Houses made of natural wood have now regained popularity. But wood is far from a homogeneous material, therefore, during the shrinkage process, slight deformation occurs; different parts of the house take on their final appearance unevenly.

This raises the problem of fastening the beams together, which will ensure reliability, on the one hand, and uniform shrinkage, on the other. The solution was found a long time ago - dowels. The element differs in size, cross-sectional shape (circle or square), and material of manufacture.

Types of dowels

There are many types of fasteners, but they are conventionally divided into groups according to material and shape. Let's consider this issue in more detail.

Material of manufacture

Two types are actively used:

- Wood. Most experts strongly recommend using a wooden tenon when constructing wooden structures. The main advantages when choosing such fasteners are given:

- Even drying. The beam and dowel should be approximately the same humidity. This will allow the shrinkage process to go through with virtually no visible changes;

- Not affected by temperature changes . The tree practically does not change its linear dimensions at different temperatures, so the fastening element will always be in place;

- No rust . Metal rusts over time, which leads to rotting of wooden surfaces in contact with it;

- There is no condensation. With a sharp change in temperature, moisture forms on steel, which is completely useless inside a load-bearing wall.

- The dowel fuses with the wall. After a certain time, the house will become monolithic, the wooden surfaces will be soldered together.

- Metal. This option also applies to a budget fastening method; waste materials (pipes, fittings) are often used. Although experts prefer the previous method, The metal dowel has its advantages:

- The top layers of wood are protected from torsion;

- Durability of the structure.

Form

There are also several main forms:

- Round section. Taking into account the fact that the holes for fastening in the log are made with a drill, the round dowel will provide the maximum contact area, guaranteeing the reliability and durability of the structure;

- Square. It is easier to make such an element; it also costs less. But that's where the positives end. When entering the hole, the edges of the tenon are deformed, and the total contact area remains minimal. Building a house this way is dangerous;

- Narrow rectangle . The easiest option to manufacture. A board of a certain thickness is taken and cut into rectangles. The only advantage is the very small thickness. Suitable for narrow timber, but installation is extremely difficult.

What is a dowel?

The word dowel itself translated from German means a large nail. A dowel or large smooth wooden dowel is used to secure a wooden structure. The size of the dowel can be very different. Most often, when constructing log houses, round dowels are used, since they are the easiest to fix. Pins can also be of square cross-section, but this shape is used much less frequently. The dowel is made from different wood materials:

- oak;

- birch;

- pine.

The latter option is less preferable, since the density of the wood is quite low and the dowel may become somewhat deformed during operation.

We make the dowel with our own hands

This type of fastener is sold in stores, but you can make it at home without much difficulty. The wooden element is made as follows:

- scraps of boards are taken, from which beams measuring 25 by 25 centimeters are cut;

- stakes are made 1.5 times the thickness of the building timber, with a diameter of 2.5 centimeters;

- The corners are cut off with an ax to give a rounded shape.

But the following must be taken into account:

- the wood for fastening must be harder than timber. Nowadays birch is most often used for these purposes;

- the dowel should not differ significantly in humidity from the main structural element;

- It is strictly forbidden to use a dowel with a knot.

We carry out calculations

Depending on the chosen fastening technology, it is possible to determine with sufficient accuracy the number of dowels and calculate their correct characteristics.

Deciding on the sizes

There are many scientific works that will help determine the diameter of the dowel. But in the professional environment of carpenters and builders, certain rules have already been formed:

- for timber with a thickness of 20 centimeters or less, a dowel with a diameter of 25 millimeters is used;

- a thicker beam is fastened with a tenon measuring 3 centimeters;

- timber thicker than 0.2 meters can be fastened with a 2.5 cm dowel, but subject to the step being reduced to a meter.

The length is determined even more simply - the most common and recommended method is to fasten two logs with a dowel one and a half beams long.

Counting the quantity

Even a small sauna will require quite a large number of spikes that need to be purchased or made, which can take a long time. Therefore, it is better to know the number of fasteners in advance.

There are fastening rules:

- the first dowel is inserted at a distance of 20 to 70 centimeters to the corner;

- the step is from one and a half to 2 meters;

- It is necessary to fasten two adjacent logs in height.

Knowing these tricks, the height of the structure, the diameter of the timber, you can easily calculate the number of dowels needed for construction.

How to install a wooden dowel in a log house, what is a dowel and what is it for?

In Fig. 1 shows a wooden dowel

Since ancient times in Rus', craftsmen, working with wood, used birch dowels, wedges, dowels and dowels to connect wooden parts in their products. The use of wooden fasteners when cutting a house is explained by the natural incompatibility of wood and steel with each other. For many centuries, the use of metal staples and nails was considered bad manners and unprofessionalism among log home builders.

The most popular fasteners, which are now widely used among professional builders of log houses, can be considered a kind of wooden nails - these are dowels.

Translated from German, the word dowel is translated as “wooden nail.”

The dowel is a wooden rod, thanks to which the crowns of the log house are fastened and fixed in height.

To make the dowel, we use smooth, knot-free wood with a moisture content of no more than 12%; as a rule, these are wood species such as oak, birch, ash, and pine.

Pins come in different cross-sections: round, square, as well as octagonal and even triangular. It is believed that round rods are more reliable and stronger due to the larger mating area of the working surfaces. As a rule, the thickness of the dowels is 25-30 mm, it all depends on the diameter of the log.

If we refer to GOST 30974-2002, then the thickness of the dowel should be 20-25 mm if the diameter of the log does not exceed 140 mm, and the thickness of the dowel should be 30 mm if the diameter of the log is over 140 mm. There are no standards regarding the length of dowels, but according to the generally accepted standard their length is usually 120-150 mm.

Fastening with dowels is carried out as follows:

starting from the hump of the top log, through holes are drilled strictly vertically (if you drill it not vertically, you can get a suspended crown), passing through 3 crowns along the diameter of the dowel so that the dowel itself fits tightly into the drilled hole. As a rule, holes are drilled at a distance of 300-500 mm. from the corner of the log house, then the drillings go in a checkerboard pattern every 1500-2000 mm. from each other.

The dowel should fit into the hole with little effort; if the diameter of the dowel is larger than the hole, a competent carpenter will not use such a dowel; if the dowel has play, then you can simply soak it in an antiseptic. Before driving the dowel into the hole, it must be antiseptic; in some cases, dowels are driven in with glue. Fixing the crowns of the log house with dowels prevents displacement and bending of the logs during drying. The dowels also take on part of the stress that occurs when the logs dry out.

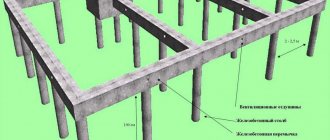

Figure 2 schematically shows how to properly fasten the crowns of a log house using dowels.

It must be remembered that with natural shrinkage, the log house shrinks, and in order to prevent the rims of the log house from hanging, the length of the dowel is made shorter than the length of the hole by 20-30 centimeters.

When building a log house, no matter what size it is, you should never neglect the rules for installing dowels, because the dowel is an additional guarantor of the quality and safety of your log house.

Fastening technology

Drilling

A powerful drill is used if it is necessary to make holes directly on the construction site, or a machine if the timber is prepared in advance.

The second method is common in the West and allows you to assemble the structure of almost any house in a few days. But it requires attentiveness, accurate drawing, and professionalism.

In the first and second cases, the rule remains unshakable - the hole must be strictly vertical.

The diameter of the drill and the thickness of the dowel must match, and for the upper tiers of the timber the hole should be even two millimeters larger. This eliminates sagging of the supporting structure due to a small vertical load. The hole is made 2 centimeters longer than necessary so that the tenon can move smoothly during shrinkage.

Clogging

Typically a sledgehammer weighing several kilograms is used. The dowel is driven inward below the edge of the beam to the end of the hole; nozzles (usually made of brass) are used for this.

Correct location

The ideal option is when the dowels are arranged in a checkerboard pattern. But a strictly vertical direction along parallel lines is also allowed and does not significantly affect the strength.

A gap of at least thirty centimeters before the start of the opening is recommended. The distance of the fastener to the corner should not exceed 70 centimeters. The step can vary from a meter to 3, depending on the material from which the timber is made (hard varieties require a smaller step).

How the log house is assembled on the dowel

In order for the building to be strong and reliable, it is not enough to simply connect the frame crowns in the corners; for better adhesion, the house is assembled on wooden dowels.

A dowel is a special smooth pin with a round or square cross-section. It must be made of stronger wood than ordinary or profiled beams intended for the walls of a house. Therefore, the best material for dowels is birch. Sometimes oak pins are found, but they are very expensive. Since hardwood wood lacks the natural protection that resin provides to pine beams, they are treated with a protective impregnation that prevents rot.

The dowel fastens the walls vertically, and the strength of the walls of the finished house directly depends on its correct nailing. Wooden “nails” are installed along the entire length of the log or beam in pre-drilled holes, and their depth should exceed the length of the dowels by three to four centimeters. The first pin is placed at a distance of no more than forty centimeters from the corner of the house, and the subsequent ones - one and a half to two meters from each other. The length of the dowels should allow them to pass through two crowns, and the diameter ranges from two and a half to five centimeters, depending on the thickness of the timber being fastened. In order to increase the stability and rigidity of the box, the dowels are staggered. In general, this work requires knowledge of many nuances, so it is better to entrust it to professionals.

Advantages and disadvantages

Like any other fastening element, the dowel has a number of positive aspects, as well as disadvantages.

Advantages:

- The spike provides reliable grip and prevents the crown from sagging;

- Provides long-term reliability under bending loads, which nails and bolts cannot boast of;

- Promotes uniform shrinkage of the house. The fastening element moves freely along a vertical plane, preventing horizontal deformations;

- The wooden product is not subject to the formation of moisture and corrosion, excluding the process of rotting;

- Extremely cheap. Even buying ready-made dowels won’t put a big dent in your pocket, allowing you to minimize your budget.

But there are also disadvantages:

- Difficult to install. Absolute vertical position, ideal selection of diameter, implies the presence of decent construction skills;

- Serious quality requirements. The presence of knots or heterogeneity of the material can lead to disastrous consequences;

- Excessive force when driving often leads to cracks in the timber. After which it needs to be changed.

Blitz tips

There is a set of installation tricks that will allow you to build your dream home that will last for many years:

- Chess order. The condition is not mandatory, but highly recommended by carpenters of all stripes;

- To avoid sagging, it is necessary to use round-shaped wooden dowels. Square products are mainly promoted by manufacturers as they are easier to manufacture;

- When clogging, you can and should reduce friction. To do this, it is enough to use a soap solution;

- It is recommended to use birch fasteners. This guarantees the reliability of the structure, gives a certain charm, and does not increase the cost of construction;

- Similar humidity between the tenon and the beam is a fundamental condition for the durability of the structure. You need to pay close attention to this;

- Feel free to use additional fasteners. Science does not stand still; modern devices can make the task much easier.

Technology of building houses using dowels

When installing dowels, you will need to drill holes for subsequent installation of the elements. To do this you will need to use a special tool. It is worth considering that the diameter of the dowels usually exceeds 25 mm. If a house is being built from timber with a cross-section of more than 150x150 mm, then the diameter of the dowels should be significantly larger. When ordering the construction of timber houses from specialized companies, the master will independently calculate the required diameter of the dowels, which will ensure the construction of a reliable and durable structure. If there are doubts about the diameter of the dowels used, then this question can be asked to the master, and he will explain the features of the choice.

There are several features when installing dowels that must be taken into account, otherwise the functionality of the elements can be significantly reduced:

- The distance between the dowels is usually one and a half or two meters. This step ensures the most reliable fastening of the timber. The first dowel must be driven in at a distance of half a meter from the corner of the house. Although the corners of the house have additional fixation, it is impossible to do without dowels.

- Drilling holes in the crowns of a log house is best done using a drill with a wood attachment. The use of other tools is not advisable.

- Dowels are used to fasten two beams together, so the hole must fit a certain distance into both crowns. If this factor is not taken into account, then subsequently the fixation will be completely useless and may violate the geometric integrity of the structure.

- The diameter of the hole should be a couple of millimeters larger than the dowel itself. It is also necessary to leave a couple of centimeters on top of the dowel to ensure correct shrinkage of the building. The wooden fastener must move freely according to its hole, since the quality of the shrinkage of the frame depends on this. In this case, the wood nail should not hang on the beam.

- The hole in the beam must be located clearly in the center, since a minimal displacement will lead to a violation of the geometry of the wooden structure.

- The dowels must be mounted strictly vertically. Non-perpendicular installation to the crowns of the log house will make it difficult for the timber to slide down during shrinkage.

- Wooden dowels are driven in only with a special wooden mallet. Using metal hammers can cause the dowel to chip, crack, or change shape.

- Fastening the crowns of the log house using dowels is carried out in a checkerboard pattern. This fastening technology ensures maximum structural reliability.

Wooden dowels do a good job of firmly holding the beam in one position and preventing the walls from bending in any direction. Also, due to the coincidence of the material, the likelihood of gaps appearing between the crowns of the timber is minimized.