Existing designs of wind generators cannot yet fully compete with the most efficient methods of generating electricity. The reason for this is the low productivity, which is ultimately a consequence of the low efficiency of the wind generator.

There are a lot of reasons, the combination of which reduces the efficiency of the device, many of them relate to the design area, others are subtle effects, but together they form an extremely stable barrier to improving the basic operating parameters. The issue is quite complex and deserves more detailed consideration.

Wind turbine performance

Efficiency is not the only qualitative indicator of the performance of a wind generator. It is noteworthy that for the end user efficiency in itself is not of practical interest, since it is too general a concept. For the device owner, more specific and targeted parameters are much more interesting:

- power

- performance

- minimum and maximum wind speed

- rotor type

- maintainability

- mast height

In practice, there may be interest in other characteristics of the installation, depending on the degree of their influence on the state and results of operation of the device. For industrial samples manufactured at the factory, familiarizing yourself with the detailed technical characteristics is not difficult - they are all indicated in the device passport.

It’s another matter if the windmill is created independently. Then there is no point in relying even on calculated data, since in practice they may not be confirmed and differ significantly from the design data. Therefore, it is necessary to test the newly created wind generator in every possible way, testing and taking readings at different wind speeds, operating modes and other operating conditions.

How to calculate a wind generator using formulas

Alternative energy obtained from wind power plants is of high interest in society. There is a lot of evidence of this at the level of real everyday practice.

Country property owners build windmills with their own hands and are satisfied with the result, although the result can be short-lived. The reason is that during the construction of the installation, the wind generator was not calculated properly.

articles:

- Calculation of a wind generator installation How to calculate the power of a wind turbine

- Calculation of wind turbine propellers

- Selection of generators for wind turbines

- Calculation and selection of charge controller

- Selecting a battery for the system

- Calculation of an inverter for a home windmill

Wind turbine calculation

Where to start calculating a system for generating electricity from wind energy? Considering that we are talking about a wind generator, a preliminary analysis of the wind rose in a specific area seems logical.

Calculation parameters such as wind speed and its characteristic direction for a given territory are important design parameters. To some extent, they determine the level of wind turbine power that will actually be achievable.

It’s hard to even imagine wind generators of such power. But such designs exist and work effectively.

However, calculations of such structures show relatively low power compared to traditional energy sources

What is noteworthy is that this process is long-term in nature (at least 1 month), which is quite obvious.

It is impossible to calculate the maximum probable parameters of wind speed and its most frequent direction with one or two measurements. Dozens of measurements will be required. However, this operation is really necessary if there is a desire to build an effective productive system.

How to calculate the power of a wind turbine

Wind generators for domestic use, especially those made by hand, have never surprised people with high power. This is understandable. One has only to imagine a massive mast 8-10 meters high, equipped with a generator with a propeller blade span of more than 3 meters. And it's not the most powerful setup. Just about 2 kW.

To service wind turbines of this power, helicopters and teams of specialists numbering up to a dozen people are used.

To calculate such a power plant, an even larger number of performers are involved

In general, if you rely on a standard table showing the relationship between the power of a wind generator and the required span of the propeller blades, there is something to be surprised about.

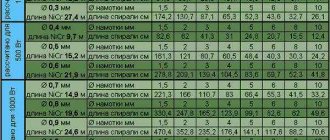

According to the table, a 10 W windmill requires a two-meter propeller. A 500-watt design will require a screw with a diameter of 14 meters. In this case, the blade span parameter depends on their number. The more blades, the smaller the span.

But this is just a theory, conditioned by wind speeds not exceeding 4 m/sec. In practice, everything is somewhat different, and the power of household installations that actually operate for a long time has never exceeded 500 W. Therefore, the choice of power here is usually limited to the range of 250-500 W with an average wind speed of 6-8 m/sec.

Table of the dependence of the power of a wind energy system on the diameter of the rotor and the number of blades. This table can be used for calculations, but taking into account its compilation for wind speed parameters up to 4 m/sec

From a theoretical position, the power of a wind power station is calculated using the formula:

N=p*S*V3/2

Here p is the density of air masses; S – total blown area of the propeller blades; V - air flow speed; N – air flow power. Since N is a parameter that dramatically affects the power of a wind generator, in fact, the actual power of the installation will be close to the calculated value of N.

Calculation of wind turbine propellers

When constructing a windmill, two types of propellers are usually used:

- Rotation in a horizontal plane (vane-type).

- Rotation in a vertical plane (Savonius rotor, Darrieus rotor).

Screw designs with rotation in any plane can be calculated using the formula:

Z=L*W/60/V

For this formula: Z – degree of speed (low speed) of the propeller; L – size of the length of the circle described by the blades; W – speed (frequency) of rotation of the propeller; V – air flow speed.

This is what the design of the screw called the “Darieu Rotor” looks like. This version of the propeller is considered effective in the manufacture of wind generators of small power and size.

The calculation of the screw has some features

Based on this formula, you can easily calculate the number of revolutions W - rotation speed. And the working relationship between revolutions and wind speed can be found in tables that are available on the Internet.

For example, for a propeller with two blades and Z=5, the following relation is valid:

| Number of blades | Degree of speed | Wind speed m/s |

| 2 | 5 | 330 |

Also, one of the important indicators of a windmill propeller is the pitch. This parameter can be determined using the formula:

H=2πR* tan α

Here: 2π – constant (2*3.14); R – radius described by the blade; tan α – section angle.

Selection of generators for wind turbines

Having the calculated value of the number of screw revolutions (W), obtained using the method described above, you can already select (manufacture) the appropriate generator. For example, with a degree of speed Z=5, the number of blades equal to 2 and a speed of 330 rpm. at a wind speed of 8 m/s, the generator power should be approximately 300 W.

Cross-sectional view of a wind power plant generator.

Demonstrative example of one of the possible designs of a home wind power system generator, assembled independently

Given these parameters, a suitable choice as a generator for a domestic wind power plant may be the motor used in the designs of modern electric bicycles. The traditional name of the part is bicycle motor (made in China).

This is what an electric bicycle motor looks like, on the basis of which it is proposed to make a generator for a home windmill. The design of the bicycle motor is ideal for implementation with virtually no calculations or modifications. However, their power is low

The characteristics of an electric bicycle motor are approximately as follows:

| Parameter | Values |

| Voltage, V | 24 |

| Power, W | 250-300 |

| Rotation speed, rpm. | 200-250 |

| Torque, Nm | 25 |

A positive feature of bicycle motors is that they practically do not need to be altered. They were structurally designed as low-speed electric motors and can be successfully used for wind generators.

Calculation and selection of charge controller

A battery charge controller is required for any type of wind power plant, including a domestic design.

The calculation of this device comes down to selecting the electrical circuit of the device, which would correspond to the design parameters of the wind system. Of these parameters, the main ones are:

- rated and maximum voltage of the generator;

- maximum possible generator power;

- maximum possible battery charging current;

- battery voltage;

- ambient temperature;

- ambient humidity level.

Based on the presented parameters, you can assemble it yourself or select a ready-made battery charge monitoring device - a controller.

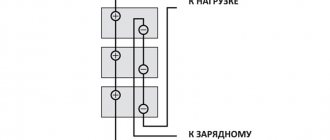

Charge controller for batteries used as part of a wind power plant.

An industrially manufactured device, when choosing which you only need to carefully study the technical characteristics for precise coordination with the existing system

Of course, it is advisable to select (or assemble) a device whose circuit would provide an easy start function in conditions of weak air flows.

A controller designed for operation with batteries of different voltages (12, 24, 48 volts) is also welcome. Finally, when calculating (selecting) the controller circuit, it is recommended not to forget about the presence of such a function as inverter control.

Selecting a battery for the system

In practice, different types of batteries are used and almost all are quite suitable for use as part of a wind energy system. But a specific choice will have to be made in any case. Depending on the parameters of the windmill system, the battery is selected based on voltage, capacity, and charging conditions.

Traditional components for home windmills are classic lead-acid batteries. They showed good results in a practical sense. In addition, the cost of this type of battery is more reasonable compared to other types. Lead-acid batteries are particularly unpretentious to charge/discharge conditions, but it is unacceptable to include them in a system without a controller.

Home wind generator battery pack. Not the best option for use, given the chaos of wires and storage requirements.

In this state of energy storage devices, one cannot count on their long-term operation.

If the wind turbine installation contains a professionally designed charge controller with a full-fledged automation system, it seems rational to use AGM or helium batteries. Both types of energy storage devices are characterized by greater efficiency and a long service life, but they place high demands on charging conditions.

The same applies to the so-called armored helium-type batteries. But the choice of these batteries for a household windmill is significantly limited by price.

However, the service life of these expensive batteries is the longest compared to all other types.

These batteries also have a longer charge/discharge cycle, but only if a high-quality charger is used.

Calculation of an inverter for a home windmill

It should be noted right away: if the design of a home wind turbine contains one 12-volt battery, there is no point in installing an inverter on such a system.

On average, household power consumption is at least 4 kW at peak loads. Hence the conclusion: the number of rechargeable batteries for such power should be at least 10 pieces and preferably with a voltage of 24 volts. For such a number of batteries it makes sense to install an inverter.

Low power inverter (600 W), which can be used for home small power installations. You can power a TV or a small refrigerator from such equipment with a voltage of 220 volts.

There is no longer enough current for the lamps in the chandelier

However, to provide full energy to 10 batteries with a voltage of 24 volts each and stably maintain their charge, you will need a windmill with a power of at least 2-3 kW.

Obviously, simple household structures cannot handle such power. However, you can calculate the inverter power as follows:

- Sum up the power of all consumers.

- Determine the time of consumption.

- Determine peak load.

In a specific example it will look like this.

Let there be household electrical appliances as a load: lighting lamps - 3 pcs. 40 W each, television receiver - 120 W, compact refrigerator 200 W. We sum up the power: 3*40+120+200 and we get 440 W at the output.

Let's determine the power of consumers for an average period of 4 hours: 440*4=1760 W. Based on the obtained power value over time of consumption, it seems logical to select an inverter from among such devices with an output power of 2 kW or more. Based on this value, the current-voltage characteristic of the required device is calculated: 2000*0.6=1200 V/A.

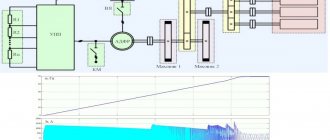

A classic scheme for the reproduction and distribution of energy obtained from a household wind generator.

However, to provide long-term energy to such a number of devices, a sufficiently powerful installation is needed

In reality, the household load on a family of three people, which is fully equipped with household appliances, will be higher than calculated in the example.

Typically, the load connection time also exceeds the required 4 hours. Accordingly, the wind power system inverter will need a more powerful one.

Conclusions and useful video on the topic

How the source data is analyzed and how the formulas are applied is presented in the video:

It is necessary to use calculated data in any case.

Whether it is an industrial power plant or one manufactured for domestic use, the calculation of each unit always ensures maximum efficiency of the device and, most importantly, operational safety.

Often, preliminary calculations determine the feasibility of implementing a project and help determine how costly or economical the project will be.

Source: https://je7.ru/kak-proizvesti-raschet-vetrogeneratora-po-formulam/

What determines the efficiency of a wind generator?

As already mentioned, the efficiency of a wind generator is derived from its technical condition , the type of turbine, and the design features of a given model. From the school physics course we know that efficiency is the ratio of useful work to total work. Or the ratio of the energy expended to perform work to the energy obtained as a result.

In this regard, an interesting point arises - the wind energy used was obtained completely free of charge, no effort was made on the part of the user. This makes efficiency a purely theoretical indicator that determines the purely design qualities of the device, while for owners the performance characteristics are more important. That is, a situation arises in which efficiency is not so important, all attention is given to purely practical tasks.

However, when operating parameters change in one direction or another, the efficiency automatically changes, which indicates its interconnection with the general condition of the device.

Calculation of wind generator power for a home or cottage

To calculate the rated power of a wind generator for organizing power supply to a private home or country property, we suggest using the following principles

To select a wind generating electrical installation, it is necessary to determine as accurately as possible the most constant direction and average wind speed at the location where the equipment is intended to be installed. It is necessary to understand that the blades of a wind generator begin to rotate at a wind speed of 2 m/s. The maximum efficiency of the installation is achieved at a wind speed of 9 - 12 m/s.

To provide electricity to a small country house, you need a generator with a rated power of at least 1 kW hour, generated at a wind speed of about 8 m/s.

The power of a wind-generating electrical installation largely depends on the wind speed and the diameter of the working propeller.

To calculate the performance characteristics of a wind turbine for a small country house, you can use the following formulas:

Calculation of a wind generator by rotation area

P = 0.6*S*V3,

Where

S – Area (m2) perpendicular to the wind direction;

V – Wind speed (meters per second).

P – Generator power, kW

Calculation of a wind generator based on the diameter of the propeller

P = D2*V3/7000,

Where

D – Screw diameter (meters);

V – Wind speed (meters per second).

P – Generator power, kW

More complex calculation taking into account air flow density

A more accurate calculation can be made using the following formula:

P = ξ • π • R2 • 0.5 • V3 • ρ • ηred • ηgen

Where,

ξ – wind energy utilization coefficient (in nominal mode for high-speed wind turbines reaches a maximum ξmax = 0.4 ÷ 0.5), immeasurable quantity

R – rotor radius, unit of measurement – m

V – air flow speed, unit of measurement – m/s

ρ – air density, unit of measurement – kg/m3

ηed – gearbox efficiency, unit of measurement – percent

ηgen – generator efficiency, unit of measurement – percent

From real life, practical calculation of wind generator power.

This formula can be found on many forums and websites on wind generators. To test the formula, I want to compare real data from two small-power wind generators with propellers almost identical in area, but one is horizontal and the other is vertical.

The photo shows two real homemade wind generators, the first is a horizontal three-bladed one with a propeller diameter of 1.5 m, the second is a vertical one 1 m wide and 1.8 m high. Without considering the data, I’ll immediately write that the horizontal power in a wind of 10 m/s is about 90 watts, and the vertical power is 60 watts. The KIEV of the first one, since the blades are made by eye, is probably 0.3, and the second vertical one seems to be well made, 0.2. Now let’s calculate the area of the propeller swept by the wind, for the first it is 1.76 m, for the second vertical it is 1.8 m. that means for horizontal 0.6*1.76*10*10*10=1056*0.3*0.8-20%=202 watts. that means for vertical 0.6*1.8*10*10*10=1080*0.2*0.8-20%=138 watts. The result is the following theoretical data, but knowing the real data, it becomes clear that the KIEV of both wind generators and the efficiency of their generators are far from good indicators. In this case, for most homemade generators that are made by eye without calculations, you can safely discount another 50% and ultimately get the real expected power from a wind turbine with a wind wheel of a certain area.

Wind power utilization rate

It should be noted that wind generators have their own specific efficiency indicator - KIEV (Wind Energy Utilization Coefficient). It indicates what percentage of the air flow passing through the working section directly affects the windmill blades. Or, to put it more scientifically, it demonstrates the ratio of the power received at the shaft of the device to the power of the flow acting on the wind surface of the impeller. Thus, KIEV is a specific analogue of efficiency, applicable only to wind generators.

Some experts argue that in theoretical studies the term efficiency for wind turbines is not applicable at all; instead, KIEV should be used.

Today, the KIEV values from the initial 10-15% (indicators of ancient windmills) have increased to 356-40%. This is due to improvements in the design of wind turbines and the emergence of new, more efficient materials and technical parts, components that help reduce losses due to friction or other subtle effects.

Theoretical studies have determined the maximum wind energy utilization factor to be 0.593.

Self-production of a vertical wind generator

A windmill with a vertical shaft is the easiest to make yourself. The blades are made from any material, the main thing is that it is resistant to moisture and sun, and is also lightweight. For the blades of a home wind generator, you can use PVC pipe, used in sewer construction. This material meets all of the above requirements. Four blades 70 cm high are cut out of plastic, plus two of the same ones are made of galvanized steel. The tin elements are shaped into a semicircle and then fixed on both sides of the pipe. The remaining blades are mounted at the same distance in a circle. The radius of rotation of such a windmill will be 69 cm.

The next stage is rotor assembly. You will need magnets here. First, take two ferrite disks with a diameter of 23 cm. Using glue, six neodymium magnets are attached to one disk. With a magnet diameter of 165 cm, an angle of 60° is formed between them. If these elements are smaller, then their number is increased. The magnets are not simply glued haphazardly, but the polarity is changed one by one. Ferrite magnets are attached to the second disk in a similar manner. The entire structure is generously filled with glue.

The most difficult thing is making the stator. You need to find a copper wire 1 mm thick and make nine coils from it. Each element must contain exactly 60 turns. Next, the stator electrical circuit is assembled from the finished coils. All nine of them are laid out in a circle. First, connect the ends of the first and fourth coils. Next, connect the second free end of the fourth to the output of the seventh coil. The result was a single-phase element of three coils. The second phase circuit is assembled from the next three coils in order, starting with the second element. The last phase to be assembled in the same way is the third phase, starting from the third coil.

To attach the circuit, a shape is cut out of plywood. Fiberglass is placed on top of it, and a circuit of nine coils is laid out on it. All this is poured with glue, after which it is left until completely hardened. No earlier than a day later, the rotor and stator can be connected. First, the rotor is placed with the magnets up, the stator is placed on it, and the second disk is placed on top with the magnets down. The connection principle can be seen in the photo.

Now it's time to assemble the wind generator. Its entire circuit will consist of an impeller with blades, a battery and an inverter. To increase torque, it is advisable to install a gearbox. Installation work has the following order:

- A durable mast is welded from a steel angle, pipes or profile. In height, it should raise the impeller with blades above the roof ridge.

- The foundation is poured under the mast. Reinforcement is required and anchors protruding from the concrete are provided.

- Next, the impeller with the generator is fixed to the mast.

- After installing the mast on the foundation, it is attached to anchors, after which it is reinforced with steel braces. For these purposes, a cable or steel rod 10–12 mm thick is suitable.

When the mechanical part of the wind generator is ready, they begin to assemble the electrical circuit. The generator output will provide three-phase current. To obtain a constant voltage, a rectifier made of diodes is installed in the circuit. Battery charging is controlled through a car relay. The circuit ends with an inverter, from which the required 220 volts are supplied to the home network.

The output power of such a wind generator depends on the wind speed. For example, at 5 m/s the electrical installation will produce about 15 W, and at 18 m/s you can get an output of up to 163 W. To increase productivity, the windmill mast is extended to 26 m. At this height, the wind speed is 30% higher, which means that the electricity generated is approximately one and a half times more.

Assembling a wind generator is a complex matter. You need to know the basics of electrical engineering, be able to read schematics and use a soldering iron.

Which designs have the highest efficiency?

Today, the highest efficiency of horizontal wind turbines, which are more efficient than vertical wind turbines, is 0.4. For vertical devices, the average value is considered to be 0.38, i.e. the indicators are close and not far from each other. From time to time, reports appear about the development of devices whose efficiency exceeds existing indicators by 2 or more times, which is very doubtful and is not confirmed by anything other than the unfounded statements of journalists who have little understanding of the subject.

However, devices with noticeably increased efficiency do exist. They are created in different design options; there are horizontal or vertical installations with increased productivity, power, and other parameters. Most of these devices are low-power systems designed for use in remote areas and supplying individual homes or properties.

For Russia, it is important to create just such devices, since energy supply needs are only in hard-to-reach and remote regions. Installation of large industrial stations there is not always possible or cost-effective.

There are known designs by inventors Onipko, Tretyakov and many other designers, which have original and elegant options for increasing productivity and, accordingly, efficiency. Most of them are still at the stage of development or preparation for mass production, since active work in this direction began relatively recently and has not yet had time to be fully realized in the form of industrial products.

Model selection

The cost of a set of wind generator, inverter, mast, SHAVR - automatic transfer cabinet directly depends on power and efficiency.

| Maximum power kW | Rotor diameter m | Mast height m | Rated speed m/s | Voltage W |

| 0,55 | 2,5 | 6 | 8 | 24 |

| 2,6 | 3,2 | 9 | 9 | 120 |

| 6,5 | 6,4 | 12 | 10 | 240 |

| 11,2 | 8 | 12 | 10 | 240 |

| 22 | 10 | 18 | 12 | 360 |

As you can see, to fully or partially provide the estate with electricity, high-power generators are needed, which are quite problematic to install on your own. In any case, high capital investments and the need to install the mast using special equipment significantly reduce the popularity of wind energy systems for private use.

There are portable low-power wind generators that you can take with you on a trip. These models are compact, quickly installed on site, do not require special care, and provide enough energy for a comfortable pastime in nature.

And although the maximum power of this model is only 450 W, this is enough to illuminate the entire campsite and makes it possible to use household electrical appliances far from civilization.

For medium and small enterprises, installing several wind power generating stations could provide significant savings in energy costs. Many European companies are engaged in the production of products of this type.

These are complex engineering systems that require prevention and maintenance, but their rated power is such that it can cover the needs of the entire production. For example, in Texas, at the largest wind farm in the United States, only 420 such generators generate 735 megawatts per year.

Ways to increase efficiency

In order to increase the efficiency of a wind generator , it is necessary to change its operating or operational characteristics in a positive direction. First of all, it is necessary to increase the sensitivity of the impeller to weak and unstable winds. Russia is considered the richest country in wind resources, but this is only due to its large area. The average indicators in our country are relatively low, the flow rates are weak or average. This forces us to find ways to improve the efficiency of the impeller .

One of the interesting proposals in this area is the “petal sail”, developed by Evgeny Tsukanov. He proposed the idea of creating a kind of one-way membrane for air flow, freely allowing wind to pass in one direction and being a dense, impenetrable barrier to flow in the opposite direction.

According to Tsukanov’s development , the blade blade consists of a mesh covered with petals. They are attached with one edge to the mesh and hang down freely, partially overlapping each other. When directed frontally, the petals are pressed against the mesh, forming an impenetrable surface that receives the full amount of wind energy. If you direct the flow from the opposite side, the petals rise under the influence of the wind and allow air to pass through without resistance.

This option requires some industrial measures, in particular, the creation of technological lines for the production of such a fabric, but the idea itself very successfully eliminates the effect of wind on the reverse sides of the blades, which will greatly increase the efficiency of vertical structures and allow one to obtain completely different results from them.

There are other methods, for example, the use of diffusers or protective caps that cut off the flow from the opposing surfaces. All these design options have their advantages and disadvantages, but, in general, they are much more efficient than traditional designs, and therefore require active development and launch into industrial production.

Vertical and horizontal wind generator

Vertical wind generator

Can be classified by rotors:

- orthogonal;

- Daria;

- Savonius;

- helicoidal;

- multi-bladed with a guide vane;

Vertical wind generators are good because there is no need to direct them relative to the wind; they operate in any wind direction. Because of this, they do not need to be equipped with devices that detect the direction of the wind.

These structures can be placed on the ground; they are simple. Making such a structure with your own hands is much easier than a horizontal one.

The weak point of vertical wind generators is their low productivity and extremely low efficiency, which is why their scope of use is limited.

Horizontal wind generator

Horizontal wind generators have a number of advantages compared to vertical ones. They are divided into one-, two-, three- and multi-lobed.

Single-bladed designs are the fastest; they spin twice as fast as three-bladed ones with the same wind force. The efficiency of these wind generators is significantly higher than that of vertical ones.

A significant disadvantage of horizontal-axial structures is the dependence of the rotor on the wind direction, which is why it is necessary to install additional devices on the wind generator that capture the wind direction.