The strength and durability of any building, be it a summer house, a two-story cottage, a bathhouse or an ordinary garage, depends on the reliability of the foundation. And a strip foundation is in most cases the most suitable for such construction. Reliable, simple and quick to manufacture, and at the same time relatively inexpensive, it meets all the requirements that most potential owners place on it. Of course, when starting to design construction, you should not forget that for any foundation of a house or garage you need high-quality, durable and reliable fittings. Without it, it is stupid to even talk about the reliability of the design.

IS IT POSSIBLE TO DO WITHOUT REINFORCEMENT IN THE FOUNDATION

A foundation without reinforcement turns out to be completely inappropriate if the soils at the building site have some mobility.

A strip foundation without reinforcement can simply be torn apart when the earth moves. Is it possible not to reinforce the strip foundation?

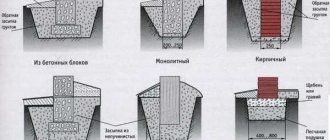

Strip foundation without reinforcement

For some types of soil, absolutely not. There is a clear example where a man decided to build a foundation on clay, in an area where most people build on stilts. As a result, its tape base was torn in several places the very next season. The reinforcement in the foundation not only strengthens the strength, but also gives elasticity.

A strip foundation without reinforcement has a reduced service life in most cases.

Is reinforcement needed in a strip foundation?

In most situations it is necessary. There is no alternative. Saving on fittings is inappropriate here. Moreover, the optimal way to fasten a reinforced frame is knitting. Using a special binding wire, you can quickly create a high-quality and durable frame. If the connections are fastened by welding, the structure of the rod is damaged. A foundation without reinforcement during the process of mandatory shrinkage, which lasts about 5 years, is highly likely to crack. Therefore, saving on frame material is unacceptable.

Is it possible to pour a foundation without reinforcement?

Technically this is quite possible and can be done many times. But you should understand exactly how reinforcement works at the base of a building or structure. It does not allow the tangential forces that develop during frost heaving to damage the integrity of the base.

This means that the foundation may not have a frame only if there is no ground movement. Otherwise it is required.

The procedure for reinforcing a strip foundation

The existing scheme for reinforcing a strip foundation for building a house requires following several mandatory rules:

- Application when carrying out reinforcement of rods of class A400

- Minimizing the use of welding when connecting rods, as this technology helps to weaken the sections

- At the corners, the frame can only be tied; the use of welding at the corners is not recommended

- The protective layer of concrete used in a particular situation must be at least 4 centimeters to protect metal elements from the negative effects of the environment and corrosion

- The use of smooth reinforcement is not recommended

- During laying, concrete must not be able to get stuck between the rods, which will eliminate control over failure due to too frequent placement of metal rods

Detailed step-by-step instructions with photos and videos provided for clarity will help you create a reinforcement frame. A significant advantage of reinforced strip foundations is the combination of high reliability and affordable cost. Steel and concrete are high-strength materials.

This is important for creating a foundation for construction on any soil, except for naturally stable and reliable rocks. In other situations, reinforcement of any foundation will eliminate damage caused by stress

How is it formed

When carrying out work such as reinforcing a strip foundation, the drawings include three groups of rods:

- Working rods used for laying along the belt

- Horizontal elements arranged transversely

- Vertical options, transverse

The task of transverse reinforcement is to connect all working elements into a single unit of reliable, innovative working rods that is stable in use. They are often called clamps.

An important feature of the work is the use of SNP and other regulatory specialized documents for activities such as reinforcement of strip foundations. When calculating, SNiP 52-01-2203 is used

In this regulatory document it is easy to find all the necessary calculations for creating reinforcement for the strip foundation of a small country house.

What requirements for concrete are determined by regulatory documents?

If you follow the order of creating reinforcement, it is important to comply with the mandatory requirements for the concrete used in a particular work. When creating a strip foundation with your own hands at the site of future construction, it is worth considering that the main characteristics of the strength of concrete structures include resistance to axial compression, readiness to withstand tension and not respond to transverse fracture

Reliability correction factors can vary from 1 to 1.5

When creating a strip foundation with your own hands at the site of future construction, it is worth considering that the main characteristics of the strength of concrete structures include resistance to axial compression, readiness to withstand tension and not respond to transverse fracture. Reliability correction factors can vary from 1 to 1.5.

Requirements for fittings

These indicators are determined by regulations and standards. A reliable foundation uses reinforcement based on rods:

- hot-rolled reinforcement of periodic profile,

- mechanically strengthened reinforcement

- heat treated reinforcement

It is GOST that makes it possible to calculate indicators of immersed limit states, which are strictly divided into groups. Indicators are determined on the basis of the requirements prescribed in state standards, which are determined on test benches. Any regulatory and technical documentation that is used to determine the reliability of reinforcement must be approved by official regulatory authorities.

What basic rules are important to consider when performing work?

As a rule, reinforcement during suburban construction and construction is carried out independently. In this case, the requirements of SNiP and GOST are not always followed so carefully.

For this reason, when considering how to reinforce a strip foundation with your own hands, it is important to adhere to some mandatory rules:

- When reinforcing the strip foundation of a future building, including 1-2 floors, rods with a diameter of 10-24 mm are used.

- The use of welded joints is not recommended

- When creating a strip foundation with your own rivers, the mandatory creation of formwork will be required

Reinforcement scheme

An example of a diagram (drawing) of reinforcement for a slab foundation.

Reinforcement of a reinforced concrete slab is carried out unevenly: additional reinforcement is required in places where walls or columns support. Such areas are called squeeze zones. The reinforcement is laid in one layer with a slab thickness of 150 mm or less. If the value is more than 150 mm, reinforcement is performed with frames. As an example, it is necessary to consider the main components of the structure.

Basic slab width

Here the scheme is a grid with a constant cell size. The pitch of the rods in both directions should be the same. Depending on the design load, it is taken within the range of 200-400 mm. For brick houses, a reinforcement pitch of 200 mm is suitable; for lighter frame houses, rods can be laid less often

It is important to take into account that according to the joint venture “Concrete and reinforced concrete structures”, the distance between the rods should not exceed the thickness of the slab by 1.5 times

Slab reinforcement diagram.

Most often, the rods are laid in two rows: upper and lower. Their joint work is ensured by the installation of vertical rods. The pitch of such rods can be equal to the pitch of the main reinforcement or taken twice as large.

The slab is reinforced at the ends with U-shaped clamps.

According to SP 63.13330.2012 (clause 10.4.9), at the ends the slab must be reinforced with U-shaped reinforcement bars, the length of these bars must be equal to 2 times the thickness of the slab or more. The rods connect the upper and lower rows of reinforcement and provide the perception of torques at the edge of the slab and the anchoring of the ends of the longitudinal reinforcement.

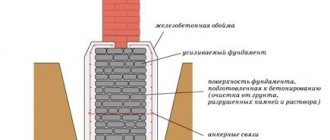

Attention! The reinforcement should be recessed into the concrete by 20-30 mm on all sides: from below, from above, from the ends. Otherwise, accelerated corrosion of the reinforcement and destruction of the structure is possible.

Punching zones

In places where supporting vertical structures support, the layout changes - the reinforcement pitch is reduced. For example, if along the main width of the slab the rods were laid every 200 mm, then under the walls it is recommended to use a step of 100 mm. This will avoid excessive pushing and cracking.

Interface area with a monolithic basement wall

The design of the slab allows it to be made flush with the ground surface, but if a basement is planned for the building, its laying depth will depend on the height of the room. In this case, it is necessary to ensure that the base and walls work together.

Reinforcement outlets in the slab for mating with monolithic walls.

To properly reinforce the foundation, it is necessary to tie together the frames of the monolithic wall and the slab. When pouring the foundation, outlets are left in the form of vertical rods; they will be the connecting link. The ends of the outlets are launched into the body of the slab (they are bent at the end to 2 heights of the slab and knitted to the main frame).

For convenience and accurate calculation of materials, a drawing is made that shows a reinforcement diagram, including data on the distance between the rods and their diameters.

Selection of fittings

When manufacturing steel reinforcement, we are guided by GOST 5781-82*. For a reinforced concrete monolithic slab, rods of class A400 (or in the outdated version All) are used. To avoid mistakes, you need to know how to distinguish rods of different classes visually.

- A240 (Al) has a smooth surface;

- A300 (All) is characterized by a periodic profile with a ring pattern;

- A400 (All), the one that is needed, has a periodic profile that forms a “herringbone” (crescent).

Important! The use of fittings of lower classes is not permitted. We recommend: What reinforcement is needed for the foundation

We recommend: What reinforcement is needed for the foundation.

Classification of steel reinforcement

There are several classifications of metal reinforcing materials.

Materials can be of different diameters and are sold in construction stores in the form of skeins.

According to the profile shape, steel rods can be:

- smooth;

- ribbed.

Marking A1 belongs to smooth profiles, and A2-A6 belongs to periodic or ribbed profiles.

More details about the classes of reinforcement can be found in the table:

| Class | Diameter in mm | steel grade |

| A1 (A240) | 6-40 | St3kp, St3ps, St3sp |

| A2 (A300) | 10-40,40-80 | St5sp, St5ps, 8G2S |

| A3 (A400) | 6-40, 6-22 | 35GS, 25G2S, 32G2Rps |

| A4 (A600) | 10-18(6-8), 10-32(36-40) | 80C, 20ХГ2Ц |

| A5 (A800) | 10-32(6-8), (36-40) | 23v2G2T |

According to production technology, fittings are divided into:

- hot-rolled rod reinforcement (GOST 5781-82). Its appearance resembles a smooth or ribbed rod;

- cold-drawn wire reinforcement (GOST 6727-80).

The basic rule says that it is better to select corrugated rods for the base, and any types are suitable as auxiliary rods

Their appearance is completely the same, the only difference is in the manufacturing technology.

Depending on the location in the frame, the reinforcement is divided into:

- transverse (used to prevent cracks in structures);

- longitudinal (which takes on part of the building loads).

But for construction work, the latter classification is more important.

Reinforcement class and steel grade

The strength of the material can be judged by the class of reinforcement. Along with the new marking, the old one is still used, so we will mention both:

- A240 (according to the old GOST - AI) is hot-rolled steel with a smooth surface, diameter - 6-40 mm. Reinforcement with a diameter of up to 12 mm can be supplied in coils and rods, more than 12 mm - only in rods. It is not suitable for foundation construction as working reinforcement, but can be used for clamps;

- A300 (AII) - reinforcement with a ring-shaped profile; it is not recommended for use in the construction of foundations, but in private construction it is still used for small buildings and non-critical objects. Naturally, it can be used as structural reinforcement;

- A400 (AIII) and A500 are ideal for foundations. The rods have a relief, the diameter ranges from 6 to 40 mm, length - from 5 to 11.7 m;

- A600 (AIV) – high-strength reinforcement, used in the construction of critical facilities, suitable for structures with prestressing;

- A800 (AV) and A1000 (AVI) reinforcement is used in the construction of multi-story buildings, bridges and other structures where special strength is extremely important.

In addition, other types of steel reinforcement are used in the construction of the foundation, the properties of which can be judged by the markings:

- the letter C indicates the ability to fasten the rods into a frame by welding (examples - A400C, A500C, A600C). A500C class fittings have recently become especially popular;

- the letter K indicates resistance to corrosion (A400K, for example);

- At in the marking means that the steel has been strengthened thermomechanically. The intermittent cooling used in this technology increases strength and corrosion resistance. A popular class of such fittings is At800.

GOSTs and technical specifications require the use of a specific grade of steel for the production of a certain type of reinforcement. The manufacturer must indicate what kind of steel he used - this is very important information for the developer, allowing him to correctly perform all the necessary calculations.

Some of the steel grades used are shown in the table below. The characteristics of each brand are the topic of a separate article. Here we only note that, for example, 35GS steel is low-alloy, and 25G2S steel is made using silicon and manganese as alloying additives. Both of these alloys are highly durable.

Which one is most often used and why?

A strip foundation is a reinforced concrete section along the perimeter of the building on which the walls are built. The strength of the entire building depends on the quality of the constructed platform.

Reinforcement in combination with concrete provides strength and compression of the structure.

For small one-story or two-story houses, metal alloys are most often needed, the diameter of which varies from 6 to 14 mm, which is tied with steel wire for strengthening.

The necessary calculation of the required amount of materials is carried out by specialists during the design of the facility. However, you can calculate it yourself. To do this, take the perimeter of the building, add to it the length of the walls that are involved in laying the strip foundation and multiply the result by the number of rods in the reinforced box.

To calculate the diameter of the reinforcement, it is necessary to calculate the cross-sectional area of the vertical bars in the platform by multiplying the length of the building by its width.

Example: The width of the strip foundation is 20 cm, and the height is 60. This means the cross-sectional area is 1000.

However, the area of the vertical rods should be 0.1% of the total horizontal section of the foundation. That is, it is necessary to multiply the previously obtained result by 0.1%.

That is, 1 cm. In a special table you can determine the required diameter.

If it is not possible to purchase the required length of reinforcement, you can install them yourself.

However, the rods must overlap each other by at least 1 m to avoid damage. In addition, the following factors must be taken into account when calculating:

- there is no need to bury the reinforcement into the foundation, since the divergence zone is located on the surface.

- For transverse and vertical finishing zones, you can use smooth reinforcement. In this way, the load on the structure can be reduced.

- the distance between elements should be 150-400 mm.

Such recommendations will help reduce the load and avoid troubles during construction.

You can watch the video for more details:

How to choose fittings

When choosing reinforcement for the ceiling, you should take into account the following rules:

- If the base is being reinforced in a one-story house or two-story building, use reinforcement of 10-24 mm in diameter. If you take a thicker diameter of reinforcement, durable material - this pleasure is expensive. And the strength itself will not be used to its full extent.

- It is optimal to take corrugated type fittings. This way it is more securely attached to the concrete and ensures complete reliability. Smooth reinforcement is inexpensive, but it does not provide the necessary adhesion and strength. The exception is the transverse type connection.

- For homogeneous soil, reinforcement with a cross-section of 10-14 mm is used. If the soil is heterogeneous, then the load increases and the cross-section is chosen with a diameter of 16 - 24 mm.

Undoubtedly, purchasing thick, corrugated fittings is quite expensive. But if the reinforcement of your dacha house or bathhouse is carried out with your own hands, the volume of work in this case is small and, accordingly, its cost will not hit the budget too much.

Rules for reinforcing strip foundations

How to properly reinforce and strengthen a strip foundation in a building according to building codes? So the rules according to the standards for safe foundation construction are as follows:

if working reinforcement is applicable, rods of at least class A400 are applicable; It is not recommended to use welding - it will simply weaken the cross-section and, accordingly, reduce the adhesion to concrete; the metal frame at the corners must be tied together - welding in this place is also unacceptable; even when choosing a clamp, it is forbidden to choose models with a smooth surface of the reinforcement; be sure to observe the protective layer in the concrete structure - it is 4 cm, and it is this layer that protects the reinforcement from corrosion and destruction; when installing the rod in the longitudinal direction, they must be connected with an overlap equal to at least 20 diameters of the selected rod, and not less than 25 cm; if metal is often located in the structure, it is important to control the size of the aggregate in the concrete composition itself, which should not get stuck between the rods;

How the reinforcement is knitted - the binding method is mandatory, since it is this kind of frame that acquires greater strength, especially in comparison with a welded one. This is due to the high probability of unnecessary burning of the metal itself, although this rule does not apply to factory structures.

Figure 3. Knitting reinforcement

Laying reinforcement

In this case, the corners of the frame are also knitted - no welding using a knitting machine, specially provided wire

Before carrying out all construction work during the process of laying and strengthening the strip foundation, it is important to prepare the tools. In practice, two installation methods are used:

- use special hooks during the work;

- or he can use a more modern and portable tool - a knitting machine that works on the principle of a gun.

So, in the first option, the hook is more suitable for constructing a small foundation, but laying the reinforcement itself with this method of knitting takes a lot of time. For connection, it is optimal to use annealed wire with a diameter of 0.8 to 1.4 mm. The use of other materials for binding is simply unacceptable, since most of them are not able to withstand the weight of the structure.

Foundation reinforcement technology

Let us consider the influence on the calculation of reinforcement of the methods of its laying and fastening, depending on the type of reinforcement

Understanding how to lay it and knit it will help you decide what kind of reinforcement is needed for a strip foundation. Material for the site moydomik.net

Laying reinforcement

As for the technology of laying reinforcement along smooth runs, the consumption for steel and fiberglass will be the same.

Corner installation of reinforcement But there can be problems with corners. The fact is that, according to technology, it is unacceptable for the ligament node to fall on the corner of the foundation.

A bend is required, which is impossible to make from composite reinforcement.

On the contrary, a steel rod is relatively easy to bend at the desired angle and ensures the main rule of corner installation - the edges of the rods must extend into adjacent sides of the foundation.

Corner connection for fiberglass reinforcement In principle, corner connection for fiberglass reinforcement can be realized using special corners.

Knitting reinforcement for the foundation

The following knitting methods are suitable for steel reinforcement:

Welding (joining, joining) of reinforcement

Welding (joining, connecting) reinforcement This is the most common method of fastening. He gives the impression of being the most reliable. However, its disadvantages are that it cannot weld rods with a diameter of 20 mm. impossible. And due to the high temperature of the welding arc, the strength of the hardened reinforcement rod is lost. At the same time, material consumption with this type of connection is reduced, since there is no need to ensure a long overlap of reinforcement when knitting.

Good to know. Welding is unacceptable when constructing a shallow foundation on heaving (loose) soils. This is due to the fact that the soil may sag, and a rigid structure will lead to misalignment of the foundation and the entire house.

Knitting reinforcement with wire

Knitting reinforcement with wire In this case, two rods are superimposed (joined) on top of each other and secured with ordinary wire. Requirements include reliable wire.

The overlap length of the reinforcement ranges from 500 to 1,000 mm. In this case, the wire consumption per node is 200 mm.

Knitting reinforcement with a gun

Knitting reinforcement with a gun Special wire staples are placed in the gun, which quickly fasten the rods together. An overlap of at least 500 mm is required.

How to knit fiberglass reinforcement?

Tying composite reinforcement with plastic clamps

Tying composite reinforcement with plastic clamps The principle of operation is the same as tying with wire.

An overlap of at least 500 mm is required.

In order to make it more convenient to work with the fittings, plastic clamps are used - bosses.

What is reinforcement and why is it needed?

Knitting reinforcement

Reinforcement is an increase in the strength of a concrete base using metal reinforcement. This technique allows you to avoid the formation of cracks in the foundation, increase frost resistance and prevent deformation.

Reinforcement is made with a special steel structure, which is then filled with concrete.

There are three types of building reinforcement:

- The horizontal type is the most common; it is the one that will evenly distribute all loads across the foundation during the operation of the building and shrinkage;

- Vertical reinforcement is used less frequently; it serves only as an additional element of strength;

- Mixed reinforcement is usually used in the corners of the house to increase the stability of the frame.

Common mistakes

All methods of corner and adjacent connections of reinforcement are aimed at maintaining the integrity of the reinforcement frame, regardless of its configuration. The strength of the strip foundation depends on the correct anchoring of the end elements of the longitudinal reinforcement. The following schemes lead to incorrect reinforcement of the corners of a strip foundation:

1. Reinforcement of the corner zones of the strip foundation with reinforcing crosses with viscous longitudinal reinforcement bars at right angles. 2. Installation of bent longitudinal reinforcement in corner and adjacent areas without anchoring.

These mistakes are the most common and can lead to destruction of the foundation at corner joints and abutments.

Corner and adjacent connections made by knitting crosswise longitudinal reinforcement bars

A typical mistake in reinforcing corners and junctions is connecting longitudinal reinforcement using the cross-knitting method. Such a reinforcement connection without proper anchoring of the rods can lead to the destruction of the concrete monolith due to multidirectional loads occurring at the corners of the strip foundation.

Rice. 9. A common mistake when reinforcing corners

Application of bent longitudinal reinforcement for reinforcement of corner joints and abutments

1. Corner connections without a connection of internal and external longitudinal reinforcement (1) do not provide rigid rod fixation. 2. Destruction of the foundation can occur not only due to the formation of transverse cracks, but also due to peeling of internal corners.

Rice. 10. Another example of incorrect corner reinforcement

Be sure to read: Is it possible to reinforce a strip foundation with fiberglass reinforcement if you are going to use it?

In order to prevent the formation of cracks, spalls and delaminations at the corners and junctions of the strip foundation, it is necessary to correctly tie the end rods of the longitudinal reinforcement and perform their reliable anchoring. Correct reinforcement of the corners of a strip foundation is the key to the reliability and durability of the building.

Good publicity

Purchasing material

Quite rarely, reinforcement is sold by linear meters. Usually sellers of fittings count it in kilograms. In order to accurately determine the required quantity, a calculation table is needed. Enterprises producing rolled metal products must use and comply with GOST 5781-82. It indicates the mass of a meter of the product. There is also GOST 2590-88, which determines the weight of round steel. I would like to clarify that the numbers in both documents are the same. Which one should you prefer? Everything will depend on the ease of use of this reference literature.

Knitting reinforcement using a special device - a knitting machine

To create this tool, you need to take several boards 20 millimeters thick, cut 4 boards along the length of the reinforcement, connect two at a distance equal to the pitch of the vertical posts, creating 2 identical templates. Next, two vertical supports are made with a height equal to the height of the reinforcement mesh. The supports are constructed with side corner stops; it is better to choose a flat area for work.

The device is used as follows: the legs of the stops are installed on two knocked down boards, the two upper boards are placed on the top shelf of the stops and fixed. That's it, the reinforcement mesh layout is ready, now you can quickly knit it. It is enough to place the vertical reinforcement struts in the marked places, fixing them with nails, install the rods on each steel lintel, doing this on all sides of the frame. Next, take a hook and wire - that’s it, you can knit. Such a device is relevant where it is planned to create many similar mesh sections.

Reinforcement scheme

For a private country house, two reinforcement schemes are used, which are performed with four or six stitches. The second option is used for foundations more than 0.5 meters wide.

Reinforcement bars with a length equal to the depth of the foundation are driven into the trench soil. Waterproofing materials are laid at the bottom of the formwork and bricks are laid. A reinforced mesh or frame is installed on top. To knit the frame, the reinforcement bars are tied into square cells, which are tied with wire.

The cell side length is 30-60 cm. The mesh is installed 50-70 mm from the edges of the trench. The mesh is laid in two rows of two or three threads. The rows are attached to the vertical pins using tie wire. After reinforcement, do not forget to make ventilation and sewer holes, only then fill the formwork with concrete.

“MariSrub” craftsmen will select the appropriate type of foundation, perform reinforcement and installation of the structure, calculate the amount of building and consumable materials, and install ventilation and sewer systems. We build high-quality and reliable wooden houses from logs and timber on a turnkey or shrinkage basis!

Requirements for fittings

To understand what reinforcement is needed for a strip foundation, it is necessary to perform calculations and consider the main types of material. To perform the work, mechanically strengthened, hot-rolled, heat-treated construction reinforcement is used. The class is selected according to maximum loads, taking into account tensile characteristics, ductility, weldability, corrosion resistance, ability to withstand temperature changes, etc.

The main brands of rods: hot-rolled rod (A), cold-deformed wire (BP), very strong rope (K). For the foundation frames, rods of the A400 (AIII) yield strength class with a crescent-shaped herringbone pattern are selected.

Proper reinforcement involves the use of the following types of rods:

- Workers - for laying around the perimeter

- Transverse vertical

- Transverse horizontal (clamps)

- Additional - usually a binding wire is used instead

To understand which fittings are best to use, you need to remember some rules. To strengthen the base of one- and two-story buildings and light structures, rods with a diameter of 10-24 millimeters are suitable. The strength characteristics of thicker (and much more expensive) reinforcement are unlikely to be used.

The rods must be corrugated, as they provide excellent adhesion to the concrete mortar; their thickness must clearly correspond to the values specified in the documents. Smooth rods are cheaper, but they will not allow you to create a reliable and durable reinforced frame. They can only be used in transverse connections where the load is not very large.

When creating a strip foundation frame on homogeneous soil, you can choose a material with a diameter of 10-14 millimeters; on heterogeneous soil, 16-24 is better. If the side of the building is more than 3 meters, the working reinforcement of the monolithic foundation is made from rods of at least 12 millimeters, but not more than 40.

The technology requires that horizontal clamps in diameter should not be less than a quarter of the working rods - usually 6 millimeters. Vertical rods for low-damage foundations of 80 centimeters or less should be at least 6 millimeters in cross-section. Having thought everything through, you can determine what diameter of rods is needed for different types of work.

Factors influencing the calculation of reinforcement for the foundation

The diagram shows an option for installing a strip foundation

The calculation of the amount of reinforcement is influenced by the following factors:

- Type of foundation.

The diameter of the reinforcement for strip foundations is 10-14 mm;

Advice. If you are not going to build a heavy building, then you can be guided by the rule - the minimum permissible cross-section of the rod (thickness) of the reinforcement for the foundation can be determined by mathematical calculation.

Formula for calculating reinforcement:

Where, D min is the minimum permissible reinforcement section;

Sd – cross-sectional area of the foundation strip.

- Purpose of fittings.

- Belt (number of reinforcement belts). The strip foundation is reinforced in two belts.

- The dimensions of the foundation are its length and width.

- Cell size. It is recommended to make no more than 500 mm.

- Number of connections.

- Required adhesive strength. The smaller the distance between the reinforcement protrusions (notches), the stronger the contact with the concrete. Smooth rods of class A1, suitable for outbuildings, low-rise buildings and weight.

Minimum diameter of reinforcement for foundation (table)

Minimum diameter of reinforcement for foundation - use - table

Reinforcement scheme

The number of longitudinal rods located depends on the width of the strip foundation; in individual construction, two options are common: with four and six rods. The second system is relevant when the dimensions of the monolith exceed 50 cm. This is due to the basic requirements for the placement of reinforcement, according to SNiP 52-101-2003: the distance between longitudinal lines should not exceed 40 cm; The recommended gap between the metal frame element and the edge of the concrete is 5-7 cm.

It is impossible to recess the rods into the center, as well as to allow them to be located near the ground due to the increased risk of corrosion. The additional rod is attached exactly in the middle, the distance between the lower and upper chords varies between 60-80 cm, this scheme is ideal for the foundation of a one-story house no more than 1 m high. Transverse and vertical rods cross each other in one node, the placement interval is from 30 up to 80 cm; for ease of calculation, it is often taken equal to 50.

Corners require special attention; in areas of stress redistribution, the frame is reinforced with curved rods. Recommended schemes include anchoring with L-shaped or U-shaped elements, or bending a longitudinal row. Supporting reinforcement is laid in the upper chord, the minimum length of one side is 50 cm. Also in these areas, the spacing of longitudinal rods is reduced, the step for foundations of a standard section is 25 cm. Fulfillment of these conditions is relevant even when constructing light buildings such as a bathhouse, a conventional wire tie in corners are not enough.

Calculation of reinforcement for strip foundations

The initial data are the geometric dimensions of the future base. The calculation is carried out at the design stage of the house, simultaneously with drawing up a diagram of the location of the rods. The process begins with the choice of diameter; for a strip foundation, it is allowed to use different types of hardware for longitudinal (main) rows and vertical and transverse ones. The minimum laid down for horizontal load-bearing rods is 12 mm, an exception is made for light buildings such as a bathhouse (but not less than 10 mm). Reinforcement of the same cross-section with the same grade of steel is used; if there is excess, it is allowed to lay products with a large diameter to form the bottom row.

Knowing the size of the belt perimeter and the number of rods, at first glance, it is easy to find the total footage. But the calculation becomes more complicated due to the need to use solid reinforcement. Ideally, the longitudinal rods are inseparable; when connecting two sections shorter than the length of the wall, the permissible minimum margin is 30 cm. Curved elements to strengthen the corners are not inferior in diameter, their total footage depends on the number of turns, areas of contact with internal load-bearing walls are included in the calculation .

The required length for transverse and vertical rods is also calculated according to the selected scheme. The easiest way is to calculate the footage per joint and multiply it by the number of nodes. Even if the frame is connected by welding, the reinforcement for the foundation is not cut to size; taking into account overlaps and starts is mandatory. It is impossible to accurately take into account the size of the protruding sections; to simplify the calculation, they are taken equal to 10% of the total footage of the mounting rods.

The nuances of knitting reinforcement

A welded connection is not suitable for strip foundation frames: in addition to increasing costs, it does not provide sufficient reliability; the joints corrode over time. The only possible method of fixation is tying with plastic clamps or steel wire. Its calculation is simple: the number of knots is multiplied by the length of the segment required to wrap around the rods and twist the ends (usually 30-50 cm), the resulting footage is converted into kg.

The recommended wire cross-section for reinforcement diameters of 12 mm and above varies between 1.2-1.4 mm. For tying, a hook and pliers or a special gun are used (an expensive tool, but justified for large volumes of work).

Calculation of reinforcement for strip foundations

Many builders use an indicator of at least 8 kg. Reinforcement for 1 cubic meter of concrete. But in this case, you will receive an extremely approximate calculation that does not reflect reality.

Once you have decided on the type of reinforcement and its diameter, you should draw up a detailed diagram of the spatial frame of the future strip foundation. Only with this approach will you be able to calculate the required reinforcement with minimal waste and optimal margin.

The simplest and most universal calculation of reinforcement for a strip foundation is based on the length of all foundation strips. But the calculation by length also does not reflect the full reality, since this approach does not take into account overlapping connections in corners, abutments, at reinforcement joints, etc. To cover them, you can set aside a reserve of 10%.

Let's look at the example of strips with a cross-section of 40*100 cm. The sides of the base of the house are 10*10 m, with one transverse in the middle (also 10 m).

Thus, the simplest calculation of reinforcement will look like this:

The total length of the tapes is 10 * 4 (these are external walls) + 10 (one internal partition) = 50 m.

When using 12 mm reinforcement as working reinforcement (4 rods), you will need: 50 m * 4 * 1.1 (10% margin) = 220 meters.

Structural smooth reinforcement 8 mm forms a square with a perimeter of 1 * 2 + 0.4 * 2 = 2.8 m. With a step of 60 cm, you will need 50 m / 0.6 = 84 such squares. That is, 84 * 2.8 = 235 meters. If you use special supports for working reinforcement (to remove the frame from the formwork), you can slightly save 40 cm from each square (its perimeter will be 2.4 m) and then you will need 2.4 * 84 = 201 meters.

If the reinforcement at the point of sale is sold by weight, then the resulting volume should be calculated and multiplied by the density of the steel.

For example, the cross-section of 12 mm reinforcement is 0.0001131 square meters. Volume 220 meters – 220*0.0001131 = 0.024882 cubic meters.

With a steel density of 7850 kg/m3. (7.85 g/cm3) we get 7850 * 0.024882 = 195 kg.

Similar calculations must be made for structural reinforcement (smooth rods).

A table in which the main diameters of steel reinforcement have already been calculated for convenience.

Calculation of working reinforcement

When constructing serious structures, detailed calculations of the strip foundation are required, which will accurately determine which reinforcement to use for a given structure. All calculations in construction are carried out according to limit states, that is, the minimum conditions under which the element will perform its function are determined.

- The first group of limit states is strength calculation. Reliability and safe operation of the structure are ensured.

- The second group of limit states is rigidity calculation. Prevents excessive opening of cracks, distortions, and large deflections.

Calculations using these formulas are labor-intensive and require technical education. To simplify the design of small private buildings, strip foundation reinforcement is taken based on minimum values.

An example of calculating rods for a strip foundation

Initial data:

- tape height - 100 cm;

- tape width - 40 cm.

It is required to construct a frame for an individual residential building. Longitudinal, transverse and vertical reinforcement is used. The vertical one is taken with a cross-section of 8 mm and is installed in increments of 25 cm. The transverse horizontal one is mounted with the same increment, but with a diameter of 6mm.

In order to determine what working fittings are needed, perform a simple calculation

- Cross-sectional area of the foundation = width * height = 100 cm * 40 cm = 4000 cm².

- Required cross-sectional area of reinforcement bars = 0.1% * 4000 cm² = 4 cm².

Next, to determine which reinforcement to use, you need to refer to the assortment. The number of rods is taken to be even in order to distribute them evenly in the lower and upper horizontal layers.

| Diameter of fittings, mm | Total calculated cross-sectional area of reinforcing bars, cm2 | Weight of 1 meter of reinforcement, kg | ||||

| 2 rods | 4 rods | 6 rods | 8 rods | 10 rods | ||

| 8 | used only for foundation heights of 15 cm or less, which is not suitable for strip structures | 2,01 | 3,02 | 4,02 | 5,03 | 0,395 |

| 10 | 3,14 | 4,71 | 6,28 | 7,85 | 0,617 | |

| 12 | 4,52 | 6,79 | 9,05 | 11,31 | 0,888 | |

| 14 | 6,16 | 9,23 | 12,37 | 15,39 | 1,21 | |

| 16 | 8,04 | 12,06 | 16,08 | 20,11 | 1,58 | |

| 18 | 10,18 | 15,27 | 20,36 | 25,45 | 2,0 | |

| 20 | 12,56 | 18,85 | 25,13 | 31,42 | 2,47 |

For this strip foundation, the minimum diameter is 12 mm according to the document “Reinforcement of elements of monolithic reinforced concrete buildings. Design Manual”, we accept it. According to the assortment, 4 rods are required: 2 are located at the bottom and 2 at the top.

Calculation of the amount of reinforcement for the foundation

Initial data:

- materials are indicated in the previous paragraph;

- the length of the strip foundation walls is 40 m.

It is required to calculate the mass of reinforcement of all diameters for a strip foundation. Working horizontal reinforcement

- Length: perimeter of the building * number of rods in the section + allowance for overlap when welding rods = 40 * 6 + 5 = 245 m.

- Anchoring of corners: number of rods in the section * number of corners * minimum anchoring length (50 reinforcement diameters) = 6 * 4 * (50 * 12) = 14.4 m.

- Weight: length*weight of one meter = (245+14.4)*0.617 = 230.3 kg of rods with a diameter of 12 mm.

Structural horizontal reinforcement The length of the rods is taken depending on the width of the tape wall minus the protective layer of concrete - 2-3 cm on each side. We accept longitudinal rods 34 cm.

- Number of rods: perimeter of the building/step of clamps (25 cm is assumed in the previous paragraph) = 40/0.25 = 160 pcs.

- Total length: quantity*length of one rod = 160*0.34 = 54.4 m.

- Weight: 54.4*0.222 (not indicated in the table above, but available in the full range) = 12.1 kg of rods with a diameter of 6 mm.

Structural vertical reinforcement Everything is as in the previous paragraph, the rods are installed with a length equal to: The height of the strip foundation minus 3 cm*2 = 100 - 3*2 = 94 cm.

- Number of rods: perimeter of the building/step of clamps (25 cm is assumed in the previous paragraph) = 40/0.25 = 160 pcs.

- Total length: quantity*length of one rod = 160*0.94 = 150.4 m.

- Weight: 150.4*0.395 = 59.41 kg of rods with a diameter of 8 mm.

For convenience, the obtained figures can be summarized in a table.

| Purpose | Diameter | total weight |

| Working | 12 mm | 230.3 kg |

| Transverse | 6 mm | 12.1 kg |

| Vertical | 8 mm | 59.41 kg |

We recommend reading:

Calculating the diameter of the reinforcement takes no more than 10 minutes, but will allow you to avoid waste of material or costs for repairing strip foundations. The table obtained in the last paragraph is convenient to use when purchasing material.

Good publicity

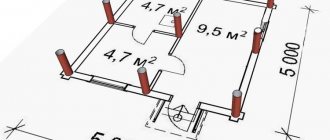

Example of reinforcement calculation

For example, it is worth calculating the reinforcement that will be required to install a foundation with dimensions of 6 by 5 m, in which there will be one load-bearing wall, 5 m long. In the diagram, a reinforcement rod with a ribbed cross-section is selected, in the amount of 4 pieces. and a diameter of 12 mm. The perimeter of the house is 22 linear meters (6+5+6+5). The length of the base along the inside of the wall will be 27 m; for calculation, the length of the load-bearing wall is added to the perimeter of the house. So, it turns out that 108 m of reinforcement will be required (27 m * 4). If you were unable to buy a rod of the required length, do not worry. You can connect metal rods to each other, and they should overlap each other by one meter when connected. The length of the overlap must also be calculated in advance.