You will learn how to use an indicator screwdriver, the rules for its standard use and how to use it in various ways from this article.

A regular indicator screwdriver is an insulated transparent handle through which a rod with a screwdriver blade at the end is passed.

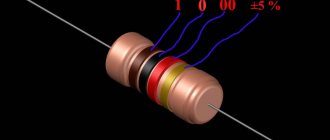

There is a resistance resistor in the handle body that reduces the current strength to a minimum value that is safe for humans.

It is directly followed by an indicator lamp, a conductive pressure spring and a contact plate.

The principle of operation of the simplest indicator screwdriver is the passage of current through the tip and the indication element, followed by its exit through the body of the master, which is grounded.

In this case, a person closes the circuit with his finger, due to which the light bulb lights up.

This screwdriver is designed as simply as possible, but its scope of application is limited.

With such a tool you can only determine phase and zero, and even then the latter - by the method of elimination.

Options with built-in batteries have wider functionality.

They allow you to determine the presence of current in a conductor without touching it with a tip.

A screwdriver detector with a built-in battery is also suitable for searching for hidden electrical wiring.

As you know, a conductor under voltage emits an electromagnetic field.

It is this field that the detector detects, but the accuracy of the search leaves much to be desired.

How to check an indicator screwdriver

Before you start searching for a phase, you must make sure that the indicator screwdriver is working properly.

To do this, it is enough to touch the wire, which is obviously energized, with the sting.

Screwdrivers with batteries are easier to check - you need to touch the contact at the end of the handle and the tip at the same time.

If the tool is working, the indicator light on its front panel will light up due to induction.

To learn how to operate an indicator screwdriver, let’s consider the main types of testing.

How does a screwdriver indicator work?

To use any device, you need to understand how it works. Of course, this fully applies to the indicator screwdriver. If you at least roughly know how it works, this will give you the opportunity to easily use it without making any mistakes.

This will also give you the opportunity to do without a multimeter, which is much more expensive and much more difficult to use. Today you can see various indicator screwdrivers in specialized stores. And each type has its own operating principle.

Contact method

To determine the phase in the AC network, you need to touch the probe of a screwdriver directly to one of the socket terminals.

If the LED lights up, this is a phase.

Otherwise, the selected terminal is zero.

Attention!

It should be remembered that if the wire is disconnected from the network, or the circuit is broken, the indicator will not light up on the phase wire.

Types of indicator screwdrivers

There are several options for the measuring device. They differ in design, operating principle, and additional functions. So, on sale are: simple tools, models with a built-in battery, electronic, non-contact.

A simple model with a neon light bulb

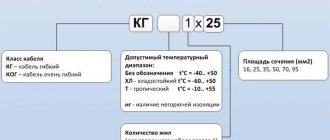

The design of the most common and accessible model consists of the following elements:

- Housing made of durable transparent plastic. It is often painted in bright colors.

- Flat tip rod.

- Resistor. The element voltage must be at least 1 ohm.

- Small neon lamp.

- Contact surface.

To make the product convenient to transport, there is a plastic clip in its upper part.

Despite its simplicity, low cost and ease of use, the device has limited capabilities. It will not be possible to measure voltage if its value is less than 60 V.

Non-contact battery-powered measuring device

Despite the external similarity with the previous version, it has a different design. For example, instead of a neon lamp, a miniature LED is used here. This significantly expands the functionality, allowing measurements to be carried out on networks with voltages less than 60 V.

The device allows you to check circuits of radio and electrical equipment, determine the functionality of fuses, and find broken wires. A bipolar transistor and an autonomous battery allow for contactless manipulation.

Measuring screwdriver with contact batteries

It is a kind of hybrid of a conventional and contactless model. This also uses an LED and a resistor. The main difference is the presence of a contact surface. This eliminates the possibility of contactless network checking.

Electronic options

Its design consists of elements:

- small rod;

- housings made of dense opaque plastic;

- miniature LCD display;

- two contact surfaces.

This is a modern, universal device. Compared to the previous ones, the electronic model has broader functions: with its help you can “ring” the electrical network for a short circuit, make contact or non-contact measurements.

The device notifies you of the results using an LED and a characteristic sound. In addition, the screwdriver has a low response threshold. This allows it to be used for setting up and repairing circuits in vehicles, electronic and household appliances. The disadvantages include the built-in battery. If the device fails or the battery runs out of charge, you will have to purchase a new screwdriver.

Contactless method

This method allows you to determine the presence of alternating voltage without direct contact with the conductor.

The screwdriver is taken by the tip and brought with the tip - the contact of the handle - to the socket.

The indicator lights up - there is voltage.

This option is suitable for searching for hidden wiring in the wall.

Remember!

Friction of the screwdriver body against any surface leads to the generation of static voltage, which can cause false positives.

The accuracy of searching for wiring in the walls of a house using a non-contact method is minimal, and is completely useless if there are fittings in the wall panels that distort the signal.

Multifunctional indicator screwdrivers with LCD displays

It is not only a voltage indicator with LED backlight and audible buzzer. The liquid crystal display displays the network voltage within the range of 12–220 V. Voltage control can be carried out in DC and AC circuits. This device can be used in electrical networks on vehicles powered by a battery.

One of the models of an indicator screwdriver with a liquid crystal display

In practice, this is a device with limited multimeter functions, showing the value of the measured parameter in digital form. Some even professional electricians do not use this option because of the high price; amateurs believe that an indicator screwdriver is a complex device, it is unclear how to use it, and it is also expensive.

The indicators have three operating modes, set by a switch. Therefore, you need to carefully study how to properly use an indicator screwdriver of this type. The sequence of actions when monitoring voltage is similar to the considered options, but when measuring, a button on the body is pressed, the information is processed electronically. The cost of such products is from 120 to 180 rubles.

Indicator screwdriver STAYER 4520-48 with three indication modes

Operating modes:

- O - contact mode with a conductor, indication is carried out by a red LED, a finger is placed on the contact plate of the housing. The dialing mode is carried out using the same method as in indicators with self-contained power supply and LED;

- L — non-contact mode, the indication is triggered when the tip of the screwdriver approaches the conductor at a distance of 1–2 cm. The green LED lights up, and there are possible options for sound signals from the buzzer;

- N - non-contact operating mode with increased sensitivity to interference, hidden wiring routes are determined, and the green LED lights up.

This screwdriver as an indicator is convenient, multifunctional, it is easy to determine the routes of hidden wiring and break points. Some say that such an indicator displays voltage values with a large error. Yes, a significant drawback is the rapid consumption of DC battery power. It is recommended to check the voltage level of the batteries more often.

How to use an indicator screwdriver

In addition to options for working with household electrical networks, there are indicator screwdrivers for use in a car.

They are designed for troubleshooting wiring in DC networks from 6V to 24V, as well as for determining the polarity of wires.

Instead of a contact on the handle, a wire with an alligator clip comes out of its end.

To find all the positive wires in the car, you need to connect the battery terminals.

Having fixed the screwdriver clamp on the machine body, probe all the necessary wires one by one.

The indicator signal indicates a plus.

The search for negative terminals is carried out in a similar way, with the difference that when using car testers, the crocodile will be connected to the positive terminal of the battery or the positive wire.

There is a voltage switch on the body of the device (usually 6V, 12V and 24V).

It must be set to the position corresponding to the vehicle's network voltage.

Attention!

To avoid short circuits when working with car wiring, the positive terminal of the battery must be disconnected.

Varieties

Indicator screwdrivers from a variety of manufacturers are available on the market. When selecting, the type of lamp is taken into account:

- regular,

- neon.

Source dependency separation:

- with battery,

- without battery.

Tester battery

Types of devices based on operating principle:

- contact,

- contactless

Modern models are available in mechanical and electronic types. Smart indicators, which come with additional functions, are included in a separate category.

You may be interested in this Features of crimping pliers

Regular screwdriver with neon lamp

An electrical appliance with a regular lamp can help when connecting electrical outlets or lamps. The units are sold at low prices and can replace digital multimeters. If we consider models with neon bulbs, they are supplied in a protected case and a metal probe is used.

Interesting! The neon lighting element is located next to the contact plate.

Test installations

Test setups are considered simple, but there are models with additional functions. For example, if you take a phase wire, it is easy to determine the voltage level. Ease of use is noted; models are supplied without batteries. An additional feature is the circuit check. If you place the sharp end against the contact, you can find out the voltage level (when the light bulb is on or off).

Laserliner products at prices starting from 600 rubles remain in demand on the Russian market. They are capable of working with current-carrying networks up to 600 volts. Initial instruments are used to determine grounding and phase. Modern devices are manufactured with shock-resistant housings. There are models with stings, as well as without them.

Important! The kit includes a screwdriver, batteries and instructions.

Interesting products have an increased level of security. Two AAA batteries are included for power supply. In addition to the indicator, there are screwdrivers with an audible signal. If you look at the parameters, the maximum voltage starts from 1,000 volts, dimensions are 156 by 26 mm, frequency is 50 Hz. In order to save battery power, manufacturers produce models with automatic shutdown.

If the device is not operated for 3 minutes, it stops working. When considering products with dual indication, most often the maximum voltage is 600 volts.

Dual display tester

Battery operated screwdriver

Battery-powered screwdrivers are compact yet effective. When replacing a socket, work must not be carried out until the phase is determined. Alternatively, you may call a qualified electrician. You could also consider a standard screwdriver with a battery.

Main nodes:

- sting,

- element insulation,

- indicator lamp,

- wire resistor,

- contact at the end

- spring,

- battery.

You might be interested in this: Checking IGBT transistors

Autonomous samples on the market are considered more in demand. Products for various consumers are produced; functionality is worth noting. The devices are suitable for detecting hidden wiring and allowing you to assess the integrity of the circuit.

Standalone sample

Important! It is allowed to work in a network of 220–250 volts. An additional feature is polarity detection. This question takes into account the operating range (on average it is from 1.5 to 36 volts).

Options with batteries are sold at prices starting from 200 rubles. There are small models with compact batteries. The tools are used by electricians when repairing apartments or servicing vehicles. Professional models are in demand in auto repair shops and workshops for servicing hydraulic and pneumatic weapons.

There are options with a thin probe, which are intended exclusively for working with boards. The cost of professional devices starts from 600 rubles. European and American products with a protected case are presented on the market. Measuring instruments have the following features:

- high voltage;

- allowed to be used in hot weather;

- various display options;

- easy to check;

- battery quality.

Products from Chinese manufacturers are included in a separate category. The probes easily show an open circuit and allow you to determine the phase. Starting price – only 100 rubles. If you need a device to operate in an electrical network with voltages above 250 V, you should take a closer look at models from a European manufacturer.

European samples

Screwdrivers are available with and without phase indicator. Technics products operate on a network from 100 to 500 volts. The length of the screwdrivers is only 125 mm. The design includes a wire resistor and uses anti-corrosion chrome plating. The device is suitable for testing fuses.

Interesting! Options called ZHENGTE are distinguished by battery protection, and additional functions include chain ringing. They have a low wear rate and can be expected to last for a long time.

Voltage testers - non-contact type

Electricians increasingly prefer non-contact indicators. There is no need to take unnecessary risks when working with exposed wires. The main goal of specialists is to quickly find the source of stray and unwanted voltage.

You might be interested in this: Checking an LED with a multimeter

Non-contact indicators

It is also suggested to check the insulation level. The products of the following brands remain in demand on the market:

- Bosch.

- Fluke.

- Laserliner.

- Pro'sKit.

- STANLEY.

- UNI-T.

Compact products are produced that look like a pen or a metal detector. The characteristics of non-contact models are capable of satisfying professionals. One of the features of modern indicators is the presence of an LCD screen. Provides audio and visual indication, providing an opportunity to quickly find out about the voltage in the circuit.

LCD type

Smart electronic indicators

When talking about a smart indicator screwdriver, users imagine a multi-functional device. Many models are designed to detect phase wires. In construction they are used for chain testing. Some portable screwdrivers can detect current. There are options with and without display. In 2021, conventional models that can operate in two modes remain in demand:

- contact;

- contactless.

There are modifications with signal LEDs that can be called professional. The devices have two indicators - red and green. The displays may show additional information.

Finding phase and zero

As for the household network, searching for phase and zero consists of simply checking the wires one by one by touching the tip of a screwdriver to their current-carrying parts.

If the indicator is on, this is a phase.

Therefore, the second wire is neutral.

Remember!

The indicator can show the phase on both contacts.

This happens when the neutral wire is broken.

If the glow is noticeably weaker on one of the conductors, this indicates the occurrence of an “induced” voltage from the phase.

As a rule, this happens when the zero is poorly grounded.

Product selection criteria

Knowing how to determine phase and zero with an indicator screwdriver, you can always quickly fix problems with the power supply of your home with your own hands. When choosing a voltage indicator, it is recommended to consider a number of characteristics. Their list includes:

- body size and shape;

- color shade and ergonomics of the handle;

- functionality;

- availability of a power source for autonomous operation of the screwdriver;

- type of indicator light: neon or LED;

- presence of display and sound signal;

- manufacturer company;

- cost of the product.

The optimal choice of voltage indicator determines the successful use of the products and the absolute safety of repair work.

Looking for a broken wire

If there is current at the entrance to a house or apartment, but there is no current in the sockets of the rooms, this indicates a broken contact.

An indicator screwdriver can approximately locate the location of the conductor damage.

To do this, the tip is placed at the place where the wire is laid, walled up in the wall.

At a break, the indicator will stop lighting.

To check an entire line of wiring, you need to take an indicator with a battery.

You need to de-energize the house, take the exposed wire in one hand, and run the tip of a screwdriver along the wire.

The indicator will stop lighting at the break.

How to use a screwdriver to test voltage

Despite the similar design and ease of use, each device has its own nuances of use.

Simple screwdriver

To determine the presence or absence of electric current in an outlet or on a section of the electrical network, carry out the following manipulations:

- Place the tip of the tip on the contact of the socket or the section of the network being studied.

- Use your finger to press on the special pole plane, which is located at the end.

If the device is working properly, there is voltage in the circuit, the screwdriver will indicate this by glowing a neon light bulb.

Self-powered and LED element

To determine the neutral or phase contact, you just need to touch the socket or section of the electrical circuit with the rod. If the device is working properly, there is no open circuit, the LED will light up brightly. You don't need to put your finger on it.

With LCD display

Allows inspection by both contact and non-contact methods. In the first case, the process is the same as when using a simple screwdriver. However, in this case, the device will notify you with an inscription on the indicator.

In the non-contact method, the device is brought as close as possible to the object being examined. Then press the button on the case. If the device is working properly and the network section is energized, a lightning bolt symbol will be displayed on the LCD display.

A modern tool allows you to quickly find damaged sections of an electrical circuit and repair various devices. It is important to remember to follow safety precautions. Experts do not recommend using non-working or faulty devices - this can lead to electric shock or incorrect test results.

Subscribe to our Social networks

Checking the extension cord

To check the performance of an ordinary household extension cord, you need to insert the tester into one of its holes, and then into the other.

If one has current and the other does not, then everything is working correctly.

The second test option is a little more complicated and for it, you need to turn off the power to the extension cord.

Then a piece of wire closes the contacts of one of the sockets.

Take one electrode of the plug with your fingers, and touch the second with a screwdriver.

The indicator lights up - the extension cord is working.

Additional possibilities for using the indicator

In addition to searching for phases in the electrical network, indicator screwdrivers also have non-obvious functions.

Checking the serviceability of incandescent lamps

In this way, you can check ordinary incandescent lamps right in the store.

You need to take the indicator screwdriver in your hand, touch the contact on the handle with your finger, and touch the central contact of the lamp with the tip.

With your other hand, grasp the lamp by the metal base. The lamp will be working properly if the indicator lights up.

Scope of application of indicator screwdrivers

The indicator screwdriver performs a number of useful functions that facilitate the process of repairing electrical circuits, setting up equipment, laying control circuits, and monitoring the condition of lighting and socket networks. Therefore, it is advisable for even an ordinary person to be able to use the indicator. First of all, all models work as voltage indicators and perform the following operations:

- the most important function of indicator screwdrivers is to ensure safety, the role of an indicator whether the circuit is de-energized or not;

- detect the presence of voltage in the network (they are used as a voltage indicator);

- separate phase wires from neutral and ground wires;

- the integrity of the conductors in the cable is checked;

- the location of the wire break in the hidden wiring is determined;

- to check the integrity of the spiral of incandescent lamps, electromagnetic coils and many other useful actions.

It is convenient to use a screwdriver; in addition to the indicator functions, one tool can also carry out mechanical work, unscrew or screw in small screws at the contact points of electrical equipment.

Checking the heating element

It is very simple to check the heating element for serviceability without removing it from the heating device, having an indicator screwdriver at hand.

You need to place your finger on its end contact, touch one of the contacts of the heating element with your sting, and touch the other contact with your other hand.

The indicator lights up - the heating element is working.

Attention!

Before checking, you need to turn off the power to the equipment and disconnect all wires from the heating element.

Determining the correct switch position

When installing switches, for convenience, they are installed in such a way that in the “up” position they close the circuit, and in the “down” position they open the circuit.

The probe allows you to determine which position is responsible for what before installation.

With the tip of a screwdriver with a finger on the end contact, you need to touch one of the switch terminals, and with a paperclip in the other hand, touch the second terminal.

The indicator lights only when turned on.