Criteria for choosing a carpet underlay

- Feel the selected substrate. It should be dense, but not hard.

- Smell the material. The artificial layer should not have any odor.

- Squeeze the material in your fist, then release. If it becomes crumpled and very slowly returns to its previous state, it is better to refuse the purchase.

- Thick and loose material will not last long. The optimal thickness of the backing for carpet is 1 cm; it should be uniform in structure and flexible.

- If the base is concrete, buy a rubber crumb backing; if the subfloor is wooden, give preference to cork.

- For synthetic-based carpet, an artificial underlay is suitable.

Important! Natural material requires an environmentally friendly layer, so purchase cork.

Which is better?

Today, manufacturers produce many types of carpet, so before purchasing it you need to pay attention to some details. Carpet can be made from different materials using different methods

In addition, carpet products are dyed in different ways. The pile itself can have different heights and even shapes

Carpet can be made from different materials using different methods. In addition, carpet products are dyed in different ways. The pile itself can have different heights and even shapes.

The materials used to make carpet can be of natural, artificial or mixed origin.

Cotton, linen, wool and jute can be used as natural fibers. Man-made options include acrylic, nylon, olefin, and latex used as lining material. Blended fiber carpet contains both synthetic and natural threads.

The type of pile is another indicator that you should pay attention to:

- The Saxony type is considered to be of the highest quality, produced using a special technology due to which the surface has a grainy appearance.

- Another inexpensive and unpretentious type that is recognized by consumers and has earned their trust is Vkroll. In the manufacture of this type, multi-colored threads are used, and the coating itself consists of several levels. Externally, this carpet looks very attractive.

- Boucle looks no less attractive. In addition to the fact that this type is quite durable, it also has an original shape, made using a method that uses special knitting knots.

- In the production of such a type as Frieze, twisted curly thread is used.

- Based on the data obtained, when choosing carpet you need to focus on the features of the room in which it will be laid.

- For a bedroom, the best option would be a high-pile carpet, but for a living room, the pile length should be shorter, so a short-pile tufted carpet would be the best choice.

- For a hallway, a good solution would be to purchase a needle-punched covering with water-repellent properties.

- For the bathroom, wear-resistant flocked carpet is suitable, which contains nylon threads, which give this coating anti-slip properties.

What is a substrate, its types and advantages

The underlay is the material that is placed between the base and the finishing coating of the lower surface of the room. The technology for finishing modern wooden floors requires the mandatory use of this product as an intermediate layer. This allows you to create maximum comfort conditions in the apartment. Any substrate

- has noise and heat insulating properties;

- serves to preserve the finished floor by eliminating points of contact with the base;

- dampens vibrations generated when impacting the floor, acting as a shock absorber.

Compound

Manufacturers produce synthetic and natural substrates. The composition and quality of the components used in the manufacture of these products affects their performance characteristics and cost.

- Polyethylene foam is the most popular product among synthetic substrates. Its main advantage is its low price. It also has other positive properties:

- retains heat excellently;

- prevents the formation of fungus and mold, which is especially important for wooden floors;

- is resistant to moisture, oils, solvents;

- Compatible with any building materials.

The polyethylene foam backing is easily cut with scissors or a sharp knife. The individual fragments are connected with tape and do not require attachment to the base. But the service life of this type is short. Such a substrate quickly “settles” and wrinkles under high loads.

- Cork backing is a natural product. It contains crushed cork tree bark. This determines its high cost. However, it is this type of layer that is better suited for wooden coverings.

Cork is an environmentally friendly product. It allows the wood to “breathe”. It does not grow mold, but it is not recommended to use it as flooring material in the kitchen and other rooms with high humidity levels. This substrate is highly wear-resistant and does not crumble or become compressed under the influence of gravity during active use of the floor. Additionally, it serves as a means for leveling the surface.

To increase the service life of the floor covering, you can use the following types of natural substrate:

- regulated cork, which includes rubber: has sound insulation, reduces the level of vibrations;

- bitumen-cork sheet is a multilayer product consisting of bitumen-impregnated kraft paper and cork chips: it does not require waterproofing.

- Coniferous backing is a recent invention - a product made from wood waste. This is a natural material. Only natural ingredients are used in its production. Therefore, such a layer is environmentally friendly. A clear advantage of this type is the release form in slabs 5-7 mm thick. This allows you to use a coniferous substrate instead of plywood or chipboard as a leveling element. It is more convenient to install and transport.

Artificial and natural materials can be placed under wooden floors, but the latter is preferable.

Thickness and dimensions

Products intended for use as a layer between the base and the floor covering have different thicknesses. Usually a 2-4 mm layer is laid under a wooden floor. It is sold in rolls 120 cm wide and 10 m long.

Cork products are compact. When unwinding the canvas, it is given time to rest and straighten. Polyethylene foam or polystyrene foam are light in weight but voluminous rolls. They lie freely on the surface and take on the desired shape. Not suitable for leveling.

How to lay

Before starting work, the required amount of carpet is calculated. It is best to take a whole canvas for the room, but if its size is not enough, then the pieces can be joined together. The material is taken in such a way that there is a margin of about 5-8 cm for the walls; the excess carpet can then be cut off.

Carpet can be laid on almost any base: concrete screed, tiles, wooden floors, on stairs, there is tiled carpet, the main thing is that the floor is smooth and clean.

If you have a concrete base, then carefully level it using putty, let it dry and completely remove the dust.

The wooden base can be leveled using chipboard sheets, the joints are sealed with putty and everything is opened with a primer.

There is another way: first, the nail heads are pushed down, then the surface is scraped, primed and filled with a self-leveling mixture for wood.

If you do everything yourself, follow these recommendations:

- lay the carpet on the floor and let it lie for at least a day until it is completely level;

- there should be no draft in the room, otherwise folds may form on the coating;

- instead of a primer, you can use a mixture of PVA and water;

- During work, the room temperature should be at least 17 degrees and humidity within 10-65%.

Very often, home craftsmen ignore laying underlay under the carpet, but experts recommend using it.

Substrate

Laying the underlay improves the heat and sound insulation characteristics of the specified coating, it gives it strength and elasticity.

Using a backing almost doubles the service life of the carpet. For this, foamed polyurethane or rubber is usually used.

In the hallway it is better to use a thin and durable underlay, but in the bedroom and nursery you can lay thicker material. At the next stage, the carpet is laid, its excess is cut off, and it is pressed using baseboards.

Tile carpet

Tile carpet is produced in the form of squares with a side size of 50 cm, it has a denser base, and thanks to its precise dimensions, its installation is carried out practically without seams.

Installation of such a covering can be carried out using double-sided tape or carpet glue.

First, the base is leveled, after which the tiles are laid, installing them using one of the methods described above.

When laying with tape, first they glue the perimeter of the room with it, then they make a grid with a cell size of about 50 cm. Now all that remains is to remove the protective film and you can glue the tiles. Thus, they first move along one lane and then move to another section.

When installing tiled carpet, you need to use wide tape, this will make it easier to glue the elements.

Features of laying on stairs

To do this, you need to purchase a special stair carpet, which has increased strength and wear resistance. When taking measurements, you need to be careful, select the material according to the width of the largest step, and if the staircase is open on one side, then do not forget to add 4 cm to the hem.

You can measure the size of the largest step, then multiply it by the number of steps and so you will get the required amount of carpet.

The simplest way is to use carpet as a path, covering only the center of the stairs. In this case, it can be removed for cleaning. But the continuous covering of the stairs looks more beautiful.

Laying underlay and carpet on a concrete floor

After the concrete floor has been leveled and all irregularities and cracks have been eliminated, the underlayment can begin to be laid. To do this, apply special glue to the concrete floor surface using a notched trowel and glue the backing. This must be done carefully, rolling out the substrate with a roller so that wrinkles and air bubbles do not form. After the backing dries and sticks, apply the same glue to it and glue the carpet. Let the carpet dry and take its shape, only then can you cut off the excess in the corners and near the walls and install the baseboards. Do not forget to adhere to the basic rules when laying, namely, apply the glue in a small layer and evenly, leave at least five centimeters on the wall, the pile should be placed in the water direction, and when gluing, be sure to roll over it with a heavy roller.

In the video below you can see how carpet is laid and what the features of the underlay are:

Floor coverings

- Laminate

- Warm floor

- Linoleum

- Tile

- Carpet Care

- Choice

- Laying

Floor construction

- Skirting

- Floor screed

- Leveling the floor

- Sound and waterproofing

- Insulation of floors

- Concrete floors

- Floor repair

- Substrate

Calculation of laminate boards Calculation of paving slabs

Tell us about us

PolGuide 2012-2019 | Information

When copying materials active link to the site is required

Pros and cons of carpet

Is it possible to lay the material on wood? Is it worth choosing it as a floor covering? You can answer this question by knowing the advantages and disadvantages.

Soft coating creates visual and tactile comfort in the room

The positive aspects of using the material include:

- a wide range of colors that can be used to easily complement the interior, expand the room or smooth out imperfections;

- good sound insulation and thermal insulation;

- the material is treated with special means that prevent the appearance of ticks, moths and other organisms;

- has high resistance to fire;

- low weight allows not to overload the floors;

- lasts a long time.

The disadvantages include:

- cannot be used in rooms with high humidity;

- stains from detergents may remain;

- sunburn;

- the standard width is 4 m, which may be inconvenient for rooms of other sizes.

Is it worth installing carpet? Yes. In most cases, its shortcomings do not have a significant impact on the operation of the material. In addition, this option will smooth out troubles from noisy neighbors. For rooms on the first floor, additional thermal insulation will not be superfluous. This floor is much more pleasant to walk on than cold ceramic tiles. In terms of heat-protective properties, linoleum or laminate cannot be compared with it.

Types and properties of the substrate

Conduct a survey on the topic “is carpet underlay necessary at all,” and many will answer that it is not needed. After all, carpet is a warm, soft and durable covering that hides minor differences in the floor plane. I'd like to believe it. But experts have a different opinion. They believe that the quality of a floor structure is determined by several factors. One of them is the use of underlay, including under carpet.

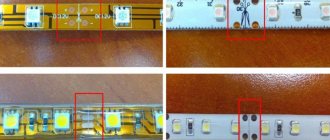

Today, manufacturers offer two types of underlays used to level the floor base under carpet:

Let's look at the most popular of them.

This is a tile material that is bonded to the base of the floor using B-2 adhesive.

A very important point is that it is necessary to strictly monitor the tightness of the contact of the plates to each other. No gaps or cracks - the floor must be monolithic.

The first sample can be used under carpet if the latter is installed on the floor using stretching technology. Its essence is that the floor covering is stretched on special hooks or gripper slats.

This type of backing material is made from crumb rubber using the hot pressing method.

Since carpeting is most often installed in children's rooms, it makes sense to splurge and purchase a cork underlay for carpet specifically for this room. It will soften the already soft material and increase its safety. After all, children most often play on the floor.

This is the most common option. Moreover, it is the cheapest and quite reliable.

As a result, the carpet underlay becomes a reflector, hydro-, steam- and heat insulator all rolled into one

The most important thing is that, as in the case of rubber samples, this one has an important quality - it is not afraid of water and high humidity. So you can safely clean with a washing vacuum cleaner.

Experts guarantee that you can walk on thick slabs laid under carpet even with shoes on. In this case, you will never push through the material, although it is easily cut with a sharp tool. This is such a paradox.

Attention! Carpet underlay can be made not only from the pure materials discussed above. Manufacturers often offer combined options that are several times better than conventional ones.

But they also need to be chosen correctly.

Identifying them is not so easy. But experts suggest one effective way. Take the backing in your hands and crumple it. If it loses its appearance, and this happens instantly, it means that the material in your hands is not of very high quality.

Some types of underlays are laid on the floor base with fixation. Typically, adhesives are used for this. But this is not at all necessary for rolled materials.

Here it is important to spread the underlay correctly so that it completely covers the floor with a high degree of tightness

Its composition will depend on the base material - concrete or wood. The most commonly used waterproof glue is PVA.

But manufacturers need to pay attention to the fact that such glue promotes shrinkage of the backing material, especially those made of natural textures. Therefore, it is better to use polymer-based adhesives for them.

Attention! Before starting work, it is necessary to place the adhesive composition and carpet backing in the room where they will be used. There they must undergo acclimatization

Special mounting option

Installation of floor coverings

To do this you need:

This method is more suitable for finishing wooden floors. If you have settled on it, and the floor in the house is a concrete floor slab, leveled with screed, then we recommend covering the base with OSB boards or plywood. Fastening of wooden tile materials is carried out using self-tapping screws.

We hope you understand that carpet underlay is a necessary thing, and in some cases even super important. If you want the carpet to last twice as long, we do not recommend laying it without a backing.

- How to properly install carpet

- How to choose the right underlay for laminate flooring

- Types of cork substrate and its laying scheme

- Let's figure out which underlay for laminate is better - an overview of existing types

If for laminate and parquet the underlay is a matter of course, then the use of underlay for carpet is often forgotten. However, if you do not neglect its flooring, this covering will last much longer and become much more comfortable. As a cost-saving option, you can buy a fairly cheap thin carpet and add a backing to it. The result of such a decision at a lower price can exceed the effect of purchasing more expensive types of carpet.

Carpet underlay - a whim or a necessity?

The main task of any well-designed floor is to cope with heavy loads, while remaining an example of aesthetics, wear resistance and hygiene. But what does “well-equipped” mean? In the understanding of experts, this can be called a floor structure erected according to technology proven over the years, using measures that can prevent sudden deterioration of the coating. One of these “measures,” of course, is the use of a substrate. What’s interesting: for laminate or parquet boards, this “auxiliary” product is purchased by default, and when the question arises whether a carpet underlay is needed, many for some reason shrug their shoulders uncertainly or, even worse, resolutely declare that “no, it’s not needed.” , explaining this by the warmth and softness of the coating itself. Professionals fundamentally disagree with this opinion; they argue that laying the underlay is an integral stage in the formation of a high-quality floor from any material, including carpet. What is a carpet underlay and what are the basic requirements for it? You will find answers to these and many other questions in this article.

Types of carpet underlays

The construction market offers the buyer a huge range of carpet underlays: among them there are both natural and artificial samples.

Let's look at some of the most popular and practical options.

- Polyurethane foam. They are suitable not only for “home use” - they are also successfully used in hotels, offices, medical and educational institutions. They can effectively hide surface unevenness and increase noise insulation in the room. The base on which the polyurethane foam substrate will be laid must be absolutely dry; its maximum permissible difference is three millimeters.

Installation technology. Apply glue to the base with a notched trowel (marking B-2). Lay the sheets of pre-cut substrate end to end.

It is necessary to ensure that the material adheres tightly to the floor, since the formation of air pockets is unacceptable!

- Polyurethane. Their base and top are made of polyethylene. Ideal for laying carpet using the stretching method (stretching the covering on hooks - gripper slats). Polyurethane samples on a paper base with a felt top are also in demand - they significantly improve the thermal insulation of the floor and conceal its unevenness.

Polyurethane foam backings

One of the most affordable options for carpet underlay is polyurethane foam. Compared to analogues, this material has the following advantages.

- Optimal ratio of cost and product quality. Despite the lowest price among similar materials, polyurethane foam has suitable performance characteristics for arranging a carpet underlay.

- Average elasticity levels create sufficient shock absorption to make movement on the floor comfortable, and the carpet fabric retains its qualities for a long time.

- The insulating properties of the material contribute to the absorption of sound and retain heat well.

- The material is quite durable, resistant to loads, moisture, and temperature changes.

- Low weight simplifies installation of the substrate and transportation of material to the work site. Laying polyurethane foam is quite accessible to a non-professional.

- The porosity of polyurethane foam contributes to the process of air exchange in the room.

Polyurethane foam substrates are low cost, retain heat well and provide excellent sound insulation

Among the brands of polyurethane foam products for substrates, the products of the Russian-Dutch enterprise Comfort are characterized by high demand and quality. The Elite series is represented by material whose square meter costs about 200 rubles. Thickness – 0.5 cm, density is 630 g/m². The sound insulation index allows you to reduce the overall noise level in the room by 26 dB. Products with a thickness of 0.8 cm have higher insulation characteristics, but such products are more expensive - approximately 290 rubles per m².

Polyurethane foam of the Luxe series is presented in three options - thickness 1, 1.2 and 1.6 cm. The price of the first type of products is about 330 rubles, the second - 390, the third - up to 440 rubles per m². The material density of 1260 g/m² determines the high strength of the substrate. The sound insulation index is 32 dB. The technical characteristics of the products in this series allow the floor covering to withstand heavy external loads for decades.

The products of such companies are very popular:

- Manufacturer's products are impregnated with special compounds against microbes, fungus, and mold. Products are sold in rolls of 25 and 10 m². The thickness of the material is 1.2 cm. Designed for residential premises with cement or wooden floors, creating underlays for carpet with a pile height of no more than 2 cm.

- HC-Blue. In addition to antifungal impregnations, reinforcing mesh and viscose fibers are added to the material, which increases the strength of the products, resistance to wear and abrasion. Such products are designed for a period during which 4 replacements of worn carpet sheets can occur. Thickness – 0.75 cm, recommended carpet height – up to 2 cm. Suitable for all types of installation.

- The company uses innovative technologies in the production of polyurethane foam. With a thickness of only 0.3 cm, the material is quite strong, elastic, and suitable for “warm” or “floating” floor systems. Another distinctive feature of the product is the self-leveling function, which allows you to smooth out all the unevenness of the base and achieve the most even surface of the coating.

A special adhesive is used to attach the polyurethane foam pad to the subfloor. Typically, a reliable connection requires 0.8-1.2 kg of adhesive composition per square meter. Polyurethane foam can also be used when laying flooring without fixing, using the stretching method.

To fix the substrate to the subfloor, use a special glue

Methods for laying carpet

The following methods are suitable for installing flooring:

- free - the carpet is fixed using skirting boards;

- using tape;

- on glue;

- the stretching method is a complex installation method and is used by professionals to install carpet in office premises.

The choice of method depends on the area of the room:

- less than 12 m2 - with double-sided tape;

- from 12 to 20 m2 - free method or with tape;

- more than 20m2 - with glue.

ATTENTION! Whatever option is chosen, the carpet must rest before installation. It needs to be straightened and left for a couple of days.

Glue mounting

This is the most popular method of installing carpet. For this, PVA glue or bustylate is used. There are also special adhesives.

- The material must be laid out on the floor, throwing one half over the other.

- An adhesive composition is applied to the half free from the floor covering. To make the fixation more reliable, it is advisable to apply glue to the entire surface. Then leave the composition for about 20–30 minutes.

- The carpet fabric is carefully laid on the glue. You need to carefully press and straighten the material so that wrinkles do not appear; you can use a roller for this.

- The entire procedure is repeated with the other half of the floor covering.

Laying with tape

In order for the product to be securely fixed, the width of the tape must be at least 5 cm. A narrower version may tear.

- First you need to stick tape around the perimeter of the room.

- Next, it is glued in the form of a grid with a pitch of 0.5 m. For a more reliable fixation, you can paste over the entire surface of the floor.

- Then the carpet is glued to the tape.

Stretching

For this method, special fastening elements are used - grippers.

- grippers are placed around the perimeter of the room;

- further, the substrate is installed on them;

- the floor covering is stretched using special equipment.

The technique is quite complex and requires special tools and good skills. Therefore, it should be performed by professionals.

Free way

The simplest method, which is ideal for rooms with a small area.

- Before installation, you need to treat the baseboards with an antiseptic composition - this will prevent fungus or mold from forming on them;

- the floor surface is cleaned of dirt and dust;

- the floor covering must be laid out on the floor;

- use a roller to smooth the carpet;

- if there is excess, it must be trimmed;

- the material is fixed with skirting boards, and in the doorway with a threshold.

Substrate

The main difference between the technology of laying carpet on concrete and flooring on a rough wooden floor is the mandatory use of a backing.

Polyurethane foam backing

For laying carpets on a concrete base, the following types of underlay are used:

- Polyurethane foam. Inexpensive and high-quality material that will smooth out unevenness and serve as additional hydro- and thermal insulation. Material thickness up to 6 mm. Polyurethane foam substrates are easy to install: they are sold in rolls. Simply unwind the lining and cut the strips to the required length. After this, the cut strips are removed, the base is coated with glue and the backing is rolled out onto the glue.

- Polyurethane. This type of substrate has a protective layer of polyethylene film. Due to this, the surface of the material is slippery, so they use stretched carpet for stretching. If you are using short-pile carpet, you can lay a polyurethane backing with a felt top.

- Made from pressed rubber crumbs. The base of this backing is made of polyjute. Of all materials it has the highest elasticity. Allows you to obtain a springy surface that is comfortable when walking.

Crumb backing

Cork substrates are not used for laying on concrete, as additional work is required to waterproof the base.

The underlay for carpet on concrete is used for the following purposes:

- Compensating the load on the carpet, which will extend its service life.

- Creating a soft and comfortable coating.

- Reliable adhesion of carpet, eliminating shifting of the covering.

- Creating a barrier to the flow of cold air from the concrete base.

- Smoothing out uneven surfaces of the base.