What is a plug socket and where is it used?

The term "plug socket" refers to a device needed to power electrical appliances. They are used for permanent installation and consist of several elements - a mounting tab, a screw, a base and a current-carrying part.

The task of a plug socket is to ensure contact between the plug of an electrical device and a metal contact group that is energized by the electrical network. In fact, all sockets for powering electrical equipment are called plug sockets.

The product is used wherever it is necessary to connect equipment to a single-phase alternating current network (220 V, 50 Hz) with or without grounding. Installed in apartments, offices, shops, laboratories, shopping centers, houses and other premises.

Design and purpose of the plug socket

Plug sockets are installed in most rooms; without them, it is impossible to turn on electrical appliances. The design of the device includes three main elements:

The last detail performs two important functions - protective and decorative. The building can be either single or double. The main part of the device is the block. The cover and contacts are attached to this element. It is usually made of carbolite or ceramics.

Sockets made of carbolite are considered more durable. But a block made of this material is found only in old-style devices. Ceramic products have one significant drawback: they are very fragile, so the device must be installed with great care, since a damaged part cannot be repaired.

Another working element of the socket is the contact, which serves as a conductor of electricity. They are made from metal alloys that have a certain degree of elasticity.

Classification

Plug sockets differ in design features, electrical circuit, number of terminals and other parameters. Let's take a closer look at each of the signs.

By type of design

Structurally, the device comes in two types:

- Hidden installation. It goes deep inside the wall, and outside there is only the outer part with a place to insert the plug. The assembly is fastened using claws, which on one side rest against the elements of the device, and on the other against the base (for example, a wall or installation box). To adjust the fastening, a special screw clamp is used.

- Outdoor installation. Unlike the type discussed above, the structural elements of such a unit are located outside. For fastening, screws are used to hold the product to the surface. The electrical part is reliably protected by a plastic housing. Additional options include backlighting, a childproof lid, a shutdown timer, etc.

- Portable. Essentially, these are extension cords, which are a plug and a socket connected by a cord of a certain length.

According to the electrical diagram

Plug sockets differ in the presence of a contact connecting the metal part of the electrical receiver to grounding.

There are two types:

- With grounding (three contacts). It is used in apartments, houses or other objects where there is a grounding circuit with low resistance. The design is made in such a way that grounding occurs before voltage is applied to the plug and the equipment itself. This feature is due to safety requirements. Used to connect equipment with a metal body: washing machine, electric stoves, etc.

- No grounding. They can be easily identified by the presence of two contacts. There is no grounding connector provided here, which reduces the level of safety when using the device. If a phase comes into contact with a conductive body, a person may become energized.

By number of pads

Structurally, plug sockets differ in the number of terminals for connection.

They are:

- Single rooms. Used to turn on only one device. To increase the number of connectors, you can use carriers or tees.

- Doubles and more. In such electrical units it is possible to connect two or more devices. The most common option is double and triple sockets.

By wire clamp type

An important point when choosing is the type of input contacts.

They are:

- Screw. The degree of tightening of the wire is regulated by a person.

- Screwless. A special feature is the clamping of the wire using special springs. They are considered more reliable, because during operation the compression ratio does not decrease due to vibrations or other influences.

Additional features

In addition to the characteristics already discussed, plug sockets are classified according to other parameters:

- By the number of poles - two and three poles.

- With or without protective contact. A special feature is the presence of metal elements connected to the ground loop.

- According to the presence of curtains. A special feature is the presence of special flaps that protect children from voltage. They open only with simultaneous strong pressure on both elements.

- Based on the material of output and input contacts. Made from brass or bronze.

- With and without a switch (RJ-45). Some models have a connector for connecting network equipment.

- By the presence of a toggle switch. Structurally, a switch is provided with which you can apply and remove voltage from the contact connections.

- For portable lamps. It is used to supply reduced voltage (12 V, 24 V) and has a different design to avoid mistakenly connecting a portable light bulb to a 220 V network.

- By the presence of backlight. Such devices have an LED light source, making it easier to connect in complete darkness. Often installed in the bedroom, hallway or living room.

The above classification allows you to understand the variety and importance of plug sockets and quickly decide on a purchase.

Design features

There are these types of sockets:

- For hidden installation. The case is hidden in the wall and secured there using special claws, and only the front part with holes for the plug remains outside. Reliability of installation is ensured by a clamping screw that adjusts the emphasis of the legs on the wall or mounting cup.

- For outdoor installation. The plug body is attached using screws or screws to the wall surface. It is also an insulator for electrical parts. Various auxiliary elements can be placed on the case: backlights, protective covers, timers, etc.

- Portable sockets. Used for temporary connection of electrical appliances.

- With protective curtains. Installed in rooms where there are children. The curtains open only when the contacts of the plug are pressed on them simultaneously.

- Sockets whose contacts are made of different materials, such as brass, bronze.

- With built-in switch. You can turn off an electrical appliance without removing the plug from the socket.

- Sockets for connecting 12 V or 24 V have a special design. This voltage is used, for example, for portable lamps.

- Some designs use backlighting. It is very convenient to connect any devices in the dark, without turning on the general lighting.

Kinds

When choosing plug sockets, pay attention to types of devices that differ in characteristics and scope of application. Electrical components for connecting the plug are of the following types.

Waterproof

Structurally, they have a special cover that protects electrical contacts from moisture. There are also other structural elements that prevent short circuits due to high humidity in the room where the unit is installed. Installed outdoors, in bathrooms, saunas and kitchens.

Waterproof sockets differ in protection class (IP). Two numbers are used for classification. The first (1-6) displays the degree of protection from dust, and the second (1-8) from moisture. The higher this parameter, the better.

For example, IP68 class sockets are used in swimming pools, fountains, and industrial equipment.

With RCD

Modern models are often equipped with a residual current device that provides voltage relief in the event of a short circuit or a sudden increase in load.

Recommended for connecting critical electrical receivers - microwaves, refrigerators and other devices.

Some models respond to voltage changes. If the level exceeds or falls below the setpoint, a shutdown occurs.

With built-in time controller

Structurally, there is a counter that provides voltage relief after a certain time. The setpoint can be set manually or specified by the manufacturer.

A plug-in device with a built-in controller will be useful where timely shutdown of power is necessary (aquarium, boiler, boiler, etc.).

According to the principle of operation of the device there are:

- With mechanical controller. The tension is relieved by loosening the spring element after a specified period of time. As a result, voltage is supplied to the electrical appliance.

- With electronic controller. Here the main function is assigned to the microprocessor, which acts on the thyristor switch and subsequently turns off the power. A special feature of the products is the ability to set several settings and even create a schedule of switching on and off.

More about sockets with a timer.

With built-in counter

A special feature of plug sockets with a meter is the presence of a display that displays the current consumption of the electrical receiver in kWh. Information is displayed using numbers at the top or bottom of the structure.

There may be a light around the plug to indicate the load level. Depending on the current, the color changes from blue (low load) to red (maximum current).

Universal household

Universal plug sockets have a standard connector shape that allows you to connect different types of plugs. Many models have a built-in USB adapter for charging various devices.

Smart plugs

A special feature of smart sockets is the ability to control the power supply and control (on/off) using a smartphone and an application installed on it.

The use of smart sockets allows you to set schedules for supplying and removing voltage, remotely checking whether equipment is turned on, and solving other problems.

More detailed information can be found at the link.

Classification options

The plug socket is manufactured in various types.

They all differ from each other and are classified according to certain parameters. This allows consumers to narrow their search for the desired model and purchase the most suitable option for them.

According to the electrical circuit used

This parameter is considered one of the main ones and divides all sockets into 2 types. Both provide a safe and reliable electrical connection.

The following types of devices are distinguished:

- Three-pole. These sockets are used only in cases where it is possible to connect to grounding. It is connected using a separate contact. The holes for the plug pins are located slightly lower than for the grounding pin. Thanks to this, three-pole devices are ideal for connecting electric stoves, air conditioners and other household appliances.

- No grounding. Unlike three-pole ones, they have only 2 contacts and are intended for the corresponding electrical wiring. However, it should not have a special grounding contact. Sockets without grounding are installed in old buildings where the old wiring has never been replaced with new ones. These devices are much cheaper than three-pole ones, but do not provide the opportunity to further protect yourself and the equipment you use.

Depending on the type of structure

According to this characteristic, two types of sockets are also distinguished. They are used for various methods of conducting electrical cables (external and hidden).

There are the following types of products:

- For outdoor installation. This option is used only when laying open wiring. The structure is attached to the wall surface using a non-recessed socket. Its basis is a plastic casing that protects the owner of the premises from all dangers associated with electricity. Modern outdoor sockets are equipped with an additional protective cover and lighting. More expensive models may also include a shutdown timer.

- With hidden wiring. The recessed type socket is used to conduct internal electricity. The body of such a device is located in a special mounting box, and all the wires are embedded in the wall of the room. Thanks to this feature, the absence of protruding parts of the structure and saving of free space is achieved. The plug is pressed against the contacts using a spring washer. One end of it reaches the stop, and the other - the body.

According to the degree of protection against moisture

All devices that are used to connect to electric current must be protected from moisture. Otherwise, there is a high probability of a short circuit.

Based on moisture resistance, sockets are divided into the following categories:

- Semi-hermetic. These simple devices are protected from water only by the housing. Therefore, they are best used in rooms with low humidity levels or no likelihood of moisture ingress. Such sockets can be installed in bedrooms, living rooms, corridors and other dry rooms.

- Waterproof. Such devices are installed in those buildings and structures where there is a possibility of high humidity (sauna, bathhouse, bathroom). Such sockets are provided with a special membrane, which performs a protective function and protects the contacts from moisture. In addition, dense and durable rubber rings can be used. There are special grooves on the body of the device through which condensate or trapped water flows. This allows most of the liquid to be removed and simplifies the operation of the protective membrane. Waterproof sockets are installed only externally.

Types of sockets

The appearance and design of electrical outlets may vary from country to country.

Let's briefly look at each type:

- "A". 2-pin plug without ground. The pins are flat, 6.35 mm wide and 1.524 mm long. They are located at a distance of 12.7 mm. The connector is used in the USA for voltages from 100 to 127 V, 60 Hz. In Japan, similar plugs are used, but the mains voltage is 100 V and the frequency is 50 Hz.

- "IN". The design is the same as the type “A” plug socket. The difference is the presence of a ground connector at the bottom. The applied voltage is from 100 to 127 V, but in some countries 220 V is supplied. It is found in Canada, the USA, and Japan.

- "WITH". Structurally, inputs are provided for two pins with a diameter of 4 or 4.8 mm. The length and distance between the sockets is 19 mm. Operating voltage: 220 V. Used in Germany, Italy, France and a number of other EU countries, as well as in Russia and Ukraine.

- "D". Feature: three round contacts arranged in a triangle shape. Initially, it was a British standard, which later became widespread in Pakistan, India and a number of other countries (those that were electrified by the British).

- "E". Unlike the previous type, the top center pin protrudes from the socket and fits into a recess on the plug. Used in France and a number of EU countries.

- "F". A special feature of the plug socket is the presence of grounding contacts at the top and bottom. In the Russian Federation, such a product is called a “Euro plug”. Grounding is performed using a special metal bracket, and the maximum current is 16 Amperes. It is used in many countries, including Germany and the states of the former USSR.

- "G". Externally it looks like a socket with three contacts. Phase and neutral have a rectangular cross-section and dimensions 6.35x3.97 mm. The distance between them is 22.2 mm. The ground contact has a different size - 3.97x7.92 mm. A fuse must be built into the plug to protect the phase wire from short circuit. Used in England and countries that were previously colonies. Also type "G" is used in Saudi Arabia.

- "H". A special type of plug socket that is not compatible with other types. The contacts are arranged in a “Y” shape. The maximum current is 16 Amps. Used in Israel (combined with other types) and in the Gaza Strip.

- "I". Structurally, the grounding contact is located in the center at the bottom, and the other two (phase and neutral) are on the right and left at the top. Unlike the “H” connector, the upper contacts are turned in the other direction. These plugs differ in maximum current and come in 10, 20, 25, 32 Amperes. Used in Australia and China. Argentina, Uruguay and several other countries.

- "J". This is a Swiss type plug socket. Outwardly it is similar to a Euro plug with the difference that the grounding contact is slightly shifted closer to the center, and the pole bases do not have insulation. If the product is not fully inserted, you may be exposed to voltage. The rated current is up to 10 A, and with grounding - 16 A.

- "TO". This is a Danish type socket that also fits type "C". Structurally, it consists of two connectors (phase and neutral) in the form of pins located at an angle. The grounding part has a cut circle forum.

- "L". It is a plug socket with three recesses in a row. The diameter of the pins is 5 mm, and the distance between them is 8 mm. Used in Italy.

- "M". Very similar to type “D”, but differs in the diameter of the pins (it is larger). The distance between the phase and neutral connectors is 2.54 cm. Used in many countries - Sri Lanka, Pakistan, Namibia, Hong Kong, Botswana, South Africa and others. Used for drying equipment and air conditioners in Israel and Singapore.

- "N". Consists of three round connectors. Looks like a "J" type. The two main ones are located at a distance of 1.9 cm, and the ground one is located 3 mm higher. Voltage - from 200 to 250 V. Current - 16 A. Used in South Africa.

Note that many countries use several types of sockets. For example, in the CIS countries you can find types C, F and E.

Types of sockets according to consumer power

The main point that you need to pay attention to when choosing a plug socket is the power of the connected devices. The best option is when there is one piece of equipment per node.

In practice, this does not always happen. People often use tees and carriers to expand their existing capabilities.

When choosing sockets, you can use a special formula. The current (Ampere) is equal to the power of the device (W) divided by the voltage (Volt).

For example, if the power of the electrical receiver is 2200 W and the voltage is 220 V, the current consumption will be 10 A.

This parameter must be taken into account when choosing a plug socket, but it is always better to take it with a reserve.

You can use the Watts to Amperes conversion calculator.

Device

When using a plug socket, you need to know its design.

The product includes the following elements:

- Front panel (front part). It covers the insides of the product from touch and is made of dielectric materials.

- Grounding contact (if provided). Located above and below. The contacts are shaped like a bracket that makes contact with a metal part on the plug. Depending on the type of wiring, the housing can be connected to zero or ground (if a separate circuit is provided).

- Input contacts. Designed for connecting electric and phase wires. The fastening can be screw or screwless (spring). Brass or bronze is used in production.

- Output contacts. They are used to accept a fork and have special rounded petals. Made from brass or bronze. Brass has a shorter lifespan due to rapid heating and the risk of damage if installed in a room with high humidity. Modern plates are made from more reliable phosphor bronze.

- Insulator. This is the central part of the socket to which the main elements of the product are attached. Made from dielectric (usually porcelain or plastic). The first option is better in terms of dielectric properties, but inferior in fragility.

- Frame. It is made of metal, which is attached to the frame (base). On the sides, as a rule, there are tabs for fixing them in a plastic box in the wall. There is a special limiter at the front that prevents the product from being sunk deeper than it should be. There may be fastenings on the surface for fixing the socket to the wall.

- Frame. Depending on the design, it can be one-piece (made together with the front part) or consist of a separate rim. At the same time, designs with two or more sockets are available for sale. Low-quality plastic is used in budget products, which turns yellow within several years.

As you can see, the design of plug sockets is simple, but has a number of features. This knowledge can help when choosing a product.

Plug socket of open and closed types

> Switches and sockets > Plug socket of open and closed types

The plug socket is part of the connector for quickly connecting electricity consumers. The design includes a housing, a plastic or ceramic base, spring contacts and terminals for connecting power. Models have a wide variety of designs.

What does a plug socket look like?

A necessary accessory that forms a detachable connection with the socket through spring contacts is a plug with metal pins.

Sockets are installed single-phase, with or without a grounding contact, as well as three-phase. The latter have 4 contacts, three of which are for phases, and one for zero or ground. Models can be recessed or overhead, waterproof, double, with a switch and built-in RCD. In this case, the principle of operation remains the same. The simple and reliable design allows anyone to connect electrical appliances to the network.

Socket device

The design includes a base (block) with a protective housing and metal contacts placed inside. They provide connections to the pins and also hold them together with the plug and wire. Metal platforms are attached to the base, to which the supply wires are screwed and where the contacts are located. In addition, there are also grounding contacts made in the form of two spring-loaded metal strips.

According to the requirements of the PUE, the apartment needs a separate grounding circuit. On the plug of the connected device there is a third ground contact connected to the housing. It is spring-loaded and additionally keeps the plug from falling out of the socket. All elements are connected using screws.

Plug socket device disassembled

The figure shows the socket with protective curtains covering the contacts. When the plug is inserted into the housing holes, they move away, providing access to the current-carrying parts. To make the curtains wear out less, they are reinforced with metal rings or strips. There are designs in which the curtains are moved back manually by turning the plate covering the socket.

Materials

Three-phase socket: features and connection

The block used to be made of ceramic, but now it is more often made of thermoplastic or special polycarbonate. The plastic base is less fragile and cheaper to manufacture. The material has high performance parameters, but is inferior in quality to ceramics, deforming from heat and having a lower breakdown voltage.

Contacts are made of bronze, brass or copper plates. The alloy must be resilient to ensure a secure connection with the pins of the plug.

Classification

Sockets are made with different types of subsequent installation and number of connectors.

Internal and external

Internal recessed type sockets are used more often. They are more convenient to use because they are mounted in the wall and connected to hidden wiring. For them, a special niche is made in the concrete into which the mounting box is attached. Models are equipped with internal steel paws with teeth. They move apart using a screw connection and, due to friction against the side walls, hold the structure in a hidden mounting box.

The device does not provide a permanent, strong connection and has to be tightened from time to time. More reliable is the method of screw fastening directly to the box, which is firmly fixed with gypsum mortar. The cable is brought to the socket through a channel inside the wall, its ends are connected to special clamps. It is important to firmly attach the ends of the wires to the contacts, otherwise sparking and burnout of the connection will occur in this place.

IP and NEMA/UL markings: decoding

When choosing a plug socket, pay attention to which room one is intended for. For example, the requirements for a product for a bathroom and a living room will be different.

In the first case, you need a waterproof option, and in the second, a standard outlet without any frills.

For convenience, two types of markings are used:

- IP stands for Internetional Perfection (international protection). Used in almost all countries of the world.

- NEMA/UL - National Electrical Manufacturers Association or National Electrical Manufacturers Association. Used mostly in the USA, but sometimes used in Europe.

After the letter designations there are numbers that indicate the degree of protection against moisture and dust. Below we provide a transcript for each type of marking.

IP decryption

Two numbers are placed next to the IP letter designation. The first one shows dust resistance, and the second one shows moisture resistance.

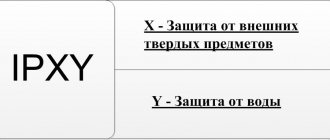

For example, consider IP XY, where X and Y are numbers from 0 to 6 in the first case and from 0 to 8 in the second.

Explanation X (dust protection):

- 0 - no protection;

- 1 - does not allow particles larger than 5 cm to pass through;

- 2 - protects against accidental penetration of solid bodies up to 1.25 cm in size (finger protection);

- 3 - protection from bodies larger than 2.5 mm (cable, wire, tool);

- 4 - excludes penetration of elements larger than 1 mm (knitting needles, tweezers, thin wires);

- 5 — protection from dust;

- 6 - maximum dust protection, including from the smallest elements.

Explanation Y (moisture protection):

- 0 - no protection;

- 1 - prevention of vertical water fall;

- 2 - protection against drops getting inside when falling at an angle of up to 15 degrees;

- 3 - resistance to drops falling at an angle of up to 60 degrees;

- 4 — protection against splashes (without reference to the corner);

- 5 - resistance to water jets at different angles;

- 6 - exclusion of water ingress due to strong and frequent exposure (for example, sea waves);

- 7 — maintaining tightness when working under water at a depth of up to one meter;

- 8 - protection from water when immersed more than a meter;

- 9 - prevention of short circuit even during long immersions, regardless of pressure.

Sometimes this marking uses another number, which shows the shock resistance of the case.

This feature is typical for the industrial sector, but in the domestic sector it is not of great importance.

There may also be letters after the numbers:

- W - additional means of protection;

- M - water ingress test passed;

- S - the test was performed in a non-working state when moisture entered;

- H - high voltage device, etc.

For example, the simplest socket is designated IP 30. This means that it does not allow bodies larger than 2.5 mm to pass through and does not protect against moisture. For “wet” rooms or outdoor installation, you need to look for more reliable options.

NEMA/UL marking: explanation

As noted, this marking is used in the USA and in rare cases in Europe. Here, the designation uses a number and a letter. Here is a brief description and correspondence with IP.

The meaning of the numbers after the Nema marking:

- 1 (IP 20, 30) - protected from dirt and finger contact;

- 2 (IP 21, 31) - used in rooms where there is a risk of dirt and moisture getting on the surface;

- 3 (IP 64) - used for outdoor installation, protected from temporary exposure to fine dust, moisture and icing;

- 3R (IP 32, 34) - withstands temporary icing and precipitation;

- 3S (IP 64) - protected from precipitation, dust, wind, snow and icing without loss of functionality;

- 4 (IP 56, 65, 66) - used for installation outdoors and near the road, where there is a risk of water or dirt;

- 4X (IP 56, 65, 66) - withstands heavy precipitation, wind, dust, water jets, icing without the risk of corrosion;

- 6 and 6P (IP 65, 66, 67) - suitable for working underwater for long periods of time, but at shallow depths;

- 11 - for objects with an aggressive environment and a risk of corrosion;

- 12 and 12K (IP 52, 65) - used for indoor installation, protected from dirt, dust and liquid drops;

- 13 (IP 54, 65) - for indoor installation where there is a risk of dirt, dust, water, oil, coolants.

Having such information at hand, it is easier to choose a power outlet and not be mistaken with the degree of protection.

Symbol on the diagram

For ease of reading diagrams and servicing electrical equipment, symbols are used. In the Russian Federation, this parameter is specified in GOST 21.614-88. It was introduced in July 1988 and completely replaced the old version of GOST 2.754-72, which was in force during the USSR.

In construction drawings and diagrams, electrical outlets are designated as a semicircle with a “spire” installed in the middle.

Depending on the type of outlet, the designation may vary.

For open installation:

- Bipolar (double) - a semicircle with two parallel “spires” at the top.

- Two-pole with protective contact - a semicircle with a horizontal stripe at the top and a “spire”.

- Three-pole with protective contact - a semicircle, a horizontal line and three stripes directed upwards.

There are also special features for hidden and indoor sockets. The main difference is that the strip does not start from the end of the semicircle, as in the cases discussed above.

In single waterproof sockets with and without protective contact, the designation is the same as in ordinary cases, but the semicircle is filled in.

If a switch comes with the socket, another “antenna” with a curved edge at the end is added next to the spire.

Sockets on the diagrams.

How to choose a power outlet based on technical characteristics

When choosing a device, understand the basic technical characteristics. They can be judged by the designation of the device.

When choosing, you need to pay attention to a number of parameters:

- current, A;

- voltage, V;

- protection (IP);

- presence of grounding;

- Climatic performance;

- dimensions;

- number of poles.

Let's consider an example of designation - RSh-Ts-20-0-01-10/220. The name indicates that you are holding a plug socket with the following parameters:

- type - recessed;

- purpose - open wiring;

- number of phases - one;

- grounding - yes;

- network - 220 V, 50 Hz.

Another example from RS-16-006:

- voltage - 250 V;

- protection - IP20;

- current - 16A;

- climatic version - UHL4;

- overall dimensions - 80x80x30;

- number of poles - two.

When purchasing a device, it is important to consider a number of additional criteria:

- Manufacturer: Schneider Electric, Legrand, IEK, ABB, Svetozar and others.

- Purpose - power, cable, information, computer, acoustic, radio, telephone, etc.

- Material - plastic, aluminum, rubber, ceramics, wood, metal, etc.

- Number of places - single, double, triple, quadruple.

- Grounding - yes or no.

- Type of wiring - open, hidden.

- Installation method: indoor, outdoor.

- Design features: built-in, overhead.

- Type of placement - portable, stationary, for example, floor sockets.

- IP protection degree (44, 54, 55, 66, etc.).

- Cover - with or without it.

- Manufacturer - Russia, China, Germany, Poland, etc.

- Maximum current - up to 32 A.

- Color - from white to black.

- Dimensions.

In practice, it is not necessary to take into account all criteria. Just look at the main parameters - type of installation, maximum current, presence of grounding and degree of protection.

Popular models

The modern market is saturated with plug sockets, so it is difficult for people without experience to make the right choice. Below we will look at the types of products and give some examples.

Three-pole socket with protective contact, 3k+n

Three-pole receptacles are devices with three poles and designed to supply 380 V.

Many models have grounding (mandatory according to the new GOST rules), and non-flammable material that is resistant to heat and fire is used for the base.

Three-pole devices, as a rule, have an external design and are equipped with rubber bushings to protect the insides from moisture and dust.

Example - socket RSh 30-0-V-A-25/380. It has a pin design and a grounding contact, designed for electrical devices of the alternating current network.

Operating frequency - 50 Hz, voltage - 380 V, rated current - 25. The product has four contacts for connection and weight 95 g.

Two-pole with grounding contact

Plug sockets with a grounding contact are classified as two-pole. This is explained by the fact that the main task is assigned only to phase and zero, and “ground” plays an auxiliary function and is used only for protection.

Ideally, to connect such sockets, you need a grounding bus in multi-story buildings or a separate circuit in a private cottage.

One example is Legrand Valena 774370. This is a socket from a world-famous manufacturer. Has a hidden type of installation. Plastic is used as the main material.

Protection degree IP 20, which requires installation only in “dry” rooms. Voltage and current are 220 V and 16 A, respectively. Dimensions (HxWxD) - 12.2x8.2x4.1 cm. Additional options include grounding.

Plug socket with switch

In modern apartments, sockets with a switch are increasingly used, allowing you to turn on electrical appliances and supply voltage to built-in lamps.

One example is a socket with a built-in Switch round switch. It is designed for a standard voltage of 220 V and a current of 6 A.

The switch is made as a push type. Protection is IP20, so installing the product in wet areas is impossible.

Structurally, the device has a housing with an enlarged surface to accommodate a switch.

A three-wire wire (phase, neutral and ground) goes to the socket, and a wire goes to the switch, breaking the phase directed to the furniture lamps.

Plug sockets with RCD

When arranging electrical wiring, safety and the preservation of human life in the event of a short circuit come first. Thus, many models have a built-in residual current device that disconnects the contacts in the event of a short circuit in the Network.

The device controls the amount of current at the input and output. If there is a large difference between these parameters, a shutdown occurs.

An example is a socket with a Brennenstuhl RCD with protection class IP54 and a rated current of 30 mA.

Model features:

- moisture protection IP 54;

- voltage - 230 V;

- frequency - 50 Hz;

- leakage current - up to 30 mA;

- response time - 30 ms;

- rated current - 16 A;

- dimensions - 2.3x1.48x0.72 mm;

- weight - 181 g;

- maximum short-circuit current - 500 A.

The model is made in Germany, which is additional proof of its quality.

Recessed type socket with hidden wiring

Such products are in greatest demand due to their convenient installation and aesthetic appearance. Built-in devices are mounted inside the wall.

A recess is first made, after which the box is inserted. When installed correctly, the product almost does not protrude above the surface.

Depending on the situation, you can install a single or double socket. When placed in the kitchen, you can plan three or more outputs to connect different electrical equipment.

If there are more than two products, they are each installed in their own box, and a common frame is put on top.

An example of a recessed type product is a Lexman Victoria built-in double socket for 16 A and 220 V. It has a protection class of IP 20. The body is made of non-flammable dense plastic. White color. Dimensions - 11.3x8.2x4 cm.

IP44 plug sockets

We have already talked above about the IP classification and the features of sockets with a high degree of protection from moisture and dust.

We will not repeat ourselves, but will give two examples:

- Schneider Electric Cedar Plus WDE000643 is a 16 A and 220 V grounded socket outlet. It has grounding contacts and protective shutters. Installation type: overhead. The product is sold assembled. Manufacturer: Poland.

- Schneider Electric Cedar Plus WDE000543. The model has a similar design and characteristics, but differs in design and color of the cover.

Alternatively, you can choose a device with two pairs of terminals, for example, the Schneider Electric Cedar Plus Grounded Receptacle with Curtains and White Cover (WDE000525).

IP20 plug socket

Models with protection class IP 20 are designed for installation in ordinary rooms without the risk of moisture and dust getting inside.

Let's highlight a few examples:

- HausMark Bela white SNG-SCP.RD20MG1WG-WH. Standard household socket with one connector for indoor installation. The rated current of the product is 16 A, and the voltage is 220 V. It is possible to connect equipment with a power of up to 3.5 kW. The housing is made of plastic and has a screw clamp.

- HausMark Alta white SNG-SCP.SQ20MG21WG-WH - dual plug socket for 220 V and 16 A. It has an internal mounting type and is intended for equipment with a power of up to 3.5 kW.

There is a large selection of models on the market, so there is no point in focusing too much attention on them.

general characteristics

The main reason for the popularity of hidden fittings is safety. Such an outlet is more difficult to mechanically damage, since for the most part it is not on the surface, but is recessed into the wall. The wiring is laid in specially made grooves, which are channels hollowed out in the wall. It is easiest to create grooves in drywall, but in the case of brick or concrete, making grooves will require serious labor costs.

Among other advantages of hidden installation, it is worth noting the greater aesthetic appeal, since only a small socket body is located on the surface. However, in some cases it is recommended to opt for open fittings (for example, in wooden buildings). You have to sacrifice the appearance of the room in order to reduce the labor intensity of the process.

Hidden type sockets are classified based on the number of sockets they contain into:

- single;

- double;

- block.

The best choice is to install a single type of device. Moreover, the installation features of a recessed type socket with hidden wiring are dictated by the characteristics of the material. For example, when working with foam plastic or drywall, you will have to proceed from special installation rules that take into account the fragility of these materials.

Connectors are available with or without grounding. Of course, from a safety point of view, devices with grounding are preferable, since such sockets cope better with voltage changes in the electrical network. You should also take into account the fact that an ungrounded device will require a deeper niche (1-2 centimeters) than a grounded one. Devices with a ground pin are connected to a ground wire. Connectors with grounding are preferred for connecting electric stoves, refrigerators, air conditioners and other large household appliances.

There are two-pin and three-pin single connectors. Their main difference with single-pin ones is how the sockets look (they can be flat or round). Nests can be symmetrical or asymmetrical. The appearance of the sockets depends on the type of electrical appliances for which they are oriented.

If it is necessary to connect several devices to one connector, it is necessary to provide a double or triple device. There are two types of double sockets: horizontal in relation to the wall and vertical.