Connecting an electric heated floor

Connection diagram for an electric heated floor

They are pieces of a heating cable of a fixed length, equipped with an installation wire for connecting to the network through a thermostat.

Such cables cannot be cut unless otherwise permitted by the manufacturer in the instructions.

Cable systems are laid in a layer of screed or in a layer of tile adhesive.

The power of the cable heated floor is selected based on the area that needs to be heated.

To do this, use the following relationships:

- At least 110-120 W/m², if the cable system is used as an additional one together with another heating system (for example, together with radiators).

- At least 150-160 W/m², if the cable will be used as the main heating system. In our climate, using heated floors as the main heating is risky due to the fact that they give off less heat than, for example, radiators. You might just start freezing in winter. In addition, if you use a cable as the main heating, then the cable laying area should be at least 70% of the heated area.

- To heat a loggia or winter garden, it is also worth taking at least 160 W/m². This is due to large heat losses through windows.

Cable system installation

As mentioned earlier, the cable can be laid either in a layer of tile adhesive or in a layer of screed.

Installation begins with preparing the surface, which must be cleaned, leveled and primed.

Heated floors can only be laid on a dry surface, that is, the screed and soil must remain “drying” for at least 21 days.

Installation in a screed and in a layer of glue is different, so we will consider these methods separately.

How do electric types of floor heating work?

Electric floor based on cables

The operation of a heated floor is based on the release of heat into the external environment through the transfer of electricity in the elements of the system. Standard types of wires are made of metals that are aimed at reducing heat loss, but in cable heating systems everything is exactly the opposite.

We recommend: Features of Fenix heated floors

Metals are selected for the maximum possible release of heat into the environment. In this case the wire consists of:

- metal threads that emit heat well;

- from polyfluoroethylene (Teflon) layers.

These types of cables are produced in the form of single- and double-core cables, and are used during installation for different purposes. If the installation and operation rules are followed, the warranty for these types of cables reaches 15-20 years:

- two-core models are equipped with an additional insulating layer, which is located in the gap between the outer covering and the layer of heat-resistant braiding of the cores. The first core conducts current, and the second acts as a heating wire. This arrangement is necessary to reduce the level of harmful electromagnetic waves;

- Single-core cables work in the same way, taking into account that they must be laid in a circle in order to converge at one place for connection.

These devices require maintaining a balance of the heat that the cable emits, as well as the amount of heat that goes into heating the room. Because of this necessity, the cables must be of the same type, otherwise there will be malfunctions.

At the final stage, the structure is filled with a layer of screed, which, after drying, is covered with a layer of flooring.

Self-regulating cables are equipped with standard wires that conduct current. The heating element is a semiconductor matrix consisting of unconnected parts.

The principle of operation of a heated floor is that the semiconductors of the matrix measure the temperature of the room and react to changes by creating a huge number of threads through which electric current circulates, heating the layers of wire and subsequently releasing heat.

Electrical resistance increases at average semiconductor temperatures, resulting in reduced room heating.

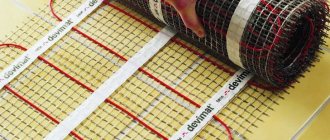

Resistive cable mats

Along with single- and double-core types of wires, there are heating mats. These are the sheets in which the cable was originally mounted. They have become widespread in the building materials market due to their simple installation, compared to separately attached heating cables.

We recommend: What are the advantages of a heated metal-plastic floor?

The set of this type of heating consists of:

- mats, which are rolled into rolls for convenience;

- adapters for correct connection.

The use of adapters is mandatory, since connecting the system directly to the network is prohibited.

If the structure needs to be deployed, then the fastening mesh is simply carefully cut without touching the wires, and turned in the desired direction. This method greatly facilitates the installation of a heating structure in a room of any shape and size, and also prevents wires from overlapping each other.

Infrared film systems

The film heating option differs in the method of heat transfer from other types. The film transmits heat through infrared radiation, similar to the sun.

Heat spreads evenly over the surface of the room, heating all objects. Most people prefer this heating method due to ease of installation and relatively low prices.

The film consists of carbon plates, on the sides of which copper strips are mounted. Direct heat is generated by the carbon part of the film.

The sheets have a width from 30 cm to 1 m, and their length reaches 40-50 meters. To separate the film into parts, cut lines are applied. Only along these lines is it allowed to divide the film to avoid damage.

The sheets are laid on the prepared base under the flooring layer. The system does not require screed.

Infrared mats carry out heating using rod-shaped emitters, which are located in the gap between two conductors.

The mats are divided into sheets up to 80-83 cm wide, and the length can be around 20 m. The rod emitters are mounted at a distance of 8-10 cm, which makes it easy to separate them in the central part.

It is worth noting the automatic regulation of this type of heating. The idea is that upon reaching the required temperature, the film stops emitting heat. This significantly reduces energy consumption.

The mats must be placed in a cement screed with a thickness of at least 2-3 cm, otherwise the temperature will not be able to regulate itself.

We recommend: How is polystyrene foam used for heated floors?

Compatible with all types of floor coverings.

Laying electric heated floors in a screed

Scheme of laying a heated floor cable in a screed.

Installation of a heated floor in a screed is carried out in several stages:

- Laying thermal insulation on the base.

- Filling the thermal insulation with the first layer of screed 1-2 cm thick.

- Laying the heating cable in loops and installing a thermostat with a sensor to control the heated floor.

- Check for damage and system functionality.

- Filling the top layer of screed with a thickness of 3-5 cm.

A metal mounting tape is used to secure the cable to the tie.

The cable is attached to the tape in the places where the loops bend, that is, along the edges of the heated area, without sharp bends or tension.

Between the edges, pieces of mounting tape are laid in increments of 0.5 meters.

Laying is done in such a way that the installation cable is located close to the junction box.

After laying the cable on the floor, its resistance is checked, the results of which are recorded in the warranty card.

Resistance determines the integrity of the cable insulation.

The resistance parameters at which the cable is considered serviceable are indicated in the instruction manual.

It is also necessary to install a thermostat with a temperature sensor. This is done according to the following algorithm:

Installing the thermostat and connecting the cable

Connecting an electric floor heating thermostat

- Niches are made in the wall for installing a junction box and a thermostat, plus grooves for laying a temperature sensor and installation cable.

- To install the temperature sensor, a special corrugated tube is placed in the groove, one end of which is plugged, and the other is connected to the thermostat. The tube must extend from the wall at a distance of at least 60 cm, in addition, it must be laid between the cable loops. This is necessary for the temperature sensor to work correctly. The bend radius of the corrugated tube must be such that the sensor can be easily removed from it if it breaks.

- After all these manipulations, the groove along with the tube is filled with screed.

- The installation cable is connected to the network through a thermostat. The connection diagram is indicated in the passport. The groove also needs to be covered.

Installation of electric heated floors under tiles

Laying an electric heated floor in a layer of adhesive

It is possible to install a cable floor heating system in a layer of tile adhesive.

The sequence of actions here will be as follows:

- The installation of a thermostat and distribution box is being prepared. That is, niches and grooves are made for the cables.

- The distribution box and corrugated hose for the temperature sensor are being installed. The end of the corrugated hose is tightly plugged to prevent tile adhesive from getting into it. After which it is necessary to check whether the sensor is removed from the hose, after which the groove is filled with a screed, and the place where the end of the hose is located is marked with a marker. This must be done so that the sensor does not accidentally end up “covered” by the cable.

- Re-clean the floor surface of debris. Then attach pieces of mounting tape to the floor to which the cable will be attached. The pieces of mounting tape are placed in the same way as when laying in a screed.

- Next, carefully attach the cable to the mounting tape. We do this in such a way that it is possible to connect the installation wire in the junction box. Do not forget that the temperature sensor must be placed between the cable loops when laid.

- We check the cable for resistance damage. Resistance parameters are described in the user manual.

- We connect the cable and thermostat. After this, we supply power for a short time and check the functionality.

- We lay a layer of tile adhesive 5-8 mm thick. and seal the grooves for the cables. We are waiting for the glue to dry.

- We lay the tiles on a new layer of glue. We are waiting for the glue to dry and you can use the heated floor.

Cable underfloor heating and flooring

Warm electric floors may not be used with all types of floor coverings. When resistive cables are installed, the finish can be made from any tile, wood plank, laminate or linoleum. As for the last two types of flooring, they should not have a heat-insulating layer.

When purchasing laminate or linoleum, it is advisable to pay attention to the presence of such characteristics of the materials as suitability for heated floors. When the heating system is installed using a resistive cord for underfloor heating, the floor surface should not be covered with carpets or heating elements should not be placed under furniture.

But a self-regulating cable can be installed anywhere. If you are going to use glue, grout and adhesive composition, you need to purchase special ones. They are intended specifically for floor heating systems, since they have greater elasticity and better thermal conductivity.

Heating mat for heated floors

Heating mat for underfloor heating is a device

that consists of a heating cable that is attached to a mesh. They are sold in the form of rolls.

No mounting tape is required to secure the mat to the floor, making floor installation easier and faster.

In addition, you can make a warm floor over the old tiles.

The mats are installed directly into a layer of tile adhesive, the thickness of which should not exceed 5 mm.

Installation of heating mat

Installation of the heating mat is carried out in the same way as installation of a cable in a layer of tile adhesive (see above).

The thermostat is installed in the same way.

Water heated floor

Warm floors of this type are a solution intended for private homes. The point of the system is to lay the pipe circuit on a prepared base.

Heating is provided by hot liquid, which is supplied to the pipe system through a circulation pump. The structure of the layers of the water system is as follows:

- foundation for future layers;

- screed (if the base has differences of more than 2-3 mm);

- layers of hydro- and thermal insulation;

- pipe circuit;

- pouring screed over pipes;

- finishing coating.

Polypropylene and metal-plastic pipes can be used for the system. The second option will last much more efficiently for decades, so it is better not to save money by buying cheap pipe options that may become unusable in the first years of service.

Water heated floor

The total thickness of all layers is around 15-25 cm, so you need to take this into account in advance when preparing the base of the room.

Infrared film heated floor

Infrared film heated floor characteristics

This type of heated floors can be laid in a layer of tile adhesive, under laminate or under linoleum.

These floors are produced in the form of rolls, which can be cut into sections of the desired length.

Heating is carried out using infrared radiation.

This type of electric heated floor is the easiest to install, which distinguishes it from the cables and mats described above.

Installation of infrared film heated floor

How to lay infrared film heated floors

As mentioned above, infrared film heated floors can be installed under tiles, decorative stone, parquet or laminate.

To install such a warm floor, the following requirements exist:

- Level the floor surface to avoid film creases.

- It is necessary to make a groove for the temperature sensor and place it in the corrugation. If the film is laid under the tile, then the end of the corrugation must be hermetically sealed. Without this, it will not be possible to replace the sensor in the event of a breakdown.

- Using a crown of the appropriate diameter is necessary.

- When laying under laminate or parquet, foil thermal insulation made of foamed polyethylene must be laid under the film.

- The maximum length of a section of a heated floor should not exceed 7-8 meters.

- The heated film floor must be laid with a distance of 10 cm from the furniture standing on the floor. To do this, the installation site must be pre-marked.

- It is advisable to place strips of film along the long wall of the room. This will help reduce the number of streaks.

The inclusion and operation of such floors is no different from those described above.

Planning the location and order of installation

The next task is to plan the location of the heated floor and calculate the cable laying pitch.

When laying, the distances from the walls should be at least 5-10 cm. This is necessary so that the cable transfers heat directly into the room and does not overheat. And when installing, for example, interior doors, you will not worry about the integrity of the heated floor. Also, indentations should be made from the location of floor plumbing, heavy furniture and large household electrical appliances (refrigerator, washing machine).

The cable laying step is calculated by the formula: 100 multiplied by S and the resulting value divided by L, where S is the area over which the heated floor is laid, and L is the length of the cable section. The minimum laying step is 8 cm. The power is calculated based on the heating area and the value per square meter. For example, the area of the room is 10 m², and the required power per m² is 100 W. The cable power will be 1300 W, and the cable length will be 20 meters.

As a rule, when purchasing an electric heated floor, we receive a heated floor kit that is completely ready for installation. Let us note once again that heated floors are purchased depending on the heated area. The heated area is calculated by subtracting the area of stationary furniture from the total floor area.

Electric heated floor area

Safety requirements for electric heated floors

- It is prohibited to shorten the length of the heating part yourself.

- It is prohibited to use one section of heated floors for rooms with different types of coverage. In this case, each room should have a separate section with its own thermostat.

- As screed and tile adhesive, you can only use mixtures that are recommended for use with heated floors.

- It is forbidden to open heat-shrinkable sleeves at the junction of the heating and installation parts of heated floors

- It is prohibited to cover the installation areas of heating sections with carpets and place furniture without legs on them. This will impair heat dissipation from the cable and may cause a malfunction.

These requirements are most universal for different manufacturers of heating cables and mats.

For safe operation, be sure to read the instructions that come with the kit.