February 15, 2021 Stroyexpert Home page » Foundation » Materials and equipment

Mixing sand with cement

Concrete is the most popular material used in modern construction. It consists of several components: binder, water and filler (sand, crushed stone). The binding component is cement. The grade of concrete depends on its quality.

First, let's get acquainted with several general rules on how to dilute cement for a foundation and how to use materials correctly:

- to obtain a high grade of concrete, it is necessary not only to choose a high grade of cement, but also to increase its consumption and consumption

- You can’t do without tools: containers, shovels, concrete mixers (if large volumes)

- You need to add water to the finished dry batch gradually. As a rule, in practice, a smaller volume of liquid is poured than expected

- if the mixing is carried out in hot and dry weather, special additives are introduced into the solutions - clays, lime. Stone wall materials, blocks and panels in contact with the mortar are moistened with water

- the water must be clean. If it is not taken from a drinking water source, testing for impurities is required

- purchased materials must have a passport with the results of laboratory tests conducted by the enterprise

- You cannot add additional water or other components to an already set solution.

- at a temperature of +18 - +22 ° C, concrete will harden and acquire all its strength properties within 28 days

- The formwork can be removed only when the structure reaches 70% of its strength characteristics. Minimum period – after 1 week (in summer at an ambient temperature of 20 °C)

How to correctly determine the brand of cement mortar

It is impossible to do without cement for building a house, construction or major repairs. For each area of application and purpose of cement mortar, a specific brand of the resulting mixture is used. Before starting work, it is necessary to make calculations with strict adherence to proportions. Otherwise, all the poorly done work will have to be redone very soon. The main rules for calculating the building mixture yourself are quite simple. To obtain the grade of the finished mortar, divide the numerical value of the grade of cement by the weight of the sand used.

Example: to dilute a mortar of M100 grade from M200 cement, you need to take cement and sand in a ratio of 1 to 2. This means that for 1 bucket of cement you should add 2 buckets of sand. Let's display an example of the calculation in numbers: 200/2=100, where the number 200 is the brand of cement, the number 2 is the number of buckets of sand, and 100 is the brand of the resulting mortar. Calculations with other brands of cement are made in a similar way.

Tables of proportions for the main types of cement mortars

The cement is a cementitious mortar of the selected brand, where M300 or M100 indicates the load that it can withstand. Instructions for the use of mortars CH 290-74 have tables with strictly regulated proportions. Construction mortars can be divided into the following types: plaster (M10, M25, M50), masonry (M50, M75, M100, M125, M150, M200), mortar used for screed (M150, M200, M300, etc.).

Cement consumption in kg per 1 sq.m of sand:

| Cement brand | Brand of solution | ||||||

| M200 | M150 | M100 | M75 | M50 | M25 | M10 | |

| M500 | 360 | 280 | 205 | 160 | — | — | — |

| M400 | 450 | 350 | 255 | 200 | 140 | — | — |

| M300 | — | 470 | 340 | 270 | 185 | 105 | — |

| M200 | — | — | — | 405 | 280 | 155 | — |

| M150 | — | — | — | — | — | 206 | 93 |

To increase the plasticity of the solution, clay or lime is added to the building mixture in the following proportions for foundations in dry soils:

| Cement brand | Volume composition (cement/lime/sand) | ||||||

| M200 | M150 | M100 | M75 | M50 | M25 | M10 | |

| M500 | 1/ 0,2/ 3 | 1/ 0,3/ 4 | 1/ 0,5/ 5,5 | 1/ 0,8/ 7 | |||

| M400 | 1/ 0,1/ 2,5 | 1/ 0,2/ 3 | 1/ 0,4/ 4,5 | 1/ 0,5/ 5,5 | 1/ 0,9/ 8 | — | — |

| M300 | — | 1/ 0,1/ 2,5 | 1/ 0,2/ 3,5 | 1/ 0,3/ 4 | 1/ 0,6/ 6 | 1/ 1,4/ 10,5 | — |

| M200 | — | — | — | 1/ 0,1/ 2,5 | 1/ 0,3/ 4 | 1/ 0,8/ 7 | — |

| M150 | — | — | — | — | — | 1/ 0,3/ 4 | 1/ 1,2/ 9,5 |

For the construction of building structures, foundations and screeds, a mixture of cement with sand and gravel is used in the following proportions:

| Cement brand | Volumetric composition (cement / sand / crushed stone) | ||||||

| M450 | M400 | M300 | M250 | M200 | M150 | M100 | |

| M500 | 1/ 1,2/ 2,5 | 1/ 1,4/ 2,8 | 1/ 2,2/ 3,7 | 1/ 2,4/ 3,9 | 1/ 3,2/ 4,9 | 1/ 4/ 5,8 | 1/ 5,3/ 7,1 |

| M400 | 1/ 1/ 2,2 | 1/ 1,1/ 2,4 | 1/ 1,7/ 3,2 | 1/ 1,9/ 3,4 | 1/ 2,5/ 4,2 | 1/ 3,2/ 5 | 1/ 4,1/ 6,1 |

Choice of cement and proportions

The proportional ratios for concrete mortar depend on the type of future construction. How strong should it be, how wear-resistant and fire-resistant?

Having decided on the type of building and selecting the required brand of concrete for it, you need to choose a brand of cement.

| Required grade of concrete (according to the project) | Cement grades, under natural hardening conditions |

| recommended/acceptable | |

| M100 | 300 |

| M150 | 300/400 |

| M200 | 400/300, 500 |

| M250 | 400/300, 500 |

| M300 | 400/ 500 |

| M350 | 400/ 500 |

| M400 | 500/ 550, 600 |

| M450 | 550/ 500, 600 |

| M500 | 600/ 550, 600 |

| M600 | 600/ 550 |

The table shows a pattern that to obtain concrete M150, M200, M250, you need a binder with an indicator twice as high as the data (for 150 - 300, for 200 - 400).

The most common brands of binders for construction are M400 and M500.

If mixing is carried out manually, the main preparation proportions for each brand of concrete are:

when choosing the M400 cement brand -

- for M100 (or concrete class B7.5) - for 1 kg of dry cement there are 4.5 kg of sand and approximately 7 kg of crushed stone

- for M200 (B15) – per kilogram of binder – 2.7 kg of sand and 4.7 kg of crushed stone

- for class B22.5 (M300) - to 1 kg - 1.9 (parts of sand) and 3.7 (crushed stones)

- for M400 (B30) - for 1 kg of binder there is a little more than 1 kg of sand and 2.5 kg of filler

when choosing brand M 500 -

- M100 - 1:5.3:7.1

- M200 - 1:3.2:4.9

- M300 - 1:2.2:3.7

- M400 - 1:1.4:2.8

Selecting a cement brand

Example:

With this brand of cement M500, the bag weighs 235 kg. You need to obtain the concrete grade M300. This means 235 kg - 1. Sand required 1:2.2. We multiply 235 by 2.2, we get 517 kg. Crushed stone is needed 1:3.7 - with a similar calculation we get 869.5 kg. Water consumption depends on the moisture state of the sand, but the approximate proportion is 1: 0.5 (117.5 l).

If there are no tables: The approximate ratio of all dry components can be taken - 1: 3: 4. This means that 1 is cement, 3 is sand, 4 is crushed stone. But still, when constructing load-bearing elements and foundations, it is worth using calculated coefficients.

In the preparation of more durable concrete grades, cement consumption is increased. Attention is also paid to sand criteria. It is recommended to use river sand as a filler: it contains less clay and other impurities. But such sands have worse adhesion to the solution, since the surface of river sand grains is smooth. Gully sand, on the contrary, adheres well to the components, but requires preliminary washing.

Why do you need to match the building mixture and the brand of material?

The brand of the finished product must match the brand of the building mixture to obtain a solid foundation or brick wall. Such a structure will be homogeneous and durable. For example, if M100 brick will be used for construction, then the building mixture should also be M100.

diluting the solution with a shovel

For greater strength of M350 brick used in construction, it is not necessary to prepare a mortar of the same grade; it will be sufficient to use PC115. Cement and sand should be diluted in a ratio of 1 to 3.5, since even for paving slabs a solution of 1 to 7 is used.

Cement consumption per 1 m3

Changing the proportions is not recommended, especially important for novice masons and builders. If the proportions are reduced, for example, 1 part cement to 3 parts sand, the mixture will turn out to be very fast-acting, and it will become almost impossible to work with it. By increasing the proportions, for example, 1 part cement to 4 parts sand, the strength of the mixture will decrease, which will increase the likelihood of it crumbling.

Calculation of concrete mixture composition

You may have to use the services of a construction laboratory, which will determine the fractional composition, volumetric weight, moisture content of inert components and the presence of impurities in them. You can request from the supplier a quality certificate, a passport of the supplied sand, crushed stone, which should contain the necessary physical data for the calculation.

Any civil engineer can calculate the composition of concrete and mortar of the required grade. To do this, you need to use recommendations from the Internet or a textbook. The results obtained reflect the dosage of the mixture components in kilograms.

In field conditions at small sites, mobile concrete mixers with a small drum capacity are used. They are loaded manually using buckets. Therefore, it is necessary to convert kilograms to volume using volumetric weight data.

Then, for each type of concrete or mortar, a dosage sheet is drawn up, which indicates how many buckets of cement, sand, crushed stone, and water should be loaded into the mixer for one batch. When calculating the composition of the BS, special attention should be paid to the water-cement ratio on which the workability and strength of the mixture depend. Clean water should be used, preferably tap water. If this is not possible, then it is imported.

Mixing

The mixing time depends on the number of revolutions of the mixer drum. Heavy concrete is mixed for 1.5-2 minutes, light concrete up to 5 minutes, mortar 3-4 minutes. A longer period may lead to stratification of the BS. When using small drum mixers, first pour in most of the cold water, then alternately add coarse aggregate, cement, sand and the rest of the water along with additives. It is advisable to use a forced mixing mixer. It makes concrete, especially mortar, of higher quality and plasticity.

The mixer must be placed at a distance of no more than 40 m from the place where the mixture is laid. Sand, crushed stone, water, cement should be nearby. The mixer must be installed on a flat surface without distortions. The finished but unused mixture should be in a mixer that rotates at low speed.

Approximate proportions

For plastering work, a cement-lime mortar is used, which does not require particularly precise dosage. Therefore, the following relationship can be applied:

- Cement (usually M500) - 1 part;

- Lime milk - 1 part;

- Sand - 6 parts.

For floor screeds, the cement mortar consists of 1 part cement and 3 parts sand. Masonry has a proportion of 1:4 (cement, sand).

Concrete of classes B3.5, B5, B7.5 , for non-critical structures, can be mixed in a ratio of 1: 3: 6 (cement, sand, crushed stone) .

The process of diluting mortar

Mortar can be of varying thickness, thickness and viscosity. Cement can be diluted with sand, lime, sawdust, gypsum, clay and slag fillers. This mixture is used for pouring foundations, screeding floors, filling planes or as a binding material. Cement is used in liquid form, so water is required for its preparation. The mixture hardens after the solution has completely dried.

Key points that a builder should know:

- Plastering walls - cement is diluted with sand in the proportion of 1 part cement to 2 parts sand.

- Construction of the foundation - crushed stone is also added to the finished building mixture. Proportions: 1 part cement to 2 parts sand and crushed stone. Note: the number of components may vary slightly depending on the tasks at hand. To obtain high strength, more crushed stone is added to the mixture; to obtain a soft and elastic solution, more clay is added.

- Water is a very important component of the mixture. The quality of the solution largely depends on its quantity. Add water carefully in small batches, otherwise you may end up with a product that is unusable.

Nowadays, there are a lot of chemical fillers on the construction market that allow you to achieve the desired consistency of the mixture, which gives a solution of ideal quality. No special knowledge is required for this; every novice mason can master them.

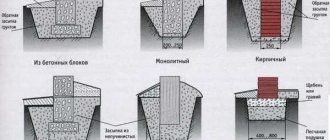

Foundation mortar recipe

In what proportions to dilute cement for the foundation depends on the qualities required of it. The heavier and more massive the building, the more dense the concrete in its foundation should be.

If the construction is carried out in a swampy area or increased fire resistance is required from the building, then the density of the concrete should also be higher. This means that the cement content in it should be higher.

For the foundation, the concrete always includes:

- sand,

- gravel or crushed stone,

- cement,

- water.

At the same time, you should not take sand that is too fine - only the one whose grain size ranges from 1.2 mm to 3.5 mm is suitable. The particle size of gravel should not be larger than 8 mm.

As for cement, different brands of cement are suitable for different foundations. The grade in it indicates the limit of its compressive strength. And the grade of concrete obtained from it takes up to 2 times less, so M400 concrete cannot be obtained from M300 cement.

Most foundations for ordinary houses and cottages are poured from a concrete solution containing 1 part cement, 2-3 parts sand and 4-6 parts gravel.

However, the density limit of concrete based on a particular cement can always be adjusted by increasing its percentage in the solution or reduced by adding sand and gravel.

Calculate the amount of concrete for a strip foundation

Calculate the amount of concrete for a slab foundation

Calculate the amount of concrete for a pile foundation

Cement mortar for foundation

For ease of mixing the mortar, a concrete mixer is used. The classic recipe for the mixture initially requires filling with water. You should proceed from the amount of cement: 1 bucket of cement to 1 bucket of water, as a rule, these components are proportional. To obtain the required consistency of the solution, water must be poured in gradually. If sand is used while it is wet, the amount of water should be reduced.

Professional masons advise adding liquid soap to water when preparing the solution to give it greater elasticity. Water with soap has the greatest fluidity, unlike ordinary water. This mixture will better wet the filler and poured surfaces. Its ability to fill small pores will reduce the number of voids and cavities. Strength and elasticity will increase significantly. Before mixing soapy water with the solution, soap and water must be combined.

As soon as the liquid soap has dissolved and foamed, you can add about half of the prepared sand. After this, cement should be added in full. Next, all components are mixed for about 5 minutes and the rest of the sand is poured. If the solution is not thick enough, add a small amount of water. How do you know the correct consistency of cement mortar? The solution should resemble sour cream, and if you draw something on it, the drawing should leave its outline.

4.8 / 5 ( 6 votes)