Understanding 3D Tiles

As a rule, the image of 3D tiles has a raster or geometric shape, which can create a distorted perception of parallel reality in the bathroom.

Modern technologies create unique conditions for developing your own business. With their help, not only young companies are developing rapidly, but also old buildings are being transformed due to 3D effects.

To make this amazing material, sand, cement, mineral additives, water and crushed stone are required. In production, a blank is made on which the image is applied. There are two types of images: templates or copyrighted (expensive).

If the buyer expresses a desire, then any 3D design can be applied to the tiles. There is no need to worry about the quality of the image, since the top of the picture is covered with a special compound that protects it from fading, abrasion and the effects of chemicals.

It is worth noting that 3D images began to rapidly gain popularity quite recently. They attract buyers with their unusually beautiful appearance, good performance and a wide variety of colors.

Profitable business under your feet

For a long time I couldn’t decide where to start my business. I wanted to enter the market with a product that would meet at least 4 criteria:

- was the one and only, i.e. had no analogues

- was really interesting and needed by people,

- did not need intensive advertising,

- did not require large expenses.

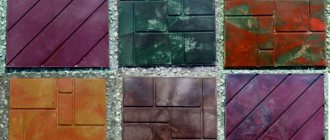

I think I've looked at all the business ideas for beginners, but none of them impressed me. And so, quite by accident, I found what I had been looking for for a long time! The ideal product that provided me with a profitable business was paving slabs with a 3D effect, recently developed in Novosibirsk! By the way, this is what it looks like:

Advantages and disadvantages of the material

Finishing the bathroom floor with 3d tiles.

Advantages: antiseptic coating. Disadvantages: one element cannot be replaced. 3D tiles have their strengths and weaknesses, however, like all currently known building materials. A machine for the production of paving slabs gives a huge advantage in choosing the shape of products, and also allows for significant savings.

Strengths:

Thanks to 3D technology, your floor can be truly unique

- Unlimited field for experiments. You can use any photograph, favorite image, etc. as a drawing.

- A wide variety of forms that comply with all government regulations. The most popular tile shapes are: pentagon, hexagon, square, triangle, etc. It is worth noting that the shape does not affect the performance of the tile.

- Huge scope for application. Material with a 3D effect can be used in production, in a country house, near cottages or near government buildings.

- High relevance and minimal production costs. Experts believed that to fully set up your own business producing paving slabs with three-dimensional patterns, it is enough to have 300 thousand rubles in your pocket. Proper organization of a business contributes to its rapid payback (no more than a year).

Weak sides:

- Price. Yes, some categories of citizens attribute price to the shortcomings of tiles, while turning a blind eye to its excellent performance qualities. The cost of paving slabs with a three-dimensional image varies between 3 - 8 thousand rubles per 1 m2. For comparison: 1 m2 of ordinary tiles rarely exceeds 500 rubles.

An analysis of the strengths and weaknesses of the tiles showed that paving slabs with a 3D effect are rightfully considered one of the best building materials for decorating sidewalks, roads and paths.

Advantages and disadvantages of the product

Our business assessment:

Starting investments – from 150,000 rubles.

Market saturation is low.

The difficulty of starting a business is 2/10.

Paving slabs with a 3D effect are a decorative coating with the following characteristics:

- durability;

- environmental cleanliness;

- attractive and aesthetic appearance;

- resistance to moisture, mold and mildew;

- strength;

- wear resistance.

The decorative material has a non-slip surface and perfectly insulates sound. 3dC paving slabs are resistant to temperature changes and ultraviolet radiation. Using it as decoration you can visually enlarge the room. The scope of its application as a finishing material is limited only by the decorator’s imagination.

The product is practically free of flaws. Only when laying it is necessary to take into account the fact that cutting the tiles can lead to disruption of the integrity of the ornament. And the base on which it is planned to install the coating must be perfectly level.

Manufacturing Features

3D tiles are made from high-quality cement-sand mixtures using vibration pressing. In production, the prepared viscous solution is compacted tightly into molds and placed on a special device - a vibrating compressor. After this procedure, the manufacturer receives a typical paving blank with a smooth surface.

Paving slab manufacturing technology

In the second stage, paint and a three-dimensional image are applied to the surface of the material. Several methods of drawing can be used in production:

UV printing allows you to apply full-color images

- Flexographic printing. When applying a pattern using this method, a photopolymerizing base is used, or less often paint on rubber. The 3D effect is achieved through the play of shadows - light colors become visible against the background of dark ones. This is how the drawing appears. The advantages of flexographic printing: low cost of the procedure, high production speed, reliability and excellent image quality.

- UV printing - this method of printing on paving slabs is characterized by an expensive procedure. It is worth noting that the high cost does not always justify its quality. Experts conducted studies that clearly showed the absence of any noticeable differences in quality between the two methods of applying paint. Despite this, UV printing still has high color rendering and a more realistic image. This type of printing uses 6 machines and several transitional shades.

It is worth noting that pictures with a 3D effect can be applied independently. To achieve these goals, it is necessary to purchase appropriate equipment.

After printing, the tile blank is sent to the next stage, where the image is pressed into place. From above, the design is filled with a transparent polymer, less often with epoxy heat-resistant resin. Next, the upper layers of the workpiece are compacted and leveled, while the print is pressed into the material.

After this, the workpiece is sent for processing with cold liquid or an air stream. After careful processing, the workpiece is removed from the matrix. At this stage, the production of 3D tiles ends. It is packed into bags and sent to distribution points.

Features of making 3D tiles

After receiving a paving blank with a smooth surface, a pattern is applied to it in one of two ways:

- Flexographic printing. In this case, a special photopolymerizing base, and sometimes rubber-based paint, is used to apply the picture. To achieve the effect of a three-dimensional image, a standard drawing technique is used - due to black shadows and light highlights, the decorative pattern becomes more realistic and “convex”. This procedure is relatively cheap, and the finished slabs are strong and durable.

- UV printing. This expensive procedure allows full-color images to be applied to the tiles. The quality of the finished products is no different from those on which the design was applied using flexographic printing. However, the color rendition of the image will be noticeably better, due to the fact that a larger range of shadows, highlights and transition shades are used to give the picture volume.

After a decorative pattern or photograph is applied to the tile, the product goes through several processing stages:

- The image is filled with a transparent polymer composition (sometimes heat-resistant epoxy resin is used for this).

- The protective polymer layer is compacted and leveled. At the same time, the print is pressed into the tile.

- A workpiece with a three-dimensional image is processed with cold liquid or a high-pressure air stream.

Thanks to this, it is possible to obtain 3D tiles without additional treatment with chemicals. Layers of paint and polymer are securely bonded, forming a durable and reliable surface.

Installation features

“3D” graphic laying of paving slabs

Installing colorful paving slabs is no different from the usual process. The sequence is the same:

- Construction debris, grass and other large objects are removed from the work area.

- A sidewalk or courtyard area is created. It is worth noting that 30 cm in depth is sufficient for a foundation.

- The foundation is poured with concrete.

- A cement-sand mixture is poured onto the set foundation.

- The cement-sand mixture is leveled.

- The tiles are laid on the leveled surface in accordance with all requirements.

Thus, 3D paving slabs are qualitatively different from well-known building materials: they have high performance qualities - they can withstand severe damage, temperature changes and the action of aggressive chemicals. As for relevance, it is slightly lower than gold mining in the world, but higher than the production of other building materials.

Paving slabs like classic concrete

Paving slabs are distinguished by some parameters that are not found in other materials for landscaping:

- ease of installation;

- ease of care;

- increased resistance to sudden changes in temperature throughout the year;

- environmental cleanliness;

- Excellent moisture and air permeability.

The construction market offers a wide selection of shapes and colors of concrete fragments; the technological method for manufacturing such products does not require large financial costs, which guarantees the mass use of paving slabs; the most common shape is considered to be a rhombus; due to the symmetry in size, it is possible to create complex patterns from such parts , visually demonstrating volume and suitable for designing both narrow zones for pedestrians and large areas in parks and playgrounds in neighborhoods.

Laying paving slabs of this format requires specialized skills in work, therefore, professional craftsmen who have accumulated experience work with diamond-shaped fragments and offer potential clients photos of completed and well-proven projects.

Absolutely new on the construction market

3D tiles are the latest development; they really have no analogues (neither in Russia nor in the world). From personal experience I was convinced that people are actually interested in her. Plus, tiles with a 3D effect do not need a large-scale advertising campaign, and they do not require a lot of money for their production and sale.

In general, there are only positive moments all around. They encouraged me to take on a new type of business.