Description

A concrete caisson is a sealed container that protects well equipment from mechanical damage. In addition, this structure provides:

- protection against penetration of animals and plants into pumps;

- concentration of water supply equipment in one place;

- protection of equipment from flooding;

- avoid freezing of pump parts.

The installation of caissons for wells, due to the tightness of the space, increases the service life of all structural elements.

In addition, equipping such a well with rings allows you to place the pumping equipment as close to the surface as possible without fear of freezing.

Types of caissons

Today, protective structures for wells are made of various materials:

- concrete (reinforced concrete);

- wooden;

- metal;

- plastic.

For a well, a concrete caisson is made from appropriate round-shaped rings. The wooden structure is similar to a traditional well, while the metal one is made from a large diameter pipe.

Let's look at how to make a reinforced concrete caisson at home.

Concrete structure

Installing a concrete caisson is easy to design, but requires the use of additional equipment, since such elements are difficult to lift by one person. Unlike its analogues, this material has a number of advantages:

- high strength;

- heavy (will not float);

- lasts a long time;

- cheap.

At the same time, caissons made of reinforced concrete rings have a number of disadvantages:

- require digging of a volumetric pit;

- during installation they require the presence of lifting equipment;

- not sealed.

A concrete well protection structure is ideal for:

- Low groundwater level.

- Areas where lifting equipment passes.

Installation of a structure made of concrete links has an attractive turnkey cost!

Concrete caisson for well

We take the same dimensions of the device - depth 2 m with overall dimensions 2.5 m. To cast a caisson from concrete, you will need the following tools:

Table: tools for casting a caisson

| Name | Purpose | Notes |

| Shovel | Preparation of concrete mixture and mixing of the solution | |

| Capacity | Preparation of the solution | |

| Concrete mixer | Preparation of the solution | Possible to rent |

| Carpenter's tool | Installation of formwork | |

| Pliers and side cutters | For working with tie wire for reinforcement | |

| Deep vibrator | Compaction of the solution when pouring | Possible to rent |

You will also need a tool to apply waterproofing to the outside of the cast housing.

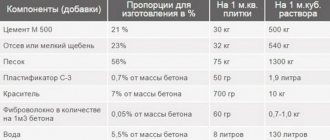

Materials for caisson

We calculate the volume of concrete that will be needed to cast a solid caisson body. A sufficient wall thickness will be 20 centimeters. Concrete grade 200 is used. The area of the walls is 2.7x2 + 2.5x2 = 10.4 m2, the volume at a height of 1.8 meters will be: 10.4 x 1.8 x 0.2 = 3.74 m3.

To make high formwork, it is better to use sheet materials: waterproof plywood or metal sheet. The area of high formwork is 2.7 x 4 x 1.8 = 19.44 m2 on the outer wall and 2.5 x 4 x 1.8 = 18 m2 on the inner wall. Total area - 37.4 m2. Based on this, you need to purchase materials, taking into account their cutting ability.

To assemble the formwork, you will also need 12 wooden blocks of 50x50 millimeters. The length of each rack is 2 meters, that is, you will need 3 six-meter bars. Jib bars and spacers can be made from available material.

The procedure for preparing for pouring a concrete body is the same as described above.

Step-by-step instructions for casting a concrete caisson body

For manufacturing, you need to perform a number of sequential operations:

- Make the base plate using the above method. After seven days, you can remove the formwork and begin further work.

- Install the formwork for the walls, while simultaneously installing the reinforcing mesh.

A metal mesh is placed inside the formwork to form a reinforcing frame

- Pour concrete into vertical formwork. As you pour, be sure to process the mass with a deep vibrator so that there are no voids or air bubbles left.

- The formwork can be removed seven days after pouring.

The concrete mixture hardens within seven days, after which work on arranging the concrete caisson can continue

- Waterproof the outer surface of the walls with bitumen mastic.

- Fill with expanded clay.

- Install the top slab using roofing felt waterproofing.

- Install the cover.

During the pouring process, it is necessary to install embedded parts for the exit of water supply pipes and power cables.

Video: how to make a concrete pit for a hydraulic accumulator

Do-it-yourself caisson for a well made of concrete rings

You can make a caisson from concrete rings yourself at home. The easiest way is to make it a buried well. Before carrying out work, you should attend a consultation with a specialist; the work plan will be fully outlined. You can visit a special organization, or you can find out the necessary information from a knowledgeable person.

Next, you should stock up on the necessary materials and equipment:

- column with a puncher;

- lifting equipment;

- burner;

- spatulas;

- shovels;

- Bulgarians;

- rollers;

- roulettes;

- boards;

- knives.

Special marks are made on the surface of the earth where the digging will be carried out.

Concrete links are ordered in advance so as not to stop work waiting for their arrival. You should order as many elements as the depth of the planned caisson. By the way, they have different diameters and heights, so when ordering, you should choose those models that are suitable for the chosen design.

Installation of rings should be carried out using only complete structures free of cracks and other defects.

Otherwise, it will be difficult to ensure the tightness of the finished structure, which will negatively affect the operation of the installed equipment. This primarily concerns spring groundwater, as well as low temperatures.

Excavation

Digging a pit should be carried out during the season when groundwater is at its lowest level. Therefore, it is not recommended to start this work during the spring flood and autumn rains. The extensive experience of the masters of such installation suggests carrying out this work in clear weather, when the soil is dense and dry.

In some cases, concrete structures lose their tightness, so the caisson must be installed in areas with a reduced amount of underground liquid. This will increase the life of the structure and reduce the number of problems.

Digging a pit can be carried out using an excavator, or it can be done manually. In the first case, the work will be done quickly, and in the second - cheaply! When digging, it is necessary to take into account waterproofing work that requires additional space. Therefore, the size of the excavated structure should be 2 m larger than the diameter of the well.

All unnecessary soil should be raised to the surface so as not to load the space of the future caisson.

The base of the structure must be solid, since the structure will literally sag. The average depth of a structure made of concrete rings is about 2 m.

Thanks to this depth, the pumping equipment is not afraid of freezing and in the resulting space a person can stand up to his full height. It is necessary to manually level the bottom inside the well with shovels in order to lay the concrete elements evenly.

Digging a hole and arranging a pit for a caisson made of concrete rings:

Waterproofing

Properly executed waterproofing is the key to long and uninterrupted service of the specified structure. Seams can be sealed using the following compounds:

- Mastic.

- "Hydraulic seals".

- "Hydrostop".

The described compositions are suitable for coating rings to achieve tightness. The internal walls of the caisson are treated with waterproofing compounds, since getting to the outside is labor-intensive. At the same time, the coating on the lower floor slab is always pressed through by water, so it is impossible to completely protect against it in a concrete caisson.

The contact point between the casing pipe and the concrete ring is also not airtight, since the coating will not be able to stay for long between two materials of heterogeneous composition.

The gaps between the installed rings in the finished structure can be coated with a concrete mixture consisting of sand and cement. The finished concrete mixture is applied into the cracks between the installed structures and waits to dry.

What is a borehole caisson and why is it needed?

A caisson is a container that is reliably protected from water penetration. Initially they were used exclusively for underwater work, but later other areas of application were found for them.

In particular, sealed chambers began to be installed on the well head. The standard caisson has a very simple design. This is a container that closes with a hatch on top.

A caisson for a well is a sealed container that protects the well head from low temperatures and groundwater penetration

A person descends through it into the chamber to carry out maintenance and repair work. At the bottom of the device there is a casing pipe inlet, and in the side walls there are inlets for cables and water pipes.

The cover, and in some cases the walls of the caisson, are insulated. Most often, polystyrene foam or foamed polymer is used for this purpose. The chamber of classical design is made in the form of a cylinder with a height of about 2 m and a diameter of at least 1 m.

These sizes were not chosen by chance. The height of the container is determined by the need to protect the equipment installed inside it from exposure to low temperatures. The water pipe insertion area and the well head must be located below the soil freezing level.

Most often, this is a depth of the order of 1-2 m. It is this value that determines the depth of the chamber bottom and, accordingly, its height.

The diameter of the container was also not chosen by chance. It must be sufficient to install the necessary equipment and accommodate a person inside who will go down to carry out maintenance or repair of the well.

When choosing a caisson, you need to understand that a structure that is too small will be inconvenient to use, and one that is too large will be too expensive. After all, sealed chambers are quite expensive equipment.

The size of the caisson must exactly match the amount of equipment that will be placed in it. In addition, it must freely accommodate a person descending to service the devices.

A sealed container buried in the ground performs two main functions:

- Protection of equipment from low temperatures. In winter, the water supplied from the well is exposed to negative temperatures. Under such conditions, it can freeze and damage or even rupture the pipeline.

- Protection from groundwater. The caisson prevents soil water from entering the well head, thereby extending the life of the equipment.

In addition, the caisson is a convenient place to place all the equipment necessary for operating the well.

A pumping station, various water purification systems, a well adapter, shut-off valves with an electric or pneumatic drive, pipelines and automation that controls an autonomous water supply system are usually installed here.

A waterproof chamber reliably protects all this equipment from unauthorized access and from damage by rodents and insects.

Chambers made of materials with high heat transfer must be additionally insulated. Only non-hygroscopic types of insulation are suitable for these purposes.