When thinking about whether it is possible to connect a heated floor without a thermostat, you should find out not only the opinion of a specialist, but also inquire about the design features, connection specifics and functionality of the system.

It is important not only to feel comfortable when stepping on a heated floor, which should not be too hot or cold due to low heating.

It is necessary to take care of saving energy and, accordingly, your own money. All this can be achieved by following the established rules and following the recommendations of experienced craftsmen.

Design features and functionality

Is it possible to connect a heated floor without a thermostat? Even if someone says that it is possible, an experienced master will answer no. The thermostat is an important component of the design.

Installation and use of additional equipment is carried out even before the pipe contours or heating mats are hidden by the finishing floor covering.

There are several objective reasons why installing a thermostat is considered necessary:

- A heated floor installed without a thermostat does not provide full comfort during its operation. It all depends on the design of the floor itself, what is used as a heating element, and what the maximum heating temperature is. If the coating heats up too much, then the thermostat will help regulate the heating and create the desired temperature in the room.

Operating a heated floor without a regulator will lead to overload of the heating element

- The constant operation of the underfloor heating system leads to the fact that the consumer is faced with increased energy costs. Timely and correct installation of the temperature sensor will allow you to set the desired level of heating of the system and, thus, save energy and material resources. The presence of such equipment will make it possible to refuse to connect the heated floor directly to the home network through an outlet, which means that the electricity consumption will not be constant, but through the “on”-“off” system. The smart device itself is able to turn off the equipment when the desired temperature level is reached.

- Caring for devices extends their service life. This also applies to the use of finishing floor coverings, which will deteriorate much faster if heating is carried out constantly.

Thermostat functions

Of course, when connecting underfloor heating to electricity, you can do without a thermostat - the system will still be able to work. But this approach has many more disadvantages than advantages.

The main task of the temperature sensor is to maintain the user-specified temperature in the room. Moreover, this happens automatically, without the intervention of the owners.

Thus, there is no need to constantly monitor the heating level of the room and manually turn the heated floor on or off. Another plus is safety. It is known that it is quite dangerous to leave the system on when leaving the house, so it is usually turned off. And when the owners return home in the evening, they find themselves in cold rooms. This is especially true in winter, when rooms quickly cool down.

Therefore, a temperature sensor is connected, at a minimum, for reasons of comfort.

Thermostat

Why do you need a thermostat?

The quality of room heating depends on what system is installed to provide it and what floor covering is laid on top.

Connecting the heated floor directly to the outlet guarantees the constant operation of the units, which means constant exposure to heat on the material laid as a covering.

The thermostat ensures optimal and precise control of cable systems designed for heating and heating applications. It is able to protect both the floor covering and the heated floor system itself from damage.

If laminate, carpet or linoleum is laid on the floor, the continuous flow of heat will lead to rapid failure of the floor covering and its rapid replacement. The laminate will begin to dry out, the seams and joints will separate and cracks will appear.

Is it possible to use heated floors without a thermostat?

Spoiler!

Using heated floors without a thermostat is definitely not allowed! Why? Let's figure it out.

What happens if you connect heating elements directly to the electrical network?

If the infrared film is connected directly to a power source, the film will be continuously heated until it reaches the maximum heating temperature. Depending on the model and manufacturer, the maximum heating temperature of a heated film floor can reach 50 °C, 70 °C, 150 °C or another value. If heat dissipation is poor, the heating film will fail and the floor covering will be damaged.

Connecting self-regulating films without a thermostat

When connecting a heating film with a self-regulating effect directly to a power source, as it heats up, its power will decrease due to an increase in resistance. This protects the film from local overheating when heat transfer from the floor surface deteriorates.

By reducing its power by 30% (Marpe Samreg PTC or Marpe Black Heat PTC 30%) or 50% (Marpe Samreg PTC+), the film will continue to heat up. Even though the maximum heating temperature of self-regulating films is limited and is often insufficient to cause them to fail, the floor covering may suffer.

Read more about the self-regulation effect in our article: How self-regulating infrared film works.

Why do you need a thermostat?

The thermostat for heated floors is designed to turn off the power supplied to the heating elements when the set temperature is reached. The thermostat allows you to control the temperature in the room, and when using thermostats with a floor and air temperature sensor, it prevents overheating of the heating elements of the heated floor and floor coverings.

Read more about how the thermostat works in our article: the principle of operation of the thermostat for heated floors.

What happens when it overheats

Let's look at what can happen to various floor coverings when overheated (the indicated temperatures are approximate and depend on the model and manufacturer, the exact values can be found in the product data sheet or by consulting the seller):

- When heated above +30 °C, the laminate may begin to creak, dry out, and release substances harmful to health.

- When heated above +26 °C, the parquet board may begin to creak and deform.

- When heated above +27 °C, natural linoleum can begin to melt and tear, and at +30 °C, PVC linoleum begins to lose color, swell, go in waves, and release phenol that is harmful to health.

- When heated above +27 °C, the carpet may begin to unravel and fade.

Thus, regardless of the type of heated floor and the floor covering used, the use of a thermostat is mandatory!

Still have questions?

You can get a free consultation on film heated floors, help in calculating the necessary components and choosing a thermostat by calling +7 or by email [email protected] .

Is it possible to connect a heated floor to an outlet?

We are talking about whether it is possible to use a heated floor without a thermostat and connect it directly to an outlet, like another household appliance (iron, vacuum cleaner).

There are, of course, features, which we will discuss below.

If it is a heating cable or heating mat . Such an installation will violate the technology described in the instructions. Therefore, this system is not covered by the warranty. We will write recommendations below.

Types of electric heated floors and thermostats

Now there are two types of electric heated floors:

- cable or sectional;

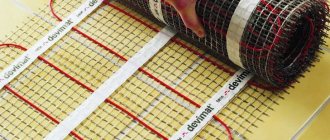

- mats, infrared film systems.

Cable heated floor

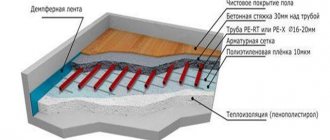

Each of these types has its own characteristics and is used in specific cases. So, if a warm floor is installed in a concrete screed, then it is better to use a cable type. Mats or film heating elements are best suited under the tiles.

Naturally, the main part of a warm floor is the heating element itself. But it works fully thanks to the thermostat, which is the heart of the system.

A thermostat for a heated floor is a device that, without human intervention, automatically regulates and maintains the optimal air temperature

It allows you to maintain the desired surface temperature. Buying a thermostat is not a problem: it can be either mechanical, with manual setting and temperature control, or fully automatic, with measurement of surface temperature, room air and selection of the most optimal parameters.

Thermostat for heated floors Electrolux ETT-16 Thermotronic Touch

Heating system without thermostat

Many people are interested in whether it is possible to connect a heated floor directly without a thermostat. Experts say this could, in theory, be done by connecting the system to a regular switch. However, you will have to constantly monitor the temperature in the room to prevent overheating and damage to the equipment. It also consumes too much electricity, so this method is inconvenient and unprofitable.

Without a thermostat, the heater runs constantly, raising the room temperature to maximum and consuming unnecessary energy. When the sensors operate, only those resources that are necessary to achieve the recommended temperature are extracted and consumed. Heated floors without a regulator can be connected, but only for a short time, so that there is no network overload and overheating of the floor covering with subsequent damage.

Temperature control

Thermostats for underfloor heating systems are available in many versions, ranging from a simple controller with a small wheel for manually setting the room temperature to a complex mini-computer with digital display and touch screen. There are also devices that are designed for a single room and thermostats that are used to regulate the temperature throughout the entire building at all times.

Many owners do not connect heated floors without a temperature sensor, even if this applies to electric mats, where self-regulation is possible. To control the temperature, thermostats are installed, which, using a built-in sensor, measure the actual value and adjust it according to the specified target parameters.

When choosing a model, you need to consider the installation location of the device. It should not be constantly exposed to direct sunlight or heat sources, as this will affect the temperature sensors. In addition, the thermostat should be placed so that it is always accessible and there is sufficient air circulation.

How to check a heated floor

Thermostat for water heated floors

Checking the floor for defects begins with some preparation. It includes checking the presence of electricity in the house, determining whether it is supplied to the temperature controller (usually it is enough to look at the indicator light that is on the device).

Next, if there is electric current, the temperature settings are checked. It happens that the regulator is simply set to minimum and it seems that the system is not heating. The position of the regulator should be carefully assessed to rule out this option. Only after you can make sure that everything is in order with the electricity supply, and the temperature is at the desired level, but the floor still does not heat up, you can move on to more serious diagnostic methods.

Attention! If a person is completely unfamiliar with electricity, then it is recommended to call a professional electrician for diagnosis to avoid injury. .

If you have at least some knowledge about electricity, then you can try to diagnose it yourself. To do this you will need to purchase a multimeter and a screwdriver. A voltage indicator helps replace a multimeter, but it is not always informative enough for accurate diagnosis.

Sometimes newly purchased equipment also needs to be checked.

But it is important to remember that an electrical cable that is not covered with a screed (especially one that is wound) cannot be turned on in the air. Of course, you can check it before filling it, but power is supplied for no longer than 5 minutes, and the wire must be completely unrolled.

Installing the Thermostat

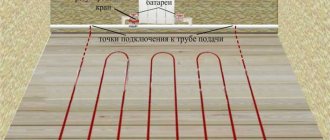

Before installation, it is necessary to draw a sketch, where the location of the sensor should be planned at a distance of at least 50 cm from windows and doors and only on internal walls. Up to three heating mats can be connected to the device.

If a room's electric underfloor heating system requires more than three heating mats, calculate several thermostats accordingly. The sensor must be between two heating cables, use the existing power connections to connect the power cord.

During installation, you need to perform the following steps step by step:

- In the pre-drilled groove in the wall and floor, install the thermostat and heating mat cables.

- Then place the temperature sensor between them (the curvature of the line must have a radius of at least 6 cm).

- After cleaning the surface, it is recommended to prime the ceiling for better adhesion.

- After laying, press the mats firmly to the base for optimal fixation, and attach the thermostat to the contacts.

- Then you need to fill the space with screed.

Before screeding and finishing work, you need to check the resistance with a multimeter. Before turning on the thermostat, you need to wait 8-10 days until the screed is completely dry.

Connecting a film infrared heated floor to a thermostat with your own hands

Film IR floor is a heating mat on which strips of carbon polymer are applied. Before installing the system, it is necessary to level the surface and lay thermal insulation.

Connection diagram for electric heated floor:

- Cut each infrared film mat to the required length and roll it towards the wall on which the thermostat is installed.

- Tape the joints of the IR sheets with tape not reaching the edges 10-20 cm. The thermal substrate should also be a single sheet with taped joints.

- Place one end of the terminal between layers of IR film. The second end of each terminal should be on top, on the side of the copper busbar.

- Clamp the terminals with pliers.

- Take a single-core wire and connect it to the terminal, clamp it with pliers.

- Connect each IR heating mat in series so that “phase” and “zero” are connected to the thermostat with two wires. Then the ground is connected.

- Insulate the terminals with bitumen tape.

- Also insulate the ends of the copper bars on the other side of the IR film strip.

- In order for the surface of the finishing coating to lie as smoothly as possible, you need to make holes in the insulating layer and “recess” the connections of the terminals with the wires into them.

- Connect the temperature sensor wire to the thermostat.

- Secure the sensor to the back of the IR film using tape.

- Check the system operation.

- The installation procedure for infrared film flooring can be considered complete. Next, linoleum, laminate, etc. are laid.

Advice! It is highly recommended to use a dense foam thermal underlay before installing the infrared floor. It is convenient to make holes and grooves in such material so that wires and connections can be hidden. The heating film mat will turn out “smooth” and the topcoat will lie perfectly.