The apartment is dusty. We should clean up. The equipment is already plugged in, you press the button, but nothing happens. It’s not clear what to do: take it to a repair shop or try to repair the vacuum cleaner yourself. Let's figure it out.

The instructions are universal and suitable for most models: AEG, Bosch Ergomaxx, Bimatek, Bissell, Black Decker, Bork, Clever Clean, Daewoo, Deebot, Dexter / Dexter, Dyson / Dyson, EIO Targa Duo / EIO Targa Duo, Electrolux Ergorapido, ZAC, TwinClean / Electrolux Ergorapido, TwinClean; Elenberg / Elenberg, GiNZZU / Ginzu, Gorenje / Gorenje, Gutrend / Gutrend, Hansa / Hansa, Hilti / Hilti, Hitachi / Hitachi, Hoover / Hoover, Iclebo / Iklebo, iLife / Ilife, Kambrook / Kambrok, Karcher SE / Karcher, Kirby / Kirby, Kitfort / Kitfort, LG Kompressor, VK / LG, LV, LG or, as is customary, LG Compressor; Makita / Makita, Metabo / Metabo, Midea / Midea, Miele / Miele, Mile or even Mille, Moulinex / Mulineks, Neato / Neato, Nilfisk / Nilfisk, OBI / OBI, Panasonic / Panasonic Panda / Panda, Polaris / Polaris, Philips HR , Triathlon/Philips Triathlon (sometimes called, excuse me, “Philips”); Rainbow SE / Rainbow, Redber / Redber, Redmond / Redmond, Roboclean / Roboclean, Rolsen / Rolsen, Roomba / Rumba, Rowenta / Rowenta, Samsung SC, VC, Twin / Samsung SC, VC, Twin; Sanyo / Sanyo, Scarlett SC / Scarlet, Seebest / Sibest, Singer / Singer, Shivaki / Shivaki, Siemens Super 510 / Siemens Super 510, Siemens-Electrogerate, Tefal / Tefal, Thomas Twin / Thomas Twin, Thomson / Thomson, XRobot / Iksrobot , VAX / Vax, Vitek / Vitek, Xiaomi Redmi / Xiaomi Redmi, Zanussi / Zanussi, Zelmer Aquawelt / Zepter / Zepter, Soviet and Russian - Buran-5m, Whirlwind, Rocket, Typhoon, Ural-3, Calm and any other manufacturers, including car vacuum cleaners, electric vacuum cleaners, robotic vacuum cleaners, battery-powered, vertical, built-in, washing, industrial, garden and construction models... Phew. If only they were repairable.

Typical breakdowns of different types of vacuum cleaners

Vacuum cleaners can have three types of dust collectors: a bag, a cyclone system and an aquafilter. Each of them has its own characteristics both in operation and in breakdowns.

Regular vacuum cleaner with bag

How it works: the blown air passes through the bag. The dust settles on the ultra-cleaning filter (HEPA) and reaches the engine compartment. The filter performs two functions - it “takes” dust and acts as a compressor. The most common malfunctions:

- Torn or clogged dust bag,

- Clogged filters

- Broken wire

- Worn carbon brushes in the motor.

How to prevent: Be careful what you vacuum. If you hear extraneous sounds during operation or severe overheating of the housing, check and replace the filters. Some models turn off themselves and clean the air filter if the air intake power drops.

Cyclone filter

How it works: the blown air passes through the dust collector, where a strong air flow is formed. The “vortex” scatters particles of debris along the walls of the tank so that they cannot return back. The waste settles in the dust collector and on the filtration system - meshes, sponges and a HEPA filter. A common malfunction: if the container is filled with debris, metal and sharp objects pierce the filter, get into the motor and break it. How to prevent: Empty the dust container before each cleaning.

"Water filter

How it works: water is poured into the dust collector (usually made as a round or square container). The air passing through the telescopic pipe whips the water into small particles and releases it under the front visor. The dust travels from the hose to the bottom of the dust collector, where it settles. What is left passes through, in the place where the moisture remains. Purified air without moisture passes through the motor and cools it.

Frequent faults:

- If a vacuum cleaner with a HEPA filter is poorly cared for, fungus and mold quickly appear due to high humidity. Mold spores are blown out during cleaning (we sense it by the smell of dampness) - requires replacement;

- in some models, thin streams of water flow at the junction of the hose and the body - the seals are wrinkled or torn.

How to prevent: fill the tank only with clean water and only up to a certain mark indicated on the body.

Clean, wash and dry thoroughly all parts involved in cleaning.

Filters

Before disassembling the housing, it is worth checking all the filters in the vacuum cleaner. It is their clogging that leads to a decrease in the power of the equipment, automatic shutdown or even burnout.

Cleaning foam filter pads is simple; just rinse them under running water and dry naturally. If a large amount of dust accumulates on the paper filter, it is recommended to replace it.

It is very difficult to purchase HEPA filters for some vacuum cleaners due to the updating of the range with new models. There is no need to despair; it is easy to make a cleaning device with your own hands. The basis is:

• old filter housing (in the form of a frame);

First you need to remove the paper accordion from the frame, which you need to thoroughly wash, dry and treat the surfaces with an alcohol-based solution (for the purpose of degreasing).

Next, the interior liner is cut out according to the parameters of the frame and fixed to it with glue, having previously applied it along the contour. The unused filter (from which it was trimmed) should be packed in a plastic bag so that it does not absorb dust during storage. Later you can replace the liner again.

Main parts of the vacuum cleaner

To determine our breakdown, let's look at how various elements of equipment work.

Filters

They are the ones who bear the brunt of waste processing. First of all, check them: excess debris impairs suction, leads to shutdown during cleaning or even burnout.

Cleaning the filter is easy - rinse it with water and let it dry without placing it on the battery or blowing it with a hairdryer.

Hose

“Clogs” may form in the hose from socks, rags, hair, pet hair, or simply a large amount of dust. If debris has already accumulated, remove it carefully so as not to damage the inside walls of the hose.

Perhaps there are no “plugs”, but the problem is a hole or crack. The problem can be solved using improvised methods:

- wrap the lesion with construction tape;

- make a patch from a thin elastic band or an overlay from silicone.

Brush

The brush collects large debris and lifts the carpet pile for more effective dust removal. Over time, it becomes clogged and stops picking up dust. It is quite easy to clean a standard brush from tangled hair, threads, wool, for example, after 2-3 cleaning cycles.

A turbo brush consists of a roller coated with plastic bristles: the roller rotates and collects debris with the bristles. Without timely cleaning, the turbo brush will clog just as quickly as a regular brush.

Cord and wire

The cord may be broken, torn, or disconnected from the control board, causing no power to flow to the motor. It needs to be replaced and the new connection must be tightly insulated.

The wire retracting mechanism may break, then the equipment will not wind the cable inside the case. What to do with this is in the instructions below.

Engine

Engine repair and diagnostics are the work of a professional. Don't even try to fix something if you don't understand electrical engineering.

How to repair a vacuum cleaner motor at home: step-by-step instructions + video

Control boards

Just like with the motor, do not try to re-solder the board without knowing its operating principle and repair rules. It could turn out even worse.

Diagnostics

Before you take on repairing a Samsung vacuum cleaner with your own hands, you need to try to determine what exactly is broken.

Correct diagnosis is very important, because the speed and cost of repairs directly depends on it. The design of the vacuum cleaner is quite simple, so before paying money to the technician, you can try to fix the problem yourself

It should be noted that breakdown is not always associated with engine malfunction. Such a malfunction can be determined by the sound of the operating unit. If the vacuum cleaner hums, whistles, makes intermittent sounds and throws out dust, you are most likely out of luck - the engine is “covered”. But it happens, for example, that the vacuum cleaner seems to be working, but the garbage is not pulled out well - then, most likely, the hose or filters are to blame. Let's take a closer look at some of the common problems with this very useful home assistant.

The most common breakdowns

Doesn't turn on

If the vacuum cleaner stops turning on or stalls while cleaning, check:

- Is the outlet working? Try connecting other electrical appliances to it;

- Are the plug and wire intact - the cord often breaks and the veins inside the sheath are torn;

- the power button “sinks” or the power regulator (on some models the speed regulator is located on the tube with a hose) is shorted due to “old age”;

- how full the dust collector and filters are - most likely they will have to be cleaned;

- whether large objects got into the hose - socks, toys, etc.;

- Is there a burning smell coming from the vacuum cleaner? Perhaps the armature winding, stator winding, or the entire motor has burned out.

In addition, the vacuum cleaner may turn off after a long cleaning due to overheating. In this case, wait half an hour and try to turn on the device again.

What to do if the vacuum cleaner stops turning on: 7 main reasons + video instructions

Doesn't collect trash

If the vacuum cleaner begins to hum and does not suck up debris well, you can provide first aid:

- Empty the dust bin.

- Check to see if there is a foreign object (such as a sock) stuck in the pipe or brush. If an object is stuck in the brush, remove it; if it is in the pipe, carefully push it with a long stick to the beginning or end of the pipe. Rinse the pipe and brush with water to remove any small debris.

- Inspect all existing filters. Rinse and thoroughly dry the fine air filter. Put it back into the device and try vacuuming.

- Check the garbage disposal: it may also contain excess garbage. If there is one, thoroughly clean or wash the fabric bag.

The vacuum cleaner has lost suction power: 5 ways to fix the problem yourself

Smells burnt

If during cleaning the engine stops and a burning smell appears or smoke starts to appear, the problem is in the winding of the electric motor. The repair will not be quick, but you can do it yourself:

- Remove all bolts from the device body.

- Remove the housing cover and wire reel. Pull out the engine.

- Unscrew the bolts from the sides and remove the rubber seal.

- Separate the housing into its components using a screwdriver.

- Remove the motor from the protective container.

- Bend the flanges and disconnect the motor, opening access to the turbine. A bolt will be waiting for you there.

- Unscrew the bolt from the turbine using a socket head of the appropriate diameter. Hold not only the stator firmly, but also all other parts.

- Unscrew everything that connects and blocks access to the brushes.

- Take out the brushes.

- Knock out the anchor using a wrench and hammer.

- Check the bearings. Grease them with oil if required.

- Replace the parts that need them and reassemble everything in reverse order.

The cord is not fixed

If after cleaning the wire refuses to return to the reel or during cleaning it randomly rolls into the “socket”:

- Remove the cover of the device.

- Pull out the drum, as well as the coil spring of the lever, along with the bushing.

- Remove the brake roller and lever.

- Replace damaged parts (coil spring, support, etc.)

- Adjust the desired cord tension in the reel.

- Assemble the drum and install it in its usual place.

- Test to see if the stopper secures the cord.

- Reassemble the structure in reverse order.

Battery won't charge

It is possible that the cordless vacuum cleaner broke down precisely because of problems with the battery, especially if it is already old. It is ideal to change the battery every 2-3 years: during this period, the battery completely loses its ability to accumulate and release energy, since there were more than 300-400 charge-discharge cycles. The suction power gradually decreases, the battery takes a long time to charge and quickly discharges. There is nothing you can do here other than a complete replacement.

Severe mechanical damage

These are problems associated with various impacts, sudden movements and other damage that have a strong impact on the condition of the unit: piercing the housing, falling out of the handle, breaking the hose fastening. In the best case, the equipment will be repaired by a service center; in the worst case, for example, if the case is badly pierced, the device cannot be repaired.

Hole in the filter

If the filter breaks, it is usually already “extremely worn out”. Sometimes the cause may be careless cleaning or washing. The main thing we can advise you is not to try to make a replacement using improvised means following lessons on YouTube. It's easier to buy a new one and be more careful when cleaning.

There is no water flowing into the hose

The reasons can be very different - from mechanical stress to natural wear and tear of devices. It is quite possible that the hose is clogged or the water pump is “covered” - check them.

Turns off during operation

The vacuum cleaner may turn off on its own and work intermittently for the following reasons:

- the filters are too dirty - input, output or both at once;

- the room being cleaned is too hot;

- the flexible hose or inlet is clogged;

- a lot of debris in the engine;

- graphite brushes inside the motor are faulty;

- inside the unit, the power contacts have come loose or broken (read: burnt);

- problems with the socket.

Check if your device has these problems and fix those that are found - clean the filter, hose, motor, plug the cord into another outlet.

The electric motor runs intermittently

If the graphite brushes become unusable, the springs that are supposed to press them against the electric motor commutator are weakened. The electric motor will work jerkily, “every once in a while.” Contact the service center for diagnostics, just do not delay.

Gives an electric shock

If you receive a discharge by pressing the power button, most likely the insulation of the wires inside the case is broken. Or a terminal has fallen off somewhere inside and is shorting to a metal part.

Other reasons:

- there are a lot of synthetic things in the house (clothing, flooring), due to friction with which static electricity accumulates;

- There is no grounding in the socket. You can fix it yourself (by connecting the yellow-green wire) or call an electrician.

Blows in the opposite direction

Most often, a vacuum cleaner works on “blowing” rather than “blowing” for two reasons:

- The engine gasket has shifted or become unusable - depressurization has occurred and a vacuum is not created in the “suction circuit”.

- the garbage bag has “gotten bad”;

- The dust container is not securely secured.

Correct them. If the problem continues, show the device to specialists.

The unit does not turn on at all

If you plug the unit into a power outlet and nothing happens, then repairing a Samsung vacuum cleaner (with your own hands, of course) should begin with a thorough inspection of the electrical part of the device. First, make sure that the outlet itself is working - to do this, plug in another device that is known to be working. If everything is in order, inspect the vacuum cleaner cord, look for scuffs, cracks, breaks or other damage. Disassemble the plug and carefully inspect the connection points with the cord. Using a tester or an electrical tester, “ring” the wire - it is probably burnt out.

If all of the above actions do not produce results, it means that the brushes are to blame or the motor has burned out. This part of the repair already falls into the more complex category.

Recommendations and lifehacks

- Before and after cleaning, inspect the filters for heavy contamination. We recommend cleaning them after each use.

- Empty the bag or container after each cleaning session.

- Store the vacuum cleaner in a dry place with minimal humidity. Try to keep water away from the engine and electrical circuits.

- Do not drag sharp objects when cleaning - they can pierce the tube, tear the corrugation, the dust collector and create many problems.

- Try not to overheat the vacuum cleaner. After each room, let him rest for a couple of minutes.

- Do not kick or hit the unit, monitor its external condition.

Let's briefly summarize the advantages

So, the good thing about a central vacuum cleaner is that you don’t have to drag around a heavy, noisy, blazing hot box with stinking dust blowing in all directions.

You simply plug a long, soft and flexible hose into an outlet on the wall (or maybe even easier - pull the built-in hose out of the wall), flip the switch on the handle and vacuum.

We recommend: Various options for installing an air conditioner on a balcony or loggia

No noise - the vacuum cleaner is humming somewhere in the garage or in the boiler room.

Without the stink and without the dust being blown into the air by the vacuum cleaner from the floor and other surfaces - your central vacuum cleaner collects all the dirt in a large disposable bag that is easy to replace, and its blowing is taken outside the house, so the remaining dust that does not end up in the bag and filter, they just fly out into the street.

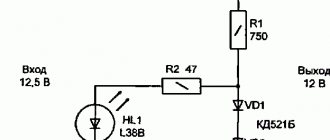

Lastly about electronics

It must be said that the electrical circuits of vacuum cleaners, except for the most expensive ones with microprocessors, are not particularly complex. The electrical circuit diagram of the vacuum cleaner, which can be considered close to typical, is shown in Fig. below. The network voltage in this case is 110 V. For a voltage of 220 V, the resistance of R1 is increased to 150 Ohms and its power to 2 W. R5 takes 330 kOhm, VR1 and VR2 each take 470-510 kOhm, R3 – 24 kOhm 2 W. The operating voltage of all capacitors is 630 V.

Electrical circuit diagram of a vacuum cleaner with power control

R3 sets the maximum power of the vacuum cleaner; it can be changed within 12-47 kOhm. VR1 is the operational power control, and VR2 is set to its minimum value, and here you need to be careful. The fact is that if the motor armature stops, every half-cycle of the mains voltage a starting current equal to 3-5 working currents will flow through it, and an expensive powerful triac (TRIAC according to the circuit) will burn out

Therefore, when setting up the circuit, the VR2 engine is first set to minimum resistance, then a voltage of 175 V is given from the LATR and VR2 very carefully, without overshoot, reduces the motor speed to 700-800 rpm

Thermal protection in such a circuit is also easy: a 1-1.5 MΩ thermistor (for a 220 V mains voltage) with an inverse logarithmic temperature characteristic is connected in parallel to C3. Physically, the thermistor must be in thermal contact with the motor housing, but be electrically isolated from it. A “cold” thermistor (at room temperature) does not affect the operation of the circuit, but when heated to 70-80 degrees, its resistance will drop to 1-0.5 R3, C3 will charge more slowly during the half-cycle, the low-power DIAC triac will open and open the TRIAC later , and the engine power will decrease by half or four. In approximately the same way, it is possible to modify most vacuum cleaners with power control, but without automatic protection.

***

2012-2020 Question-Remont.ru

cope itemtype=”https://schema.org/Article” data-nonce=”a60280afaf”>

cope itemtype=”https://schema.org/Organization”>

Further actions

After the nut is unscrewed, it will be easy to pull out the washer, as well as the impeller located under the washer. Next, the cyclone mechanism is removed and the anchor bearings are already visible. All that remains is to unscrew the four retaining plates and lightly tap the manifold on the reverse side to disconnect the rotating mechanism from it. Shock absorbed bearings can be identified by looking at them as well as by spinning them. In cyclone vacuum cleaners, often, during long-term operation, the balls inside the bearings are destroyed. In this case, the only way out is to purchase and install new options.