Types of electric boilers

The following types of electric heating boilers are available on the market:

- heating elements . The heating element of such devices are tubular electrical elements. They are installed in the heat exchanger tank and ensure the operation of the boiler.

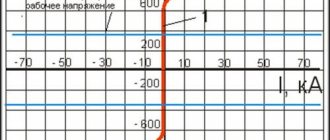

- Electrode . In this case, heating is carried out by supplying current to the water. Heating is possible due to the fact that water contains a certain amount of salts that allow electricity to pass through. When electricity is supplied, water particles move and heat up, providing heat transfer.

- Induction . In such devices, the heat exchanger is a ferromagnetic rod installed in a dielectric tube. When current passes through an inductor wound around a pipe, eddy currents arise, which generate heat.

In addition to boilers, you can find electric radiators on sale. Structurally, such devices are ordinary sectional batteries, each of which has its own heating element built into it. To create complete heating for your home, you will need several such devices - installing an electric heating boiler in a private house is good because its power initially covers all requirements, unlike radiators.

Features of electric heating equipment

There is a widespread belief that all types of electric heaters provide savings of about 30-40%, and installation of an electric heating boiler will be as profitable as possible. The values described are large, and in theory they allow you to save a significant amount on heating. As a rule, the reason for such efficiency is given as reduced power - i.e. When calculating a heating system, you need to assume that heating one square meter of room requires about 60 W of energy instead of the required 100 W.

Everything said in the previous paragraph is the erroneous opinion of most users. It is not advisable to compare direct heating devices in terms of efficiency, since they will all be equal. This statement is based on the law of conservation of energy, according to which energy cannot appear out of the blue and disappear into nowhere.

In relation to electric heating devices, this means that all generated energy will be converted into heat. Of course, this phenomenon will be accompanied by certain losses - nevertheless, part of the heat will certainly dissipate in the air and will not be transferred to the coolant. But the volume of losses directly depends on the insulation of the device body, and not on the type of heating equipment. In addition, the heat released outside will directly warm the room where the boiler is installed.

If we look at the problem from the other side, then heating is designed to compensate for heat losses, the amount of which is determined by:

- The quality of building insulation, which is completely independent of the efficiency of the heating boiler;

- The difference in temperature in the house and outside, which also does not depend in any way on the heating equipment used.

To summarize, we can definitely say that the type of heat source has no relationship with the thermal power required to heat the building - which means that the vaunted efficiency of electrical devices is simply absent.

However, this only applies to efficiency - each electrical device has special performance qualities:

- Electric radiators . Such devices load the electrical network evenly, so there are no wiring requirements.

- Induction boilers . Such heating equipment is compact and reliable. The latter quality is due to the fact that there is no heating element in the heat exchanger, and the power controller and coil are located outside, so water does not have any effect on them. In addition, induction boilers can work with any coolant.

- Electrode boilers . Differ in smallest sizes. Such boilers require constant replacement of electrodes, since they dissolve in water over time. Only water containing a certain amount of salts can be used as a coolant.

- Heating element boilers . The main problem of boilers with heating elements is the constant deposition of scale on the heating elements (this factor is irrelevant for closed heating circuits, in which the amount of salts is initially limited). In addition, these devices are quite large in size.

Tasks

Before undertaking the implementation of any project, you need to clearly formulate its goals. Here is their list.

Safety

It consists of three components:

- Reliable automatic shutdown . The electrical circuit must prevent electric shock to the user and ensure that the power is turned off in the event of a short circuit;

- Correct wiring calculation . When the boiler is operating at full power, it should not heat up: high temperatures can damage the insulation. This is especially important when installing hidden wiring;

- Coolant pressure control . As the temperature of water or antifreeze increases, their volume increases. In a closed circuit, this means a rapid increase in pressure, threatening pipes and radiators. The boiler piping circuit must prevent exceeding the critical pressure;

For a closed (that is, not communicating with the atmosphere and operating with excess pressure) autonomous heating system, the norm is 1.5 kgf/cm2, the maximum permissible pressure is 2.5-3 kgf/cm2.

Economical

An electric boiler is the source of the most expensive heat among all modern boilers for autonomous heating. The electrical power of a boiler with a minimum error is equal to its thermal power, that is, the price of a kilowatt-hour of thermal energy is equal to the cost of a kilowatt-hour of electricity (at the beginning of 2021 - about 5 rubles).

For comparison, the owner of a gas boiler costs heat 7-8 times cheaper (about 70 kopecks per kWh), and a wood-burning boiler costs four times less (1.2 rubles/kWh).

The main reason for the popularity of electric heating is its complete autonomy. The boiler does not require the owner’s attention from the word “at all”: it is capable of maintaining the temperature you set in the house indefinitely. However, the owner of an electric boiler, of course, wants to reduce his electricity bills. I will tell you how to do this in the corresponding section of the article.

Electric boiler wiring

The piping of electric heating boilers should include the following elements:

- Circulation pump . This piping element ensures the movement of coolant along the heating circuit, thereby ensuring heat transfer to heating devices.

- Expansion tank . The key purpose of the expansion tank is to receive excess coolant when it overheats excessively. The absence of a tank can lead to rupture of pipes or damage to elements of the heating system.

- Safety valve . Using a safety valve, excess coolant is discharged into the sewer. The valve only works in emergency situations - for example, when water boils when the pump stops or when the tank overflows. The pressure at which the valve operates is usually equal to the maximum pressure in the system.

- Automatic air vent . This element ensures independent removal of air from the heating system circuit. In the absence of an air vent, coolant circulation will be difficult, and the system itself will make a lot of noise.

- Pressure gauge . The presence of a pressure gauge makes it possible to monitor the pressure level in the heating system pipeline. The pressure gauge scale must be designed for at least 4 bar.

The expansion tank, air vent and safety valve are a safety group of the heating boiler. The installation of an electric boiler in a private house must be accompanied by the installation of a security group.

Installation stages

Installation of the harness consists of several stages:

- First, marking and installation are done. To avoid a short circuit in the event of a boiler leak, it is placed away from the water supply. To install this device, dowels or anchor bolts are used. The boiler is leveled horizontally and vertically using a level. When choosing a floor-standing model, place a special stand under it.

- Then the electric boiler is connected to the heating system using adapters and couplings. Before this, the water is first shut off using taps of any type.

- After completing the connection of the boiler to the system, it is necessary to complete the electrical part of the structure, which consists of an RCD and a circuit breaker. To connect the boiler it is necessary to make grounding. All electrical cables are placed in a special casing and laid in channels intended for wiring. The cable cross-section depends on the power of the equipment.

- After the electrical part, grounding is done and the heating system is tested.

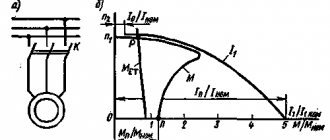

Selecting a circulation pump

For a circulation pump, two parameters are important - pressure and performance. The amount of pressure in most cases is practically irrelevant. The minimum pressure for the weakest pumps is 2 meters, which is quite enough to ensure normal operation of the heating system of any private home.

Pump performance is more important and the following formula is used to calculate it:

- Q = 0.86 * R / Dt, where

- R – total radiator power or boiler power,

- Dt is the temperature difference in the supply and return circuits (in autonomous systems this value is 20 degrees).

Boiler piping location

Each strapping element must be installed in a strictly defined location:

- The pump is mounted directly in front of the boiler, in the area where the coolant temperature is minimal;

- The safety group is installed behind the boiler, since it is at this point that the pressure increases the most when circulation stops;

- The expansion tank can be installed anywhere, but no closer than twice the pump pressure when installed before it, and no closer than eight times the pump pressure when installed behind it (if these requirements are not met, the tank membrane will wear out too quickly).

In boilers with heating elements, all piping elements are often mounted in the equipment itself, i.e. it turns out a smaller copy of a full-fledged boiler room. Do-it-yourself installation of an electric boiler with heating radiators is usually carried out in a circuit break using two ball valves, which allow, if necessary, to turn off the boiler without draining all the coolant.

Connecting the boiler to the electrical network

The do-it-yourself electric heating boiler connection diagram is implemented in accordance with a number of rules:

- You can connect any electrical devices with a power of no more than 3.5 kW to the outlet;

- Equipment with a power of up to 7 kW can be connected to the distribution panel (in this case, the important factor is the cross-section of the wire);

- With boilers with a power of over 8 kW, there is a special conversation - usually such boilers have a three-phase circuit, and connecting a three-phase heating boiler to the electrical network is only possible if the latter is designed for 380 V;

- You can also connect an electric boiler with your own hands through a separate machine, and the operating limit of the machine should only be one step higher than the maximum operating current.

Connection diagram of an electric boiler to a 380 V power supply (three-phase)

The general electrical diagram for connecting a 380 V electric boiler is as follows:

As you can see, the line is protected by a three-phase residual current circuit breaker; grounding is necessarily connected to the boiler body.

As usual, according to tradition, I am posting a connection diagram for a three-phase electric boiler with a combination of an automatic switch (AB) plus a residual current device (RCD) in a circuit, which is often cheaper and more accessible than Diff. machine.

It is convenient to select protective automatic ratings and cable cross-sections for three-phase electric boilers of various capacities using the following table:

In three-phase electric boilers, three heating elements are usually installed at once, sometimes more. Moreover, in almost all household boilers, each of the tubular electric heaters is designed for a voltage of 220 V and is connected as follows:

This is the so-called “star” connection; for this case, the neutral conductor is connected to the boiler.

The heating elements themselves are connected to the network as follows: one end of each of the tubular electric heaters is connected by a jumper, the remaining three free phases are alternately connected: L1, L2 and L3.

If your boiler has heating elements designed for a voltage of 380 V, their connection diagram is completely different and it looks like this:

This connection of the heating element of an electric boiler is called a “triangle” and at the same voltage of 380 V, as in the previous “Star” method, the boiler power increases significantly. In this case, a neutral conductor is not required, only phase wires are connected, and the electrical connection diagram looks like this:

Do not deviate from the connection diagrams acceptable for your electric boiler, if there are heating elements for 220V with a three-phase connection, do not change the circuit to a “triangle”. As you understand, theoretically you can reconnect them and get a voltage of 380 V on the heating element, respectively, increasing their power, but in this case they will most likely simply burn out.

How to determine the correct connection diagram for heating elements with a star or triangle and, accordingly, what voltage they are designed for?

If the instructions for connecting your electric boiler are lost or there is simply no way to refer to them, you can determine the correct connection diagram at home as follows:

1. First of all, inspect the terminals of the heating element; most likely, the manufacturer has already prepared the contacts for a specific circuit. So, for example, for connecting a star and heating elements for 220V, three terminals will be connected by a jumper. 2. The very presence of the zero terminal - “N”, indicates that the heating elements are 220 V and they must be connected according to the “Star” circuit. At the same time, its absence does not mean that the heating element is 380 V. 3. The most reliable way to find out the voltage of the heating element is to look at the markings indicated either on the flange to which the tubular electric heaters are attached

Or, on the heating element itself, its parameters are necessarily extruded:

If you cannot find out for sure the voltage for which your electric boiler is designed and the connection diagram for its heating element, but you “really need to” connect it, I advise you to use the “Star” circuit. With this option, if the heating elements are designed for 220 V, they will work normally, and if they are rated at 380 V, they will simply produce less power, but most importantly they will not burn out.

In general, there are different cases, and it is very difficult to cover them all in the format of one article , so be sure to write your questions, additions, stories from personal experience and practice in the comments, this will be useful to many!

Pipes for electric boilers

The issue of choosing heating pipes is quite important and always requires a lot of effort. However, installing an electric boiler in a private house does not impose any special requirements on pipes - it is quite possible to use the same metal, plastic and metal-plastic pipes that are used to install any heating systems.

Nuances arise only when using polypropylene pipes:

- Do-it-yourself installation of an electric heating boiler is only possible when using pipes reinforced with aluminum foil - this material compensates for the thermal expansion of the pipe when heated and will reduce it several times. It is very important that the connection of the electric boiler to the heating system is carried out by a specialist.

- Long straight sections of pipeline must be equipped with compensators. Compensators of any type are suitable - U-shaped, ring and bellows. These elements will prevent pipes from bending when heated coolant passes through them.

- Straight sections of the pipeline can only be secured with movable fasteners, for example, sliding clamps.

- When laying pipes in the walls, the grooves must be made with a small margin - this will prevent the destruction of the groove seal when the pipeline expands.

Heating devices

If the installation of an electric boiler has virtually no effect on the efficiency of the heating system, then the same cannot be said about heating devices - heat transfer directly depends on the choice of these elements. The most effective design that works great in combination with electric boilers is underfloor heating.

Structurally, heated floors are tubular heat exchangers located under the floor covering or screed. During operation, they release energy to the entire floor surface, thereby ensuring uniform heat distribution.

Using heated floors provides several advantages:

- Warm floors are one of the most comfortable heating systems. The thing is that first of all, heat is transferred to the floor, so it becomes warm to the touch, and you can happily walk on it without shoes. With increasing altitude, the temperature decreases, due to which the most comfortable temperature regime for the human body is formed.

- The use of heated floors allows you to reduce the average temperature in the room. Classic convection heating assumes that to maintain a temperature of 20 degrees, you need to heat the air under the ceiling to 30 degrees. As a result, the average temperature will be about 25 degrees. In the case of heated floors, to maintain 20 degrees, you can warm the floor to 22 degrees. The temperature under the ceiling in this case will be about 18 degrees, and the average value will remain at the proper level. Due to this phenomenon, it is also possible to reduce heat loss, since the temperature difference in the house and outside decreases.

To do without coolant, you can install a heating system from cable or film heated floors. Such designs allow you to maintain a stable temperature regardless of external factors.

Boiler selection and connection diagram

When choosing a device, you should not rely on recommendations from sellers. All devices use electricity the same.

There are no “energy-saving” or other economical devices among them. This is a marketing ploy by sellers. When choosing, you should pay attention to how the boiler will be used.

So, electrode devices are the cheapest, but they have limitations; they cannot be used with heated floors. But induction ones are quite expensive, and repairs are only possible in a workshop.

The connection diagram for an electric boiler does not depend on the type of heater. Household devices are mounted on the wall. The wall should be reliable, better if it is load-bearing. For installation of devices, a special boiler room or furnace room is usually allocated.

If the installation is carried out in a wooden house, then an iron or basalt gasket is installed between the boiler and the wall. To connect an electric boiler, a circuit is assembled in the boiler room. Which is a control panel.

With circuit breaker and RCD device. In addition, the electric boiler connection diagram includes an automatic temperature control system. All supply wires must be laid in a protective armor sleeve.

And the location of the wires should be higher than the water pipes. If a leak occurs, the wiring will remain dry and there will be no short circuit. If the house is large enough, then warm floors are often installed.

In this case, the connection diagram for the electric boiler includes the installation of an electric pump, and energy savings can be achieved by installing a two-tariff meter.

Electrical installation in a three-phase network

The diagram for connecting an electric boiler to a three-phase network is more complex, but even a beginner can do it.

The three phases must be connected as follows:

Please pay attention to the following nuances:

- Each water heater comes with a technical passport, which must indicate the manufacturer’s recommended wiring diagram for the electric boiler. Be guided only by this document in your case, because... The examples provided on the Internet may not always be suitable for your heating system.

- Be sure to protect the boiler with a circuit breaker and RCD. These devices will prevent overload of the unit, short circuit and current leakage in the electrical network.

- The wiring must be grounded.

For your attention, a visual project of electric heating in a two-story dacha using a boiler:

In addition, we recommend watching a video that clearly demonstrates connecting a 380 V electric boiler:

Related materials:

Greetings, comrades! Do you know how to connect an electric boiler to electricity? Are you interested in what elements should the boiler piping include? Today I want to answer these questions in detail and as clearly as possible and tell you which electric boiler connection diagram will allow you to heat your home at minimal cost.

Heating system installation

When installing the device, the following conditions must be met:

- The distance to the ceiling must be at least 80 cm;

- When mounted, the distance to the floor should not be less than 50 cm;

- The minimum distance from the body to the walls is 5 cm or more;

- There must be at least 50 cm to the pipelines;

- A distance of 70 cm is recommended in front of the boiler.

With this arrangement, there will be no difficulties with both operation and repair. To ensure safe operation, when choosing wires, you must focus on the connected power.

Selecting a connection cable

Providing the cottage with hot water supply

There is often a need to provide hot water. This can be solved in several ways:

- Install a double-circuit heating unit;

- Connect an indirect heating boiler to the single-circuit boiler;

- Install a separate water heater (boiler), which provides autonomous hot water supply.

In the case of installing an autonomous water supply, it is necessary to connect pipelines with hot water to consumers.

And the connection diagram for an electric water heater is carried out separately and is not synchronized with the heating. This connection diagram involves connecting the electric water heater to a separate control panel, where circuit breakers are installed, and an RCD is also mounted. The selection of wires is carried out based on the installed power conditions.

When selecting a section, you can rely on the table below. This is a typical scheme for turning on hot water supply when the boiler requires a separate connection.

Using a double-circuit boiler does not require any changes to the electrical connection circuit. Hot water supply pipes are connected to the second circuit of the device.

However, both options are not particularly economical.

In order to make fuller use of the heating capabilities, a scheme is used where an indirect heating boiler is mounted to the boiler and is connected to the heating pipes using a three-way valve connected to the boiler.

It is controlled by an electrical signal from the automation. This connection has its advantages. This is the use of heating water for secondary heating of hot water coolant. The boiler itself does not have its own heating element.

What is the distinctive feature of such containers? In houses with an average family, it is enough to install a tank of 500 liters to meet the needs for hot water. At the same time, you can significantly reduce the cost of heating water.

The use of storage tanks can reduce the cost of heating water. When used correctly, heating occurs at night when the night tariff is in effect.

During the day, heated hot water will be consumed. Despite the obvious advantages of this scheme, there is a drawback. When the water is heated, a three-way valve in the boiler disconnects the batteries from the boiler. All the heat goes to heating the liquid in the tank. If the container is large and the power of the heating boiler is not high, there is a danger in cooling the house.

The automation is configured in such a way that the boiler has priority when heating. The valve will switch only after the water has heated to the set temperature. When organizing such water supply, this factor should be taken into account.

With this hot water supply scheme, the water is heated only in the cold season, when the heating is on. In summer it is necessary to connect an additional boiler. Which is an additional inconvenience.

Connecting an electric boiler to a heating system

Wall-mounted mini-boiler rooms with a built-in expansion tank, pump and safety group are operated in closed heating systems with forced circulation, operating under pressure. The connection is extremely simple and does not require display in the form of a diagram: the supply and return pipelines are connected to the corresponding pipes of the electric boiler.

Note. The automation of such heat generators monitors the pressure in the heating network using a sensor. If the coolant pressure is below the set threshold (usually 1 Bar), the device will not turn on.

Next, we would like to present typical diagrams for connecting electric boilers to heating systems for the following cases:

- when you need to install a unit that is not equipped with its own pump and expansion tank;

- parallel operation in tandem with a solid fuel or gas boiler;

- piping with buffer tank;

- connecting the dual-circuit version of the unit to the heating and hot water mains;

- connection to an indirect heating boiler.

The safety group protects the system from overpressure and relieves excess air.

The first diagram illustrates the connection of an electrode or induction boiler to a closed-type heating network with a membrane expansion tank. A safety group is installed on the direct outlet section of the supply pipe, followed by a shut-off ball valve. The pump and filter - sump filter are equally well placed on the supply or return side.

Note. This and subsequent diagrams do not conventionally show the make-up pipeline. It should be inserted into the heating return line.

The heating element version of the electric boiler, which is not equipped with an expansion tank, safety group and pump, is connected in a similar way. If it is necessary to organize a connection to an open-type gravity (gravity) heating system, then the pipelines are laid with a slope of 3 mm per linear meter, and the circulation pump is mounted on the bypass.

The ability to work by gravity does not give the circuit a big advantage - without electricity, the boiler will still turn off

An open expansion tank is located at the top point of the network. To ensure stable gravity flow, the manufacturer of electrode boilers “Galan” recommends maintaining the height of the vertical section between the heater and the tank at 2 meters. Accordingly, the tank is placed in the attic of a private house.

Comment. Installing a wall-mounted electric boiler, whose pipes face downwards, will not allow the coolant to circulate naturally due to convection. An example is units of the Evan or Proterm brand. Heaters with side and top fittings - “Galan”, “VIN” and the like - are suitable for gravity systems.

Connection with other boilers and heat storage tank

To connect an electric heat generator together with a solid fuel boiler, use a circuit with two check valves, a surface-mounted thermostat and a room temperature controller. This connection option provides automatic “pickup” of the cooling system by the electric boiler after the firewood load burns out.

Check valves prevent the coolant from flowing into the adjacent circuit and moving in the opposite direction

The algorithm of the circuit looks like this:

- The TT boiler acts as the main one, the electrical apparatus is in standby mode.

- When a portion of firewood or coal burns, the air temperature in the building begins to decrease. When cooling reaches a user-set threshold, the room thermostat turns on the electric heater.

- An overhead thermostat detects a drop in temperature in the return of a solid fuel boiler and turns off its pump.

- After loading firewood into the firebox, heating is resumed and the thermostat starts forced circulation. Using its own sensor, the electric boiler “sees” the heated coolant and does not start working until the next command from the thermostat. The expert explains the operating principle in more detail in the following video:

Note. The piping method is also suitable for other types of boilers - gas, diesel, and so on. Please note one nuance: the electric heater is used here as a backup heat source.

Connecting to a buffer tank, shown in the next diagram, also allows you to combine several heat sources and accumulate a sufficient amount of energy in the tank. The heat accumulator is very useful in a situation where the electric heater operates at night, taking advantage of a cheap tariff. During the day, the device is inactive, and the building is heated with heat from a buffer tank.

In this scheme, you can organize the operation of the electric heater according to a schedule using a timer

The task of the mixing unit with a three-way valve is to supply the radiators with water at the required temperature, because the heat accumulator is “charged” to 80-90 °C. If the rooms have underfloor heating water circuits, a second mixing unit is made for them, preparing the coolant at a temperature of 35-45 °C (maximum - 50 °C).

Schemes with hot water supply

There are two ways to get hot water from an electric boiler for household needs:

- purchase and install a double-circuit heating unit;

- connect an indirect heating boiler to a single-circuit boiler.

In the first case, the device is connected according to the standard diagram shown in the picture. There are a minimum of difficulties here; the main thing is to correctly install the shut-off valves.

For ease of cleaning, the mud pans should be in a horizontal position.

The connection with the indirect heating boiler is carried out through a three-way switching type solenoid valve. At the command of the thermostat built into the storage tank, the element switches the coolant flow to heat water for hot water supply or heating radiators. Loading the boiler is a priority: until the tank warms up to the set temperature, the radiator network will not receive heat.

Basic rules for installation

When installing a heating system, you should adhere to basic safety rules. All devices must be grounded, i.e., a ground loop must be installed near the cottage or individual house.

This requirement is mandatory for using a three-phase voltage of 380 V. But even when using low-power boilers when connected to a 220 V network, it is also desirable to have a grounding loop.

To ensure that the connection of the electric heating boiler does not fail during the heating season, installation and calculations should be entrusted to professionals.

Which will make calculations of the thermal load. Using the volume of the room, and based on the data obtained, select the required boiler and boiler. After which they will calculate the electrical cables, switching and protective equipment.

From the previous article on how to choose an electric boiler, we know that there are three methods for heating the coolant. Accordingly, there are three types of boilers: heating element, induction and electrode. Today we will tell you about connecting an electric boiler to a heating system. Installation is carried out in two stages. The first stage is connecting to the heating system, and the second - to the electrical network. Considering that the units can operate on both 220 and 380 volts, the connection diagrams to the power source are slightly different. You need to know how to properly connect an electric heating boiler to a network with different power levels.

Boiler heating element connection diagrams

Option 1. Connection diagram to a single-phase network

Typically, three single heating elements in such a design are placed so that the contacts from different heating elements are located opposite each other.

To connect a heating element to 220 Volts, you need to connect three contacts from different single spirals with a jumper and connect them to the working zero.

The three remaining contacts also need to be connected and connected to the working phase. This will ensure that all heating elements are turned on simultaneously for heating when power is applied.

However, the connection is not made directly this way, and for every second contact the heating element is connected to a phase after its own machine or, what is done more often, it is connected from its own control line (automation).

Option 2. Three-phase connection

If we look at the heating elements for boilers sold, we will see that almost all of them are labeled as 220/380 Volt heating elements.

If you have this version of the heating element, and you have the opportunity to connect to a three-phase power supply of 220 Volts or 380 Volts, then you need to use connection diagrams called “star” and “delta”.

According to the “star” circuit of 220 Volts, three phases, you need to connect the three contacts of single heating elements with a perm and connect them to the working zero. Apply to the second free contacts via a phase wire. Each single heating element will operate from 220 Volts, independently of each other.

According to the “triangle” circuit of 380 Volts, you need to connect contacts 1-6, 2-3, 4-5 with jumpers, for single heating elements 1-2.3-4.5-6 and supply phase wires to them. Each single heating element will operate at 380 Volts, independently of each other.

Connecting a heating element electric boiler

Please note that electric boilers do not require a chimney.

The heating element electric boiler is the most common for heating residential premises. This is because it is cheap and easy to maintain. Connecting an electric boiler to a heating system using heating elements begins with allocating space for its installation. In principle, it does not matter where to put it, the main thing is that it is convenient for you. Such units do not emit any gases, so they do not need a chimney, unlike a gas boiler. We talked about installing a chimney in a heating system in one of the previous articles.

Tools and materials

Installation and installation of an electric boiler requires the use of

:

- tape measure, building level, pencil or marker;

- hammer drill/electric drill;

- fasteners (the diameter of the anchors must correspond to the diameter of the drill);

- electrical wires, cables (the cross-section is determined at the stage of preparation for installation);

- metal or metal-plastic pipes;

- fittings, fittings corresponding to pipes.

It is also important to have a pre-prepared diagram for installing the electric boiler in the heating system and the user manual that comes with the unit.

Connecting an electrode electric boiler

Please note that the pump is not positioned correctly.

The electrode boiler is the smallest representative in the niche of home heaters. Sure, there are different models with multiple electrodes, but the most common and well-known is the small single-electrode boiler. Such a unit can be installed on the circuit either in a vertical or horizontal position. In addition, the circuit for connecting an electric boiler to a heating system may consist of several heaters. They can be assembled into unique registers from boilers by serial or parallel connection.

The device does not have a built-in safety group, therefore the connection diagram for the electric heating boiler after it in the supply provides for:

- pressure gauge;

- air vent;

- emergency valve.

It is very important to make reliable grounding. The coolant is heated by electric waves; if the grounding falls off, someone who touches the pipes will receive an electric shock.

Devices up to seven kilowatts operate on 220 volts. More powerful units require a 380 volt network. Location of contacts on the electrode boiler:

- the electrode is a phase (one or three contacts, depending on the network 220 or 380 volts);

- the housing is zero and grounding.

Electrical diagram for connecting an electric heating boiler:

This diagram shows how to connect an electrode boiler to a three-phase network.

Only phase wires are suitable for the electrode, and on the body there are two contacts with zero and ground. The pump is connected via the control unit. The minimum that should be included when connecting electric heating boilers is temperature sensors that regulate the operation of the heater. It is possible to assemble any control that suits your operating conditions. You need to install a pump in front of the electrode boiler, despite the fact that even without it the boiler is capable of raising water several meters. Connecting an electric heating boiler of the ion type is impossible without salt preparation of the coolant.

Such units can only work if the water in the system has a certain level of salt. By adjusting the amount of salt in the water, you can reduce or increase the resistance of the coolant. The boiler passport contains a plate that indicates the necessary parameters for the heater to operate, such as current strength. It is inversely proportional to the amount of salt in the coolant. To control the quality and composition of the coolant, it is better to install a special filter for it.

To make water heating with your own hands you will need a tool and minimal skills. There is nothing particularly difficult if everything is done in a timely manner and correctly.

Interesting facts about heating a country house with hydrogen can be read at this address.

Connection diagram of an electric boiler to a 220 V power supply (single-phase)

As you can see, the 220 V boiler supply line is protected by a differential circuit breaker, which combines the functions of an automatic circuit breaker (AB) and a residual current device (RCD). Also, it is mandatory to connect grounding to the device body.

The heating elements or heating elements (if there are several of them) in such a boiler are designed for a voltage of 220V, respectively, a phase is connected to one end of the tubular electric heater, and zero is connected to the other.

To connect the boiler, you need to lay a three-wire cable (Phase, Working zero, Protective zero - grounding).

If you were unable to find a suitable differential automatic switch or it is simply too expensive in the line of protective automatics you have chosen, you can always replace it with a combination of Circuit Breaker (AB) + Residual Current Device (RCD), in which case the diagram for connecting a single-phase boiler to the electrical network looks like So:

Now all that remains is to select the cable of the required brand and cross-section and the ratings of the protective automatic equipment for proper electrical wiring to the electric boiler.

When choosing, you need to start from the power of the future boiler, and it is best to count with a reserve, because in the future, if you decide to change the boiler, you will no longer be able to choose an older model (more powerful), without serious alterations to the wiring.

I will not burden you with unnecessary formulas and calculations, but will simply lay out a table for selecting cables and automatic protective equipment depending on the power of a single-phase 220 V electric boiler. Moreover, the table will take into account both connection options: through a differential switch and through a combination of Circuit Breaker + RCD.

For installation, the characteristics of a copper cable of the VVGngLS brand, the minimum permissible PUE (electrical installation rules) for use in residential buildings, will be indicated, while calculations are made for a route from the meter to the electric boiler 50 meters long; if your distance is greater, you may need to adjust the values.

Table for selecting protective automatic equipment and cable cross-section according to the power of a 220 V electric boiler

The residual current device (RCD) is always selected one step higher than the circuit breaker paired with it, but if you cannot find an RCD of the required rating, you can take the protection of the next level, the main thing is not to take it lower than required. There are usually no particular difficulties or discrepancies when connecting a 220V electric boiler, so we move on to the three-phase version.

Connecting an induction electric boiler

This is how an induction electric boiler is suspended. The fastening must be reliable, it is quite heavy.

The most common induction boiler has the shape of a pipe with a cross-section of about 20 cm and a length of almost a meter. This is a domestic product called “VIN”. The electric boiler is connected to the heating system through two pipes:

Such a boiler does not have any additional circuits, only high-temperature heating circuits. The device is hung on a wall no lower than 80 cm, with nothing touching the body along the perimeter of 30 cm. Circulation without a pump is impossible. The supercharger is placed, as always, in front of the boiler. A safety group for the heating system is installed at the supply. Under the cover of the device there is access to the terminals. There can be two or four of them, depending on whether the unit is three-phase or single-phase. The device must be grounded.

An induction boiler can easily cope with large volumes of coolant, so its installation can be accompanied by the installation of a heat accumulator. These are tanks containing coolant with a volume of 200 liters or more. The average size of a heat accumulator is 300-500 liters. It collects heat and releases it when the boiler is turned off, thus increasing the time between turning on the heater.