Linoleum is a popular floor covering, the use of which is quite wide. The material is used for laying on surfaces made of wood, concrete or other coverings. But it should be remembered that before installation, preparation of the floor for linoleum is required. The lifespan of linoleum depends on the quality of the base, so different surfaces should be prepared correctly. More details about preparing the floor for subsequent linoleum flooring will be discussed in this article.

How to prepare a floor for linoleum

Features of working with linoleum

The process of laying linoleum cannot be called complicated, especially if the work is done with simple household types of material. When installing linoleum in commercial buildings, it is still recommended to seek help from specialists, because special equipment is usually used to cover a large area. Depending on the type of coating and the area to be covered, the surface preparation technology may differ.

Preparing a concrete floor for linoleum

But there are general points, including:

- preparatory stage (cleaning the base of various debris and household items);

- leveling the base (the surface before installation must be free of flaws);

- strengthening the floor using special tools , if necessary.

How to prepare the floor for laying linoleum

On a note! After preparing the surface, you need to wait some time for it to dry completely. This is an important condition, because laying linoleum on a wet floor will not allow for reliable fixation.

Linoleum with image

Preparing the rough base foundation

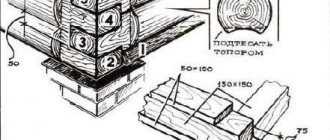

Preparing a concrete floor for laying linoleum should include a whole range of work. Most often, the base is made of reinforced concrete slabs, which require not only insulation, but also waterproofing.

Floor filling diagram.

Sequence of work:

- If necessary, reinforced concrete floor slabs are leveled using cement mortar.

- Organize sound and heat insulation from fiberglass or mineral wool boards.

- Waterproofing can be made of glassine, roofing felt, a special membrane, or polyethylene film.

- If the differences between the slabs are significant, then a layer of cement-sand screed is applied, the thickness of which depends on the work already performed. For example, a layer with a thickness of 20 mm is laid on a regular slab, and a layer of 40 mm thick is laid on the insulation.

- Linoleum is being laid, the thickness of which should be 3-6 mm. Often a special underlay is laid under the linoleum, which increases the comfort of using the floor covering.

The concrete base for work is prepared simply:

- First you need to examine its surface to determine what kind of work is needed. After this, all cracks and potholes are filled with mortar, i.e. are tamponed.

- If necessary, the first layer of cement filling is performed; it will allow the floor to be as level as possible. Linoleum is not so thick, so all the unevenness and potholes will be immediately felt when walking, and the canvas itself will quickly wear out. Therefore, pouring is a necessary step.

- If there is already linoleum on the floor, then you should not remove it. It is better to examine the canvas first. If there are no breaks or traces of mold, then it can be used as an excellent leveling substrate.

Related article: Interior arches made of plastic - finishing ideas

Only after all the preparatory work has been completed and the cement base has dried, can a new coating be laid using the chosen method.

Preparing various surfaces

There are several factors that influence floor preparation technology, but the most important of them are the budget for the planned renovation and the type of coating in the room. The flooring can be concrete, parquet or ceramic tiles. Some owners decide to lay linoleum on top of the same material.

How to eliminate bubbles on linoleum

But if the house already has a certain coating, then during work it is necessary to build on this factor.

Preparing different surfaces for linoleum

Concrete covering

A perfectly flat concrete floor slab is a rare case, so most owners are forced to prepare the surface for subsequent laying of linoleum. First of all, the surface is cleaned of dirt and dust, after which dispersion putty is applied to the slab. For this you need a flat spatula. The composition used will fill all irregularities in the form of shells, cracks or chips. After the putty dries, the base is perfectly smooth.

Preparing concrete for linoleum

On a note ! If necessary, you can go over the surface with a sanding machine so that the floor covering is without any unevenness. Sanding after polymerization of the putty is especially effective.

Sanding concrete floor

Wooden floor

A wooden base is also perfect for linoleum, and the preparation of such a floor is quite simple. First of all, it is necessary to conduct a visual inspection of the floor for the presence of mold. If it does exist, then it is advisable to dismantle the floor and make a concrete screed. If there are no traces of fungus, you should also check the floor for strength - all fasteners must be well fixed (strengthen the structure if necessary).

Laying linoleum on a wooden floor

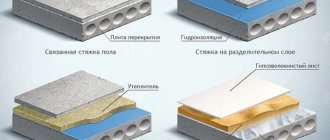

Substrate for concrete base

For a concrete floor under linoleum, it is recommended to select a special underlay that will not only make the base warmer, but also extend the service life of the material. Today, various types of substrates are used for these purposes, which differ in the method of installation, cost, operating features, and characteristics. Among the most popular options it should be noted:

Methods for laying laminate flooring.

- Cork materials. Such substrates are made from special cork chips; the fabric does not withstand heavy loads. Furniture, household appliances, even sharp heels are destructive for this material; such a substrate will not last long. But it will serve for excellent thermal insulation and sound insulation. It is recommended to lay cork materials in bedrooms and children's rooms, where they fully meet all operating requirements. Cork is most often produced in the form of large slabs, which are simply laid on the surface of the concrete floor and secured with double-sided tape.

- Natural jute substrates are considered strong and durable, although their cost is quite high. They are not subject to rotting and are not afraid of moisture. They are installed as simply as possible and can be used for any room.

- Substrates made of natural flax fiber are almost in no way inferior to jute ones, but their cost is lower, which is often in favor of this particular material. They are laid quickly and their performance properties are high.

- Combined substrates made from a mixture of materials such as wool, jute, linen are impregnated with special antifungal drugs and fire retardants. They are resistant to different types of loads and impacts, and their cost is quite affordable. Can be used in any room, supplied in rolls and slabs. Used for thin linoleum when the floor needs to be additionally insulated.

- Foam substrates are low in price, but their quality is not the best. They wear out quickly and do not provide all the necessary properties. Within a couple of years after use, the material is pressed through, breaks easily, and requires replacement. It is laid quickly, the roll is simply rolled out over the surface, after which the joints are taped with construction tape.

Related article: Treatment of laminate flooring after installation on the floor

Choice of linoleum

After preparing the base, you can begin laying linoleum, but for this you need to choose the appropriate type of material. Below are the most common types of linoleum.

Types of linoleum

Table. Review of different types of linoleum.

| Name of material, photo | Short description |

| Alkyd | Ecological material consisting of alkyd resins, pigments and special fillers. This composition makes linoleum a heat- and sound-insulating floor covering. Among the disadvantages of alkyd linoleum, it is worth highlighting its low resistance to temperature changes. |

| Colloxylin | High-quality material with high elastic properties. Colloxylin linoleum is moisture resistant, so it is excellent for rooms with high humidity. |

| Rubber | Another type of linoleum, which is suitable for different substrates (concrete, wood, etc.). The material has high thermal insulation properties and consists of relatively inexpensive components. This makes rubber linoleum affordable. |

| PVC linoleum | Excellent material made from PVC. Among the advantages of such linoleum, it is worth highlighting its antistatic and moisture resistance. Available with different types of bases (fabric, non-fabric or foam). |

| Relin | High-quality rubber-based linoleum, characterized by elasticity, strength and durability. Relin is mainly used in rooms with high humidity levels. |

| Nitrocellulose | The composition of nitrocellulose linoleum includes stabilizers, dyes and colloxylin. This is a waterproof material with high elasticity. As a rule, this material is installed in apartments of multi-storey buildings, where the owners do not use strong chemicals. |

Types of linoleum - classification, characteristics

Linoleum is one of those materials that do not limit your choice. And we are talking not only about color variety, but also about the presence of additional properties. Of course, the presence of additional features affects the cost of the material, which must be taken into account when choosing linoleum. As soon as the material is selected and purchased in the required quantity, you can begin its installation.

What are the sizes of linoleum

How to level the floor under linoleum before laying, proper preparation for installation

[hana-code-insert name='yandex' /] The first thing to do to prepare the floor for linoleum

, is to free the room from furniture, because for high-quality work you need a completely empty room, so that furniture and other objects do not interfere with the main task. Then remove old baseboards and flooring, such as old linoleum or parquet.

[Show slideshow]

Next, inspect the floor for unevenness. It is worth noting that leveling the base is a top priority, regardless of which floor is taken as the basis.

Leveling a wooden floor under linoleum can be done in three ways. The first of them is less expensive, but more labor-intensive. Having assessed the degree of wear of the boards, it is advisable to replace the most damaged ones or, if this is not possible, then firmly screw all loose boards to the joists with screws, and fill up the cracks and irregularities. If there is a very large difference at the joints of the boards, a plane is used.

The second method involves installing sheets of plywood or OSB boards, which are fixed with screws.

The third is applying the screed. Special compositions for wooden floors allow such work to be carried out as quickly and efficiently as possible. First, the loose boards are secured, they are firmly screwed to the main joists, and then the large gaps between them are filled with putty. Check the base again for unevenness, and if it is smooth, clean it thoroughly, after which a screed no more than 10 mm thick is applied. Such mixtures, as a rule, are self-leveling, do not require additional processing and harden well.

Leveling the floor under linoleum when the base is concrete is done using a solution of cement and sand. To begin with, control beacons are installed. Secure them with a solution. Then fill the base with the mixture and distribute it using the rule. Then leave to dry for about a day. Once the screed hardens, the preparatory stage can be considered complete.

Laying linoleum

Before starting installation work, the linoleum must be carefully unrolled and left on the floor for a day so that the material has time to level out during this time and take the shape of the floor covering. Such actions will help make further work easier. Only after this can you proceed directly to installation. Below are step-by-step instructions, following which will help even beginners cope with laying linoleum.

Features of laying linoleum

Step 1 . Using a tape measure, measure the dimensions of the room (width and length). Doorways must be taken into account. Add 6-7 cm to the obtained values. Vacation is needed to take into account the curvature of the walls.

Measure the length and width of the room

Step 2 . Cut the required piece of material using a utility knife. Use a ruler to make the cut line as straight as possible. Otherwise, difficulties may arise during further installation.

Cut the linoleum into the required pieces

Step 3 . If there is at least one flat wall in the room, lay the linoleum close to it, leaving a small gap or pressing it tightly. Carefully cut off all excess.

Press the linoleum to a flat wall

Step 4 . Secure the linoleum sheets before installing them on the wall by gluing regular double-sided tape to the floor. This will prevent the material from shifting during trimming.

Apply double-sided tape to the floor

Step 5 . Adjust the patterns on the linoleum at the joints. Of course, if the material is plain, then there is no need to adjust it. It is recommended to make a small overlap between the linoleum sheets (no more than 3 cm). Throughout the process, make sure that the patterns on different sheets of linoleum match.

Adjust drawings on linoleum

Step 6 . After fixing the linoleum to the base, perform trimming, cutting off excess material little by little. It is necessary to do the trimming little by little so as not to spoil the material (it is easier to cut off small pieces of linoleum several times than to cut off excess at one time).

Cut off excess linoleum

Step 7 . Apply glue to the surface of the base using a spatula. It is advisable to start applying glue from the joint. To see where the adhesive is applied, draw a thin line on the base with a pencil. For gluing, use only high-quality products.

Apply glue to the base

Step 8 . Remove all air from under the linoleum after gluing by rolling it thoroughly. Only after rolling can you begin the final cutting of the material at the joint. Now you need to wait some time until the glue has completely dried and install the joining profile. At this stage, the process of laying linoleum can be considered complete.

Remove air lumps

After removing the air, do the final trimming of the linoleum.

Prices for Tarkett linoleum

linoleum tarkett

Base under linoleum

Before you begin laying the flooring, you must carefully prepare the subfloor.

Linoleum is elastic in its structure, and over time it repeats all the shapes of the base on which it is laid. Therefore, any base before installation must meet the following requirements:

- Durable and smooth surface;

- Solid subfloor;

- No traces of paint;

- No moisture or greasy stains.

Plywood base

Compliance with these conditions will help extend the life of the coating.

On a concrete base

Remember that laying linoleum on a concrete floor is carried out at a temperature not lower than 18C and a humidity not higher than 68%. Before laying, the floor covering is spread out, leveled, and time is given for the material to “settle.” Then they begin cutting the material.

The covering is laid out taking into account the location of the pattern, and a margin of 10 cm is left at the edges. After gluing the coating, the remnants can be carefully trimmed. All seams formed should be positioned away from the window in the direction of the light so that they are invisible. For installation you will need the following tools: roller, knife, ruler.

Preparing the concrete base

There are several options for laying linoleum on a concrete floor, which can be combined if desired:

- Without glue - the method is fast, used in small spaces;

- With adhesive tape - in this case, the linoleum is secured with adhesive tape, which extends its service life;

- Using mastic or glue is the most effective method of installation, and is necessary for large areas.

Installation with glue

The choice of installation option depends on the area of the room and the loads. But to avoid the formation of folds and waves, it is better to glue it. It is also determined in each specific case whether a substrate is needed for laying linoleum on a concrete floor.

On a wooden floor

A wooden floor can act as a base for decking. A linoleum underlay on a wooden floor is not required, since the floorboards retain heat well. Only the floor needs to be prepared before laying. Replace unusable boards, clean them, hammer in all protruding nails and seal all cracks and crevices.

Base wooden floor

After leveling, a primer is applied to the wooden floor, which creates a protective layer against moisture, insects and mold. After the boards have completely dried, you can begin laying the flooring material.

Sometimes plywood is laid on a wooden floor as an underlay for linoleum. In addition, plywood can thus hide all the unevenness of a wooden floor. The plywood is laid offset, cleaned, and the seams are sealed with putty.

Laying without underlay

Laying linoleum is the same as on a concrete floor. In the process, the question arises: is a backing for linoleum on plywood additionally needed, as insulation? Of course, it can be used as an additional measure to extend the life of the flooring material.

See which insulation is best to use under linoleum on a wooden floor. Usually these are soft and loose materials that easily take shape.

Linoleum on linoleum

It is possible to lay a new coating on old linoleum if there are no defects on it and it is impossible to remove it from the floor surface. In this case, the old coating will serve as an insulating layer.

Restoration of defects on old linoleum

If there are flaws or tears on the old coating, restoration is first required. After that, the surface is sanded with sandpaper and a primer is applied. Only after such preparatory work can new flooring material be laid.

For ceramic tiles

When laying linoleum on ceramic tiles, first clean the tiles of all contaminants and seal the seams flush with the tiles. After the leveling solution has dried, you need to polish the surface well, after which the final screed is done. After the screed has dried, the flooring can be laid. It is recommended to lay linoleum on a substrate to avoid sagging at the seams.

Screed on top of ceramic tiles

It is difficult to lay linoleum on glossy tiles. This will require significant financial and physical costs. Therefore, such flooring should be removed rather than covering it.