just want to make a major overhaul, then you need to remove the old covering and remove the clean floor, also remove the thermal insulation and everything that is left there. Then check the condition of the subfloor and joists and determine if there are any bad boards, which, if discovered, will have to be completely replaced. And only after this the installation of the vapor barrier of the ceiling will begin.

Return to contents

Laying material on the floor

In order to install a vapor barrier in your home, you need to follow simple steps that do not require special skills. For wooden floors, film materials are often used; one of the favorites is Izospan.

We lay isospan on the supporting frame of the subfloor; to attach the vapor barrier, use a construction stapler or galvanized nails.

We lay Izospan on the supporting frame of the subfloor, and we must ensure that the canvases overlap each other and the width is 15-20 cm. To attach the vapor barrier, you can use a construction stapler or galvanized nails, but manufacturers still recommend using adhesive tape. So, before you buy the material, you need to find out more about the fastening method. Using tape it is possible to create a solid coating without cracks. When laying it, be sure to make sure which side is facing the insulation so that moisture does not accumulate and spoil the insulation.

How to determine how much waterproofing film you need to buy

There are free online calculators on the Internet that will allow you to make accurate calculations. If the work is carried out by a construction company, the manager calculates the quantity.

If you need to calculate it yourself, then you need to proceed from the volume of work.

Polyethylene waterproofing film is sold in ready-made rolls (standard 75 square meters). 13% of the material is used for the overlap density (10 square meters). This means that when calculating, the area on which waterproofing needs to be done is divided into 65 square meters. This gives you the number of rolls you need to purchase.

Modern materials will provide protection from any external influence. Insulation can be tailored to climate conditions, especially low or high temperatures and even humidity levels. It is important that the installation proceeds without disturbances. Then the film will serve for many years, extending the life of the building and structural elements.